VMI VIBER X5 MKIII User manual

VIBER X5

MKIII™

Instrument Manual

Version: 1.6 Eng

2015-11-27

FW 2.24

VMI International AB

Gottorpsgatan 5 SE-582 73 Linköping, Sweden

Copyright© 2012 by VMI International AB. No copying or reproduction of this information may be undertaken without

written permission of VMI International AB. Due to continuous product development the information in this document

may be changed without further notice.

Important information

Safety precautions

Vibration measurement and balancing involves measurement on rotating machines. Keep

a safe distance from rotating parts and secure transducers and transducer cables away

from rotating parts. Always follow internal, local and national security regulations! When

working with weights on the rotor always secure the start switch with a locking device and

also use the emergency switch for double safety. This is especially important when the

machine can be remotely controlled.

VMI takes no responsibility for any accidents on people and machines.

VMI and our authorized dealers will take no responsibility for damages on machines and

plants as the result of the use of VIBER X5 MkIITM measurements.

Even though great efforts are made to make the information in this manual free from

errors and to make the information complete for the user, there could be items we have

missed, because of the large amount of information. As a result of this, we might change

and correct these items in later issues without further notice. Also changes in the VIBER

X5 MkIITM equipment may take place that affect the accuracy of the information.

VMI develops and manufactures vibration measurement instruments for solving vibration

related problems and balancing of machinery on site. We have more than 30 years of field

experience and product development. We continue to provide a measurement service,

which means that we ourselves use the equipment we develop, and continuously improve

it. Because of this we dare to call ourselves measurement specialists.

Table of Contents

IMPORTANT INFORMATION 4

CHAPTERS 7

1. INSTRUMENT OVERVIEW 8

1.1. INTRODUCTION 8

1.2. SCOPE OF SUPPLY 9

1.3. INSTRUMENT BASICS 10

2. DATA STORAGE AND TRANSFER 28

2.1. FILES 28

2.2. CONNECTION 30

2.4 FAQ REGARDING DATA STORAGE AND TRANSFER 31

3. HELP 32

4. ROUTE 32

4.1. ROUTE INTRODUCTION 32

4.2. TRANSFER A ROUTE TO OR FROM THE INSTRUMENT 33

4.3. MEASURING IN ROUTE 33

4.4. INSTRUMENT ROUTE SETTINGS 35

4.5. INSTRUMENT ROUTE MANAGER 36

4.6. ROUTE VIEWER 36

5. SETTING UP MEASUREMENTS 39

5.1. GETTING STARTED WITH MEASUREMENTS 39

6. RECOMMENDED VIBRATION LEVELS 45

6.1. ISO STANDARD 10816-3 46

6.2. RESONANCE 47

6.3. RECOMMENDED TRANSDUCER LOCATIONS: 48

7. MEASURE (OFF-ROUTE) 49

7.1. UPGRADE MEASUREMENTS 51

7.2. TOTAL VALUE 51

7.3. BEARING CONDITION (BC) 54

7.4. SPECTRA 57

7.5. ENVELOPE 60

7.6. TEMPERATURE 65

7.7. SPEED 66

7.8. PHASE 68

7.9. COAST UP70

7.10. COAST DOWN 72

7.11. ORBIT 74

7.12. DATA LOGGER 77

7.13. VIBSHAPE 81

8. BALANCING 94

8.1. BALANCING THEORY 95

8.2. BALANCING APPLICATION MENU 95

8.3. BALANCING SETTINGS 96

8.4. ISO 1940-1 SETTINGS 97

8.5. BALANCING WINDOW DESCRIPTION 99

8.6. 1- AND 2-PLANE BALANCING 99

8.7. EDIT TRIAL WEIGHT 102

8.8. BALANCING REPORT 103

8.9. RESIDUAL UNBALANCE 104

8.10. RESPONSE MATRIX 104

8.11. BALANCING FILES VIEWER 106

9. INSTRUMENT MAINTENANCE 108

9.1. BATTERY MANAGEMENT 108

9.2. POWER SAVING GOOD PRACTICE 109

10. TROUBLE SHOOTING 110

11. TECHNICAL SPECIFICATION 115

12. INDEX 1167

DECLARATION OF CONFORMITY 120

7

Chapters

To help you navigate through this manual it is organized in chapters.

Chapters Page No.

1. Instrument Overview. This chapter provide a general introduction of

the VIBER X5 MkIII™, it also describes the scope of supply, the basics

on how to use and navigate in the instrument and also the general

settings.

2. Data Storage and Transfer. This chapter covers how the files are stored

in the instrument and how to transfer them internally, to a PC or

network for further analysis. It also describes how to update VIBER

X5™ with new firmware.

3. Help. This chapter describes the instruments context sensitive help

function.

4. Route. This chapter describes the instruments route function.

5. Setting up Measurements. This chapter describes the different general

settings that can be made in the applications and when to use them.

6. Recommended Vibration Levels. This chapter describes the ISO

standard 10816-3 and which vibration levels that is recommendable. It

also describes resonance and where to place the transducers for best

result.

7. Measure (Off Route).This chapter describes the applications in the

Measurements menu. These programs are used to make analysis on

location or when you need to make additional measurements during

Route. It also explains how to expand (upgrade) your instrument with

additional applications and Advanced Settings.

8. Balancing. This chapter describes how to use the one and two plane

balancing application in the VIBER X5 MkIII™

9. Instrument Maintenance. In this chapter are presented maintenance

guidelines to keep your instrument in good condition.

10. Trouble Shooting. If your instrument does not work correctly, this

chapter includes a symptom list, the probable cause of the problem

and what action you should take.

11. 11. Technical Specification

12. Index

8

32

39

44

49

31

94

108

117

110

115

28

1. Instrument Overview

This chapter provide a general introduction of the VIBER X5 MkIII™, it describes the scope of

supply, the basics on how to use and navigate in the instrument and general settings.

1.1. Introduction

The VIBER X5 MkIII™ is an advanced 3 channel vibration analyzer. Together with SpectraPro®

PC software it is a valuable tool for predictive maintenance.

The VIBER X5 MkIII™ is capable of measuring, processing, displaying and storing a wide range

of measurement parameters. You can collect various types of field data; examples are

vibration information, bearing measurements, temperature, speed and other process

variables that enable you to expand its functionality by adding new modules to improve your

analysis capabilities. You may also use the VIBER X5 MkIII™ for 1 or 2 plane balancing.

Features of VIBER X5™:

FAST

VIBER X5 MkIII™uses a new generation of floating point DSP processor from Texas

Instruments (C6700 series), which ensures a very short data processing time.

RUGGED

Made for hard use in hard environments IP65 casing and operating temperature of -20 to

+70 °C

COMPATIBLE

VIBER X5 MkII™ uses SpectraPro® condition monitoring software to manage data. Using an

existing database, it may be used together with Easy VIBER, Easy Balancer and XVIBER

instruments, just the way it is, with no other changes.

EASY TO USE

VIBER X5 MkIII™has a graphical user interface, a right and left hand operated keyboard and a

user friendly context sensitive HELP.

The measurements are grouped so that a novice user can easily handle them, but also the

experienced users have access to the advanced measurement menus.

FLEXIBLE

The instrument works with all standard type of vibration transducer in the market.

In the Route measurement you may define a customized transducer for any measurement

point; this makes most signals accessible, in order to get additional information that might

improve the condition measurement quality.

The instrument is compatible with any external tachometer and also with standard 4-20 mA

process transducers (flow, pressure, temperature a.s.o.).

OPEN SYSTEM

The storage device with all user data can be connected to a PC through a USB cable, as with

any USB mass storage device. No driver is required.

All user data, including route data, is stored as files. To include this data into another

monitoring system, you require the monitoring systems communication protocol

specifications.

9

RELIABLE

VIBER X5 MkIII™is an essential tool for the monitoring of machine health. It has a high

performance VS cost value and offers reliable measurements to ISO standards in

combination with a range of features.

Portable vibration monitoring is important part of condition assessment. Regular vibration

measurement offers a cost effective and advanced complement to online visual inspections

and an outstanding analysis alternative.

VMI consciously follows the professional principles in all spheres of our activities to deliver

competitive products and top-of-line services at competitive prices to our customers. Quality

of products and services is of prime importance for us.

We welcome customer suggestions and feedback, in order to improve consistently and

remain preferred suppliers of products and services.

1.2. Scope of supply

A standard delivery of the VIBER X5 MkIII™will have:

1 pc. VIBER X5 MkIII™ with hand straps

2 pc. High performance accelerometers (VMI192)

2 pc. Transducer cables (1 m)

1 pc. Extension tip

1 pc. Battery charger

1 pc. USB cable for transfer data to PC,

PC software

oBalancing viewer

oData Logger viewer

oRoute viewer

oXY Shape Application

1 pc Robust, airtight, chemical resistant, dust- and waterproof, IP68, carrying case.

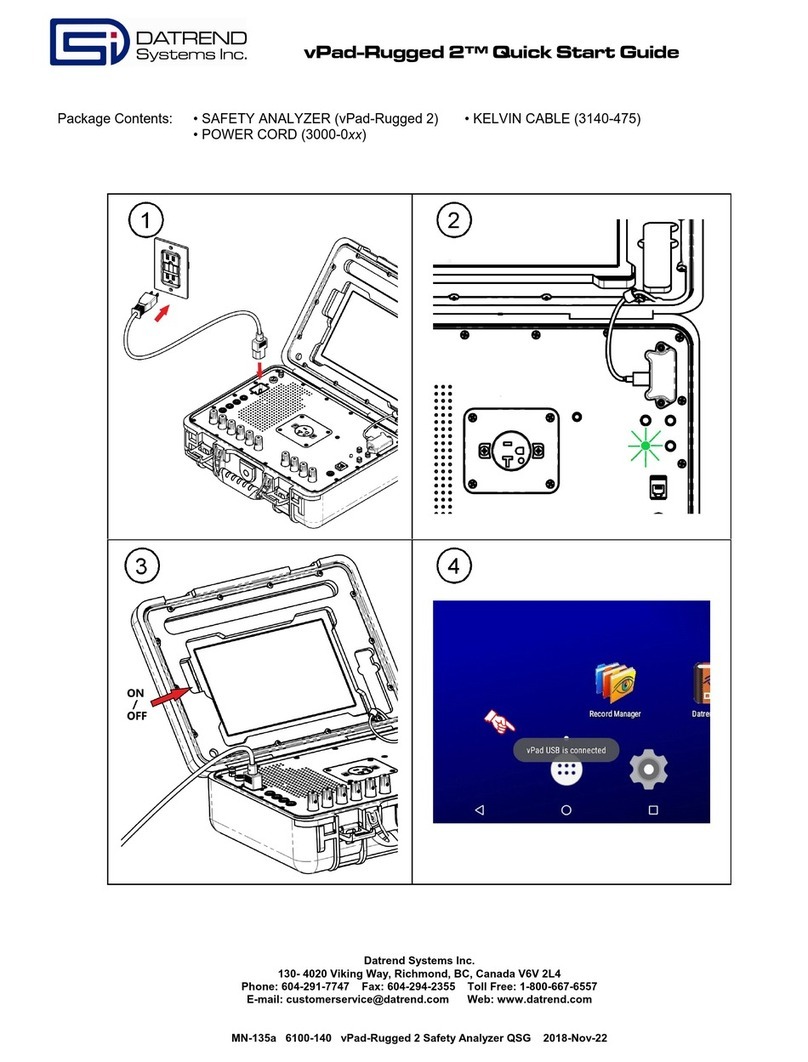

Figure 1-1: Example of supply (example might differ from actual)

10

1.2.1. Optional Accessories

The VIBER X5 MkRII™ have a wide variety of accessories. Contact VMI or your local

distributor for more information of what is available. Here are some examples:

Additional applications

Expand your VIBER X5 MkIRI™ with additional software with a onetime license fee.

PC software

SpectraPro®Orange, route and analyzing program

Vibshape™, modal analysis program

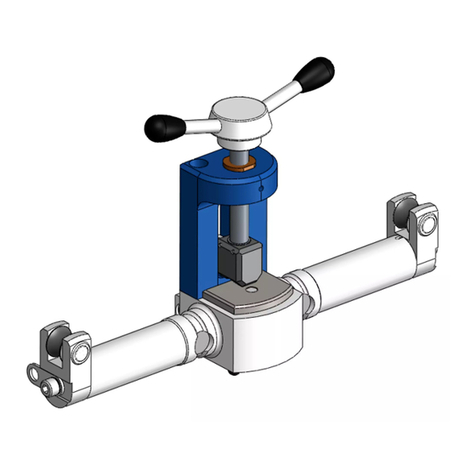

Balancing kit

Software for balancing, external laser tachometer with 5m cable, 5m extension cables for

Vib1 and Vib2 transducers, adjustable magnet holder for the tachometer and a pocket

scale. The VIBER X5™ case is designed with space for the Balancing kit items

Current probe

Enables speed measurement and analysis of electric motors without the need to stand

close to or come in contact with rotating machine parts.

Carrying case shoulder strap

Headphones

Standard or with noise cancelation.

Transducers

Accelerometers, Velocity transducers, Proximity probes.

RPM Transducers

Laser, Optical, Namur, Electromagnetic

Cables

Transducer cables, extension cables, armored cables etc.

1.3. Instrument basics

This section contains basic information about how to operate the instrument and what

different keys and symbols means.

11

Keypad

The VIBER X5™ has double sets of the most frequently used keys, that’s too allow operation

by both left and right hand.

Key

DESCRIPTION

ON/OFF. Used to switch ON or OFF the Instrument.

OK key

ESC key

MENU key

Aux key

UP Arrow key

RIGHT Arrow key

Light Key

ON/OFF key

Ctrl key

DOWN

Arrow key

Red & Blue LED

Green LED

F1 key

F2 key

F3 key

F4 key

Display

LEFT

Arrow key

12

1.3.1.1. Keypad LED’s

The keypad has two LED’s with 3 colors (Blue & Red and Green):

Blue& Red LED, When the key is pressed, the Blue LED will indicate that the next pressed

key will generate a combined code ( key + Key pressed).

When key is pressed, if a LED is ON, the LED will simply be turned off and no key code will

be generated.

If automatic power save mode is activated the led will flash between red and blue a few

seconds before the instrument will switch off to alert you, press any key if you want to keep

the instrument running.

Red LED flashes when the Instrument does not start properly or refuses to start.

Green LED, this will be lit when a valid key is pressed.

1.3.2. Front Panel

OK (Enter). Used to start a measurement(or resume the measurements from

HOLD status), confirm an action or go forward in a menu.

AUX. Used to stop a measurement.

ESC (Escape). Used to Cancel an action or to return to the previous menu.

Arrows (UP, DOWN, LEFT, RIGHT). Depending on the context, are used to

change the selected items, move cursors or together with Light key change the

LCD backlight intensity.

MENU. Used to access MENU shortcut window. Depending on context it is also

used to save changes in edit controls or to select an item.

Ctrl. Used only together with other keys (mainly function keys), to generate

alternative key codes.

Light. Used together with UP or DOWN Arrow key, to adjust the LCD backlight

intensity. Used alone to restore the set intensity, when the Instrument is in

power saving mode.

Function keys (F1, F2, F3, F4). Used to select an action in the shortcut bar

displayed above the keys. They are also used together with Ctrl key to select

actions shown in the second (blue) row of shortcut bar.

Front Panel

13

Cable Connector (solder view)

14

Auto Detection Transducer Connections

15

Cable Connector (solder view)

1.3.3. Status Bar

Most of the screens have a header showing the system status.

The window header displays:

Current date and time

Current menu description

Audio amplifier status (when the function is activated)

Charging status (when the function is activated)

Battery status

Battery icon indicates:

Green= charged battery

Yellow= weak battery.

Red= you should charge as soon as possible.

Charger icon may be:

Green= indicates that the battery is charging.

Red= the external charger stopped the charging process. The external charger still

supplies the Instrument. The red indication shows that the battery temperature is too

high or the charging process is in idle mode. Normally, after a while the charging

process automatically starts.

Blue= charger is connected but the battery charging has ended

Not showing= not connected

Audio amplifier icon may be:

Green= enabled

Not showing= disabled

Audio Amplifier

Charger

Battery

Date / Time

Menu description

1-2: Status Bar

16

1.3.4. Shortcut bar

On the bottom of the screen, the program will display the present available shortcuts that

can be used by pressing the function keys.

Example shortcuts in Route:

Depending on the context, some shortcuts may be disabled (as (F2)-”View Spectrum” in

the example above) or not assigned.

The shortcut bar may have one or two rows depending on the context.

The bottom row (the background have gray color) refers to the actions selected with (F1),

(F2), (F3) and (F4).

The upper row refers to the actions selected with key combinations (Ctrl)+(F1),

(Ctrl)+(F2), (Ctrl)+(F3) and (Ctrl)+(F4), to indicate that the blue (Ctrl) key

should be used for this action the background for the second row is also blue.

+

+

17

Tip: By keeping the Arrow pressed the selected task will automatically change to the next in

line. When reaching the last task in the line press the Arrow key once more if you want to

jump to the first task.

1.3.5. Application Selection

The instrument has a graphical interface to access different

application programs.

In the application selection menus, each of the applications is

represented as a small picture/icon with a short description

beneath.

The applications are hierarchically organized.

A selected task/icon will have a green color. In Figure 1 the application menu “System Tools”

is selected.

To run a task, select it by using the arrow keys and press (OK).

To return to higher hierarchy press (ESC) key.

1.3.6. Settings menus

When you select a measurement you first enter into the

settings menu for that measurement.

To edit the value of a specific parameter, first select it, using

(UP) or (DOWN)Arrow keys. It will be highlighted.

To start editing, press (RIGHT)Arrow key. Depending on

the parameter type, editing may consist of:

1. Selection from a list

Last selected value has a check mark before description. The

current value is highlighted.

To change the current value, just move the selection using

(UP) or (DOWN)Arrow keys and press (OK) or (MENU) to save. To exit without

changes, press (ESC).

2. Edit a numeric value or a description

On the right side of the parameter description, a single line

editor is displayed.

The shortcut bar will change, to indicate the available options:

(F1)-Delete one character on the right side of the cursor

(F2)-Delete one character on the left side of the cursor

(F3)-Delete all characters

(F4)-Toggle edits procedure between insert and overwrite mode.

Figure 1-4: Highlighted parameter

Figure 1-3: Instrument Settings menu

Figure 1-5: List Selection

Figure 1-6: Single line editor

18

The program filters the keys to be valid for parameter value. If a number is required, an

alphanumeric character will be ignored. If a file name is required, the first character must be

alphanumeric.

To save the new value, press (OK). To remove changes press (ESC).

After changing the parameters, you may press (ESC) to return to higher level menu or

(OK) to continue with a measurement menu.

1.3.7. Virtual Keyboard

Virtual keyboard is used to write user notes to be saved

together with the measurements.

Notice that the status bar will change, to indicate the

available shortcuts:

(F1)-Delete one character on the right side of the

cursor

(F2)-Backspace, delete one character on the left side

of the cursor

(F3)-Clear

(F4)-Insert

(Arrow keys) –Change character

(Ctrl) + (Arrow keys) move cursor

Select a character with (MENU) key.

To save, press (OK).

To discard changes, press (ESC).

1.3.8. Menu Overview

Figure 1-8is an overview of how the different application/icon menus are organized (note the

picture is only an explanatory example, some applications existing and available for the

instrument may not be included).

The menus are organized in hierarchy with the main menu on top.

Figure 1-7: Virtual Keyboard

Figure 1-8: Menu Overview

19

1.3.9. Main menu

In the main menu, besides being the first screen from which you

navigate to the different application programs, you can also see:

The battery status in V (Volt) and % (Percent)

The serial number of the instrument

Program version running

When pressing (ESC) key (jumping back in hierarchy) this is where you will finally end up

(sometimes you need to press the (ESC) key several times since you only go back one step

in hierarchy for each press on the button).

In the main menu you can choose between:

Settings. This group of programs provides the configuration procedures for the

instrument

Connection. This is used when connecting to a PC.

Help. This menu is a direct access to the help system in the actual context. The Help

menu is also available in any static menu by pressing the (MENU) key and select

Help.

Route. Is used when machines are measured on ordinary basis

Measure. In this menu all measurements (off route) applications are located.

Balancing. Enter into the balancing menu.

Files. Files menu is used when you want to view, copy or handle your stored files.

Signal Generator Function. Enter to Enable/Disable and to configure the signal

settings.

1.3.10. Instrument Settings

This group of programs provide the configuration

settings for the instrument.

From the Main menu select Settings.

In Instrument Settings Menu you have the following applications:

System Tools. Check the instrument functions

General. set the general instrument parameters

Transducers. Edit the Transducers to be used

Select Sensor. Choose which transducer to be used

Update. Update the instrument firmware and applications.

Factory Reset. Restore default settings.

When using the Instrument for the first time, we recommend you to make your own settings,

depending on application. Check that the instrument date/time is properly configured so

that the saved data can be identified with ease.

Figure 1-9: Main menu

Figure 1-10: Instrument Settings

Selection

20

Figure 1-13: Key code

1.3.11. System Tools

System tools are used in order to check the

instruments functions and have following sub

menus: Keypad, Display, Format and Bias

From Main menu select Settings and System Tools.

1.3.11.1. Keypad

This tool performs a keypad test. When you are not

sure that one or more keys are working properly,

you can perform this test.

From Main Menu select Settings, System Tools and Keypad.

Every time you press a key, that key name and the

corresponding key code will be shown, like in Figure 1-13.

1.3.11.2. Display

This tool performs a color display test. You can

visually observe if the screen colors are as

expected and if some pixels are defective.

From Main Menu select Settings, System Tools and Display.

In Display test, the screen is filled with a color as the other half

contains procedure instructions.

Press (F1), (F2), (F3), (F4) keys to change fill

color to white, red, green or blue.

Press (OK) to change the half of the screen which is

currently tested.

Press (ESC) to exit.

If the colors do not appear correctly, the display unit should be changed in a VMI Service

Centre.

Figure 1-11: System Tools selection

Figure 1-12: Keypad selection

Figure 1-14: Display selection

Figure 1-15: Display instructions

Table of contents

Other VMI Measuring Instrument manuals