Voith BTG MEK-3000 User manual

User Manual

MEK-3000

Rotating Consistency Transmitter

Copyright© 2021 BTG Instruments AB

The contents of this document are subject to revision without notice due to continued progress

in methodology, design, and manufacturing. BTG shall have no liability for any error or

damages of any kind resulting from the use of this document.

All rights reserved. No part of this document may be copied, photocopied, published,

reproduced, translated or converted into electronic or machine-readable form

without written permission of BTG Instruments AB.

Original Instructions

BTG Instruments AB, 2021

© BTG 2021 User Manual MEK-3000 M2071/8en I

Table of contents

Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Product Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.3 Type Plate Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.4 CE Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Communication Platform CPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.1 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.3 Type Plate Explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.4 CE-Declaration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5.5 Supplier's Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Installation Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Process Site Selection for Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Dilution Water Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3 Process Site Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3.1 MEK-3000 Dimensions and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.2 Weld-in Saddle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.3 Measuring Chamber with Weld-in Stud . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.4 Measuring Vessel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.5 Sensing Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.6 Propeller and Hub recommendations . . . . . . . . . . . . . . . . . . . . . . . . 29

II User Manual MEK-3000 M2071/8en © BTG 2021

4 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Saddle / Weld-in Stud / Measuring Vessel Installation . . . . . . . . . . . . . . 32

4.2.1 Saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2.2 Weld-in Stud for Ø180 mm Flange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2.3 Measuring Vessel with Saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2.4 Weld-in Stud for Ø270 mm Flange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.5 Measuring Vessel for Ø270 mm Flange. . . . . . . . . . . . . . . . . . . . . . . . . 41

4.3 Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.3.1 Check Mechanical Sealing Movability . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3.2 Mount the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.3.3 Mount / Dismount the Dirt Cap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.4 Mounting of Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.4.1 Inspection Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.5 Connection Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.5.1 Flushing Water Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.5.2 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.6 Communication Platform CPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.6.1 Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.6.2 Cabling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.6.3 Connection Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.6.4 Backup Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.6.5 RS-485 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5 Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6 Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1 Maintenance Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1.1 Regular Maintenance of the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1.2 General Maintenance Advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.2 Service Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.2.1 Removing the Transmitter from the Pipe . . . . . . . . . . . . . . . . . . . . . . . 68

6.2.2 Changing O-rings and Sealings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.2.3 Changing the Electronics Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.2.4 Changing Sensing Element and Propeller/Hub . . . . . . . . . . . . . . . . . . . 71

6.2.5 Changing the Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

© BTG 2021 User Manual MEK-3000 M2071/8en III

6.3 Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

6.3.1 Calibration Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.1 HCM-8000 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.2 FCM-8000 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.3 Alarms and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

7.4 Raw Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.5 Life Cycle Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.6 Pulp Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7.7 MEK-3000 Documentation Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8 CPM Operation Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.1.1 Software Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.1.2 User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.1.3 How to Read This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.1.4 Parameter Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.2 Menu Structure Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.2.1 Measurement/Sample Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.2.2 Calibrate Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8.2.3 Configure Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.2.4 Diagnostics Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.2.5 Backup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.3 General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.3.1 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.3.2 Calibration Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.3.3 Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.3.4 Check Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.4 Measurement/Sample Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

8.4.1 View Device Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.4.2 View Instrument Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.4.3 View/Edit Basic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.4.4 Take Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

IV User Manual MEK-3000 M2071/8en © BTG 2021

8.5 Calibrate Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8.5.1 View Calibration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8.5.2 View Correlation Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.5.3 Basic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.5.4 Lab Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.6 Configure Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.6.1 General Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.6.2 Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.6.3 Sensor Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

8.7 Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

8.7.1 Life Cycle Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

8.7.2 Configure Alarm Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8.7.3 Configure Warning Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

8.7.4 View Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

8.8 Backup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.8.1 Store Data on a Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.8.2 Restore Data from a Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

8.8.3 Format Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

8.8.4 Store Data and Log Tables on Memory Card . . . . . . . . . . . . . . . . . . . 136

8.8.5 Configure Logging Update Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

9 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

9.1 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

9.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

9.3 Sensing Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

9.4 Propellers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

9.5 Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

9.6 CPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

9.6.1 CPM-1400 with HCM/FCM-8000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

9.6.2 CPM Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Important Information

© BTG 2021 Important Information, MEK-3000 - Rev. A 1

Important Information

This user manual contains all necessary instructions for installation, operation,

maintenance, and basic service of the MEK-3000

NOTE!

Always read the safety instructions before installation and service of the

Analyzer!

The instrument is operated using the CPM communication platform.

For guidelines on how to navigate and configure the CPM, see the CPM

Operation Guide enclosed as appendix with this manual.

Recycling

Recycle the instrument and all replaced parts according to local, first and

foremost national, laws and regulations. Contact BTG to get detailed

information on how to disassemble and recycle the instrument safely.

BTG should have no liability for any error or damage of any kind due to

disassembly or recycle work done.

Important Information

2 Important Information, MEK-3000 - Rev. A © BTG 2021

Safety Instructions

© BTG 2021 Safety Instructions - Rev. A 3

1 Safety Instructions

General

All BTG products(1) are designed according to Sound

Engineering Practice and for the Pulp and Paper

Industry.

These Safety Regulations are based on a risk analysis

carried out in accordance with the requirements of

relevant CE directives in order to comply with European

standards for CE marking.

This document provides general safety instructions that

apply when operating with BTG products to reduce the

risk of accidents. A BTG product is not hazardous in

operational mode if these Safety Regulations are

adhered to.

These Safety Regulations MUST be read before

installing any BTG product. Be careful to follow the

safety routines when installing the product, when

removing the product for service, and when carrying out

service on the product.

Use warning signs for safety information!

Mounting parts, such as measuring vessels and weld-in

studs, are dealt with in accordance with the pressure

vessel standards of specific countries.

Always take precautions when handling equipment in

pressurized pipes.

All installation, operation, service, and other handling

must be carried out by trained and authorized personnel

and according to valid standards.

Personnel must familiarize themselves with the

potential hazards indicated on the product they are

working on to understand which instructions apply. If

questions arise regarding safety instructions, contact

BTG for clarification.

For personal and functional safety: Use only parts that

have been manufactured or approved by BTG.

Local Regulations

First and foremost National Regulations must be

adhered to followed by any Local Regulations.

The National and Local Regulations supersede this

document. Should neither the National nor Local

Regulations cover a particular point within this

document, then the Regulations set out in this

document should be adhered to.

Target Group

The target group for this document is all personnel who

work with products delivered by BTG. These personnel

must familiarize themselves with the instructions in this

document.

Competence Requirements

It is presumed that all personnel who work on products

delivered by BTG have the necessary education,

training, experience and competence required to adapt

actively the personal safety requirements and the

protective measures to their work situation.

English language is typically used for all product

information provided by BTG Instruments AB, thus it is

required that the target group should have sufficient

knowledge in English language in order to understand

all product information, including in particular safety

related information.

How to read the Safety Instructions

The following conventions are used in a BTG manual:

DANGER!

A DANGER! admonition is used when there is a hazard

with a risk for injury or possible death to a person.

WARNING!

A WARNING! admonition is used when there is a risk

for damage to program, device, machine, sampler and

so on.

CAUTION!

A CAUTION! admonition is used when there is a risk of

system failure, service interruption, disturbances to

plant operation, a measuring application and so on.

The admonitions above are hierarchic. A DANGER!

admonition includes the possibility of both a WARNING!

and a CAUTION! admonition.

(1) Theterm "product"isused inthisdocument asa general

reference to Instruments, machine parts, or equipment.

Safety Instructions

4 Safety Instructions - Rev. A © BTG 2021

Safety Regulations

The symbols below are examples of danger signs found

in instructions, manuals, and on products delivered by

BTG.

Safety Regulations for Installation and

Service

Always turn off all power and other supplies before

performing any service or maintenance on the

product.

All welding or bolting must take place in accordance

with current standards and regulations.

All handling of electrical units must take place in

accordance with current standards and regulations.

Use approved lifting gear during installation to prevent

injury. Ensure that the equipment is anchored solidly

during installation.

If a motor with rotated parts are switched on, there is

risk of injury by crushing or cutting if the cover has been

removed. Take care when working close to a propeller

and a sensor if these are exposed.

Take every professional precaution before servicing. Do

not wear gloves or rings which may get caught in the

machinery! Use approved protective clothing during

installation and service to prevent injury.

Before removing a product from a measuring chamber

or opening an inspection cover, check carefully that the

line is empty.

Hot or corrosive liquid flowing out under pressure

may cause serious chemical burn injuries!

Take care when opening the cover of a electronic box

with built-in power supply unit.

This contains live parts which may cause electric

shocks.

Live parts are protected against normal contact

provided that the connections are made correctly.

When a product is exposed to dangerous basic or acidic

corrosive media, it should be removed from the pipeline

regularly for inspection. Replace any damaged seals. If

pressurized parts on a product or a weld-in stud have

corroded, check that the material is correct for the

application.

Leakages may cause personal injury or damage to

equipment due to corrosion or burning!

Beware of high temperatures during installation and

service to prevent injury.

DANGER

Hazardous voltage

in the equipment

DANGER

Crushing

DANGER

Cutting

DANGER

CHECK PIPES!

Risk for corrosive,

toxic, or aggressive

liquids or gases

with high pressure or

high temperature.

DANGER

Use protective

clothing

DANGER

High

emperatureT

DANGER

Risk for personal

injury and

possible death

Product Introduction

© BTG 2021 Product Introduction, MEK-3000 - Rev. B 5

2 Product Introduction

2.1 General

The MEK-3000 TwinTorque takes in-line, rotating, consistency measurement

state-of-the-art to a new level. Combining the most robust measuring method

with the unique TwinTorque technology results in unrivalled performance in a

format providing significantly reduced installation and maintenance costs. The

transmitter is supplied by single-phase power via the Communication Platform

(CPM).

Aside from the MEK-3000 standard model, two special versions are available:

MEK-3015, equipped with a protector for protection against unscreened pulp,

and MEK-3050, equipped with a larger flange. In new installations the small

flange version yields minimized pipe connections, while the large flange

version fits to the conventional studs and measuring vessels.

The versatility of the MEK series is retained with the new MEK-3000. Hence, it

can be optimized for every application in the entire process; from the blow line

after the digester, in screening and washing stages, and in the bleach plant

through to the machine chest. Its total flexibility is accompanied with ultra-high

measurement precision with a construction providing extreme compactness,

minimized maintenance requirements, and longer life time.

The MEK-3000 is operated using the CPM, which ensures compatibility with

present and future communication interface requirements, from analogue

output with HART® to field buses.

The MEK-3000 is the fifth generation of rotating transmitters from BTG, and is

based on the successful and widely proven MEK rotating transmitters, sold in

more than 30,000 units. Bringing BTG’s unsurpassed experience and success

with rotating consistency measurement together with the TwinTorque

technology thus creates new opportunities in consistency measurement and

control.

Fig 1 MEK-3000

Product Introduction

6 Product Introduction, MEK-3000 - Rev. B © BTG 2021

2.2 Technical Data

General

Type

MEK-3000 in-line rotating consistency transmitter for pulp suspensions

Manufacturer

BTG, Säffle, Sweden

Measuring Principle

Rotating shear force measurement

Quality Assurance

Quality-assured in accordance with ISO 9001. Designed in accordance with relevant CE

standards.

Function Specifications

General

Pressure Rating

PN16 (16 bar at 20°C, 230 psi at 68°F) with Ø270 mm flange

PN25 (25 bar at 20°C, 360 psi at 68°F) with Ø180 mm flange

User Interface

Illuminated display and keypad on the CPM

Alarm and Diagnostics

Motor and electronics supervision, high/low temperature and load levels, etc.

Calibration sets

Four separate calibration sets, individually programmable, and externally controllable using a

binary-coded switch

Communication Platform

For information about the communication platform, including input and output signals, see

section 2.5: Communication Platform CPM

Process Specifications

Consistency Limits

1 - 16% fiber consistency, depending on type of pulp and sensing element.

Flow Limits

0.5 - 5 m/s [1.6 - 16.4 fps] depending on application

Process Temperature Limits

Min. 15 °C [60 °F]

Max. 120 °C [248 °F]

Ambient Temperature Limits

Max. 50 °C [122 °F] without water cooler

Max. 60 °C [140 °F] with water cooler

Damping

Set between 0 and 99 s.

Product Introduction

© BTG 2021 Product Introduction, MEK-3000 - Rev. B 7

Support System Specifications

Flushing Water

Standard quality water, with no impurities larger than 200 m [8 thou].

Recommended flow: 0.5-1.5 l/min [0.13-0.4 gal/min.]

Min. 0.5 bar [7 psi]

Power Consumption

Max. 320 VA

Supply Voltage

100-240 ±10% V AC, 50/60 Hz, Single phase to CPM

Supplied with 24 V DC from the CPM

Cooling

Optional water cooler available for operation in hot environment

(ambient temperature up to 60 °C [140 °F])

Max. cooling water temperature: 20 °C [68 °F]

Performance Specifications

Repeatability

= 0.002% Cs

Physical Specifications

Mounting

Mounted to the pipe through a measuring vessel or a weld-in stud depending on pipe size and

transmitter flange type

Transmitter Flange

Ø180 mm: Min 200 mm [8"] pipe using weld-in stud

80-150 mm [3-6”] pipe using measuring vessel or saddle

Ø270 mm: 100-250 mm [4-10"] pipe using measuring vessel

Min 300 mm [12"] pipe using weld-in stud

The transmitter can be mounted in a horizontal, vertical or inclined pipe.

Materials

Housing: Aluminum, painted with epoxy/polyurethane.

Cover: ABS/PC with EMC-shield inside

Wetted parts: Stainless steel equiv. to EN 1.4404/ASTM 316L or Avesta 254 SMO depending

on application

Degree of Protection

Equivalent to IP65, NEMA 4x

Weight

15kg [33 lb.] with Ø180 mm flange

19 kg [42 lb.] with Ø270 mm flange

Product Introduction

8 Product Introduction, MEK-3000 - Rev. B © BTG 2021

2.3 Type Plate Explanation

1. Transmitter model

2. Mechanical sealing code

BSW, RSW

First letter; Mechanical sealing type:

• B = Metal bellows type

• R = Roplan type

Second Letter; Material

• S = Silicon carbide

Third letter; Water flushing option:

• W = Model with water flushing

3. Manufacturing number

BTG internal product identification number.

4. Sensing element type

Available types: A, B, C, G, H, I, J

5. Warning sign

The device is designed for industrial use. Installation, handling and

service must only be carried out by trained and authorized personnel and

according to relevant standards. Read the manual for detailed information

and pay special attention to the warning signs!

6. CE-marking

The MEK-3000 is approved according to CE directives.

7. EAC-marking

The MEK-3000 conform to all technical regulations of the Eurasian

Customs Union.

8. Pressure rating

PN 16 or PN 25

9. Wetted parts made of

EN 1.4404/ASTM 316L or 254 SMO

RubberPropellerPressure rating

Sensing element

No

Wet parts made of

Type

BTG Instruments AB, Industrigatan 1-3, 661 32 Säffle, SWEDEN

MEK-3000 SWR 12345678

EN 1.4404/ASTM 316L C

PN 16 Hub EPDM

5

12

3

108 9

1 2 4

11

6 7

Fig 2 Type sign

Product Introduction

© BTG 2021 Product Introduction, MEK-3000 - Rev. B 9

10. Propeller type

Large, Small, or Hub (no propeller)

11. Rubber quality in wetted parts

FPM (Standard) = Fluorocarbon rubber for pH 1-12.

EPDM = Ethylene Propylene rubber for pH 8-14.

12. QR code

QR code to scan for more information about the MEK-3000 on the site:

www.btg.com/mybtg/en/instruments/mek-3000.

Product Introduction

10 Product Introduction, MEK-3000 - Rev. B © BTG 2021

2.4 CE Declaration

When using the units in combinations other than those tested for, BTG can not

guarantee CE directive conformity.

The units in combination with customer-installed external devices may conform

with EMC and safety requirements when properly installed and CE-marked

equipment is used.

The system operator is responsible for CE directive conformity.

Conformity must be verified by inspection.

Declaration of Conformity

CE mark

CONSISTENCY TRANSMITTER

TYPE: MEK-3000

BTG INSTRUMENTS AB

P.O. Box 602

661 29 Säffle

Sweden

This declaration of conformity is issued under the sole responsibility of the manufacturer.

We declare that the above Consistency Transmitter conforms to:

2014/35/EU Low Voltage Directive, LVD

2014/30/EU Electromagnetic Directive, EMC

2014/68/EU Pressure Equipment Directive, PED

The following harmonized standards have been practiced:

IEC/EN 61010-1:2010 Safety requirements for electrical equipment for measurement, control, and laboratory

use - Part 1: General requirements

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use - EMC requirements

Part 1: General requirements

EN 13480-5:2013 Metallic industrial piping - Part 5: Inspection and testing

EN 13480-3:2017 Metallic industrial piping – Part 3: Design and calculation

Authorized Signature: ………………………………… Date: 2021-03-30……………………

Name: Björn Fahlin…………………………………… Position: Director of Operations

Product Introduction

© BTG 2021 Product Introduction, CPM - Rev. C 11

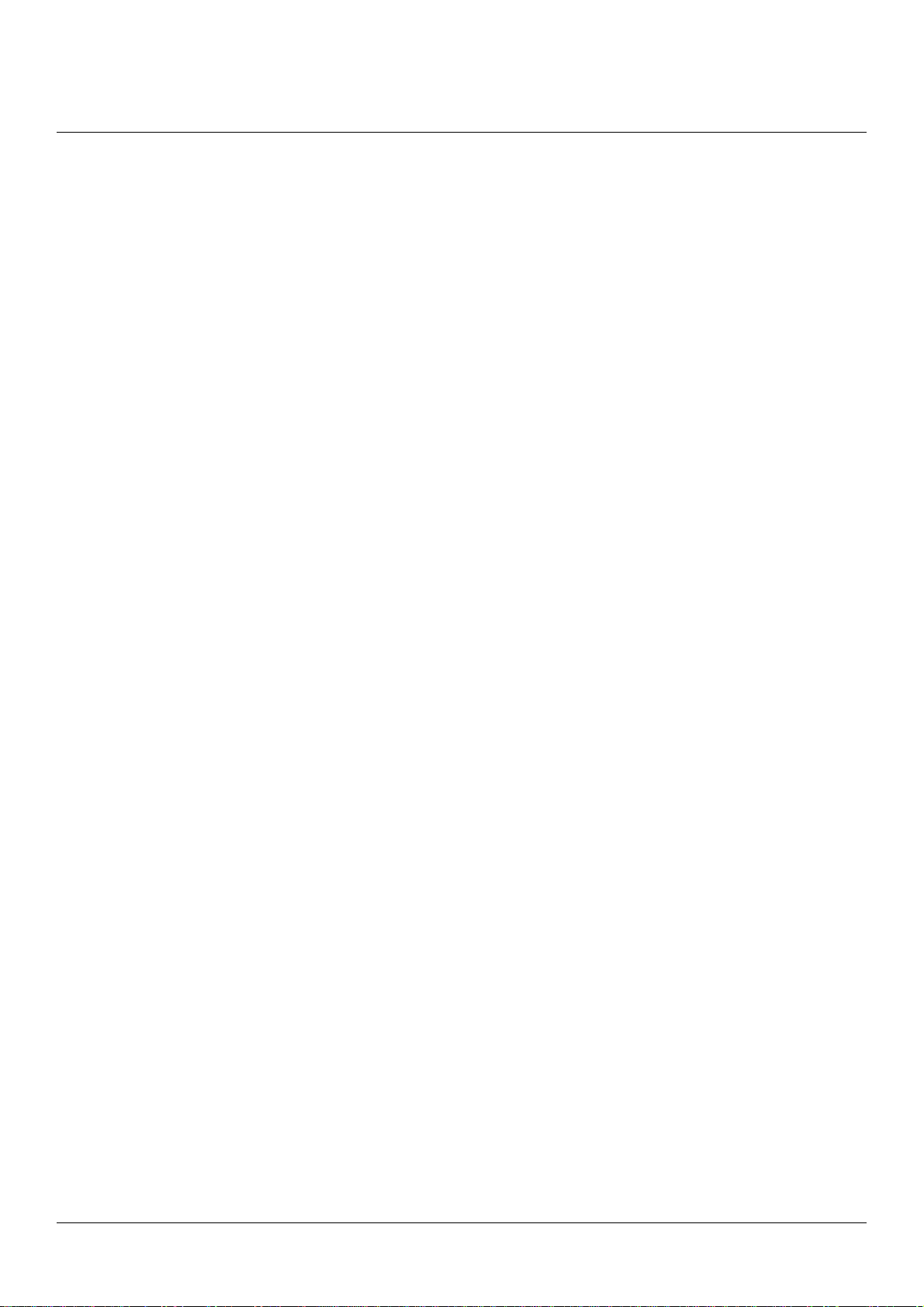

2.5 Communication Platform CPM

The CPM is delivered as a complete unit from BTG, normally in conjunction

with an instrument.

The CPM has the following functions:

• Local display and console for full configuration and operation of the

instrument

• Large illuminated display for easy reading

• Protected from splash and sun

1

3

2

6

4

5

7

Fig 3 CPM overview

1. Protective cover

2. Front cover

3. Scroll keys

4. LCD display with

backlight

5. Function keys

6. Closing screw

7. Cable glands

Product Introduction

12 Product Introduction, CPM - Rev. C © BTG 2021

2.5.1 Technical Data

General

Type

CPM Communication Platform.

Manufacturer

BTG, Säffle, Sweden.

Quality Assurance

Quality-assured in accordance with ISO 9001.

Product Safety

Fulfills all relevant CE-directive requirements, RCM listed, and ETL listed.

Radio Approvals

US, Canada, EU, Japan, Australia, and New Zealand.

Emission / Immunity / Safety

FCC Part 15 Class B

EN 61010-1:2010

EN 61326-1:2013

EN 301489-1 V2.1.1

EN 301489-17 V3.1.1

EN 300328 V2.1.1

EN 300893 V1.8.1

UL 61010-1:2012 Ed.3 +R:29Apr2016

CSA C22.2#61010-1-12:2012 Ed.3+U1;U2

Function Specifications

HCM-8000

Hart communication module using HART® protocol.

Equipped with slot for SD memory card.

Analog output (AO1)

4 - 20 mA. Galvanic isolated. Current limited to min. 3.9 and max. 20.5 mA.

Loop load signal: Voltage supply/load 24 V DC

Active or passive output

Superimposed signal over 4 - 20 mA current loop according to standard HART® protocol.

Analog input (AI1)

4 - 20 mA 250 Ω input resistance

Digital input (DI1 - DI3)

Galvanic isolated

High-ohmic = logical 0

+24 V ≥ 12 mA = logical 1

Digital output (DO)

Galvanic isolated

Maximum 120 mA

Maximum 30 V DC

Product Introduction

© BTG 2021 Product Introduction, CPM - Rev. C 13

FCM-80x0

Fieldbus communication module programmed for PROFIBUS.

Equipped with slot for SD memory card.

Output / Input signal

PROFIBUS (PA)

CCM-8200

Network Interfaces:

Wired Network Connectivity

Ethernet, 10/100 Mbit - RJ45.

Ethernet interface supporting up to 100baseTx.

IEC 11801:2002 CatV compliant M12 type D socket.

The interface supports Auto MDI-X (crossover).

Wireless Network Connectivity

Wi-Fi, Dual-band 802.11 a/b/g/n/ac 1x1

CPM User Interface

Illuminated display. Key pad for adjustment of instrument settings.

Product Introduction

14 Product Introduction, CPM - Rev. C © BTG 2021

Support System Specifications

Supply Voltage

Power supply unit 100 - 240 V AC, 50-60 Hz.

AC input range: 90 - 264 V continuous operation.

Disconnecting Device

An external 2-pole switch close to the CPM is required. The switch must be approved in

accordance with the IEC 60947-2 and IEC 60947-3 requirements.

Power Consumption

100 - 300 VA

Altitude

0 to 2000 m (0-6560ft) without any restrictions.

2000 to 6000 m (6560 to 20000ft) reduce output power or ambient temperature.

Altitude de-rating = 5 W / 1000 m or 5 °C / 1000 m.

Humidity

5 to 95% r.h (IEC 60068-2-30)

Over-voltage Category

Category III: IEC 62103, EN 50178, altitudes up to 2000 m

Category II: altitudes from 2000 m to 6000 m

Degree of Pollution

2: IEC 62103, EN 50178, not conductive

Physical Specifications

Materials

Casing: Polycarbonate thermo plastic

Cable fittings: Polyamide thermo plastic

Storage Temperature

Max. 80 °C (176 °F)

Min. -25 °C (-13 °F)

Operation Temperature

Max. 50 °C (122 °F)

Min. 0 °C (32 °F)

Degree of Protection

IP 65, comparable to NEMA 4x and better, the CPM is intended for use indoors.

Weight

CPM: 2 - 2.5 kg (4.4 - 5.5 lbs) depending on configuration

Cables

Power supply flexible cable: 0.3 - 2.5 mm2 (AWG = 28-12)

Signalling cable: 0.2 - 2.5 mm2 (AWG = 24-12)

Transmitter Cable

Standard length: 10 m [33 ft]

Cable Inlets

There are cable glands for signal cables (diameter 4-8 mm) and for power supply cable

(diameter 4-12 mm) in the bottom of the CPM.

Table of contents

Popular Transmitter manuals by other brands

BWI Eagle

BWI Eagle AIR-EAGLE SR PLUS 36-HH-9 quick start guide

IFM

IFM TA3 Series installation instructions

St. Jude Medical

St. Jude Medical Merlin home EX1100 user manual

SOR

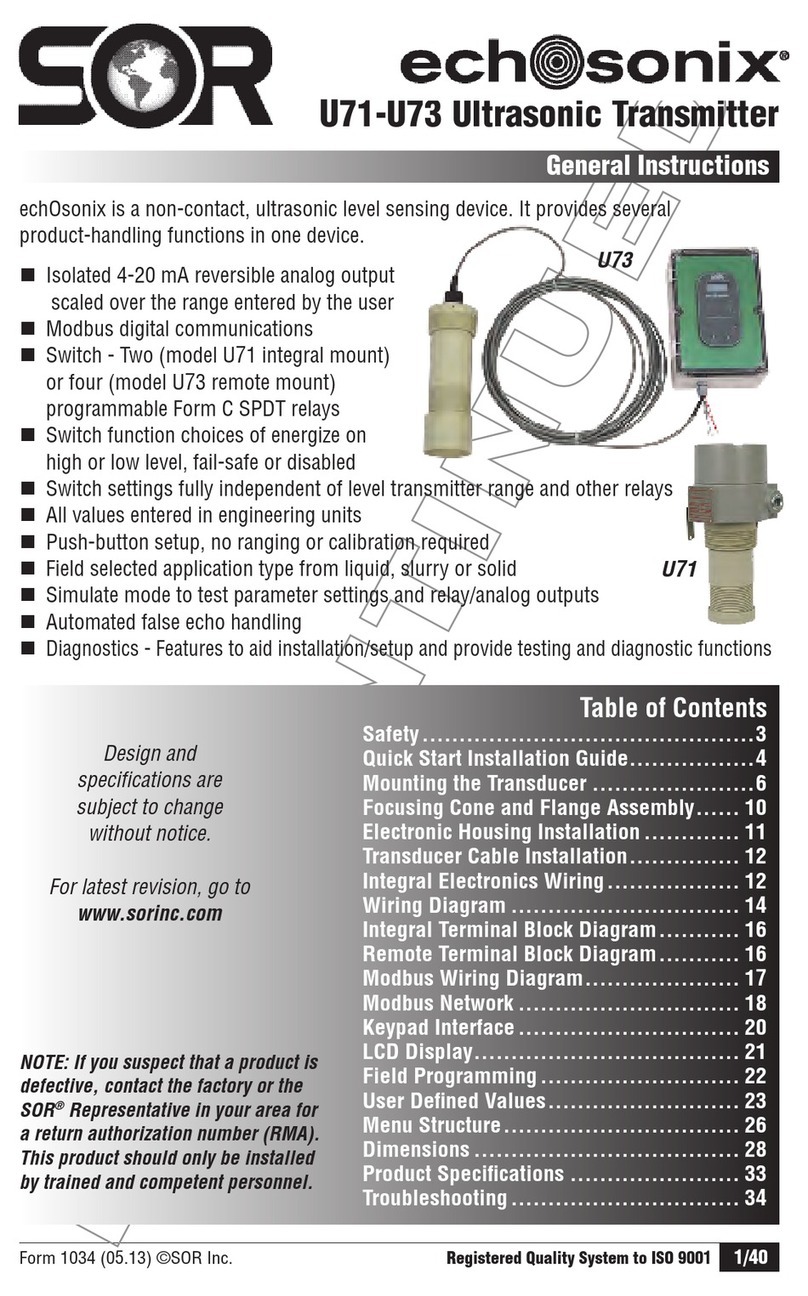

SOR echosonix U71 General instructions

Nice

Nice FLOX1R Installation instructions manual

Creative

Creative BLASTER TRANSMITTER user guide