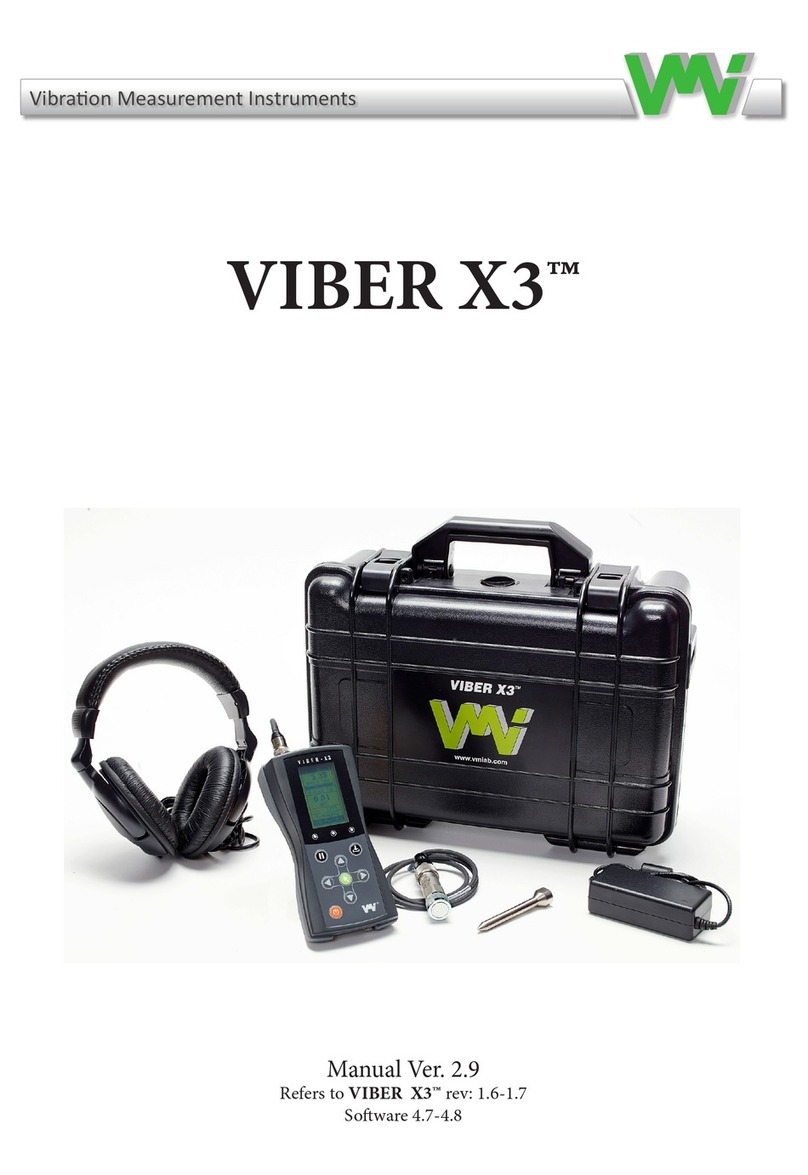

VMI Viber X Series User manual

VIBER X1™ Manual

VIBER X1™ Manual

Ver. 1.0

VIBER X

™

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Our X series of hand-held instruments

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines.

Keep a safe distance to rotating parts and secure transducers and transducer cables

from rotating parts. Always follow internal, local and national security

regulations! When working with weights on the rotor always secure the start

switch with a locker and also use the emergency switch for double safety. This is

especially important when the machine is remote controlled.

VMI International AB takes no responsibility for any accidents on people and

machines.

VMI International AB and our authorized dealers will take no

responsibility for damages on machines and plants as the result

of the use of VIBER X1™ measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of this,

we might change and correct these items in later issues without

further notice. Also changes in the VIBER X1™ equipment may

take place that affect the accuracy of the information.

VIBER X1 VIBER X2 VIBER X3

VIBER X5 MKIII

3

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines.

Keep a safe distance to rotating parts and secure transducers and transducer cables

from rotating parts. Always follow internal, local and national security

regulations! When working with weights on the rotor always secure the start

switch with a locker and also use the emergency switch for double safety. This is

especially important when the machine is remote controlled.

VMI International AB takes no responsibility for any accidents on people and

machines.

VMI International AB and our authorized dealers will take no

responsibility for damages on machines and plants as the result

of the use of VIBER X1™ measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information

complete for the user, there could be items we have missed,

because of the large amount of information. As a result of this,

we might change and correct these items in later issues without

further notice. Also changes in the VIBER X1™ equipment may

take place that affect the accuracy of the information.

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating

machines. Keep a safe distance from rotating parts. Secure transducers

and cables from rotating parts. Always follow company, local and national

security regulations!

VMI International AB and our authorized dealers will take no

responsibility for either damages on machines and plants or accidents on

people as the result of the use of VIBER X

™measurements.

Even though great efforts are made to make the information in

this manual free from errors and to make the information complete for the

user, there could be items we have missed, because of the large amount of

information. As a result of this, we might change and correct these items

in later issues without further notice. Also changes in the VIBER X™

equipment may take place that affect the accuracy of this information.

4

Instrument overview

The VIBER X1™ is a portable Vibrometer to be used in preven-

tive and active maintenance work, especially on rotating machin-

ery.

A complete set consist of an instrument, carrying bag, a vibration

transducer with magnet support and charger.

VIBER X1™ is measuring the effective velocity (mm/s RMS)

in the frequency range 2 – maximum frequence. The range can be

set by adjustable filters, high pass filters can be set 2 Hz or 10 Hz,

low pass filters can be set at 1 000 Hz or maximum frequency.

This range covers most of the frequencies that will occur for the

majority of mechanical failures and imperfections. Examples are

unbalance, looseness, resonance, misalignment of shafts and gears,

cavitations and other fluid generated vibrations.

The judgements of the measured levels are supported by several

vibration standards. The close comparison between vibration

levels and actual wear of the machinery will build up local

knowledge. This experience should be used to optimise the type of

action required when higher vibrations are found.

A common standard for judgement of vibrations is ISO 10816-3

and may be available from domestic standardisation authority.

This standard is an upgrade of older standards that has been in use

for several decades and has a worldwide acceptance as a

good judgement for continuous and long lasting operation of

machinery.

Instrument overview

The VIBER X

™is a portable vibrometer to be used in

preventive and pro-active maintenance work, especially on

rotating machinery. A complete set consists of an instrument,

soft carrying bag, a vibration transducer with magnet support.

VIBER X™ measures the velocity (mm/s RMS) in the two

frequency ranges 10 - 1000 Hz or 2 Hz – maximum frequency

(16000 Hz depending on version of VIBER X™ and trans-

ducer). The instrument has the capability to measure up to 40

kHz, the limiting factor is the accelerometer.

This range covers most of the frequencies that will occur for

the majority of mechanical failures and defects. Examples

are unbalance, looseness, resonance, misalignment of shafts,

vibrations.

VIBER X™ 10 - 1000 Hz is designed for companies that

uses the recommendation ISO 10816-3. This standard, is used

for decades around the world.

The vibration alerts are supported by several vibration stan-

dards. The close comparison between vibration levels and

actual machinery wear will build up your knowledge. Use

this experience to determine the action required when high

vibrations are found.

5

Vibraon Measurement Instruments

Functions

Press the start key and the instrument starts to measure

vibration, default is 2 – maximum frequency range, the diodes

indicates low and high pass fi lters setting.

The instrument will be shut off automatically after approximately

4 minutes if no key are used during the time.

This button can be used if the digits need a higher brightness to be

more visible.

The Viber X1™ is one of few analogical instrument that has

adjustable frequency ranges. To measure in other frequency

range, use the up/down arrows to change the fi lters. The fi lters

LED will light up to show the fi lter in use. This can be a useful

feature; comparison can be done with measurements in the

same range. Notice that the old ISO standard had 10 -1000 Hz

as frequency range. We recommend you to use 2 – 1000 Hz

as a standard range.

Start of the instrument

Improving the light

Changing frequency range

Manual Viber X1_121002.indd 5 10/3/12 9:26 AM

Power on the instrument

Press the On/Off key and the instrument starts to measure

vibration, default is 10 - 1000 Hz or 2 Hz – maximum

frequency range depending on version. The instrument shuts

off automatically after approximately 4 minutes if no key is

pressed.

Vibraon Measurement Instruments

Battery check

VIBER X1™ has an embedded battery check, when less than 10 %

of the battery capacity remains, the battery LED will fl ash.

Press this symbol key and the measurement of bearing condition

will start. The instrument measures instantaneously a bearing

condition value in the range between 500 Hz to 20.000 Hz.

To go back to vibration measurements, press the symbol once

more.

Placing of the measuring point

The measurements should be taken on or as close to the bearing as

possible and in horizontal, vertical and axial directions.

Bearing condition

Manual Viber X1_121002.indd 6 10/3/12 9:26 AM

Start measuring vibration on the machine then, press the

symbol key for bearing condition measurement. The instru-

ment measures instantaneously a Bearing Condition value in

the range between 500 Hz to 16 000 Hz. To return to vibration

measurement, press the symbol again.

Vibraon Measurement Instruments

Functions

Press the start key and the instrument starts to measure

vibration, default is 2 – maximum frequency range, the diodes

indicates low and high pass fi lters setting.

The instrument will be shut off automatically after approximately

4 minutes if no key are used during the time.

This button can be used if the digits need a higher brightness to be

more visible.

The Viber X1™ is one of few analogical instrument that has

adjustable frequency ranges. To measure in other frequency

range, use the up/down arrows to change the fi lters. The fi lters

LED will light up to show the fi lter in use. This can be a useful

feature; comparison can be done with measurements in the

same range. Notice that the old ISO standard had 10 -1000 Hz

as frequency range. We recommend you to use 2 – 1000 Hz

as a standard range.

Start of the instrument

Improving the light

Changing frequency range

Manual Viber X1_121002.indd 5 10/3/12 9:26 AM

Vibraon Measurement Instruments

Battery check

VIBER X1™ has an embedded battery check, when less than 10 %

of the battery capacity remains, the battery LED will fl ash.

Press this symbol key and the measurement of bearing condition

will start. The instrument measures instantaneously a bearing

condition value in the range between 500 Hz to 20.000 Hz.

To go back to vibration measurements, press the symbol once

more.

Placing of the measuring point

The measurements should be taken on or as close to the bearing as

possible and in horizontal, vertical and axial directions.

Bearing condition

Manual Viber X1_121002.indd 6 10/3/12 9:26 AM

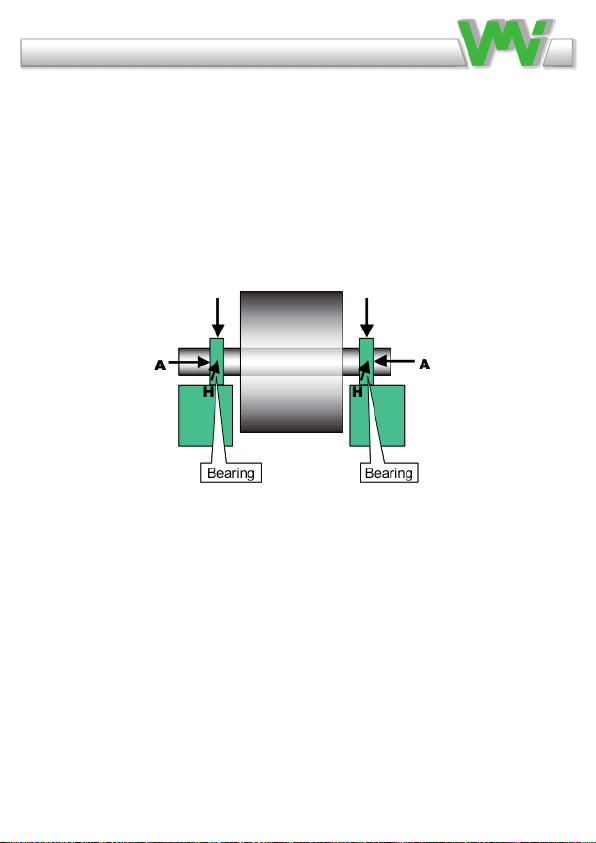

Measuring point location

Measurements should be taken on the bearing housing or as

close as possible and in the horizontal, vertical and axial direc-

tions. This is also explained in the standard ISO-10816.

6

V V

Vibraon Measurement Instruments

Functions

Press the start key and the instrument starts to measure

vibration, default is 2 – maximum frequency range, the diodes

indicates low and high pass fi lters setting.

The instrument will be shut off automatically after approximately

4 minutes if no key are used during the time.

This button can be used if the digits need a higher brightness to be

more visible.

The Viber X1™ is one of few analogical instrument that has

adjustable frequency ranges. To measure in other frequency

range, use the up/down arrows to change the fi lters. The fi lters

LED will light up to show the fi lter in use. This can be a useful

feature; comparison can be done with measurements in the

same range. Notice that the old ISO standard had 10 -1000 Hz

as frequency range. We recommend you to use 2 – 1000 Hz

as a standard range.

Start of the instrument

Improving the light

Changing frequency range

Manual Viber X1_121002.indd 5 10/3/12 9:26 AM

7

Vibraon Measurement Instruments

How to make good measurements

The sensitivity direction of the transducer coincides with the

centre axis of the transducer. The transducer end (with the

magnetic support) is pushed fi rmly against the measurement

point. The main purpose is to make the complete transducer to

fully participate in the motion of the measurement point. Try to

hold the transducer in a vertical, horizontal or axial direction as

possible, even if the machine surface does not have these

directions. Read the instrument held with the free hand. Note a

stable reading as well as a fl uctuating one, since the fl uctuation

itself is valuable information regarding the reason for the

vibration.

When the transducer is mounted with the magnet the frequency

range of the measurement is reduced to about 2 000 - 3 000Hz

depending on the fl atness of the measuring surface.

Note!

When using the magnet the bearing condition value can be

substantially changed.

Vibrations at high frequencies can sometimes cause measurement

lack of confi dence. Pressing the transducer more fi rmly should

not change the reading. If in doubt, always try to adjust the

contact point fi rst. Secondly, if necessary, mount the transducer

with the M6 stud.

All normal measurements on vertical or horizontal machinery

should follow the three perpendicular axes of true vertical,

Manual Viber X1_121002.indd 7 10/3/12 9:26 AM

How to make good measurements

The sensitivity direction of the transducer coincides with the

center axis of the transducer. Place the accelerometer on the

measurement point. Wait a few seconds for the accelerometer

to come to a steady state to reduce noise from the accelero-

meter. If you are connecting to a non-magnetic surface, push

rmly against the measurement point. Make sure it is a proper

contact with the machine. If measurement are taken on a

curved surface, make sure the accelerometer is attached and

not moving back and forth. Measure a vertical, horizontal and

axial direction, if possible. Note if the reading is stable or uc-

tuating. The non-stable reading is also valuable information

used to determine the vibration cause.

When the transducer is mounted with the magnet, the reliable

frequency range of the measurement is reduced to about 2000

– 3000 Hz depending on the atness of the contact between

magnet and surface.

Note!

Using the magnet can change the bearing condition value.

High frequency vibration can sometimes be difcult to collect

because high vibration does not transmit through the machine

for long distances. Pressing the transducer more rmly should

not change the reading. If in doubt, always try to adjust the

contact point rst. Secondly, if necessary, mount the transdu-

cer with the M6 stud.

8

horizontal and axial directions. The reason is that you should keep

to the main stiffness directions caused by normal non symmetrical

properties of the foundation, piping, supports etc. It will result in

better understanding if the basic measurements are made in this

way.

The VIBER X1™ is mainly intended for measurements against

the housing and bearings of machinery according to the intentions

of the standards. You can also use it to measure other parts such

as piping, valves, etc. Note that in some cases the mass of the

transducer may influence the reading. A good rule is to consider

readings on surfaces that are lower in mass than 10 times the mass

of the transducer.

All normal measurements on vertical or horizontal machinery

should follow the three perpendicular axes of true vertical,

horizontal and axial directions.

The VIBER X

™is mainly intended for measurements

against the machinery housing and bearings. And designed for

fans, pumps, chemical motors and compressors.

VIBER X

™can also be used to measure other components

such as piping, valves, etc.

Note

the reading. A good rule is to avoid readings on things that

have only 2-3 times the mass of the transducer.

9

How to interpret vibration measurements

A user with no previous experience to interpret the results is

recommended to use the ISO 10816-3 standard.

The standard normally calls for a measure in velocity based on

mm/s RMS. To better understand what this measure means it can

be helpful to consider the reading as a mean value of the back and

forward motion. This measure gives a good understanding of the

amount of “break down energy”, causing mainly wear and fatigue

work, in the machine or the structure being measured.

The instrument is measuring the total RMS-value of the vibration

in actual frequency range. This RMS-value is an average sum of

all the measured vibrations.

Example:

If the simultaneous vibration caused by unbalance is (4mm/s), by

misalignment (2 mm/s) and by the gear mesh (5 mm/s) then the

total vibration measured with VIBER X1™ is 6.7 mm/s.

Total vibration =

Notice that a reduction of the unbalance from 4 mm/s to 1 mm/s

will reduce the total value from 6, 7 mm/s to 5, 5 mm/s.

√4 * 4 + 2 * 2 + 5 * 5 = 6.7mm

How to interpret vibration measurements

A user with no previous experience, we recommend to use the

ISO 10816-3 standard.

The standard normally calls for a velocity measurement in

mm/s RMS. To better understand what this measurement

means, think of it as how fast the machine is

moving back and forth. This measure gives a good understan-

ding of the amount of “break down energy”, causing mainly

wear and fatigue in the machine or the structure.

The instrument measures the total RMS vibration value in the

frequency range. This RMS value is the average sum of all the

measured vibrations.

Example:

If the simultaneous vibration caused by unbalance is (4mm/s),

by misalignment (2 mm/s) and by the gear mesh (5 mm/s)

then the total vibration measured with VIBER X™ is 6.7

mm/s.

Total vibration = √4 * 4 + 2 * 2 + 5 * 5 = 6.7mm

Notice that a reduction of the unbalance from 4 mm/s to 1

mm/s will reduce the total value from 6, 7 mm/s to 5, 5 mm/s.

10

Vibraon Measurement Instruments

The ISO standard is classifying the machines differently if the

machines are considered as fl exible or rigid mounted. This refl ects

the location of the machines stiff-body resonance’s related to the

basic running speed of the machine.

For instance, a machine supported by rubber or springs have

resonance’s at low running speeds. The machine starts vibrate

at certain low rpm. When the speed is increased above these

resonance frequencies the vibration is reduced. This machine is

considered fl exible.

A resonance can easily be found when a fl exible machine is

running up or down in speed. The resonances are located at

the rpm´s where the vibration has a local maximum level.

Manual Viber X1_121002.indd 10 10/3/12 9:26 AM

The ISO standard classies the machines differently if the machi-

nes are exible or rigid. This reects the location of the machine’s

stiff-body resonance related to the basic running speed of the

machine.

For example, a machine supported by rubber or springs have a

resonance at low running speeds. The machine starts vibrate at

a low RPM. When the speed is increased above these resonance

frequencies, the vibration is reduced. This machine is considered

exible.

Resonance is easily found when a exible machine is running up

or down in speed. The resonances are located at the speed where

the vibration has a local maximum level.

Rigid

1.4

mm/s

2.8

4.5

11

Group 2 and 1 Group 4 and 3

Rigid Flex. Flex. mm/

s

2.3

3.5

7.1

Extraction’s from ISO 10816-3

Industrial machines with power above 15kW and nominal

speeds between 120 - 15000 RPM.

Group 1:

Large machines with rated power

above 300kW. Electrical machines

with shaft height H > 315mm.

Operating speed ranges from 120 to

15000 RPM.

Group 2:

Medium-sized machines with a rated power above 15kW up to and

including 300kW. Electrical machines with shaft height between

160 < H < 315 mm. Operating speed normally above 600 RPM.

11

Vibraon Measurement Instruments

Modern machines often run at high speed and bearing-supports

are fl exible, foundations should/can be evaluated as fl exible, even

when it is not mounted on rubber or springs.

The ISO 10816-3 standard allows for slightly higher limits when

a foundation is considered fl exible than when if it is rigid.

A conclusion from this is also that a resonance condition in

principle is not allowed or at least must be avoided at operating

speeds. In practice this also includes the double speed as well as

any other natural excitation frequency such as blade passage etc.

A great advantage with proper vibration measurements and the

use of vibration standards is that you can judge the future

maintenance cost reliably already at fi rst start-up. If you fi nd

levels above 3 mm/s RMS, you can be rather sure that the machine

will cause increased activities in maintenance.

The specifi c cost and action is of course individual to the

machine design.

The next logical step is therefore to apply more advanced

analyzers like VIBER X2™, X3™ or X5™ to learn the frequency

behind the vibration and thus the exact mechanical fault.

The practice of this is beyond the scope of this manual.

Manual Viber X1_121002.indd 11 10/3/12 9:26 AM

Group 3:

Pumps with multivane impeller and with separate driver with

rated power above 15kW.

Group 4:

Pumps with multivane impeller and with integrated driver

with rated power above 15kW.

Modern machines often run at high speed and bearing-

supports are exible, foundations should/can be evaluated as

exible, even when it is not mounted on rubber or springs.

The ISO 10816-3 standard allows for slightly higher limits

when a foundation is considered exible than rigid. A conclu-

sion from this is a resonance condition should not be allowed

or at least must be avoided at operating speeds. In practice,

this also includes the double speed as well as any other natural

excitation frequency such as blade passage.

A great advantage with proper vibration measurements and

the use of vibration standards is that you can judge the future

maintenance cost reliably at start-up. If you nd levels above

3 mm/s RMS, it’s a risk that the machine will have higher

maintenance cost. The specic cost and action is specic to

the machine design.

The next logical step if you want to improve the accuracy of

measurements is to use more advanced analyzers like VIBER

X2™, X3™ or X5™ to learn and detect the frequency behind

the vibration and thus the exact mechanical fault. The practice

of this is beyond the scope of this manual.

12

Vibraon Measurement Instruments

Recommended vibration levels in mm/s and

common fi ndings

The following is in part an extraction of the old standard ISO 2372

class 4, large machines on fl exible foundations, with some com-

mon fi ndings added.

This simplifi ed list can be used, as a fi rst indication, when

approaching a machine newly commissioned or after some

time in operation.

Take as a rule to investigate the reason for any machine that vi-

brates above 3 mm/s RMS.

• 0 – 3 mm/s

Small vibrations - None or very small bearing wear. Rather low

noise level.

• 3 – 7 mm/s

Noticeable vibration levels often concentrated to some specifi c

part as well as direction of the machine. Visible bearing wear.

Seal problems occur in pumps and increased noise level. Keep

the machine under observation and measure at smaller time inter-

vals than before to detect a deterioration trend if any.

Compare vibrations to other operating variables.

Manual Viber X1_121002.indd 12 10/3/12 9:26 AM

Recommended vibration levels in mm/s and common ndings

The following is an extraction of part of the old standard ISO

2372 class 4, large machines on exible foundations, with

some common ndings added.

Use this simplied list as a rst indication, when approaching

a newly commissioned machine or after some time in opera-

tion. Investigate the reason for any machine that vibrates

above 3 mm/s RMS.

• 0 – 3 mm/s

Small vibrations - None or very small bearing wear. Rather

lownoise level.

• 3 – 7 mm/s

Noticeable vibration levels are often concentrated to some

specic part as well as direction of the machine. Visible

bearing wear. Seal problems occur in pumps and increased

noise level. Keep the machine under observation and measure

at smaller time intervals than before to detect a deterioration

trend if any. Compare vibrations to other operating variables.

• 7 – 18 mm/s

Large vibrations. Bearings running hot. Bearing wear-out

causes frequent replacements. Seals wear out, leakage of all

kinds evident. Cracks in welding and concrete foundations.

Screws and bolts are loosening. High noise level. Plan action

soonest. Do your best to discover the cause. You are wearing

down investments quickly.

13

Vibraon Measurement Instruments

• 7 – 18 mm/s

Large vibrations. Bearings running hot. Bearing wear-out cause

frequent replacements. Seals wear out, leakage of all kinds evident.

Cracks in welding and concrete foundations. Screws and bolts are

loosening. High noise level. Plan action soonest. Do your best to

reveal the reason. You are wearing down investments quickly.

• 18 – mm/s

Very large vibrations and high noise levels. This is detrimental to

the safe operation of the machine. Stop operation if technically

or economically possible considering the plant stop cost. Few

machines can withstand this level without damage. Reduce any

further running time to an absolute minimum.

Manual Viber X1_121002.indd 13 10/3/12 9:26 AM

Vibraon Measurement Instruments

Recommended vibration levels in mm/s and

common fi ndings

The following is in part an extraction of the old standard ISO 2372

class 4, large machines on fl exible foundations, with some com-

mon fi ndings added.

This simplifi ed list can be used, as a fi rst indication, when

approaching a machine newly commissioned or after some

time in operation.

Take as a rule to investigate the reason for any machine that vi-

brates above 3 mm/s RMS.

• 0 – 3 mm/s

Small vibrations - None or very small bearing wear. Rather low

noise level.

• 3 – 7 mm/s

Noticeable vibration levels often concentrated to some specifi c

part as well as direction of the machine. Visible bearing wear.

Seal problems occur in pumps and increased noise level. Keep

the machine under observation and measure at smaller time inter-

vals than before to detect a deterioration trend if any.

Compare vibrations to other operating variables.

Manual Viber X1_121002.indd 12 10/3/12 9:26 AM

• 18 – mm/s

Very large vibrations and high noise levels. This is detrimental

to the safe operation of the machine. Stop operation if techni-

cally or economically possible. Few machines can withstand

this level without damage. Reduce any further running time to

an absolute minimum.

Press the bearing symbol. The instrument measures the bearing

condition value. Bearing condition value is the RMS value of

all high frequency vibrations in the range of 500 Hz to 16 000

Hz. Bearing condition are measured in the unit g.

Bearing condition value

We use acceleration because high frequencies give a larger sig-

nal compared to velocity, if measured in acceleration. When

the balls or rollers rotate inside the bearing, a wide-band noise

and vibration occurs. This noise and vibration increase if the

bearing is poorly lubricated, overloaded due to misalignment

or has a damaged surface.

If the selected frequency band includes low frequencies, the be-

aring condition value would also include vibrations from unba-

lance, misalignment, etc. and not only from bearing vibrations.

Vibraon Measurement Instruments

Press the bearing symbol and the instrument measures the bearing

condition value.

Bearing condition value is RMS value of all high frequency vibra-

tions in the range of 500 Hz to maximum frequency.

This average has the unit g (= m/s²)

Bearing condition value

The bearing condition value in VIBER X1™ is an average value,

RMS value, of all high frequency vibrations between 500 Hz and

maximum frequency.

This value is an average with the unit “g” because high frequen-

cies give a larger signal compared with velocity, if it is measured

in acceleration.

When the balls or rollers rotate inside the bearing a wide-band

noise and vibration arises. This noise and vibration are increased

if the bearing is poorly lubricated, overloaded due to misalignment

or has a damaged surface.

If the selected frequency band includes low frequencies, the

bearing condition value would also include vibrations from

unbalance, misalignment, etc. and not only from bearing vibrations

and would therefore be diffi cult to interpret.

If the selected frequency band only includes very high frequency

noise and vibrations we would need special vibration transducers

that are very rigidly and closely mounted to the bearing because

Bearing condition

Manual Viber X1_121002.indd 14 10/3/12 9:26 AM

Bearing condition symbol

14

Press the bearing symbol and the instrument measures the bearing

condition value.

Bearing condition value is RMS value of all high frequency vibra-

tions in the range of 500 Hz to maximum frequency.

This average has the unit g (= m/s²)

Bearing condition value

The bearing condition value in VIBER X1™ is an average value,

RMS value, of all high frequency vibrations between 500 Hz and

maximum frequency.

This value is an average with the unit “g” because high frequen-

cies give a larger signal compared with velocity, if it is measured

in acceleration.

When the balls or rollers rotate inside the bearing a wide-band

noise and vibration arises. This noise and vibration are increased

if the bearing is poorly lubricated, overloaded due to misalignment

or has a damaged surface.

If the selected frequency band includes low frequencies, the

bearing condition value would also include vibrations from

unbalance, misalignment, etc. and not only from bearing vibrations

and would therefore be difficult to interpret.

If the selected frequency band only includes very high frequency

noise and vibrations we would need special vibration transducers

that are very rigidly and closely mounted to the bearing because

Bearing condition

If the selected frequency band only includes very high fre-

quency noise and vibrations, we would need special vibration

transducers that are very rigidly and closely mounted to the

bearing because the machine structure works as a mechanical

VIBER X

™measures the bearing

condition value between 500 Hz to 16 kHz. Normal machi-

nery vibrations rarely have vibrations above 500 Hz.

Note!

A high bearing condition value is an indication and a recom-

mendation to continue with other fault analysis. High bearing

condition values can appear at gear boxes, converting machi-

nes with cutters and similar machines without any bearing

faults because they “naturally” produce frequencies above 500

Hz.

15

Vibraon Measurement Instruments

the machine structure works as a mechanical fi lter for high

frequencies.

VIBER X1™ is measuring the bearing condition value between

500 Hz to 20 kHz. Within this frequency range a common

experience exist in the evaluation of the bearing condition level.

Normal machinery vibrations rarely have vibrations above 500 Hz.

Note!

A high bearing condition value is an indication and a

recommendation to continue with other fault analysis.

High bearing condition values can appear at gear boxes,

converting machines with cutters and similar machines without

any bearing faults because they “naturally” produce frequencies

above 500 Hz.

Manual Viber X1_121002.indd 15 10/3/12 9:26 AM

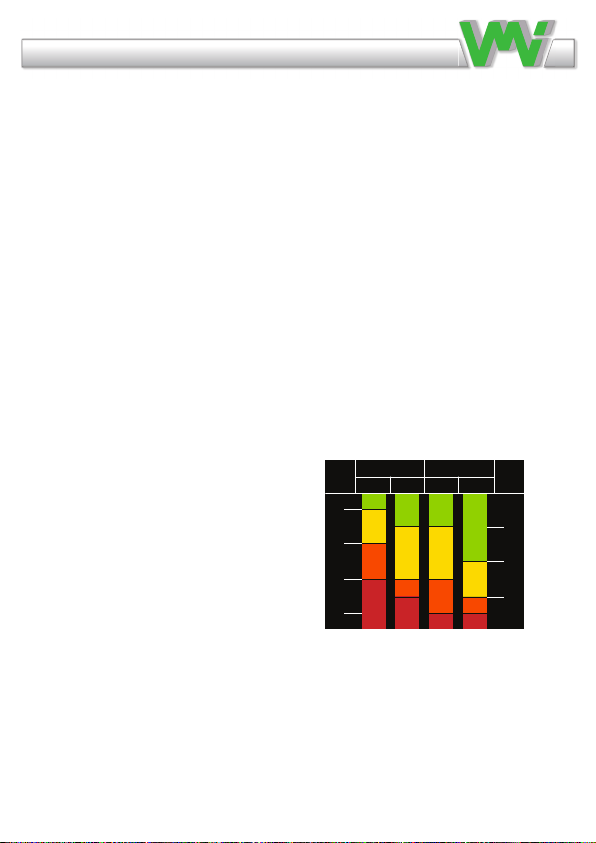

Bearing condition value with unit “g” RMS

The diagram below is a guide to identify the bearing condi-

tion value. If vibrations of other causes (e.g. ow surge, gear

mesh) are within in the frequency range 500 – 16 000 Hz this

can give a high bearing condition value, without the bearing

being damaged. A high bearing condition value can also be

indicated if the bearing is poorly lubricated or overloaded.

Vibraon Measurement Instruments

Bearing condition value with unit “g” RMS

The diagram above is a guide to identify the bearing condition

value. If vibrations of other causes (e.g. fl ow surge, gear mesh) are

within in the frequency range 500 – 6400 Hz this can give a high

bearing condition value, without the bearing being damaged.

A high bearing condition value can also be indicated if the bearing

is poorly lubricated or overloaded.

Manual Viber X1_121002.indd 16 10/3/12 9:26 AM

Bearing condition value with unit “g” RMS

The diagram above is a guide to identify the bearing condition

value. If vibrations of other causes (e.g. ow surge, gear mesh) are

within in the frequency range 500 – 16 000 Hz this can give a high

bearing condition value, without the bearing being damaged.

A high bearing condition value can also be indicated if the bearing

is poorly lubricated or overloaded.

16

Bearing condition value with unit “g” RMS

The diagram above is a guide to identify the bearing condition

value. If vibrations of other causes (e.g. ow surge, gear mesh) are

within in the frequency range 500 – 6400 Hz this can give a high

bearing condition value, without the bearing being damaged.

A high bearing condition value can also be indicated if the bearing

is poorly lubricated or overloaded.

Technical data VIBER X

Accelerometer Standard nom 100

mV/g

(Adjusted to the

instrument)

Input amplitude

range

Max 199.9 mm/s

Max 19.99 gBC

Dynamic range 60 dB (159.16 Hz)

Frequency range

10 - 1000 Hz

2 - 30 000 Hz

Available for

500 - 16 000Hz

units mm/s and g-value

Amplitude RMS

Signal processing Analog

Inaccuracy

±4 %

±5 %

Alkaline AAA

LED display 7 segment, 4 digits

IP65

range -20 to 50°C

Weight 285 gram

Size (L x W x H) 125mm x 70mm x 40mm

TM

Minimum 12 hours continuos measuring

two options

Vibration

Bearing condition

Vibration

Bearing condition

Vibra�on

Bearing condi�on

17

TECHNICAL SPECIFICATIONS VIBER X1™

INPUT SENSITIVITY: 100mV/g calibrated at 156.15 Hz.

MEASURING RANGE: Velocity: 0-200 mm/s RMS

FREQUENCY RANGE: Total level 2-3200 Hz

Adjustable filters: 2-10, 1000 - maximum

Hz

Bearing condition 500 Hz – 20 kHz

WEIGHT: 270 gram with accelerometer and

batteries

The measurement mainly follows

ISO10816-3.

ACCURACY*: Better than +/- 3 %

* This value can be higher, close to the filters cut off frequency.

BATTERY TYPE: 3 pc of AAA Rechargeable

VIBRATION TRANSDUCER*

The accelerometer VMI 192 has a sensitivity 100mV/g +/-10%.

MAGNET SUPPORT

Length: 20mm, Diameter: 15mm, Magnet force: about 14kg

Note!

You must avoid to use other accelerometers bacause of the calibration.

If you change accelerometer the instrument must be calibrated to

preserve the accuracy.

Technical data VIBER X

.

You should avoid using other accelerometers

because of instrument calibration. If you

change the accelerometer, the instrument

must be calibrated to preserve the accuracy.

TM

Note 2. Wait until the instrument has stabilized

resonably well, before starting measurement.

Note 1.

18

Technical specifications for VMI 192

Sensitivity (+/-10%) 100mV/g

Frequency response (±3dB) 0.4–13000Hz

(±10%) 1.0-9000Hz

Dynamic Range ±80 g, peak

Internal resonance 26000Hz

Settling time <2 Seconds

Bias Voltage 10-14VDC

Temperature range -50 to 121 °C

Maximum Shock Protection 5000 g, peak

Electromagnetic Sensitivity CE-Certified

Weight (without magnet) 51 grams

Mounting stud M6 Adapter stud

Mounting Torque 2.7-6.8 Nm

• We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

Declaration of conformity

VMI declares that the Viber X1™ is manufactured in conformity with national and

international regulations.

The system complies with, and is tested according to, following requirements:

EMC Directive: 2004/108/EC

Low Voltage Directive: 2006/95/EC

8 August 2011

Vibration Measurement Instrument International AB (VMI)

•We reserve the right to modify or improve the designs or

Declaration of conformity

VMI declares that the VIBER X

™is manufactured in conformity

with national and international regulations.

The system complies with, and is tested according to, following

requirements:

EMC Directive: 2004/108/EC

Low Voltage Directive: 2006/95/EC

8 August 2011

Technical specifications for VMI 192

Sensitivity (+/-10%) 100mV/g

Frequency response (±3dB) 0.4–13000Hz

(±10%) 1.0-9000Hz

Dynamic Range ±80 g, peak

Internal resonance 26000Hz

Settling time <2 Seconds

Bias Voltage 10-14VDC

Temperature range -50 to 121 °C

Maximum Shock Protection 5000 g, peak

Electromagnetic Sensitivity CE-Certified

Weight (without magnet) 51 grams

Mounting stud M6 Adapter stud

Mounting Torque 2.7-6.8 Nm

• We reserve the right to modify or improve the designs or

specifications of our products at any time without notice.

Declaration of conformity

VMI declares that the Viber X1™ is manufactured in conformity with national and

international regulations.

The system complies with, and is tested according to, following requirements:

EMC Directive: 2004/108/EC

Low Voltage Directive: 2006/95/EC

8 August 2011

Vibration Measurement Instrument International AB (VMI)

19

Vibraon Measurement Instruments

Warranty disclaimer

VMI warrants the products to be free from defects in material and workmanship

under normal use and service within two years from the date of purchase and which

from our examination shall disclose to our reasonable satisfaction to be defective.

Warranty claimed products shall be returned prepaid to VMI for service. We reserve

the right to repair or to replace defective products. Always try to explain the nature

of any service problem; by e-mail or telephone. Check fi rst all natural problems,

like empty batteries, broken cables, etc. If returning the product, be sure to indicate

that the purpose is to make repairs and indicate the original invoice number and

date of shipment.

Warranty exclusions

Damage not resulting from a defect in material or workmanship or by other than

normal use. Damage resulting from repairs performed other than by an authorized

service centre. The limited two year warranty and remedies contained herein are in

lieu of all other warranties, expressed or implied including any warranty of mer-

chantability and any warranty of fi tness for a particular purpose, and all other rem-

edies, obligations or liabilities on our part. In addition, we hereby disclaim liability

for consequential damages for breach of any expressed or implied warranty,

including any implied warranty of merchantability and any implied warranty of

fi tness for a particular purpose. The duration of any implied warranty which might

exist by operation of law shall be limited to one year from the date of original retail

purchase.

NOTE: Some countries do not allow the exclusion or limitation of consequential

damages, and some countries do not allow limitation on how long an implied

warranty lasts, so the above exclusions or limitations may not apply to you. This

warranty gives you specifi c legal rights and you may also have other rights that

vary from country to country. If you have problems with your instrument during or

after the warranty period, fi rst contact your distributor you purchased the unit from.

Manual Viber X1_121002.indd 19 10/3/12 9:26 AM

Warranty disclaimer

VMI warrants the products to be free from defects in material and workmanship

under normal use and service within 2 years from the date of purchase and which

from our examination shall disclose to our reasonable satisfaction to be defective.

Warranty claimed products shall be returned prepaid to VMI for service. We reserve

the right to repair or to replace defective products. Always try to explain the nature

of any service problem by lling in the form found on the website www.vmiab.com

and attach it in an email to VMI. Check rst all natural problems, like empty batte-

ries, broken cables, etc. If returning the product, be sure to indicate that the purpose

is to make repairs and indicate the original invoice number and date of shipment.

Warranty exclusions

Damage not resulting from a defect in material or workmanship or by other than

normal use. Damage resulting from repairs performed other than by an authorized

service center. The limited two year warranty and remedies contained herein are in

lieu of all other warranties, expressed or implied including any warranty of mer-

chantability and any warranty of tness for a particular purpose, and all other reme-

dies, obligations or liabilities on our part. In addition, we hereby disclaim liability

for consequential damages for breach of any expressed or implied warranty, inclu-

ding any implied warranty of merchantability and any implied warranty of tness

for a particular purpose. The duration of any implied warranty which might exist by

operation of law shall be limited to one year from the date of original retail

purchase.

NOTE: Some countries do not allow the exclusion or limitation of consequential

damages, and some countries do not allow limitation on how long an implied

warranty lasts, so the above exclusions or limitations may not apply to you. This

warranty gives you specic legal rights and you may also have other rights that

vary from country to country. If you have problems with your instrument during or

after the warranty period, rst contact your distributor you purchased the unit from.

VMI International AB

Sweden • www.vmiab.com

This manual suits for next models

5

Table of contents

Other VMI Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Audioscope

Audioscope 3000 operating instructions

Evoqua

Evoqua WALLACE & TIERNAN DEPOLOX 5 E instruction manual

National Instruments

National Instruments PXIe-4163 Getting started guide

DEWESOFT

DEWESOFT SIRIUS Technical reference manual

PCE Instruments

PCE Instruments PCE-VT 3700-ICA user manual

Kobold

Kobold APS-Z operating instructions