VMI VIBER X3 User manual

Vibraon Measurement Instruments

Manual Ver. 2.9

Refers to VIBER X3™ rev: 1.6-1.7

Soware 4.7-4.8

VIBER X3™

VIBER X3™

Manual

Ver. 2.5

Vibraon Measurement Instruments

Index

1 Important information 3

2 Introduction 4

3 Scope of supply 5

4 Instrument keypad and LED´s 6

5 Setting Menu and Functions 7

6 Screen descriptions 8

7 Warning messages 14

8 How to interpret vibration levels 15

9 Vibration analysis 17

10 Balancing with VIBER X3™ 21

11 Trend View soware 30

Technical data VIBER X3™ 52

Vibraon Measurement Instruments

2

Vibraon Measurement Instruments

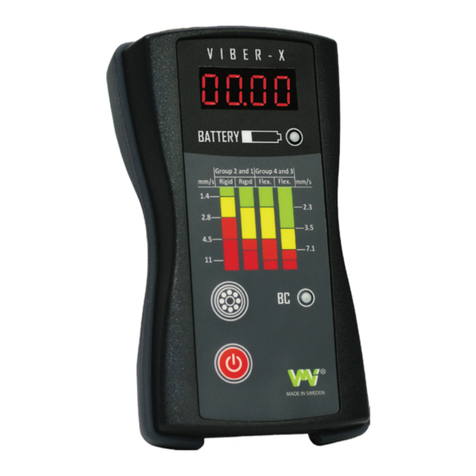

Our X series of hand-held instrument

VIBER X1 VIBER X2 VIBER X3

VIBER X5

Manual Viber X1_121002.indd 2 10/3/12 9:26 AM

VIBER X1™VIBER X2™VIBER X3™

VIBER X5™

Our x-series of hand-held instrument

Vibraon Measurement Instruments

3

1 Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating

machines. Keep a safe distance to rotating parts and secure transducers and

transducer cables from rotating parts. Always follow internal, local and na-

tional security regulations! When working with weights on the rotor always

secure the start switch with a locker and also use the emergency switch for

double safety. This is especially important when the machine is remote con-

trolled.

VMI takes no responsibility for any accidents on people and machines.

VMI and our authorized dealers will take no responsibility for damages on

machines and plants as the result of the use of VIBER X3™ measurements.

VMI has the aim to improve and develop our products, why surely an up-

graded version of this manual will be distributed in the future. As a result of

this, we might change and correct these items in later issues without further

notice. Also changes in the VIBER X3™ equipment may take place that

affect the accuracy of the information.

Vibraon Measurement Instruments

4

2 Introduction

VIBER X3™ is designed for maintenance/repairer and operators personnel. It is an excellent

tool, for basic condition monitoring checks, easy to use and reliable for status analyse. The VI-

BER X3™ instrument has the following features:

• Accuratemeasurementsin4selectablefrequencyranges.

Gives higher reliability.

• Real-timemeasurementofthetotalvibrationlevelandtheBearing

Condition(BC),measuresanddisplayedsimultaneously,facilitate

analysisofBearingfaults.

• HeadphonesetwithvolumecontrolandhighpasslterforBearingnoise detection.

CanbeusedwithoutBCmeasuringandtrending,tosavetime.Usesiftherearemany

smallBearingsasinprintingmachinesorconveyorsandsimilarapplications.

• ListeningtobearingsoundwhilecomparingthedisplayedBCvalue.

• Fastandeasyfaultanalysisscreendisplayingthevehighestpeaks

with amplitude and frequency one by one.

• Measurementunitsandmeasurementpresentationmaybeselectedby

the user from the following list:

•g-value=(RMS,PeakorPeak-Peak)

•a=m/s2(RMS,PeakorPeak-Peak)

•V=mm/sec(RMS,PeakorPeak-Peak)

•V=inch/sec(RMS,PeakorPeak-Peak)

•D=mils(RMS,PeakorPeak-Peak)

•D=μm(RMS,PeakorPeak-Peak)

•

BearingConditionmeasurementsinawidefrequencyrange(0,5-16kHz).

• Built-ininfraredtemperaturesensor,unitsin°Cor°F.

• Barindicatorshowsmeasurementstability.

•

Vibration,temperatureanddangeralarmsbyredandyellowcolourLED’s.

• Fastbatterychargingcapacityusinganexternalcharger,providedinthe delivery.

• Displaywithbacklight.

• AdjustableAuto-shutoffforenergysaving.

• Dustandwaterproof,forroughuse(IP65).

Vibraon Measurement Instruments

5

A complete delivery is:

• VIBERX3™, machine condition analyzer

• Ahighperformanceaccelerometer

• 1mtransducercable

•Extensiontip,magnet

• Batterycharger

• Headphones

• Datastoragewith“VMITrendView”software,installation

instructions and user manual

• Printedmanualforinstrumentandsoftware

All this together are available in a sturdy, airtight, chemical resistant,

dust-andwaterproofIP68case.

3 Scope of supply

Vibraon Measurement Instruments

6

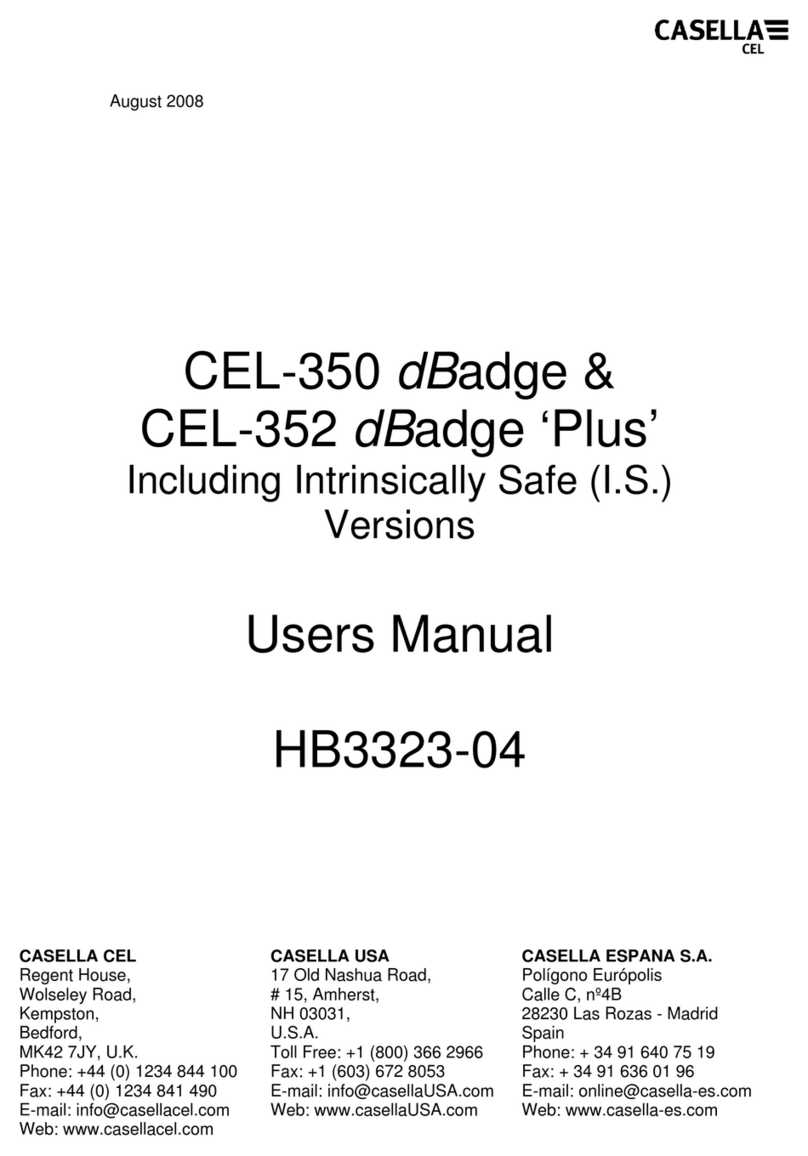

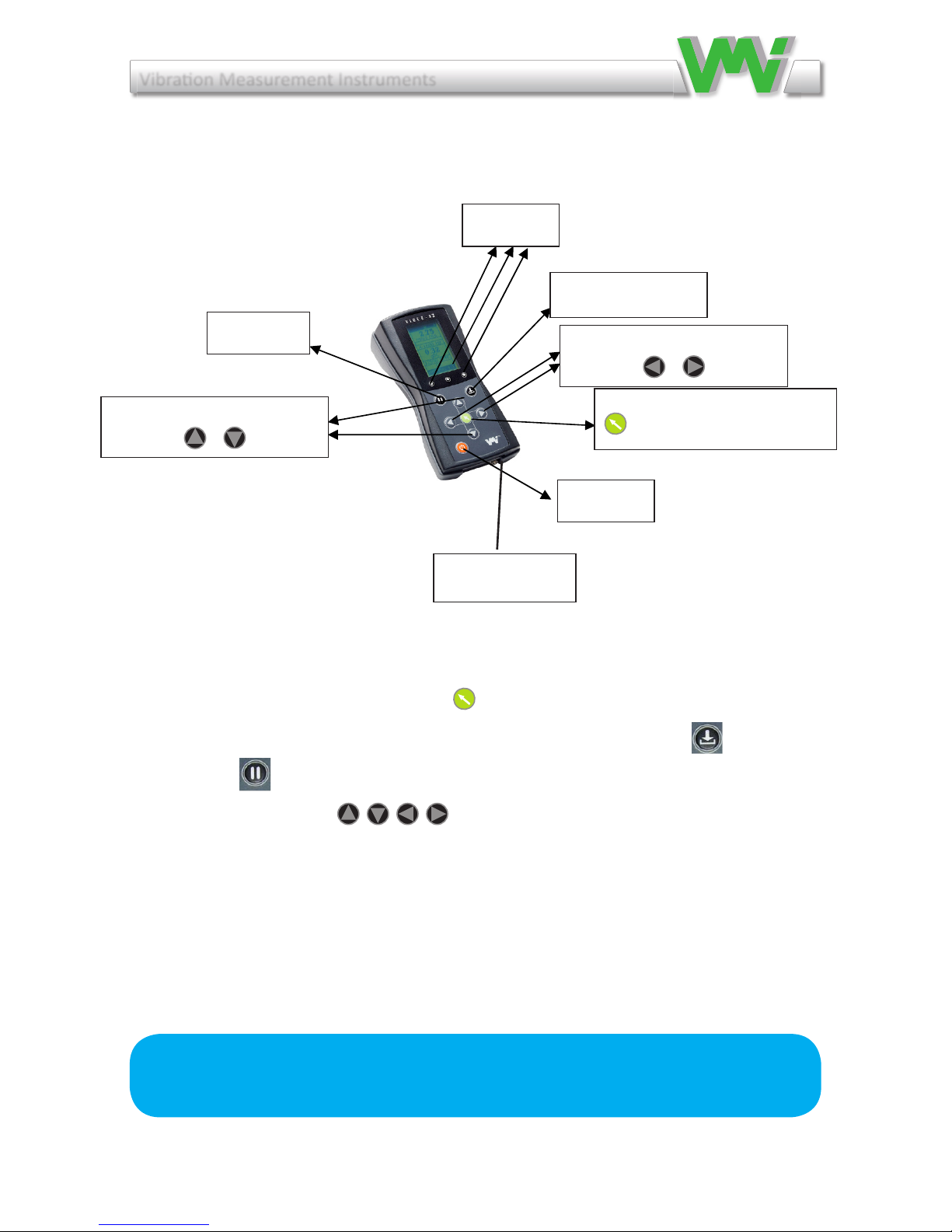

The VIBER X3™ keypad

1ON/OFFOrangekey

1MENUandACCEPTGreenkey

1HoldforSAVEkeyforRouteandBalancingmeasurements

1Holdkey

4Arrowwhitekeys

1GreenLEDlights,whenanykeyispressed.

1YellowLEDlights,whenthemeasurementisabovethewarningsetlevel.

1RedLEDlights,whenthemeasurementisabovethedangersetlevel.

3

Scope of supply

A complete delivery is:

• Viber X3™, machine condition analyzer

• A high performance accelerometer

• 1 m transducer cable

• Extension tip

• Battery charger

• Head phones

All this together are available in a sturdy, airtight, chemical resistant, dust- and waterproof IP68 case.

Instrument keypad and LED’s

The VIBER X3

™ keypad

1 ON/OFF Orange key

1 MENU and ACCEPT Green key

1 Save key for Route measurement or Balancing measurements

1 Hold key

4 Arrow white keys

3 Leds*

Green LED lights, when any key is pressed.

Yellow LED lights, when the measurement is above the warning set level.

Red LED lights, when the measurement is above the danger set level.

LED’s

SAVE key

Right and left Arrow key

ON/OFF

MENU and ACCEPT

Green

key

Up and

D

own Arrow key

HOLD key

NOTE: As default, when the instrument starts, the transducer power is

ENABLED

4 Instrument keypad and LED´s

Hold for SAVE key

LED´s

HOLD key

ON/OFF

Right and left Arrow key

MENU and ACCEPT

Green key

Up and down Arrow key

Signal and

headphone jack

◀

Vibraon Measurement Instruments

7

5 Setting Menu and Functions

IntheFunctionandSettingMenuyoucansetorchoosemenusorfunctions

byusingArrowsandgreenButtonfornavigation.

1. Vibration: Green button choose to measure vibration

2. Temperature: Green button choose to measure Temperature

3. Audio: Green button choose to open Audio mode, make start of liste

ning possible, default is enabled.

4. Balancing:Greenbuttonchoosebalancing,chooseaneworanOngoing

5. Settings:Useformakesettingsforthefunctions:

•Instrument,Backlighton/off,Auto-shutoff,Language(Imple

mentedlanguagesare:English,Swedish,French,German,Romanian,

Czech,Spanish,PortugueseandFinnish).

•Transducer,sensorsensitivityandpowerOn/Off

•Vibration,SetlevelandenableordisableAlarm,Warning,Unitsdisplayed

•Temperature,Unit,Emissivity,setlevelandenableordisableAlarm,

Warning

•Audio,FilterOn/off,Soundenableordisable

6. Upload: Choose to upload saved measurements and balancing results

7. Delete:Usedtoremovestoredmeasurements.

ToremoveonemeasurementfromtheVIBERX3™memorylist:usethe

”Hold for Save”button.Thefunction”delete”inthemenufordeletion

canalsobeusedtoviewstoredmeasurementsinVIBERX3™memeory

list,exitfromthememorylistwiththe”Hold for Save”button.

Functions

Vibration

Temperature

Audio

Balancing

Settings

Upload

Delete

Delete

Clear mem.

ALL vib.

ALL temp.

ALL bal.

Vibration

Temperature

Balancing

BACK

Vibraon Measurement Instruments

8

6 Screen descriptions

6.1 Analysis measurement screen

In the analysis screen you are able to see the total value as well as the amplitude and

frequencyofthevehighestpeaksinthespectrumrange.Ifyouhaveenabledthe

audio(seeaudioscreen)youmayalsoatthesametimelistentothebearings.

In the upper right corner you will see the battery status and if the charger is plugged

in or not.

Measurement status can be one of following:

- Measuring(Vibrationmeasuringisongoing)

- Autoranging(Theinstrumentiscalculatingthebestmeasurementlevelrange)

- Averaging(Averagingofthemeasureddata)

- OK(Themeasurementisstable)

-Overow (The signal is too high – the measurement is incorrect/not readable.)

Incaseofamplitudeoutofrange,thevalueisshownas3stars(***).

Whenthemeasurementisstable,thelastmessagelineshowsOK.

5

1Analysis measurement screen

In the analysis screen you are able to see the total value as well as the amplitude and frequency of the five first peaks

in the spectrum range. If you have enabled the audio (see audio screen) you may also at the same time listen to the

bearings.

In the upper right corner you will see the battery status and if the charger is plugged in or not.

Measurement status can be one of following:

- Measuring (Vibration measuring is ongoing)

- Ranging (The instrument is calculating the best measurement range)

- Averaging (Averaging of the measured data)

- OK (The measurement is stable)

- Overflow (The signal is too high –the measurement is incorrect/not readable.)

In case of amplitude out of range, the value is shown as 3 stars (***).

When the measurement is stable, the last message line shows OK.

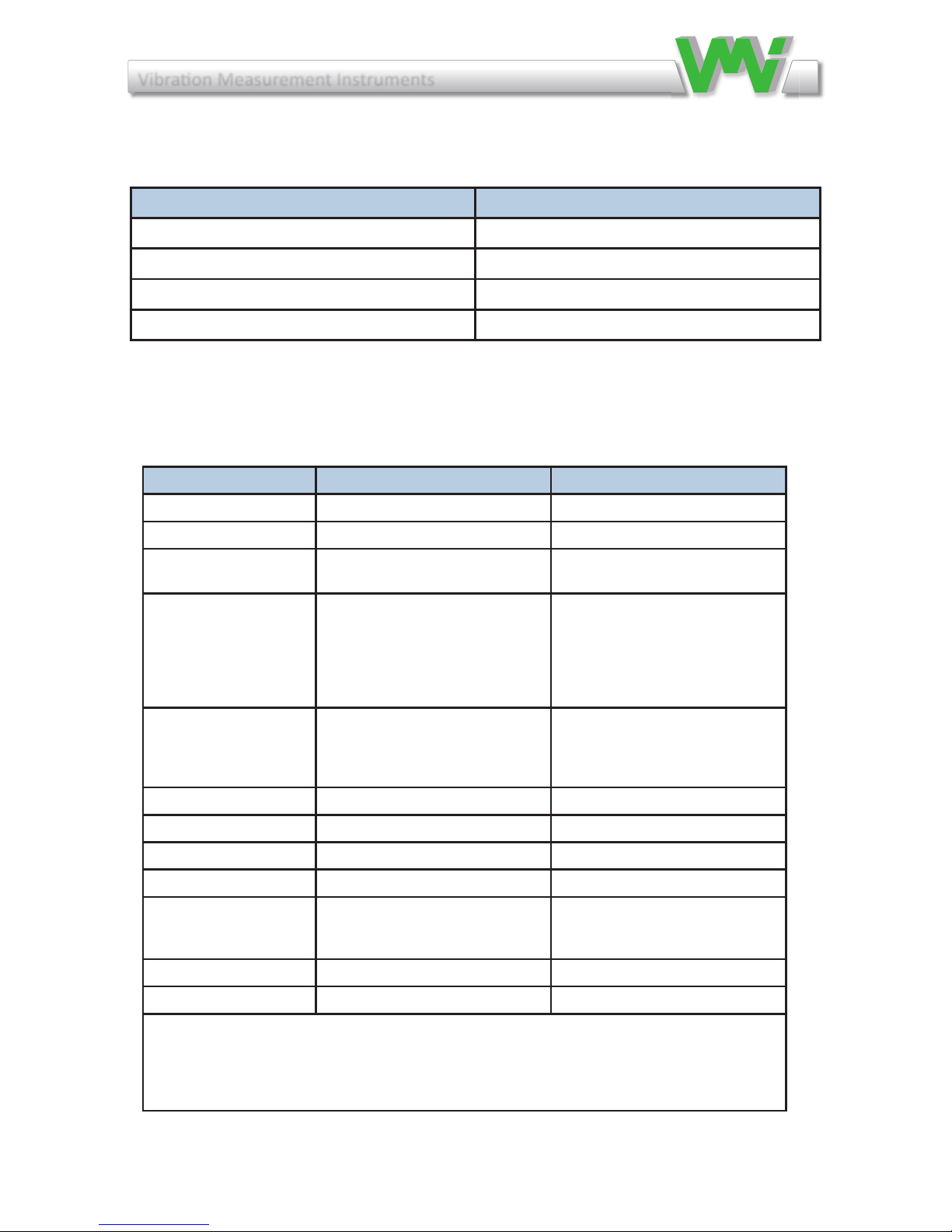

The Frequency range of the peaks in relation to the frequency range setting is described in the below table, the limit

of the maximum frequency of the peak is 1 000 Hz or 60 000 CPM.

Frequency range

Frequency range of the peaks

2 to 1600 Hz

120 to CPM

4 to 1000 Hz

240 to 60000 CPM

4-3200 Hz

CPM

8 to 1000 Hz

480 to 60000 CPM

10-1000 Hz

CPM

10 to 1000 Hz

600 to 60000 CPM

When pressing the (UP) or (DOWN) arrow keys, in the Vibration Screen, the measuring unit is temporarily

changed.

When the (MENU) key is pressed, the Analysis Settings menu is shown.

Select an item with the (UP) and (DOWN) arrow keys.

Change the settings of the selected item with the (LEFT) and (RIGHT) arrow keys.

Auto-shutoff

DISABLED

Settings

20 sec.

Unit

mm/s rms

Range

2-1600 Hz

To exit Settingsmenu, just press again the (MENU) key.

All settings, except disabled transducer power, will be stored into the permanent FRAM memory.

NOTE: As default, when the instrument starts, the transducer power is ENABLED.

Selected item

Frequency /CPM

Measurement status

Total value

measurements

presentat

Measurement Stability bar

Frequency range

Peak number

Indicates battery status and if it is charging

Amplitude

5

1Analysis measurement screen

In the analysis screen you are able to see the total value as well as the amplitude and frequency of the five first peaks

in the spectrum range. If you have enabled the audio (see audio screen) you may also at the same time listen to the

bearings.

In the upper right corner you will see the battery status and if the charger is plugged in or not.

Measurement status can be one of following:

- Measuring (Vibration measuring is ongoing)

- Ranging (The instrument is calculating the best measurement range)

- Averaging (Averaging of the measured data)

- OK (The measurement is stable)

- Overflow (The signal is too high –the measurement is incorrect/not readable.)

In case of amplitude out of range, the value is shown as 3 stars (***).

When the measurement is stable, the last message line shows OK.

The Frequency range of the peaks in relation to the frequency range setting is described in the below table, the limit

of the maximum frequency of the peak is 1 000 Hz or 60 000 CPM.

Frequency range

Frequency range of the peaks

2 to 1600 Hz

120 to CPM

4 to 1000 Hz

240 to 60000 CPM

4-3200 Hz

CPM

8 to 1000 Hz

480 to 60000 CPM

10-1000 Hz

CPM

10 to 1000 Hz

600 to 60000 CPM

When pressing the (UP) or (DOWN) arrow keys, in the Vibration Screen, the measuring unit is temporarily

changed.

When the (MENU) key is pressed, the Analysis Settings menu is shown.

Select an item with the (UP) and (DOWN) arrow keys.

Change the settings of the selected item with the (LEFT) and (RIGHT) arrow keys.

Auto-shutoff

DISABLED

Settings

20 sec.

Unit

mm/s rms

Range

2-1600 Hz

To exit Settingsmenu, just press again the (MENU) key.

All settings, except disabled transducer power, will be stored into the permanent FRAM memory.

NOTE: As default, when the instrument starts, the transducer power is ENABLED.

Selected item

Frequency /CPM

Measurement status

Total value

measurements

presentat

Measurement Stability bar

Frequency range

Peak number

Indicates battery status and if it is charging

Amplitude

Indicates battery status and if it is charging

Total value

Measurment Stability bar

Frequency range

Peak number

Amplitude

Frequency /RPM

Measurment status

If alarm is activated levels will be displayed if not **** are displayed

Vibraon Measurement Instruments

9

The following item settings are available:

The frequency appears as follows:

Frequency range Frequency range of peak detecon

2 - 400 Hz 2 - 400 Hz

6 - 1600 Hz 6 - 1600 Hz

11 - 3200 Hz 11 - 2000 Hz

10 - 1000 Hz 10 - 1000 Hz

Item Value Notes

Backlight ENABLED or DISABLED

Auto-shuto ENABLED or DISABLED Shuto aer 60 seconds

Seng 20 sec, 30 sec, 40 sec, 1 min, 2 min

and 3 min Set the Auto-shuto

Unit

g (RMS, Peak or P-P)

m/s2 (RMS, Peak or P-P)

mm/s (RMS, Peak or P-P)

µm (RMS, Peak or P-P)

inch/sec (RMS, Peak or P-P)

mils (RMS, Peak or P-P)

Range

2 - 400 Hz

6 - 1600 Hz

11 - 3200 Hz

10 - 1000 Hz

Alarm * ENABLED or DISABLED

Warning Default value 6.00 Keep key pressed to auto-repeat

Danger Default value 11.0 Keep key pressed to auto-repeat

Language ** (Depending of rmware version)

Sensivity (mV/g)

During calibraon the transducer

sensivity can be adjusted between

0,1 to 99999 mV/g

Do not change aer instrument cali-

braon. Set sensivity in accordance

with the transducers

Transducer power ENABLED or DISABLED 4 mA for accelerometer

Frequency RPM or Hz

* Can only be set for units mm/s and in/s RMS

** Standard languages are: English, Swedish, French, German, Czech, Romanian, Spanish, Portuguese and

Finnish. For another language please contact your instrument supplier for avaliability

Vibraon Measurement Instruments

10

2

Warning!

Incorrect setting of the emissivity factor

can lead to considerable errors of

measured temperature.

Direct the IR temperature transducer towards the surface you want to measure. Keep a distance of approximately 200-500 mm (8- 20 inches)

between the instrument and the object. Reduce the distance between the object and the instrument in accordance with the surface size.

Note: when you get the temperature that differs most to the surroundings, then you probably have got the right direction.

The measurement surface size related to the distance 8:1

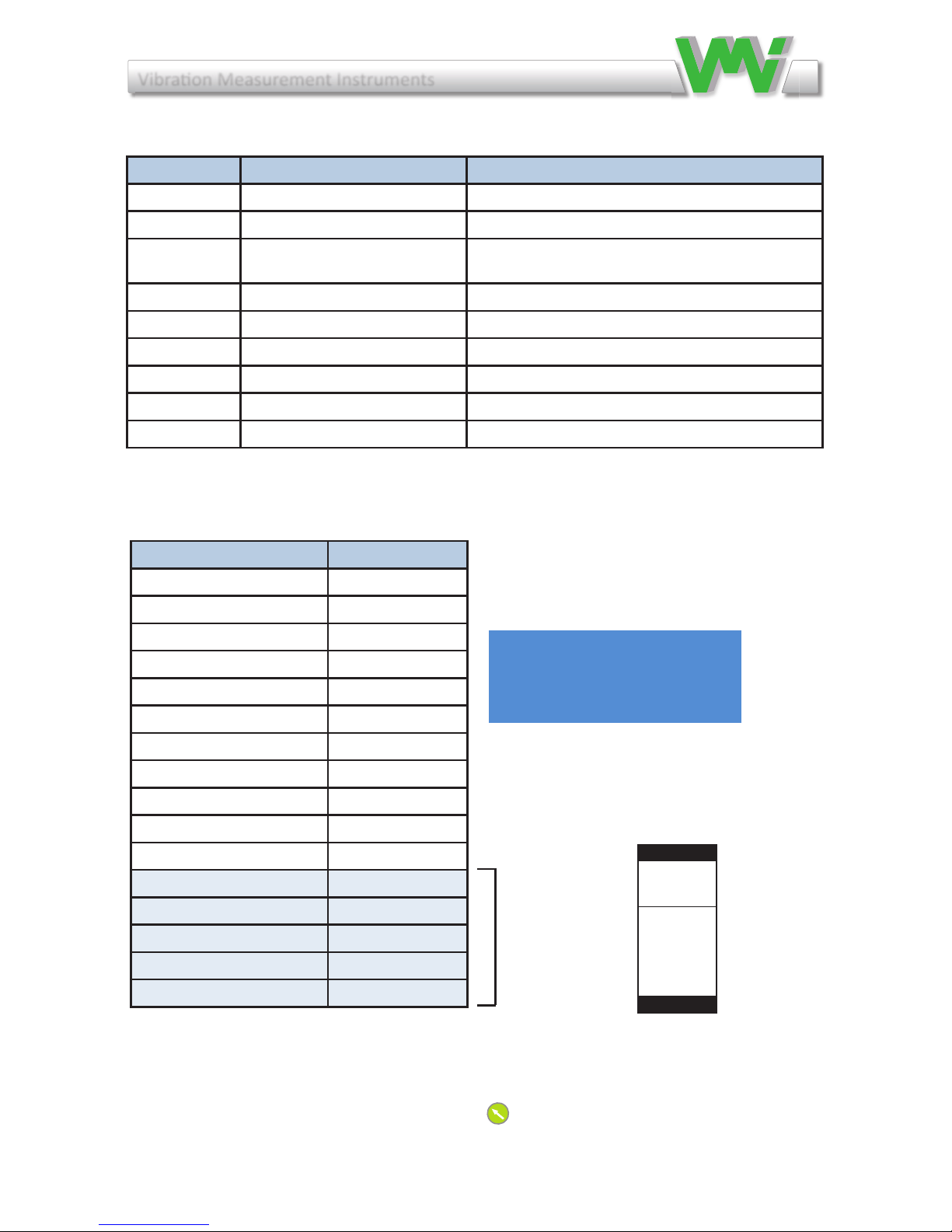

Emissivity:

Set the coefficient for surface reflection factor (Emissivity factor) using the table below or check via a contact probe.

Select the item with (UP) and (DOWN) arrow keys.

Sound screen

Listening to a machine sounds enables analysis of gears and low speed bearings (<300 rpm) in an alternative way and can improve analysis

speed and quality. Viber X3™ makes it possible for the user to listen to the machine while at the same time seeing the vibrations in the

instrument display.

Note that you must choose the Vibration Screen while the sound is enabled the see the vibration signal.

When a headphone set is connected to the Viber X3™, the Sound Screen can be used to adjust the sound volume (depending on hardware

version there is also a volume control on the headphone cord). Before changing volume, the SOUND function must be ON. Sound output

status is enabled (ON) or disabled (OFF) in the Sound Settings menu.

Material

Emissivity

factor

Heat sink, black anodized

0.98

Paper

0.97

Black paint, matt

0.97

Ice, smooth

0.97

Wood

0.94

Glass

0.94

Rubber, hard

0.94

Transformer paint

0.94

Concrete

0.93

Br

ick, mortar, plaster

0.93

Porcelain

0.92

Steel, oxidized

0.79

Cooper, oxidized

0.76

Steel, heat treated surface

0.52

Copper

0.04

Aluminium, bright

0.04

Warning!

To protect your hearing, you should always remove the headphones from your

ears when you move the sensor or re

-

connect the cable.

2

Warning!

Incorrect setting of the emissivity factor

can lead to considerable errors of

measured temperature.

Direct the IR temperature transducer towards the surface you want to measure. Keep a distance of approximately 200-500 mm (8- 20 inches)

between the instrument and the object. Reduce the distance between the object and the instrument in accordance with the surface size.

Note: when you get the temperature that differs most to the surroundings, then you probably have got the right direction.

The measurement surface size related to the distance 8:1

Emissivity:

Set the coefficient for surface reflection factor (Emissivity factor) using the table below or check via a contact probe.

Select the item with (UP) and (DOWN) arrow keys.

Sound screen

Listening to a machine sounds enables analysis of gears and low speed bearings (<300 rpm) in an alternative way and can improve analysis

speed and quality. Viber X3™ makes it possible for the user to listen to the machine while at the same time seeing the vibrations in the

instrument display.

Note that you must choose the Vibration Screen while the sound is enabled the see the vibration signal.

When a headphone set is connected to the Viber X3™, the Sound Screen can be used to adjust the sound volume (depending on hardware

version there is also a volume control on the headphone cord). Before changing volume, the SOUND function must be ON. Sound output

status is enabled (ON) or disabled (OFF) in the Sound Settings menu.

Material

Emissivity

factor

Heat sink, black anodized

0.98

Paper

0.97

Black paint, matt

0.97

Ice, smooth

0.97

Wood

0.94

Glass

0.94

Rubber, hard

0.94

Transformer paint

0.94

Concrete

0.93

Br

ick, mortar, plaster

0.93

Porcelain

0.92

Steel, oxidized

0.79

Cooper, oxidized

0.76

Steel, heat treated surface

0.52

Copper

0.04

Aluminium, bright

0.04

Warning!

To protect your hearing, you should always remove the headphones from your

ears when you move the sensor or re

-

connect the cable.

6.2 Temperature measurement screen

Inthetemperaturescreenyouseethetemperatureoftheobjectyouare

measuring.

Temperature measurement status can be one of following:

Averaging(Averagingofthemeasureddata)

OK(Themeasurementisstable)

Overow

(Thesignalistoohigh–themeasurementisincorrect/notreadable.)

Incaseofamplitudeoutofrange,thevalueisshownas3stars(***).

Whenthemeasurementisstable,thelastmessagelineshowsOK.

AvailablemeasurementunitsareCelsius(°C)andFahrenheit(°F).

DirecttheIRtemperaturetransducertowardsthesurfaceyouwanttomea-

sure. Keep a distance of approximately 200-500 mm (8- 20 inches)

betweentheinstrumentandtheobject.Reducethedistancebetweenthe

objectandtheinstrumentinaccordancewiththesurfacesize.

Note:whenyougetthetemperaturethatdiffersmosttothesurroundings,

then you probably have got the right direction.

Auto-shutoff

DISABLED

Settings

20 sec.

Unit

mm/s rms

Range

2-1600 Hz

To exit Settings menu, just press again the (MENU) key.

All settings, except disabled transducer power, will be stored into the permanent FRAM memory.

1.1 Temperature measurement screen

In the analysis screen you see the temperature of the object you are measuring. If you have enabled the audio (see audio screen) you may also

at the same time listen to the bearings.

In the upper right corner you will see the battery status and if the charger is plugged in or not.

Temperature measurement status can be one of following:

Ranging (The instrument is calculating the best measurement range)

Averaging (Averaging of the measured data)

OK (The measurement is stable)

Overflow (The signal is too high – the measurement is incorrect/not readable.)

In case of amplitude out of range, the value is shown as 3 stars (***).

When the measurement is stable, the last message line shows OK.

Available measurement units are Celsius (°C) and Fahrenheit (°F).

Stability bar

Temperature

Current emissivity factor

Measurement status

NOTE: As default, when the i

nstrument starts, the transducer power is ENABLED.

Selected item

Themeasurementsurfacesizerelatedtothedistance8:1

When(MENU)keyispressed,theTemperatureSettingsmenu is shown.

Vibraon Measurement Instruments

11

2

Warning!

Incorrect setting of the emissivity factor

can lead to considerable errors of

measured temperature.

Direct the IR temperature transducer towards the surface you want to measure. Keep a distance of approximately 200-500 mm (8- 20 inches)

between the instrument and the object. Reduce the distance between the object and the instrument in accordance with the surface size.

Note: when you get the temperature that differs most to the surroundings, then you probably have got the right direction.

The measurement surface size related to the distance 8:1

Emissivity:

Set the coefficient for surface reflection factor (Emissivity factor) using the table below or check via a contact probe.

Select the item with (UP) and (DOWN) arrow keys.

Sound screen

Listening to a machine sounds enables analysis of gears and low speed bearings (<300 rpm) in an alternative way and can improve analysis

speed and quality. Viber X3™ makes it possible for the user to listen to the machine while at the same time seeing the vibrations in the

instrument display.

Note that you must choose the Vibration Screen while the sound is enabled the see the vibration signal.

When a headphone set is connected to the Viber X3™, the Sound Screen can be used to adjust the sound volume (depending on hardware

version there is also a volume control on the headphone cord). Before changing volume, the SOUND function must be ON. Sound output

status is enabled (ON) or disabled (OFF) in the Sound Settings menu.

Material

Emissivity

factor

Heat sink, black anodized

0.98

Paper

0.97

Black paint, matt

0.97

Ice, smooth

0.97

Wood

0.94

Glass

0.94

Rubber, hard

0.94

Transformer paint

0.94

Concrete

0.93

Br

ick, mortar, plaster

0.93

Porcelain

0.92

Steel, oxidized

0.79

Cooper, oxidized

0.76

Steel, heat treated surface

0.52

Copper

0.04

Aluminium, bright

0.04

Warning!

To protect your hearing, you should always remove the headphones from your

ears when you move the sensor or re

-

connect the cable.

Emissivity:

Setthecoefcientforsurfacereectionfactor(Emissivityfactor)usingthetable

below or check via a contact probe.

The following temperature settings are possible:

ToexitSettingsmenu,justpressagainthe(MENU)key.All settings will be

storedintothepermanentFRAMmemory.

To change Emissivity factor, in the Function menu go to Settings then go to

Temp scroll down to Emissivity and use the arrow keys to change the value.

Temp

°C

Emissivity

0,98

Alarm

DISABLED

Warning

60,0 °C

Danger

80,0 °C

ACCEPT

Item Values Set the Auto-shuto me

Backlight ENABLED or DISABLED

Auto-shuto ENABLED or DISABLED

Seng 20 sec, 30 sec, 40 sec, 1 min,

2 min, 3 min Set the Auto-shuto me

Unit °C or °F

Alarm ENABLED or DISABLED

Warning 0,00 - X Keep key pressed to auto-repeat

Danger 0,00 - X Keep key pressed to auto-repeat

Language If nothing else is specied at order English will be pre set

Emissivity 0,79 - 1,00 Should be set in accordance with the target surface

Material Emissivity factor

Heat, sink, black anodized 0.98

Paper 0.97

Black paint, ma 0.97

Ice, smooth 0.97

Wood 0.94

Glass 0.94

Rubber, hard 0.94

Transformer paint 0.94

Concrete 0.93

Brick, mortar, plaster 0.93

Porselain 0.92

Steel, oxidized 0.79

Copper, oxidized 0.76

Steel, heat treated surface 0.52

Copper 0.04

Aluminium, bright 0.04

Don’t use

Vibraon Measurement Instruments

12

6.3 Sound screen

Listeningtomachinesoundsenablesanalysisofgearsandlowspeedbearings(<300

RPM)inanalternativewayandcanimproveanalysisspeedandquality.

VIBER X3™ makes it possible for the user to listen to the machine while at the

same time seeing the vibrations in the instrument display.

NotethatyoumustchoosetheVibrationScreenwhilethesoundisenabledto see

the vibration signal.

When a headphone set is connected to the VIBER X3™, the Sound Screen can

beusedtoadjustthesoundvolume(dependingonhardwareversionthereisalso

avolume control ontheheadphone cord).Beforechanging volume, theSOUND

functionmustbeON.Soundoutputstatus is enabled (ON) or disabled (OFF) in

the Sound Settings menu.

Warning!

To protect your hearing, you should always remove the headphones from

your ears when you move the sensor or re-connect the cable.

2

NY BILD MED BACK

Filter:

When the filter status is set to YES a high pass filter is activated enabling the user to only listen to machine noise in high frequencies.

Audio:

When Audio is ON, using the (UP) and (DOWN) arrows, the sound level can be adjusted. To do this, press and keep the (UP) or

(DOWN) arrow pressed. The volume will increase/decrease slowly. Depending on hardware version the headphone set can also be equipped

with a volume control on the cord.

As safety precautions and to save battery the audio settings are always reset, turning the audio off, when the instrument is started.

When the (MENU) key is pressed, the Sound Settings menu is shown.

Settings

Backlight

ENABLED

Auto-shutoff

DISABLED

Settings

20 sec.

HP Filter

ON

1.2 Balancing screen

If you choose in the function menu, balancing.

Selected

item

Note: With a headphone inserted, at the

maximum volume level, the power

consumption will increase with 150 mA. To

save the battery power, turn the audio off

when it is not used. When the battery

voltage is beginning to be too low and

headphone set is plugged-in, the instrument

will be automatically reset. When the

instrument is reset, as default, the sound is

disabled. In this way the instrument can

continue to run for a while longer without

the need of charging the batteries.

Sound volume

Filter status

Sound status

Filter:

WhenthelterstatusissettoYESahighpasslterisactivatedenablingtheuserto

only listen to machine noise in high frequencies.

Audio:

WhenAudioisON,usingthe(LEFT)and(RIGHT)arrows,thesoundlevel

canbeadjusted.Todothis,pressandkeeptheLEFTortheRIGHT arrow

key pressed. The volume will increase/decrease slowly.

Dependingonhardwareversiontheheadphonesetcanalsobeequipped

with a volume control on the cord.

As safety precautions and to save battery the audio settings are always reset, turning

the audio off, when the instrument is started.

Whenthe(MENU)keyispressed,theSoundSettingsmenuisshown.

2

NY BILD MED BACK

Filter:

When the filter status is set to YES a high pass filter is activated enabling the user to only listen to machine noise in high frequencies.

Audio:

When Audio is ON, using the (UP) and (DOWN) arrows, the sound level can be adjusted. To do this, press and keep the (UP) or

(DOWN) arrow pressed. The volume will increase/decrease slowly. Depending on hardware version the headphone set can also be equipped

with a volume control on the cord.

As safety precautions and to save battery the audio settings are always reset, turning the audio off, when the instrument is started.

When the (MENU) key is pressed, the Sound Settings menu is shown.

Settings

Backlight

ENABLED

Auto-shutoff

DISABLED

Settings

20 sec.

HP Filter

ON

1.2 Balancing screen

If you choose in the function menu, balancing.

Selected

item

Note: With a headphone inserted, at the

maximum volume level, the power

consumption will increase with 150 mA. To

save the battery power, turn the audio off

when it is not used. When the battery

voltage is beginning to be too low and

headphone set is plugged-in, the instrument

will be automatically reset. When the

instrument is reset, as default, the sound is

disabled. In this way the instrument can

continue to run for a while longer without

the need of charging the batteries.

Sound volume

Filter status

Sound status

Settings

Instrument

Transducer

Vibration

Temp

Audio

BACK

Vibraon Measurement Instruments

13

Note: With a headphone inserted, at

the maximum volume level, the power

consump on will increase with 150

mA. To save the ba ery power, turn the

audio o when it is not used. When the

ba ery voltage is beginning to be too

low and headphone set is plugged-in,

the instrument will be automa cally

reset. When the instrument is reset,

as default, the sound is disabled. In

this way the instrument can con nue

to run for a while longer without the

need of charging the ba eries.

Notera: Med hörlurarna isatta är den maximala volymnivån

150 mA. Stäng av ljudet när det inte används för att spara

batteri.

Vibraon Measurement Instruments

14

7 Warning messages

The following message may appear in normal operation:

Warning messages

The following message may appear in normal operation:

This message may appear if the calibration data is lost from the permanent FRAM memory or if the calibration data are

corrupted.

In such cases, the instrument must be re-calibrated; otherwise it will measure incorrectly. The message appears only

once, and then default calibration data is used.

When this message appears, the battery voltage is too low to ensure a correct running condition. The measurements may

be invalid! The instrument battery pack must be charged immediately, using the external charger. In order to temporarily

decrease the power consumption, the backlight will be switched OFF. The instrument can still work, but only for a short

while. If even in this condition the voltage remains low, the instrument will shut off in 20 sec.

This message appears only if the Auto-shut off setting is enabled. The user may cancel the shut-off condition, pressing any

key except ON/OFF. If no key is pressed the instrument will shut off in 5 seconds.

This message appears only if the Transducer power setting is enabled and indicates that the

transducer is missing or is out of order.

When the Transducer power setting is disabled, the user has the possibility to use another external source for the vibration input (a signal

generator or a buffered output from another device).

When the instrument starts, the Transducer power setting is always ENABLED. When this message appears, it will remain on the screen, even

if the transducer is plugged-in. To continue the normal running mode in such a condition, switch the screen temporarily to another menu.

When you come back, the message disappears.

2 Battery status bar

In every measurement screen, at the upper side, a battery status bar is shown.

The status bar indicates the battery voltage, as follows:

External charger plugged into the instrument. Battery is charging.

If the charger is removed, the status bar shows the remaining battery voltage:

When the voltage exceeds 4.0 V, the battery status bar indicates full battery.

If the battery voltage drops to less than 3.5 V, the instrument will shut-off in 20 sec.

Lift the battery cover by removing the two screws on the back side of the instrument.

Warning messages

The following message may appear in normal operation:

This message may appear if the calibration data is lost from the permanent FRAM memory or if the calibration data are

corrupted.

In such cases, the instrument must be re-calibrated; otherwise it will measure incorrectly. The message appears only

once, and then default calibration data is used.

When this message appears, the battery voltage is too low to ensure a correct running condition. The measurements may

be invalid! The instrument battery pack must be charged immediately, using the external charger. In order to temporarily

decrease the power consumption, the backlight will be switched OFF. The instrument can still work, but only for a short

while. If even in this condition the voltage remains low, the instrument will shut off in 20 sec.

This message appears only if the Auto-shut off setting is enabled. The user may cancel the shut-off condition, pressing any

key except ON/OFF. If no key is pressed the instrument will shut off in 5 seconds.

This message appears only if the Transducer power setting is enabled and indicates that the

transducer is missing or is out of order.

When the Transducer power setting is disabled, the user has the possibility to use another external source for the vibration input (a signal

generator or a buffered output from another device).

When the instrument starts, the Transducer power setting is always ENABLED. When this message appears, it will remain on the screen, even

if the transducer is plugged-in. To continue the normal running mode in such a condition, switch the screen temporarily to another menu.

When you come back, the message disappears.

2 Battery status bar

In every measurement screen, at the upper side, a battery status bar is shown.

The status bar indicates the battery voltage, as follows:

External charger plugged into the instrument. Battery is charging.

If the charger is removed, the status bar shows the remaining battery voltage:

When the voltage exceeds 4.0 V, the battery status bar indicates full battery.

If the battery voltage drops to less than 3.5 V, the instrument will shut-off in 20 sec.

Lift the battery cover by removing the two screws on the back side of the instrument.

This message may appear if the calibration data is lost

fromthepermanentFRAMmemoryorifthecalibration

data are corrupted. In such cases, the instrument must be

re-calibrated; otherwise it will measure incorrectly. The

message appears only once, and then default calibration

data is used.

When this message appears, the battery voltage is too

low to ensure a correct running condition. The measure-

ments may be invalid! The instrument battery pack must

be charged immediately, using the external charger. In or-

der to temporarily decrease the power consumption, the

backlightwillbeswitchedOFF.Theinstrumentcanstill

work, but only for a short while. If even in this condition

thevoltageremainslow,theinstrumentwillshutoffin20

sec.Batterychargeshouldnotbeterminatedbeforethe

greenLEDlighthasgoneout.

This message appears only if the Auto-shut off setting

is enabled. The user may cancel the shut-off condition,

pressinganykeyexceptON/OFF.Ifnokeyispressedthe

instrumentwillshutoffin5seconds.

This message appears only if you have forgot to connect

the transducer, or if transducer is broken.

When the Transducer power setting is disabled, the user has the possibility

to use another external source for the vibration input (a signal generator or a

bufferedoutputfromanotherdevice).

Whentheinstrumentstarts,theTransducerpowersettingisalwaysENAB-

LED.Whenthismessageappears,itwillremainonthescreen,evenifthe

transducer is plugged-in. To continue the normal running mode in such a

condition, switch the screen temporarily to another menu.

When you come back, the message disappears.

Warning messages

The following message may appear in normal operation:

This message may appear if the calibration data is lost from the permanent FRAM memory or if the calibration data are

corrupted.

In such cases, the instrument must be re-calibrated; otherwise it will measure incorrectly. The message appears only

once, and then default calibration data is used.

When this message appears, the battery voltage is too low to ensure a correct running condition. The measurements may

be invalid! The instrument battery pack must be charged immediately, using the external charger. In order to temporarily

decrease the power consumption, the backlight will be switched OFF. The instrument can still work, but only for a short

while. If even in this condition the voltage remains low, the instrument will shut off in 20 sec.

This message appears only if the Auto-shut off setting is enabled. The user may cancel the shut-off condition, pressing any

key except ON/OFF. If no key is pressed the instrument will shut off in 5 seconds.

This message appears only if the Transducer power setting is enabled and indicates that the

transducer is missing or is out of order.

When the Transducer power setting is disabled, the user has the possibility to use another external source for the vibration input (a signal

generator or a buffered output from another device).

When the instrument starts, the Transducer power setting is always ENABLED. When this message appears, it will remain on the screen, even

if the transducer is plugged-in. To continue the normal running mode in such a condition, switch the screen temporarily to another menu.

When you come back, the message disappears.

2 Battery status bar

In every measurement screen, at the upper side, a battery status bar is shown.

The status bar indicates the battery voltage, as follows:

External charger plugged into the instrument. Battery is charging.

If the charger is removed, the status bar shows the remaining battery voltage:

When the voltage exceeds 4.0 V, the battery status bar indicates full battery.

If the battery voltage drops to less than 3.5 V, the instrument will shut-off in 20 sec.

Lift the battery cover by removing the two screws on the back side of the instrument.

Warning messages

The following message may appear in normal operation:

This message may appear if the calibration data is lost from the permanent FRAM memory or if the calibration data are

corrupted.

In such cases, the instrument must be re-calibrated; otherwise it will measure incorrectly. The message appears only

once, and then default calibration data is used.

When this message appears, the battery voltage is too low to ensure a correct running condition. The measurements may

be invalid! The instrument battery pack must be charged immediately, using the external charger. In order to temporarily

decrease the power consumption, the backlight will be switched OFF. The instrument can still work, but only for a short

while. If even in this condition the voltage remains low, the instrument will shut off in 20 sec.

This message appears only if the Auto-shut off setting is enabled. The user may cancel the shut-off condition, pressing any

key except ON/OFF. If no key is pressed the instrument will shut off in 5 seconds.

This message appears only if the Transducer power setting is enabled and indicates that the

transducer is missing or is out of order.

When the Transducer power setting is disabled, the user has the possibility to use another external source for the vibration input (a signal

generator or a buffered output from another device).

When the instrument starts, the Transducer power setting is always ENABLED. When this message appears, it will remain on the screen, even

if the transducer is plugged-in. To continue the normal running mode in such a condition, switch the screen temporarily to another menu.

When you come back, the message disappears.

2 Battery status bar

In every measurement screen, at the upper side, a battery status bar is shown.

The status bar indicates the battery voltage, as follows:

External charger plugged into the instrument. Battery is charging.

If the charger is removed, the status bar shows the remaining battery voltage:

When the voltage exceeds 4.0 V, the battery status bar indicates full battery.

If the battery voltage drops to less than 3.5 V, the instrument will shut-off in 20 sec.

Lift the battery cover by removing the two screws on the back side of the instrument.

Vibraon Measurement Instruments

15

8Howtointerpretvibrationlevels

Auserwithnopreviousexperience,shouldusetheISO10816-3standard.

Thestandardnormallycallsforavelocitymeasurementinmm/sRMS.To

better understand what this measurement means, think of it as how fast the

machine is moving back and forth. This measure gives a good understanding

oftheamountof“breakdownenergy”,causingmainlywearandfatiguein

the machine or the structure.

The instrument measures the total RMS vibration value in the frequency

range.ThisRMSvalueistheaveragesumofallthemeasuredvibrations.

Example:

Ifthesimultaneousvibrationcausedbyunbalanceis(4mm/s),bymisalign-

ment(2mm/s)andbythegearmesh(5mm/s)thenthetotalvibrationmea-

sured with VIBER X3™is6.7mm/s.

Noticethatareductionoftheunbalancefrom4mm/sto1mm/s

willreducethetotalvaluefrom6,7mm/sto5,5mm/s.

Total vibraon(RMS)=√4*4+2*2+5*5=6,7mm/s

Vibraon Measurement Instruments

16

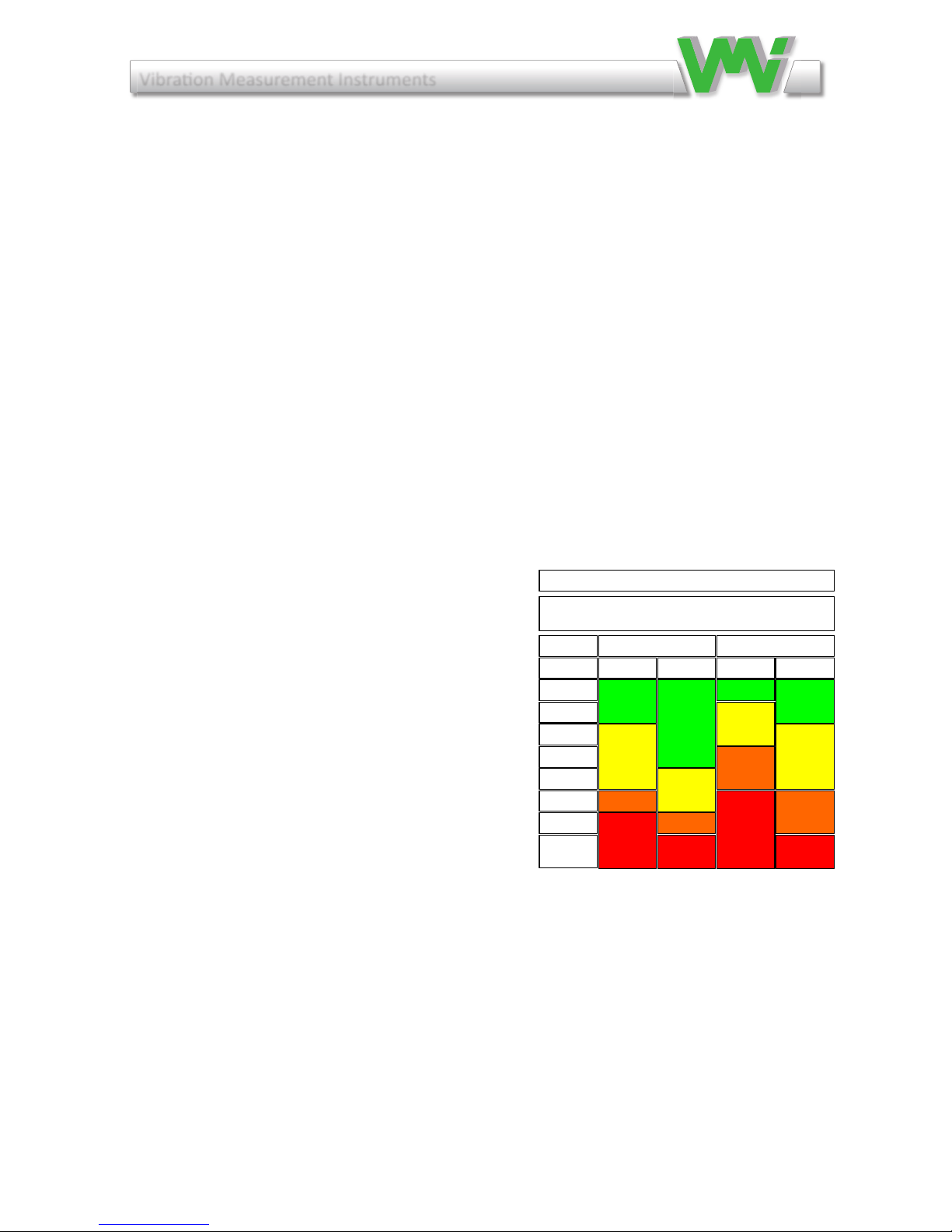

8.1 ISO standard 10816-3

TheISOstandard10816-3classiesmachinesdifferentlywhetherthemachi-

nesareconsideredasexibleorrigidmounted.Thisreectsthelocationof

the machines stiff-body resonances related to the basic running speed of the

machine.

Forinstance,amachinesupportedbyrubberorspring,haveresonancesat

low running speeds. The machine starts vibrate at certain low revolutions.

When the speed is increased above these resonance frequencies, the vibra-

tionisreduced.Thismachineisconsideredexible.

ModernmachinesthathavehighRPM’sandexiblebearingsupportsand

foundations,canbetreatedasexible,evenwhentheyaren’tmountedon

rubber or springs.

Group 1:

Largemachineswithratedpowerabove

300kW.Electricalmachineswithshaft

heightH>315mm.Operatingspeed

rangesfrom120to15000RPM.

Group 2:

Medium-sized machines with a rated

powerabove15kWuptoandincluding

300kW.Electricalmachineswithshaft

heightbetween160<H<315mm.

Operatingspeednormallyabove600RPM.

Group 3:

Pumpswithmultivaneimpellerandwithseparatedriverwithratedpower

above15kW.

Group 4:

Pumpswithmultivaneimpellerandwithintegrateddriverwithratedpower

above15kW.

2

3.1 ISO standard 10816-3

The ISO standard 10816-3 classifies machines differently whether the machines are considered as flexible or rigid

mounted. This reflects the location of the machines stiff-body resonances related to the basic running speed of the

machine.

For instance, a machine supported by rubber or spring, have resonances at low running speeds. The machine starts

vibrate at certain low revolutions. When the speed is increased above these resonance frequencies, the vibration is

reduced. This machine is considered flexible.

Modern machines that have high rpm’s and flexible

bearing supports and foundations, can be treated as

flexible, even when they aren’t mounted on rubber or

springs.

Group 1:

Large machines with rated power above 300kW.

Electrical machines with shaft height H > 315mm.

Operating speed ranges from 120 to 15000 rpm.

Group 2:

Medium-sized machines with a rated power above 15kW up to

and including 300kW.

Electrical machines with shaft height between

160 < H < 315 mm.

Operating speed normally above 600 rpm.

Group 3:

Pumps with multivane impeller and with separate driver with rated power above 15kW.

Group 4:

Pumps with multivane impeller and with integrated driver with rated power above 15kW.

4Vibration analysis

4.1 Recommended vibration levels in mm/s and common findings

The list and table below can be used, as a first consideration, when you approach a machine newly commissioned or after

some time in operation. Investigate the reason for any machine that vibrates above 3 mm/s RMS. Do not leave levels

above 7 mm/s without analyzing consequences.

0 –3 mm/s | 0 –0,12 in/s

Small vibrations - None or very small bearing wear. Rather low noise level.

3 –7 mm/s | 0,12 –0,28 in/s

Noticeable vibration levels often concentrated to some specific part as well as direction of the machine. Noticeable

bearing wear. Seal problems occur in pumps etc. Increased noise level; try to investigate the reason. Plan an action during

next regular stop. Keep the machine under observation and measure at shorter time intervals than before to detect a

deterioration trend if any. Compare vibrations to other operating variables.

7 –11 mm/s | 0,28 –0,43 in/s

Large vibrations. Bearings running hot. Bearing wear-out cause frequent replacements. Seals wear out, leakage of all

kinds evident. Cracks in welding and concrete foundations. Screws and bolts are loosening. High noise level. Plan action

soonest. Do your best to reveal the reason. You are wearing down investments quickly.

Rigid Flexible Rigid Flexible

Group 1 and 3 Group 2 and 4

Industrial machines with power above 15kW and

nominal speeds between120 -15000 r/min

mm/s

Unit

0-1.4

1.4-2.3

2.3-2.8

2.8-3.5

3.5-4.5

4.5-7.1

7.1-11

11--

Extraction's from ISO 10816-3

Vibraon Measurement Instruments

17

9 Vibration analysis

Recommendedvibrationlevelsinmm/sandcommonndings

The list and table on previous page can be used, as a rst consideration,

when you approach a machine newly commissioned or after some time in

operation.Investigatethereasonforanymachinethatvibratesabove3mm/s

RMS.Donotleavelevelsabove7mm/swithoutanalyzingconsequences.

0 – 3 mm/s | 0 – 0,12 in/s

Smallvibrations-Noneorverysmallbearingwear.Ratherlownoiselevel.

3 – 7 mm/s | 0,12 – 0,28 in/s

Noticeablevibrationlevelsoftenconcentratedtosomespecicpartaswell

asdirectionofthemachine.Noticeablebearingwear.Sealproblemsoccurin

pumpsetc.Increasednoiselevel;trytoinvestigatethereason.Plananaction

during next regular stop. Keep the machine under observation and measure

at shorter time intervals than before to detect a deterioration trend if any.

Compare vibrations to other operating variables.

7 – 11 mm/s | 0,28 – 0,43 in/s

Largevibrations.Bearingsrunninghot.Bearingwear-outcausefrequentre-

placements.Sealswearout,leakageofallkindsevident.Cracksinwelding

andconcretefoundations.Screwsandboltsareloosening.Highnoiselevel.

Planactionsoonest.Doyourbesttorevealthereason.Youarewearingdown

investments quickly.

11–mm/s|0,43−in/s

Very large vibrations and high noise levels. This is detrimental to the safe

operationofthemachine.Stopoperationiftechnicallyoreconomicallypos-

sibleconsideringtheplantstopcost.Noknownmachinewillwithstandthis

levelwithoutinternalorexternaldamage.Reduceanyfurtherrunningtime

to an absolute minimum.

Vibraon Measurement Instruments

18

9.1 Resonance

Aresonancecaneasilybefoundwhenaexiblemachineisrunningupor

downitsspeed.TheresonancefrequenciesarelocatedattheRPM’s,where

the vibration has a local maximum level.

To understand a resonance you can compare with the string of a guitar. The

string has its natural basic tone that will ring as soon as the string is struck.

The actual frequency of the tune depends on the stiffness and the distributed

mass of the string.

All machines have similar built in ”tones” with corresponding properties

consisting of stiffness and a mass in the form of mechanical strings such as

shafts,beams,oorsand in all mechanical parts. If anynaturalexcitation

(=alternatingforce)inthemachinehasthesameornearlythesamefrequen-

cyasaresonancefrequencythevibrationwillbeampliedinthismachine

part, and a much higher vibration level will occur.

To identify, measure the vibration levels in three perpendicular directions at

thebearings.Ifyoundameasurementwithatleastthreetimeshigherlevel

than in the other directions, consider resonance as a likely possibility. The

resonance is amplifying the mechanical force and thus gives a high vibration

in that direction. The resonance makes the machine unnecessarily sensitive

to mechanical forces.

Actions to handle a resonance are different depending on its location, opera-

ting conditions etc. It will normally require experience to alter the situation.

Onereasonisthatthemodicationcanaffectthebasicmechanicaldesign

of the machine and normally require the competence of a machine designer.

Werecommendhowevertoconsidersuchmodicationssincethechangeof

the resonance frequency normally is cheap compared to the high maintenan-

cecostthatwillfollowanyattempttorunamachineundertheinuenceof

a resonance.

Sometimesit´spossibletochangethespeedofmachines,whichoftenisa

simple solution.

Table of contents

Other VMI Measuring Instrument manuals