AB

Plastic control horn

...................3

2x12mm screw

...............6

Apply the epoxy

both side

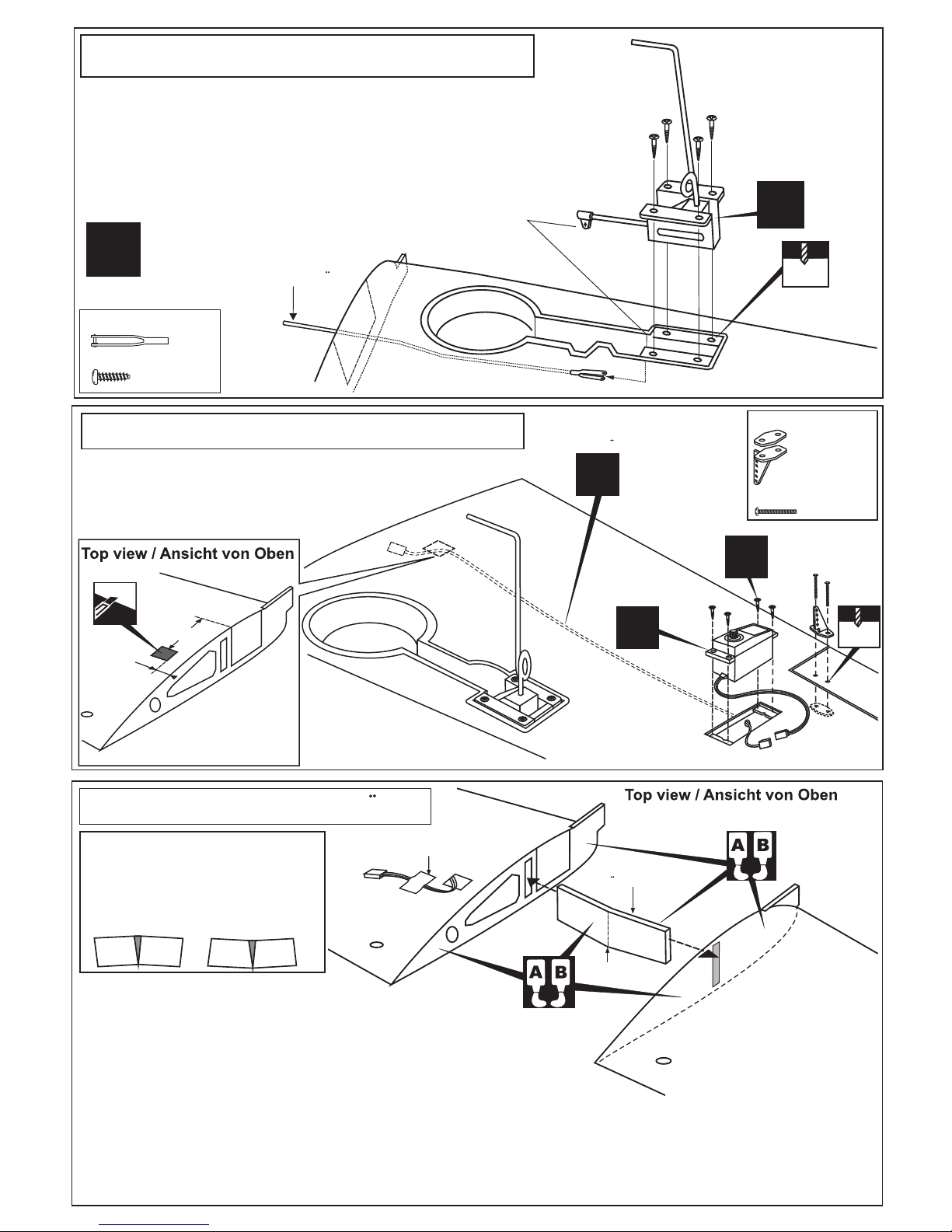

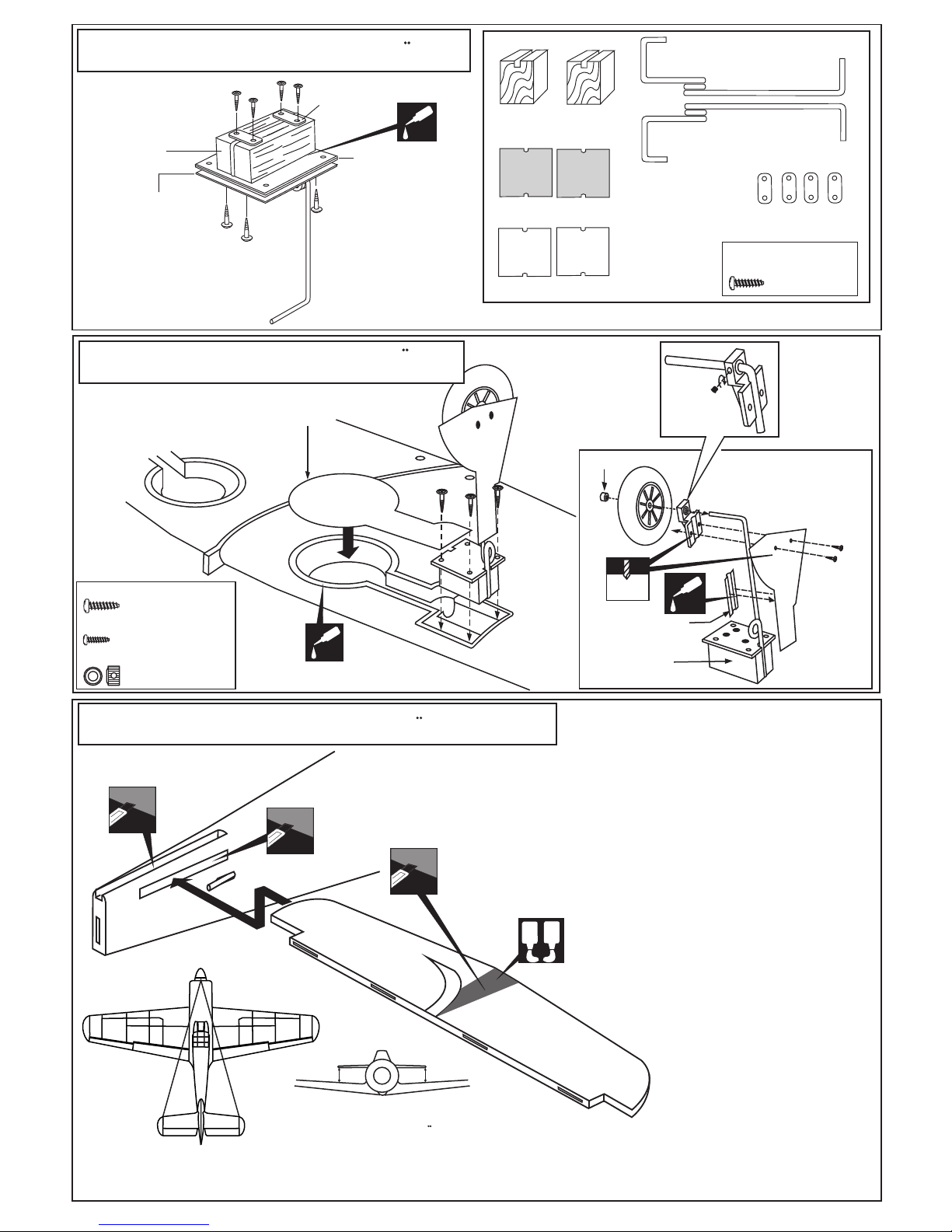

1-Trial fit the vertical stabilizer in place . Check the alignment of the

vertical stabilizer. When you are satisfied with the alignment, use a

pencil to trace around the right and left of the stabilizer where it

meets the fuselage.

2-Remove the vertical stabilizer from the fuselage. Using the sharp

hobby knife, carefully cut away the covering inside the lines which

were marked above.

3-Spread epoxy (30 minute) onto the right and left and bottom of the

vertical stabilizer along the area where the covering was removed

and to the fuselage where the vertical stabilizer mounts.

4-Install the vertical stabilizer into the fuselage and adust the align-

ment as described in steep 1.l

Allow the epoxy to cure before proceeding to next step.

10- Vertical stabilizer / Hohenleitwerk

Cut away only

the covering

both side*

BB’

AB

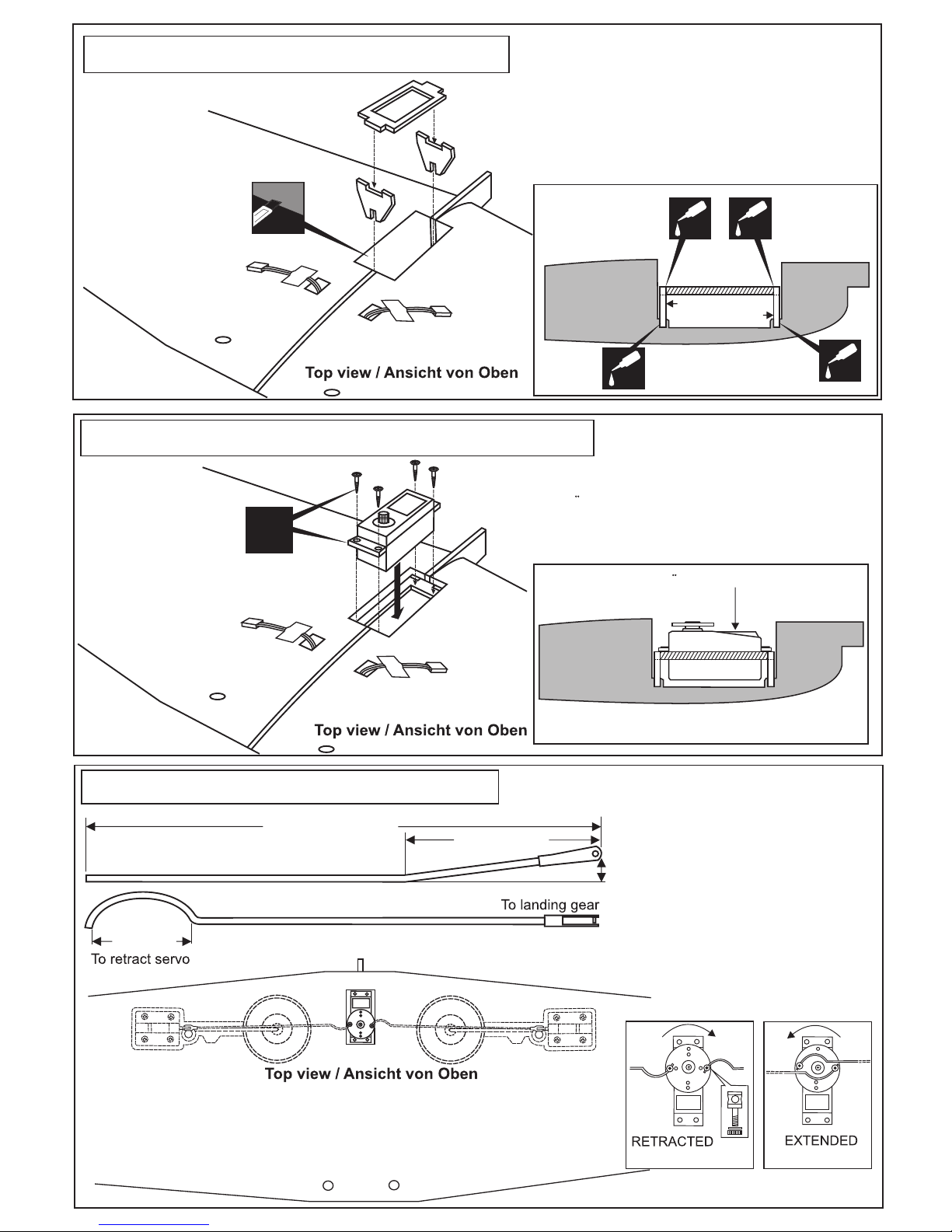

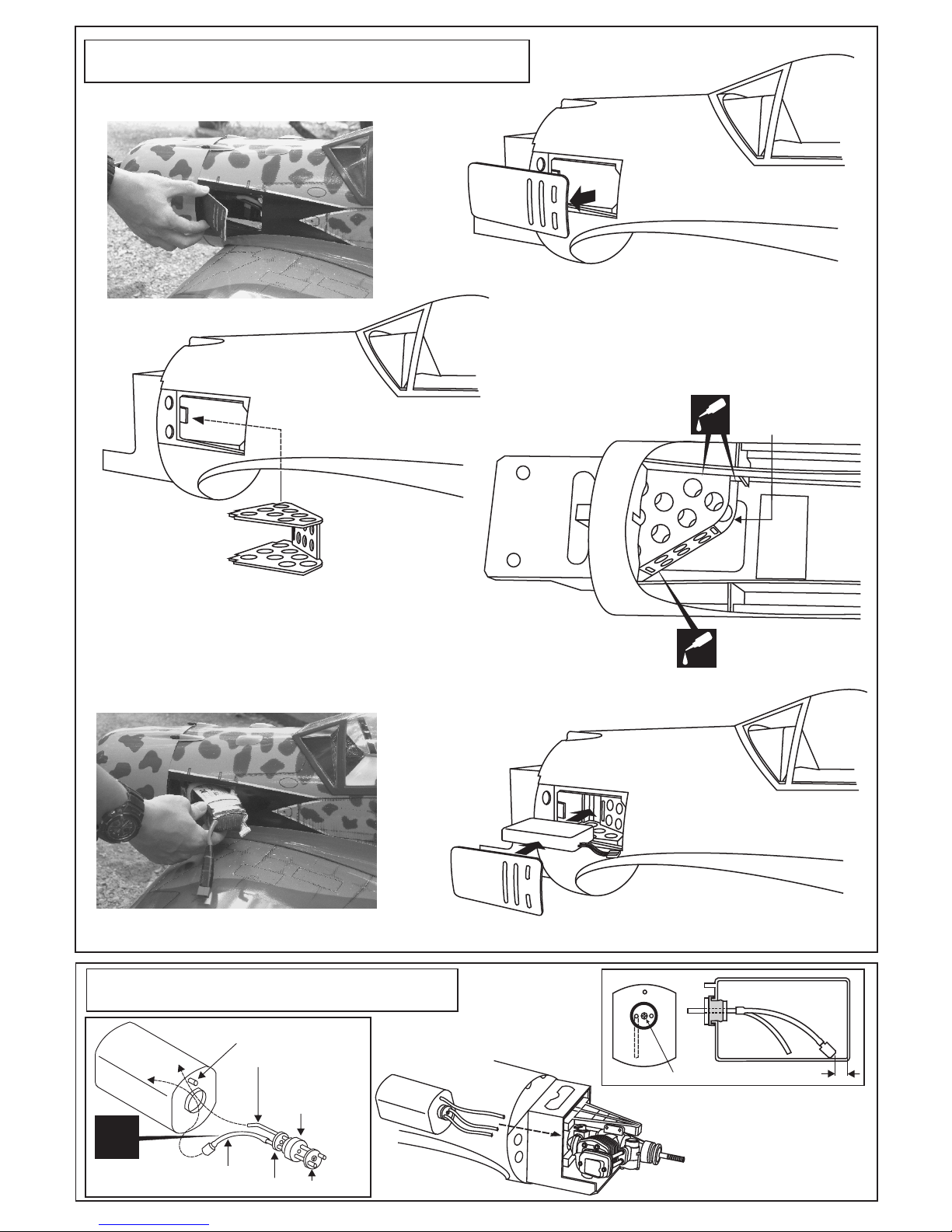

Apply a thin layer of machine oil or petroleum jelly to only the pivot point of

the hinges on the elevator, then push the elevator and its hinges into the

hinge slots in the trailing edge of the horizontal stabilizer. There should be a

minimal hinge gap and the end of the elevator should not rub against the

horizontal stabilizer.

When satisfied with the and alignment, hinge the elevator to the horizontal

stabilizer using 5 minute epoxy. Make sure to apply a thin layer of epoxy to

the top and bottom of both hinges and to inside the hinge slots. Repeat the

previous procedures to hinge the second elevator to the other side of the

horizontal stabilizer.

12- Control horn / Ruderhorn

3/8” (10mm)

2x12mm screw

B=B’

Securely glue together. If coming off during flight, you lose

control of your air plane!

Vergewissern Sie sich, sauber geklebtzu haben. Andernfalls

konnen Probleme mit der Flugeigenschaft auftreten!

Securely glue together. If coming off during flight, you lose control of

your air plane!

11- Elevator / Hohenruder

2mm

2mm

5O5O

2x12mm Blechschraube

Ansicht von unten

Bottom view

* WARNING: When removing any covering from the airframe,

please ensure that you secure the cut edge with CA or similar

cement. This will ensure the covering remain tight.

Hinge STABILIZER

Apply thin CA

both the top and

bottom.

CA

CA