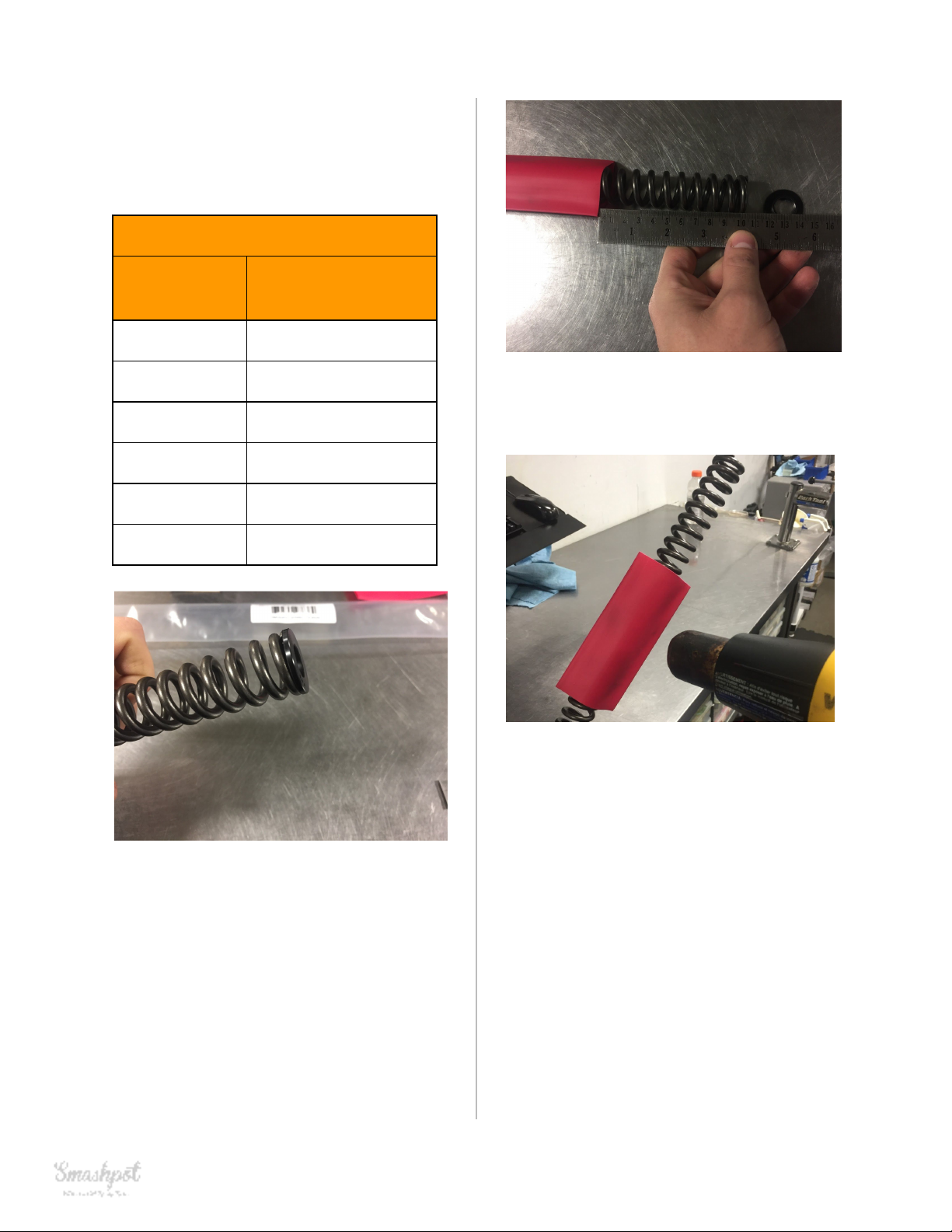

11. Install the COIL SPRING, SPRING

PERCH and SPRING COLLAR onto the

assembly. Ensure the SPRING PERCH is

positioned between the COIL SPRING and

the SPRING COLLAR. Correct preload

needs to be set such that the SPRING

COLLAR is tightened 1-4mm beyond the

point at which the COIL SPRING is first

contacted by the SPRING PERCH and has

no play along the length of the cartridge

tube.

Preload needs to be adjusted using the

included spacers so that the spring is

properly secured when approximately 9mm

of INNER TUBE thread is exposed (min

8mm, max 10mm). Too little preload may

result in the spring moving around and

causing noise - too much may result in

topout noise. If you are experiencing

substantial topout noise even with minimum

preload, please contact us.

Insert a 2mm allen key through the hole in

the INNER TUBE to prevent it from rotating

if required.

12. Check that the COIL SPRING is

adequately pre-loaded so that it is not able

to rattle around. One or two of the 2mm

SPRING SPACERS (part number:

13-07-3-08) may be required for appropriate

preload. Position the longest spacers

closest to the COIL SPRING and the

shortest spacers furthest away as this help

stabilise the spring assembly during use.

**NOTE: Getting preload right is necessary

for proper operation of the fork. Too much

or too little can cause substantial noise.

ADDITIONAL STEPS (13 & 14)

FOR PIKE 29er FORKS ONLY

13. All PIKE kits include a 20 mm long

TOPCAP ADAPTOR to be used when

installing the kit in a 29in fork. 27.5in PIKES

do not require this adaptor. All other kits

do not include or require this adaptor either.