1 of 4

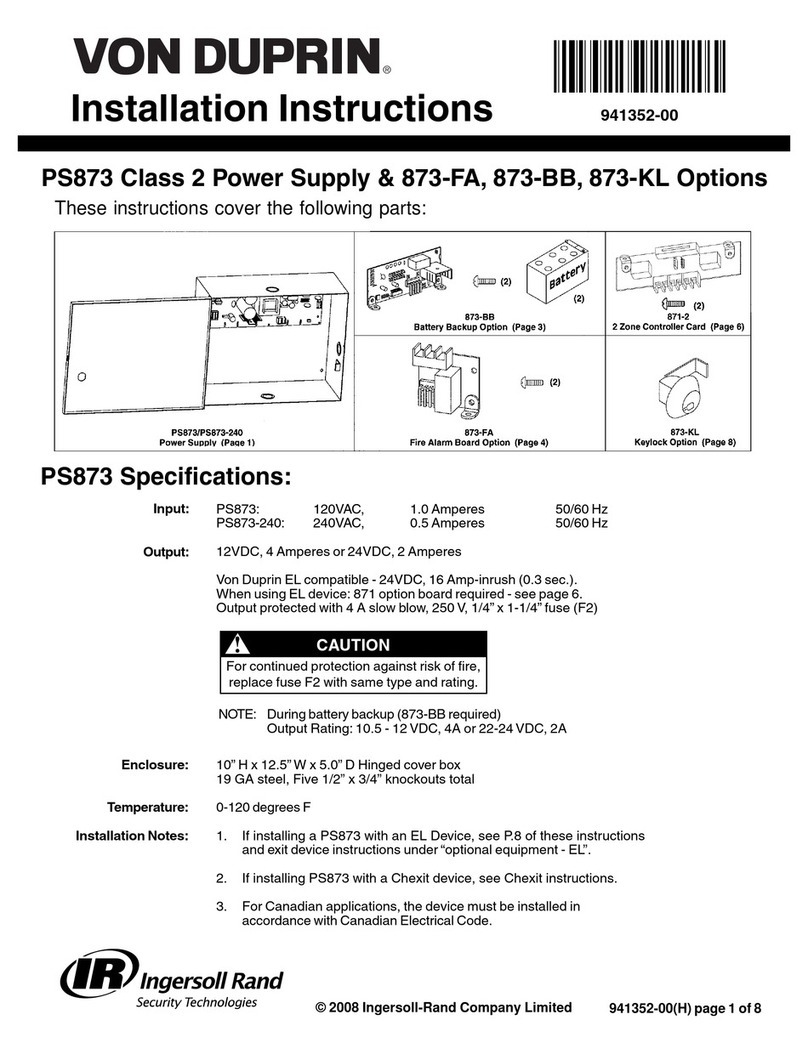

These instructions cover the following parts:

Installation

Instructions

PS914 Power Supply

© 2010 Ingersoll-Rand Company

1-877-671-7011

44487056 Rev. 10/10_a

44487056

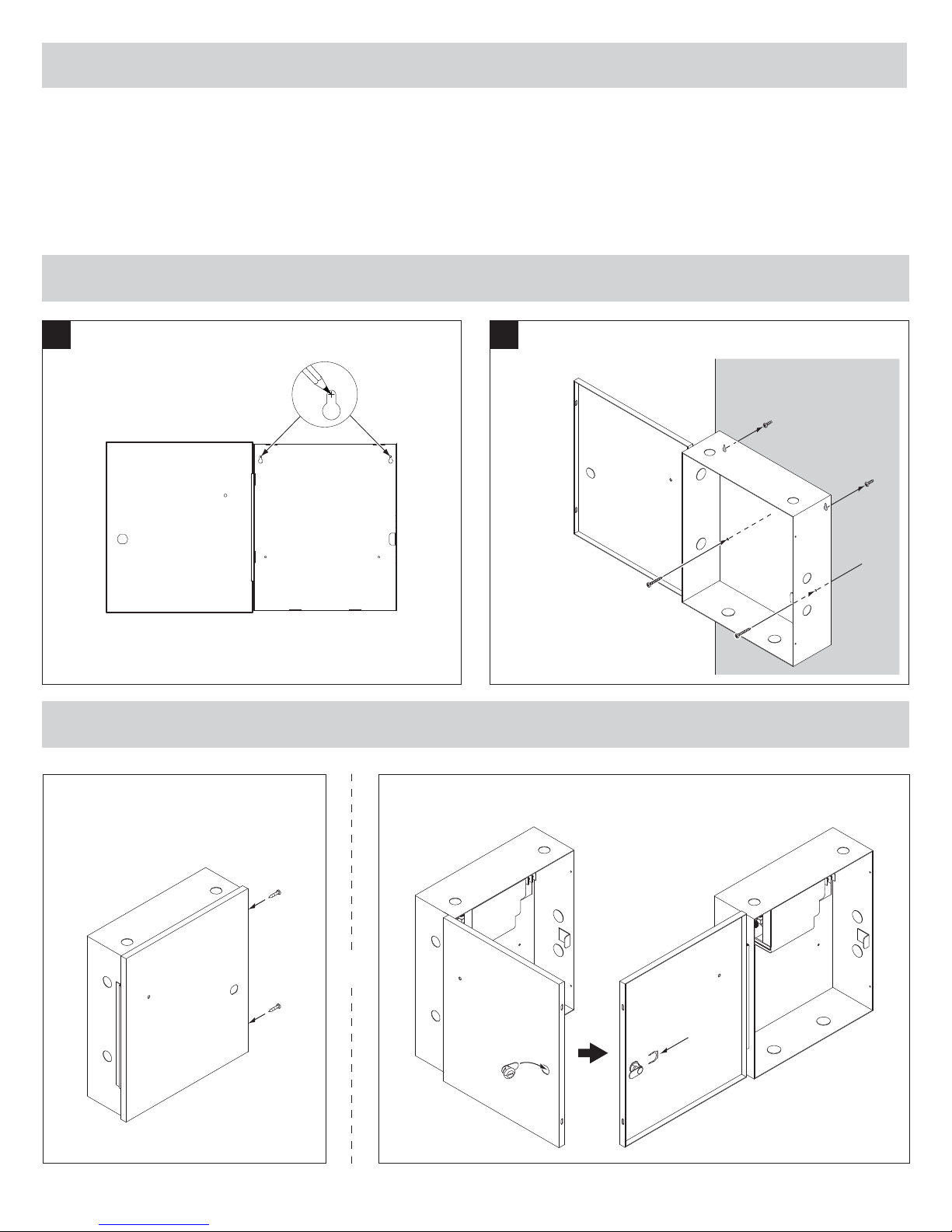

To avoid risk of electric shock, turn off AC power

before installing or servicing PS914 power supply.

DANGER:

!

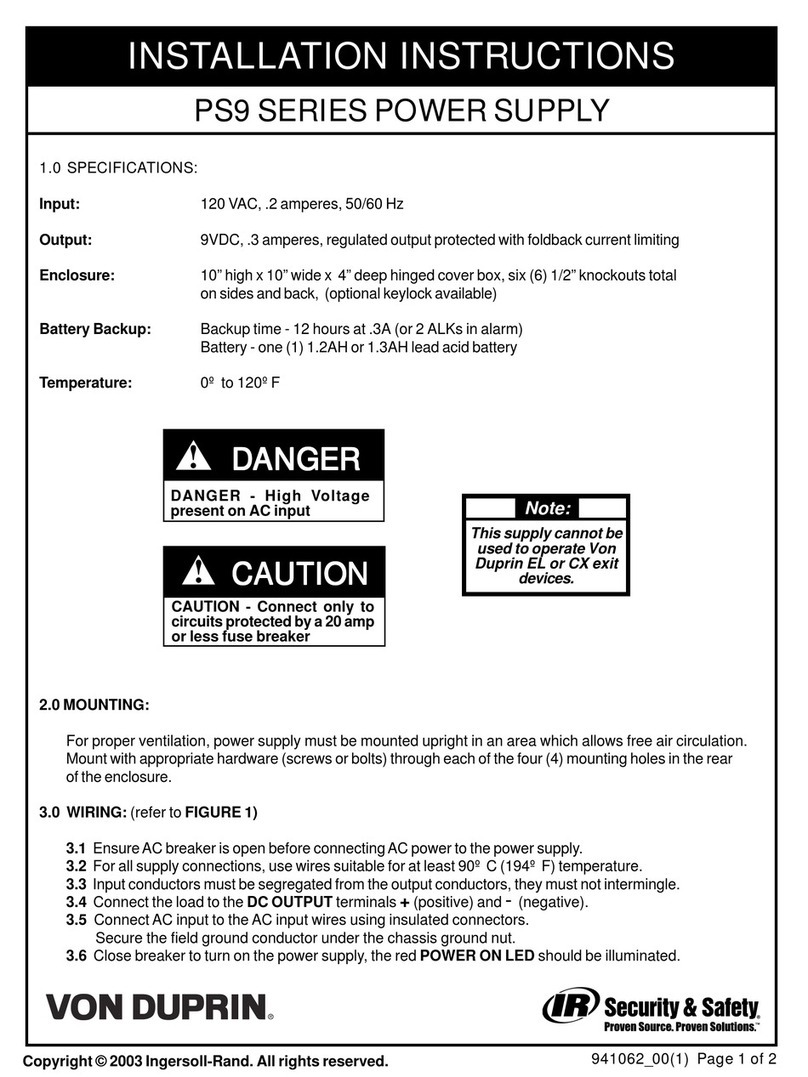

PS914 Power Supply Specifications:

Input 120/240 VAC, 1.4 A, 50/60Hz, High Voltage Class 1 Wiring Required

Output 4 Amp DC @ 12/24 VDC

May be used to power Von Duprin & Falcon EL device at 24VDC, 16A, 300ms

Enclosure 14” H x 12” W x 4” D (8 knockouts, 1/2” or 3/4” )

Temperature Range 32°-120° F (0°- 49° C)

Fuse F1, T6.3A

250 VAC

Compliance UL 294, ULC-S318, RoHS, & FCC Part 15, Class 2 Output

Compatible Boards

(Optional, 2 boards maximum)

900-2RS

900-2Q

900-4R

900-4RL

900-8F

900-8P

Fire Alarm Input Board (Optional) 900-FA (Requires one option board above)

Battery Backup Board (Optional) 900-BB

AC Monitor Output Form C Contacts, 30 VDC, 1 Amp, Resistive Load

For protection against risk of fire, replace fuse with same type and rating

CAUTION:

!

INST. INSTRUCTIONS - 44487056

INST. INSTRUCTIONS - 44487098

INST. INSTRUCTIONS - 44487106

INST. INSTRUCTIONS - 44487080

INST. INSTRUCTIONS - 44487106

INST. INSTRUCTIONS - 44487106

INST. INSTRUCTIONS - 44487072

INST. INSTRUCTIONS - 44487064

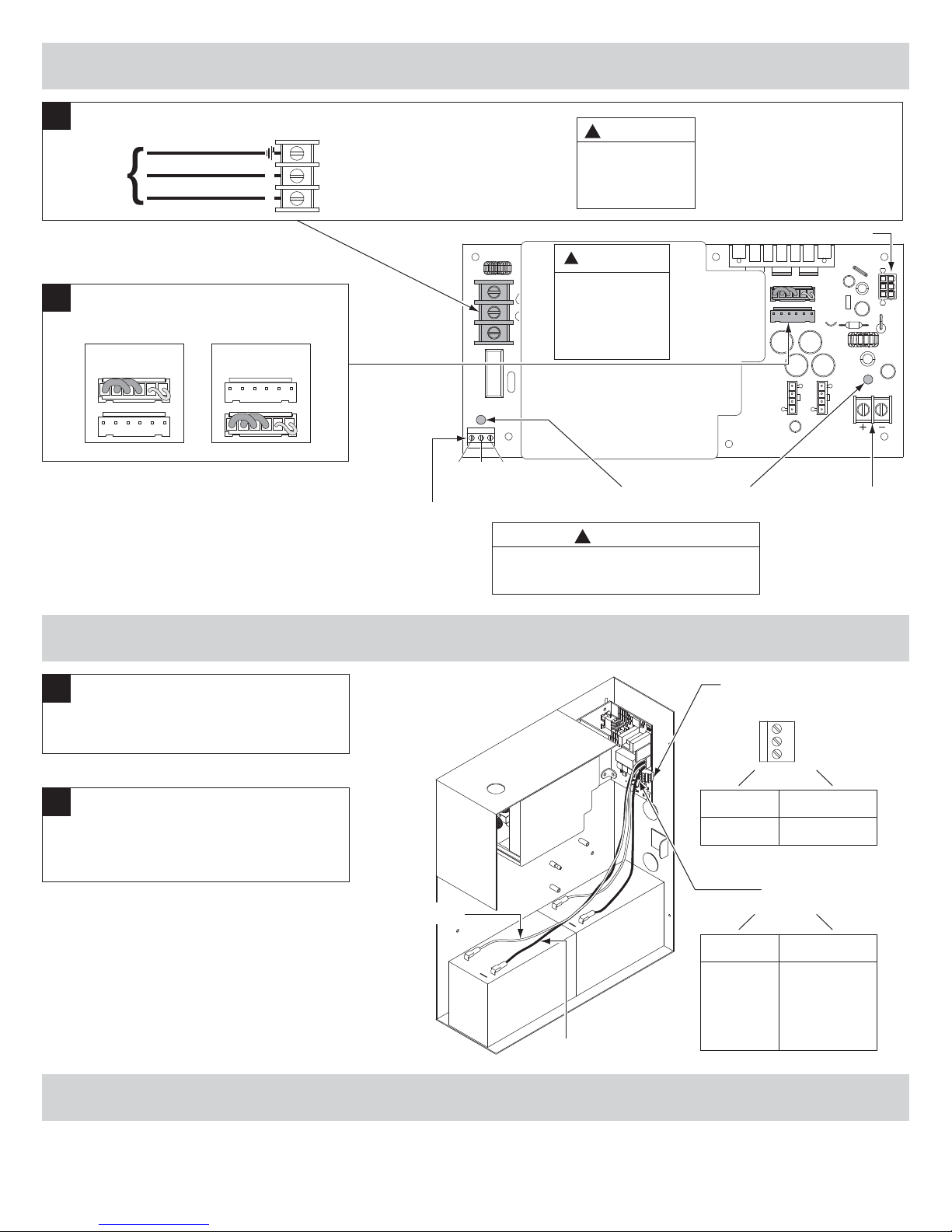

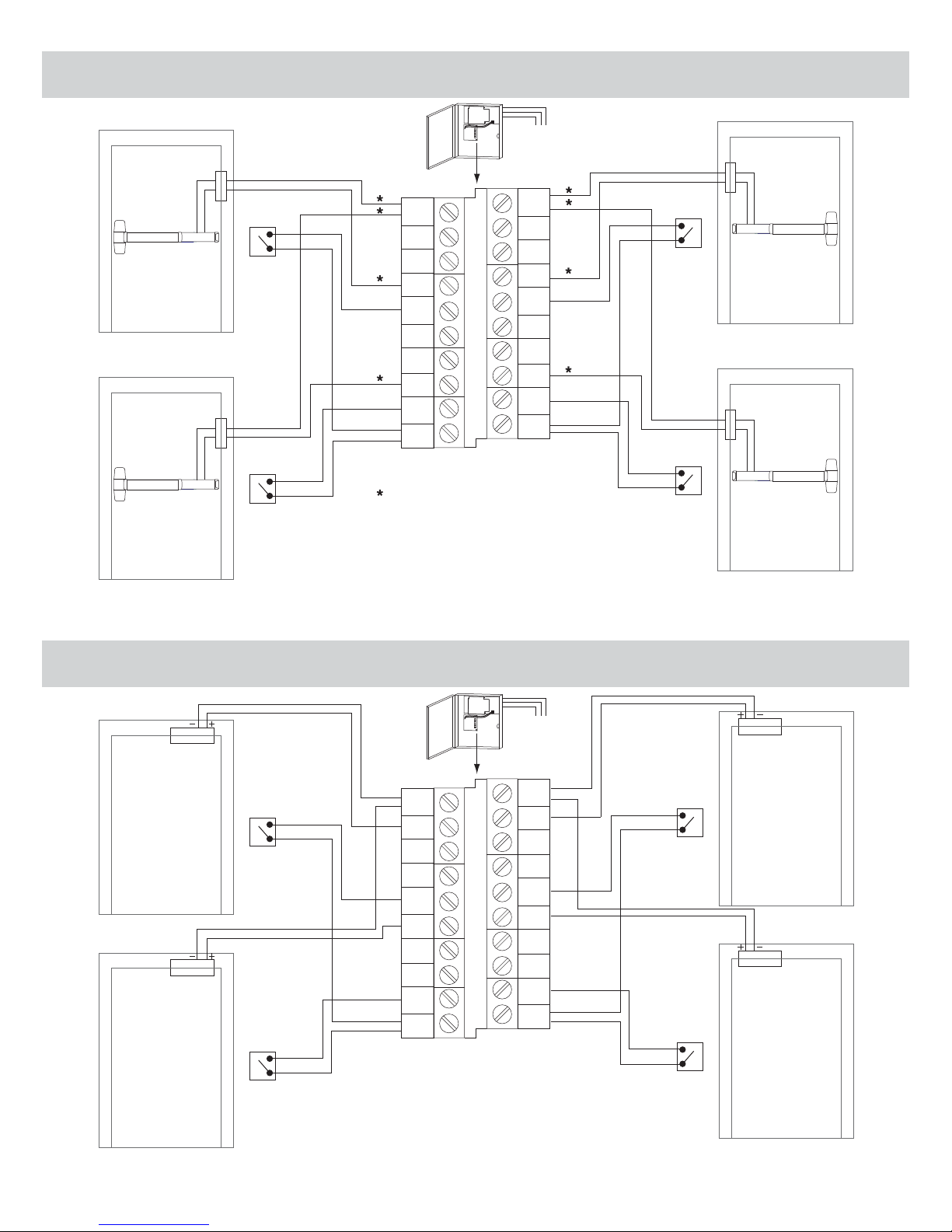

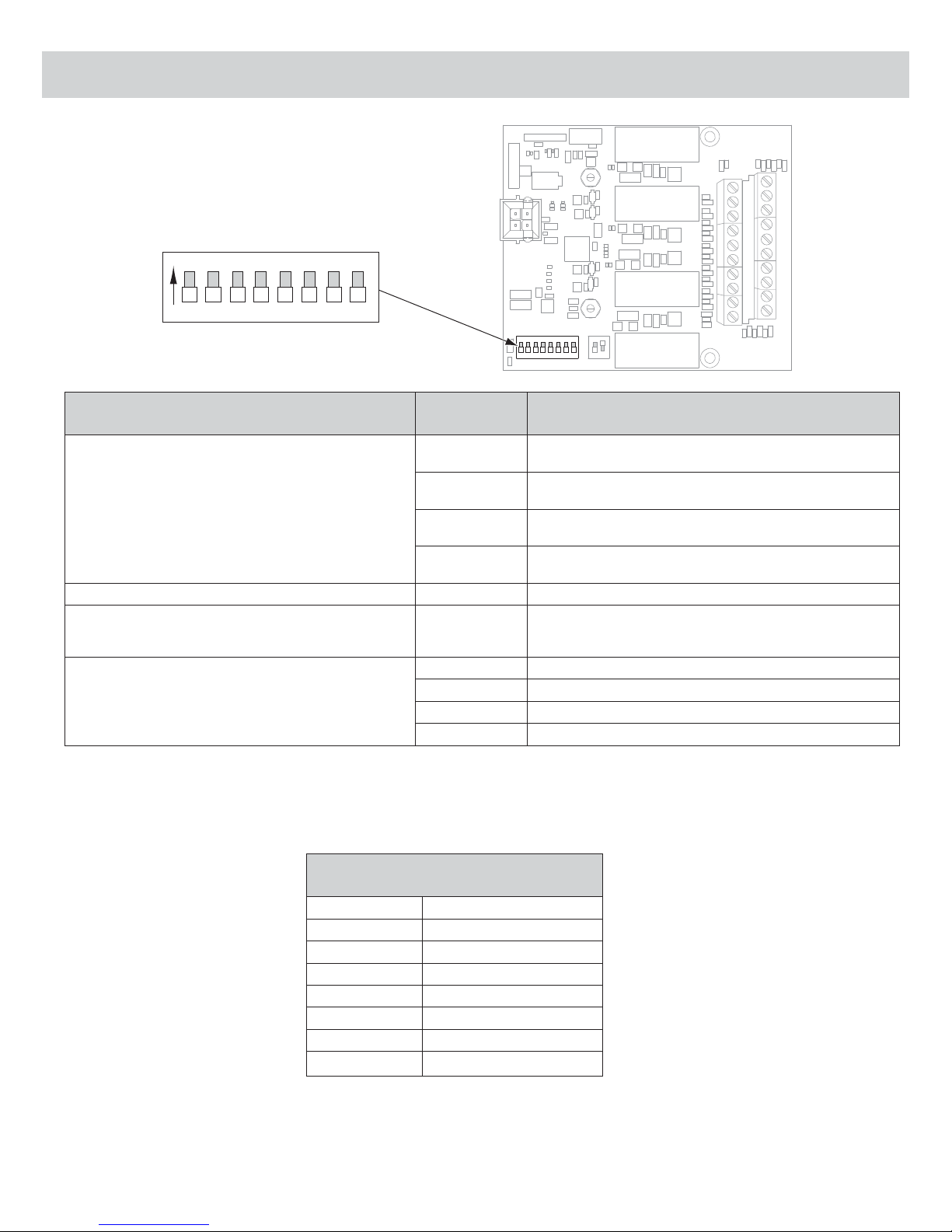

Inputs I1,I2 Dry contacts required (Closed = Active)

Connect control contacts between SC (Signal Common) and any input

Outputs O1,O2 • 12/24VDC, 3A (wet) when AC powered • 9.6-13.2VDC or 19.2-26.4VDC when battery powered

• May be used with PS914 to power EL device at 24VDC, 16A, 300ms

• Maximum load cannot exceed power supply ratings or 3A for outputs combined

Board Input Power Board requires 0.1A max. of power supply output current to operate

Temperature Range 32°-120° F (0°- 49° C)

Compliance UL 294, ULC-S318, RoHS, & FCC Part 15

Fire Alarm Input Accepts 900-FA Fire Alarm Board (Optional)

900-2RS Specifications:

900-BB Battery Backup

(optional)

Page 3

900-2RS (optional) - Page 4

(2 Zone EL Control -

Individual/Sequential)

900-KL Keylock

(optional)

Page 2

PS914 Power Supply

Pages 1-3

F1

DANGER

!

!

DANGER:

!

WARNING:

!

WARNING: