•

De

s

ign

and function

Fuel sy

st

em

LH2.4

-

240

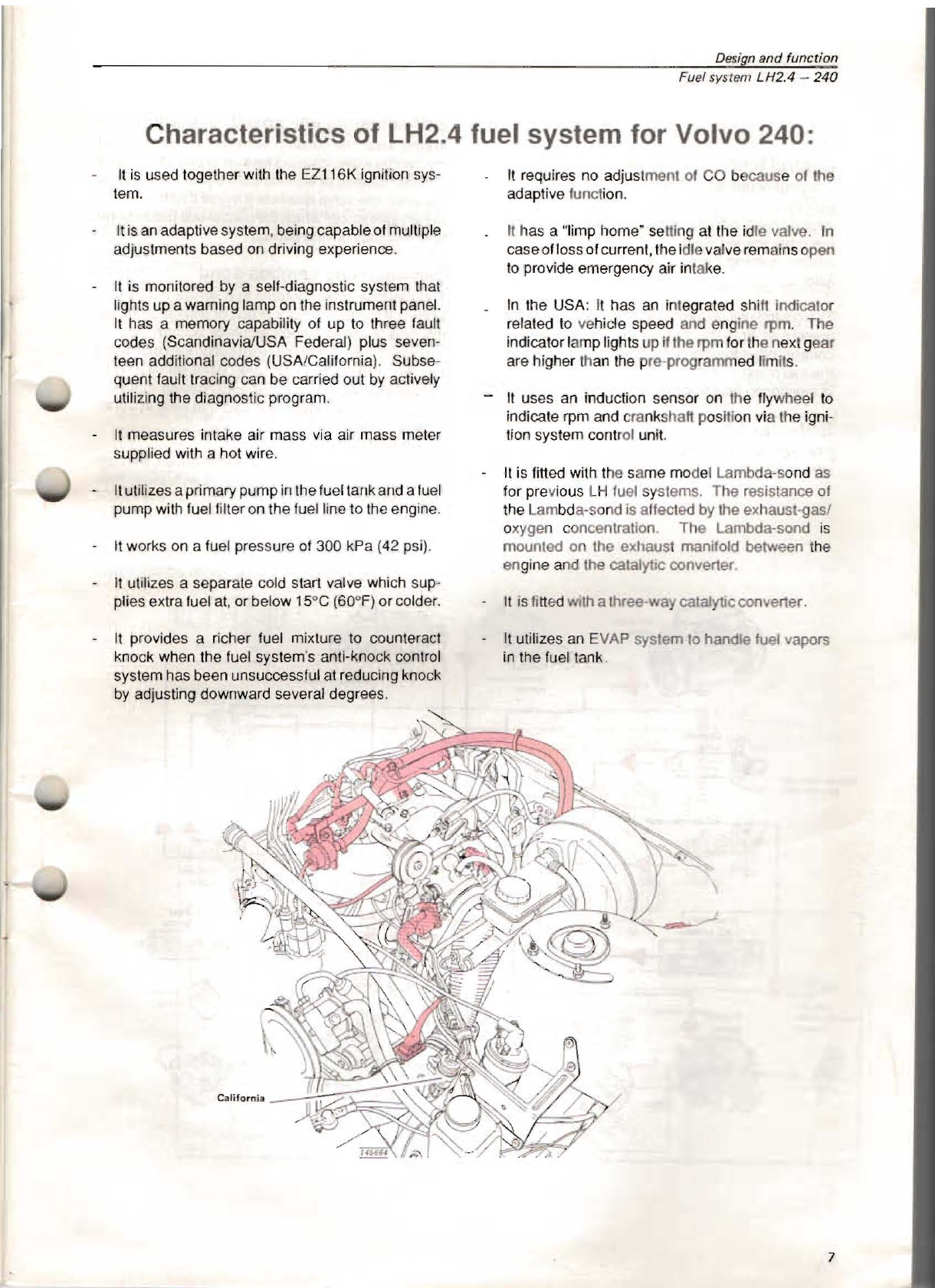

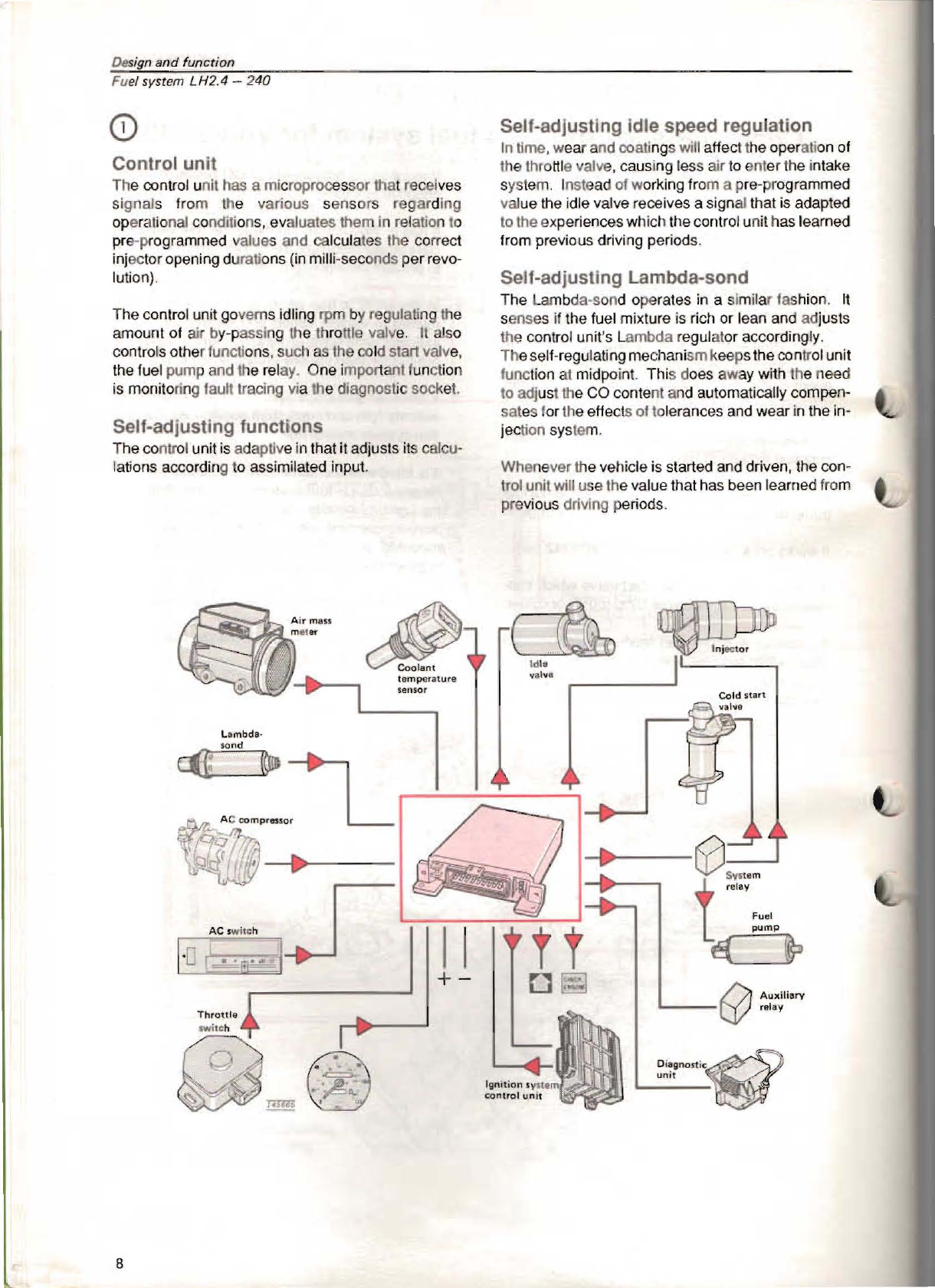

Characteristics of LH2.4 fuel system for Volvo 240:

It

is

used together with the EZ116K ignition sys-

tem.

It

is

an

adaptive system.being capable of multiple

adjustments based on driving experience.

It

is monitored by a self-diagnostic system that

lights up a warning lamp on the instrument panel.

It

has a memory capability of up to three fault

codes (Scandinavia/USA Federal) plus seven-

teen additional codes (USA/California). Subse-

quent fault tracing can be carried out

by

actively

utilizing the diagnostic program.

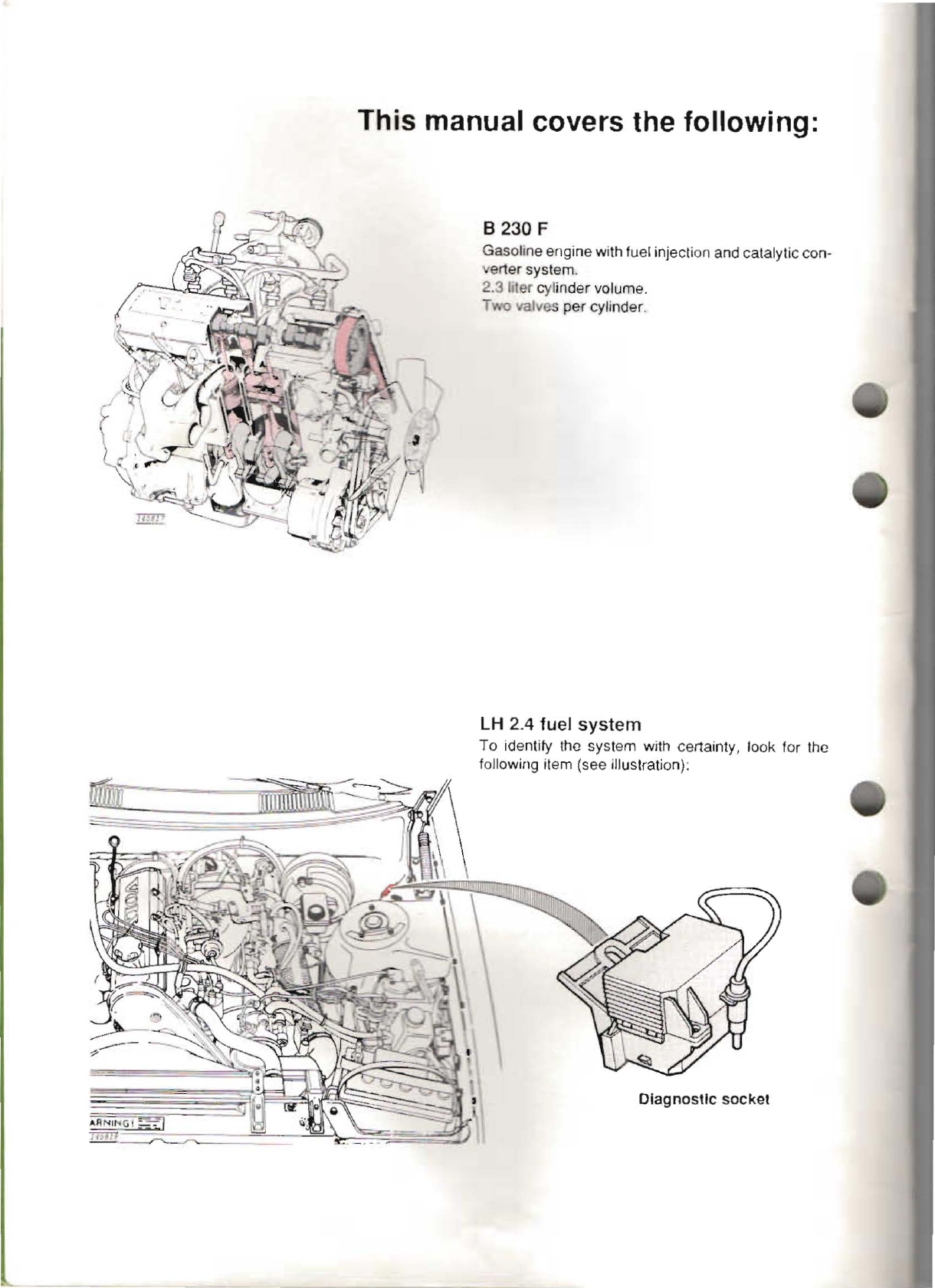

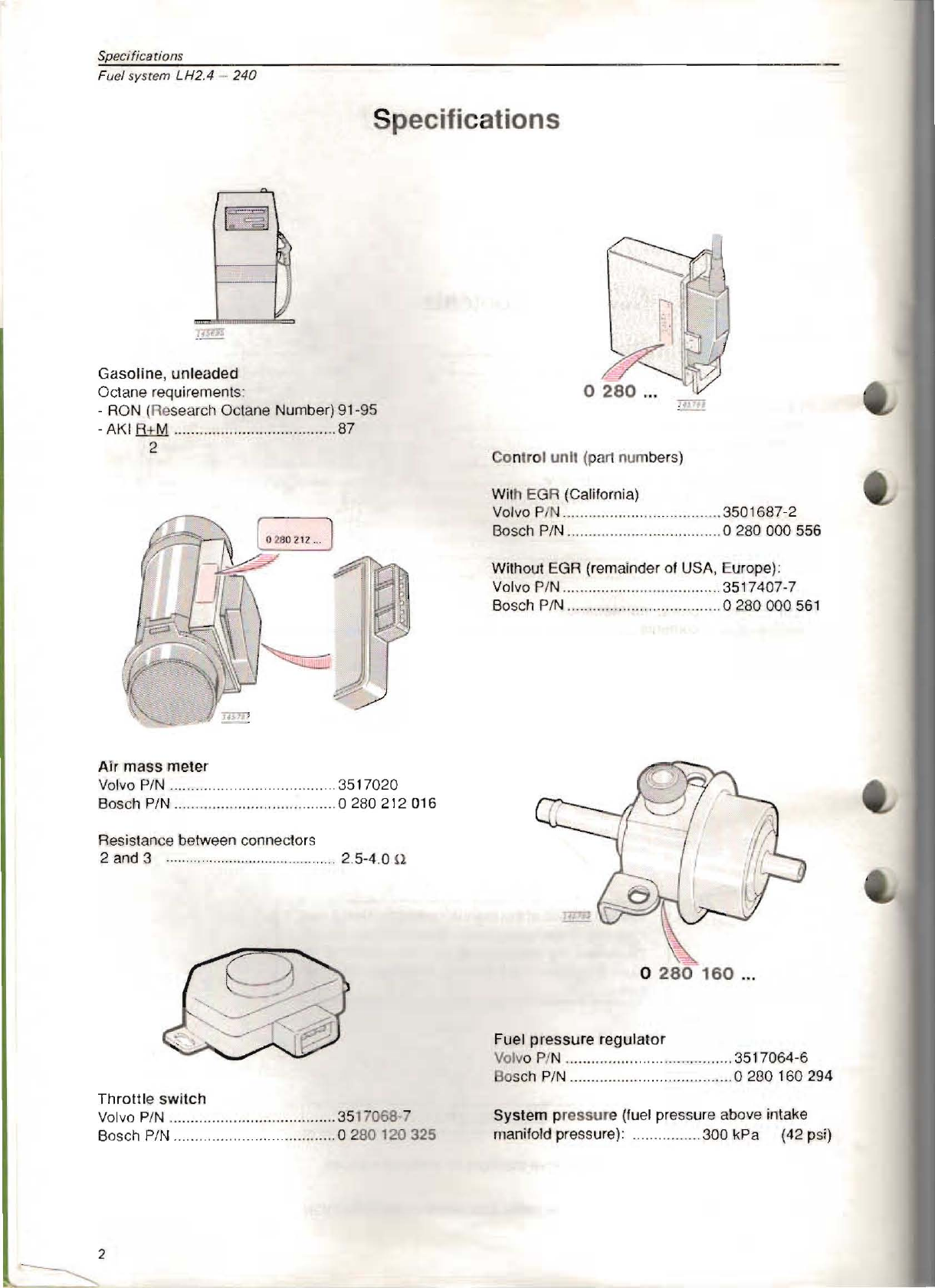

It

measures intake air mass via air mass meter

supplied with a hot wire.

It

utilizesaprima

ry

pump in the fuel tankand a

fuel

pump with fuel filter on the fuel line to the engine.

II

works on a fuel pressure of 300 kPa (

42

psi).

It

utilizes a separate cold slart valve which sup-

plies extra fuel at.or below 15°C (60"

F)

or cotder.

It

provides a richer fuel mixture to counteract

knock when the fuel system's anti-knock control

system has been unsuccesslul at reducing knock

by

adjusting downward several degrees.

It

requires no adju

st

ment of CO because of the

adaptive function.

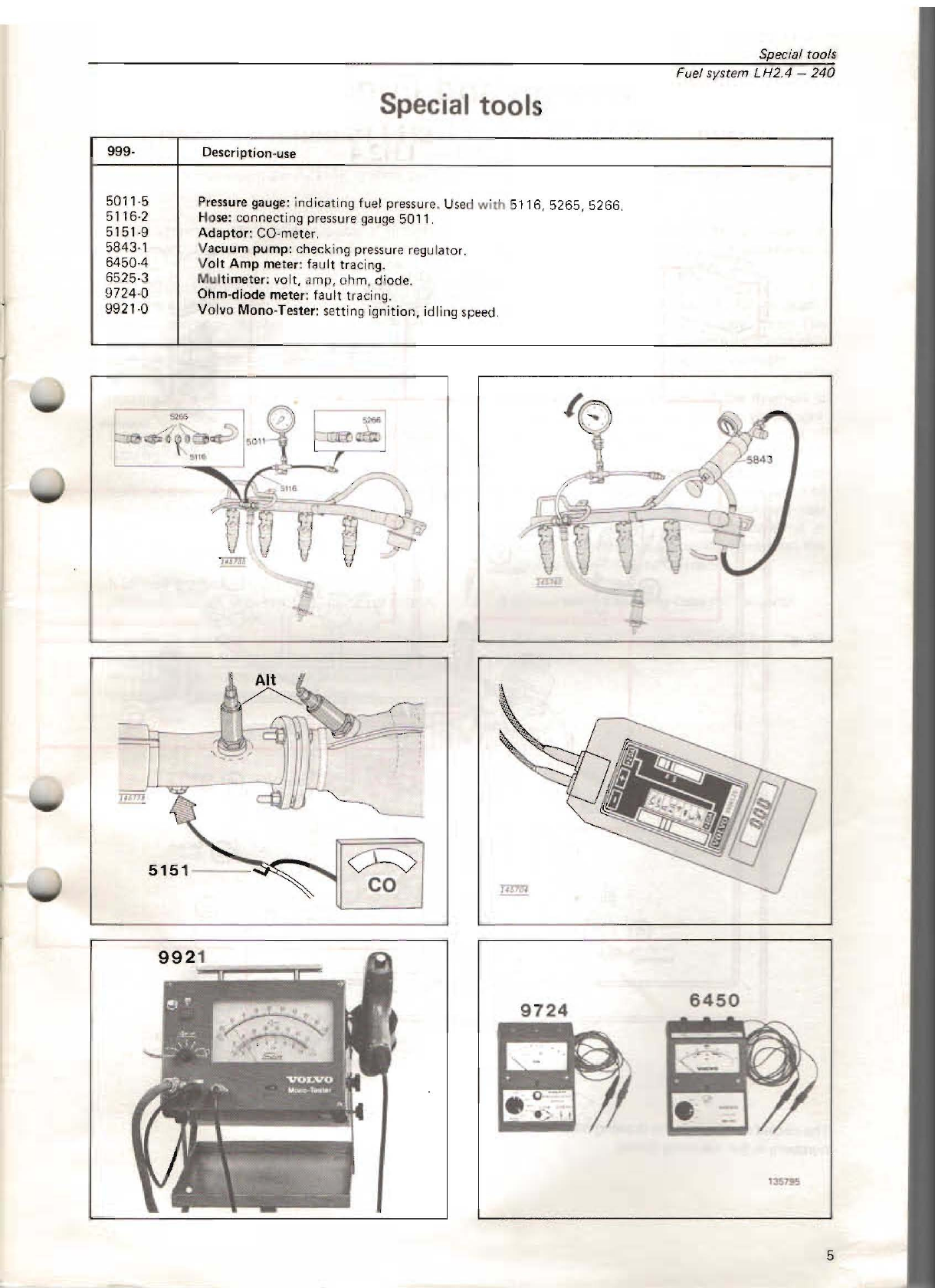

It

h

as

a "limp home"

se

Mi

ng at the idle valve In

caseoflossofcurrent. the idlev

al

ve

rema

in

sopen

to

provide emergency air intake.

In

the USA:

It

has

an

integrated shi

ft

Indicator

refated

to

vehicle speed and engine rpm. The

indicatorfamp lights up ifthe rpm for the next gear

are higher th

an

the pre-programmed limit

s.

-It uses an induction sensor

on

th

e

fly

whe

et

to

indicate rpm and c

ra

nk

shaft posi

ti

on

vi

a the igni-

tion system control uni

t.

It

is fitted with the same

mo

del Lambda-so

nd

as

for previous l H fuel

sy

stems. The resistance of

the Lam

bd

a-sond is affect

ed

by

the eXhaust-

gasl

oxygen concentration The Lambda-sond is

mounted on the exhaust manifold between tile

engine and Ihe catalytic conver1er.

It

is

fi

tt

ed

WIth

a three-way catalylJc conver1er.

It

utilizes an EVAP system

to

handle fuel vapors

in the fuel tank.

7