Voda Plumbingware Eclipse User manual

Voda Plumbingware (NZ) Ltd | Freephone: 0508 367 366 | 5 Hewlett Street, Port Whangarei 0110 | vodaplumbingware.co.nz

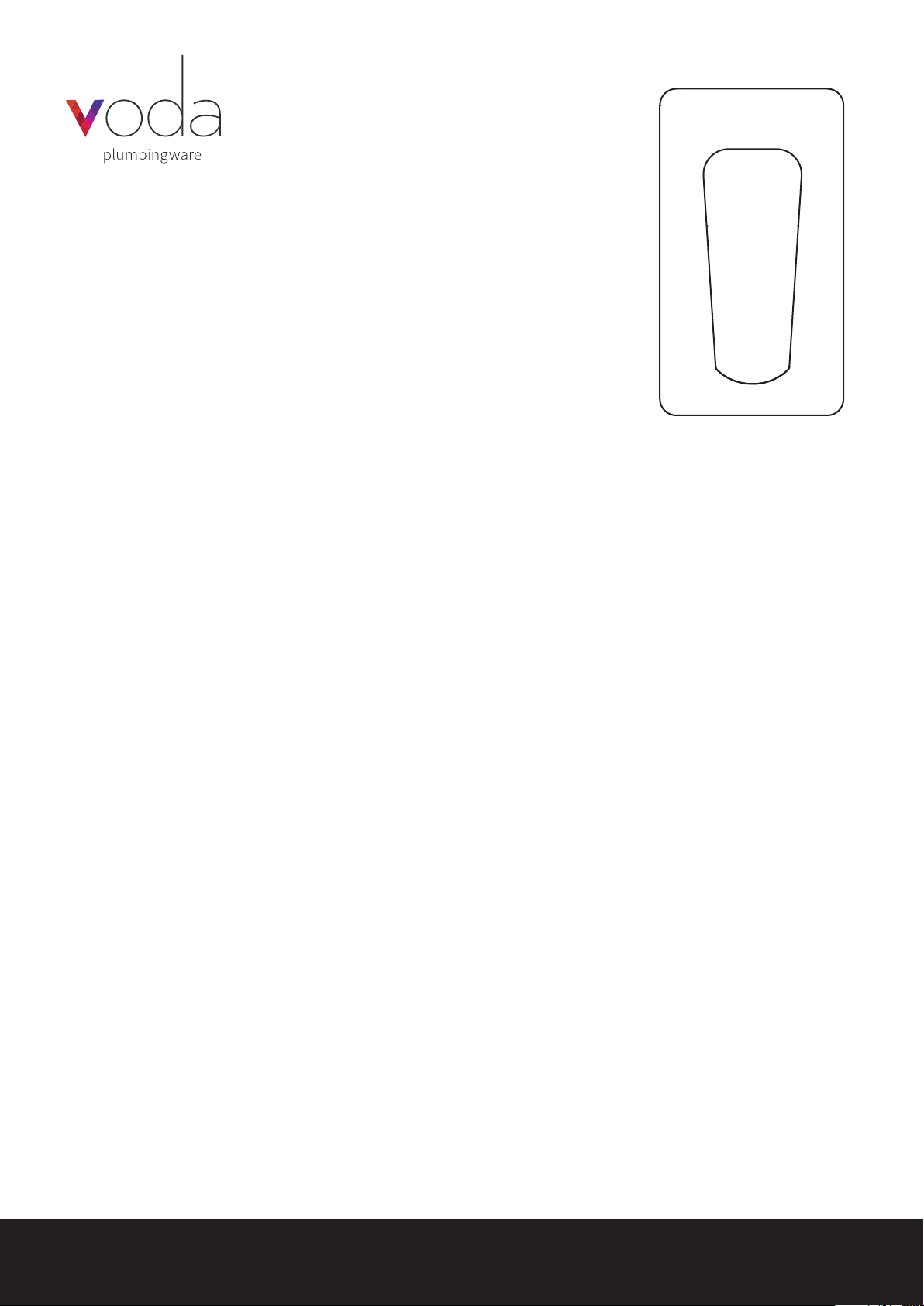

Eclipse Shower Mixer

Congratulations on your purchase of this high quality product from Voda Plumbingware.

Please read the following before installation and retain (along with your receipt) for future reference.

TECHNICAL SPECIFICATIONS

Suitable for All Pressures

Minimum Pressure = 35kPa

Maximum operating Pressure = 500kPa*

Maximum operating Temperature = 65 deg. Celsius

For domestic use only.

CONFIGURATION

Mains Pressure systems Prior to installation, remove the valve inserts from both inlets.

Unequal Low systems Install as supplied.

Important note: Only slide showers that are equipped with a large internal bore hose and open flow single

function handset will work eectively with this shower mixer. We recommend this mixer be used with an

Eclipse Slide Shower (VECL61RCH or VECL61SCH) for optimum performance. If the cold pressure dierence is

greater than 10/1 ratio (i.e. 400kPa cold and 35kPa hot), we recommend installing the needle valve (supplied)

preferably directly to the cold water feed port on the shower mixer, or anywhere on the cold feed pipe.

Equal Low systems Prior to installation, remove the valve inserts from both inlets.

INSTALLATION

*FOR PRESSURES EXCEEDING 500kPa INSTALL A PRESSURE REDUCING VALVE. THOROUGHLY FLUSH ALL

PIPES TO ELIMINATE ANY REMAINING DIRT AND RESIDUE, AND INSTALL INLINE FILTERS. FAILURE TO DO SO

MAY VOID THE WARRANTY.

Installation must comply with Section 5.4 of AS/NZS 3500 Standard with regard to Isolating stop cock use. Shower

mixers must be water tested with the outlet open, to prevent damage to cartridge seals; due to back pressure.

All pipe work must be flushed prior to the installation of this mixer, accessible inline filters must be installed in the

pipework for both the hot and cold inlet supply to prevent particles from damaging the ceramic cartridge.

Back Flow Prevention: Where back flow prevention is required, install

our Back Flow Prevention Valve at the supply elbow hose connection

of the handpiece.

Any water seepage ex- the cartridge cavity opening can be stopped by retightening the large brass retaining nut.

If you have performance issues please check there are no flow restrictors between the hose and the handpiece, or

the hose and the shower elbow. Remove any restrictors with rubber washers.

Plumbers Note: Do not pressure test this mixer under static pressure.

TROUBLESHOOTING

1. Is the lever between 7 and 8 O’clock? When installed correctly the lever should be close to 7 O’clock position, at 38°C, delivering about 6L per minute,

where the relative hot/cold pressures are not greater than 10:1. We recommend installing the supplied Needle Valve when there is a greater than 10/1

ratio of cold to hot kPa (The needle valve should be about an 1/8th turn open), or if the hot/cold mix is temperamental.

2. If the lever is beyond 8 O’clock position, it is likely:

– One of the valve inserts has been removed from the hot/cold ports;

– The supply elbow has a restrictive bore (i.e. less than 10mm);

– The supply hose has a bore size less than 9.5mm;

– The handpiece is not a free-flow single function model

– The WELs restrictor hasn’t been removed.

– The Pressure reducing valve has not been readjusted (the feed valve on the LP Hot water cylinder should always be readjusted when installing a new

mixer, because the head pressure drops over time. To readjust the Feed Valve (Pressure reducing valve) – turn the adjuster screw clockwise until the first

drips appear from the relief pipe (protruding from the roof) or relief valve then back it o half-a-turn and re-secure the locking nut.

3. If the hot/cold mix is temperamental where the lever positon is within 7-8 O’clock position, either the hot or cold pressures will just require a slight tweak.

4. Check that the hot and cold supply lines have not been incorrectly plumbed in, i.e. such as the cold supply connected to the hot inlet and hot supply

connected to the cold inlet. This is especially bad for Unequal Low systems as the hot port on the shower mixer body can enlarge meaning that the valve

inserts will also need to be swapped.

5. *When using with Unequal Low systems,it needs to be remembered the requirement for a minimum of 450mm of straight outlet pipe, before any

bends.

WARRANTY

PLEASE CALL US BEFORE REMOVING TAPWARE OR UNDERTAKING ANY REPAIR WORK.

Please refer to our website for warranty information: www.vodaplumbingware.co.nz/warranty

In the unlikely event that this product fails during its warranty period, phone our Customer Service team

immediately on 0508 367 366 – as unauthorised removal of the product may void the warranty.

CARE AND MAINTENANCE

SHOULD NOT BE CLEANED WITH ACIDIC, CAUSTIC/ALKALINE, ABRASIVE OR CITRIC CLEANERS.

A so, damp cloth is recommended for cleaning (Not a Micro fibre cloth). Mild soap solutions can also be used on

occasion.

Voda Plumbingware (NZ) Ltd | Freephone: 0508 367 366 | 5 Hewlett Street, Port Whangarei 0110 | vodaplumbingware.co.nz

HOTsupply only

COLDsupplyonly

Min 45mm

Max60mm

Seal with silicon

if necessary

IMPORTANT:

450mm Minimum

Straight Distance*

115mm Faceplate

150mm Faceplate

**Min = Ø60mm

**Max = Ø700mm

90mm Faceplate

**Min = Ø60mm

**Max = Ø70mm

**Cut To Suit Faceplate

ATTACH PROOF OF PURCHASE HERE

421 3

Table of contents