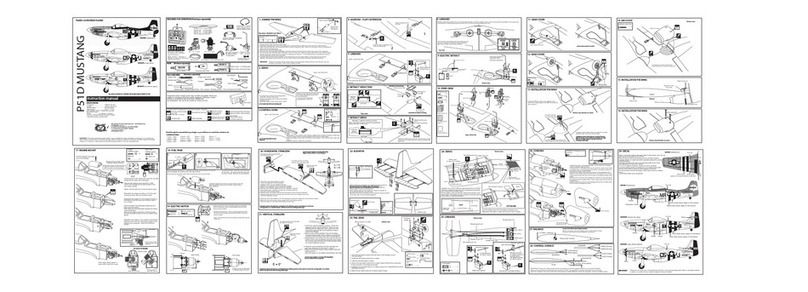

4- Main wing/installing the main gear

3x12 mm screw

4mm collar

Cut away only the film

BOTTOM VIEW

Nylon strap

Main gear

1- Locate the main landing gear struts and place

them into the landing gear slot as show. Make

sure that the ends of the struts are inserted into

the holes in the landing gear channel.

2- Position the four nylon straps across the landing

gear struts. Using the eight 3x12mm screws

located in the hardware bag, fasten the landing

gear to the bottom of the wing as show.

3- Slide one wheel onto each of the

landing gear axles and secure them

with the supplied wheel collars

* WARNING: When removing any covering from the airframe,

please ensure that you secure the cut edge with CA or similar

cement. This will ensure the covering remain tight.

FUSELAGE - TOP VIEW

1-Insert the Z-bend into the hole on the throttle lever of your engine. Note: It maybe

easier to temporarily remove the carburetor from the engine to insert the Z-bend.

It may also be necessary to slightly enlarge the hole to accept the Z-bend.

THROTTLE

CABURETOR

1/16”

6 -Engine

2

Nose gear

control horn

Nose gear

1

5

6

5- Nose gear

2-Set the engine on the engine mounting beams. Adjust the pacing of the beams

so they are centered in the relation to the mounting plate and so they are almost

touching both sides of the engine crankcase.

3-Position the engine on the engine mount beams so the distance from the prop

hub to the fire wall is 5mm

4-Using a pencil, mark the engine mounting plate where the four holes are to be

drilled

5-Remove the engine and drill a 9/64”(3.5mm) hole through the beam at each of

the four marks made in step 4 above.

6-Reposition the engine on the mounting beam, aligning it with the holes. Secure

it in place with the four 1/8x25/32”(3x20mm) screws.

1-Securely attach the nose gear mount to the fire-

wall using the four 3x15mm screws

2-Insert the white plastic tube into the fuselage,

through the firewall.

3-Insert the Z-bend of the nose gear control pushrod

into the hole on the nose gear control horn.

4-Insert the pushrod into the plastic tube

5-Position the nose gear control horn on the center of

the nose gear mount.

6-With the screw hole facing forward,slide the straight

end of the nose gear on to the nose gear mount.

7-When satisfied with the fit and alignment, secure the

nose gear control horn in place with 1/8x13/32”(3x10mm)

set screw.

TOP-VIEW

...4

3x15mm screw

(1/8x19/32”)

3

Set screw

1/8x25/32”(3x20mm) screw

3 ~ 5mm

! Engine thrust on balk head is already adjust at factory