3

1. EXAMINE FOR BAD SOLDER JOINTS

Good solder joints have a bright surface nish

and concave contour, with the lead wire

protruding from the joint. The concave shape is

the result of surface tension and is a posive

indicaon that the solder has bonded to the

component lead.

Be suspicious of any joints which appear as a

‘blob’ of solder with no lead protruding.

Cracked joints are not always this easy to spot.

Be suspicious of any joints which are

mechanically stressed or subject to vibraon.

Examples are connectors, wire terminaons or

heavier components. These will be the rst joints

to give problems.

Less extreme cracking in a joint may only be

visible under magnicaon with good lighng.

To repair a joint, rst remove the exisng solder.

Examine and, if necessary, mechanically clean

the surfaces before resoldering.

Photo credit, Wikimedia

Commons

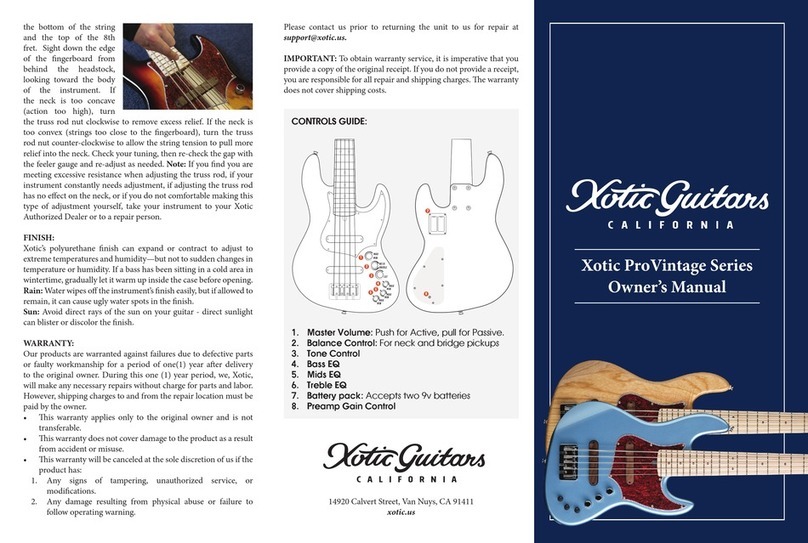

Some helpful items when fault-nding; jeweller’s loupe, head torch and

illuminated magnifying glass

Photo credit, Wikimedia

Commons