TOLLS REQUIRED

Hobby knife

Needle nose Pliers

Phillip screw driver Awl

Scissors Wire Cutters

/ Erforderliches Werkzeug Hex Wrench

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

Sander

SILICON

EPOXY A

EPOXY B

CA

GLUE

Epoxy Glue ( 5 minute and 30 minute type)

Silicon Glue

Cyanoacrylate

Glue

Masking tape - Straight Edged Ruler - Pen or pencil - Rubbing alcohol - Drill and Assorted Drill Bits

Read through the manual before you begin, so you will have an overall idea of what to do.

1.5mm

AB

!

CA

L/R

Assemble left and right

sides the same way.

X

Drill holes using the stated

size of drill

(in this case 1.5 mm Ø)

Use epoxy glue

Take particular care here Hatched-in areas:

remove covering

film carefully

Not included.

These parts must be

purchased separately

Check during assembly that these

parts move freely, without binding

Apply cyano glue

/ Klebstoff

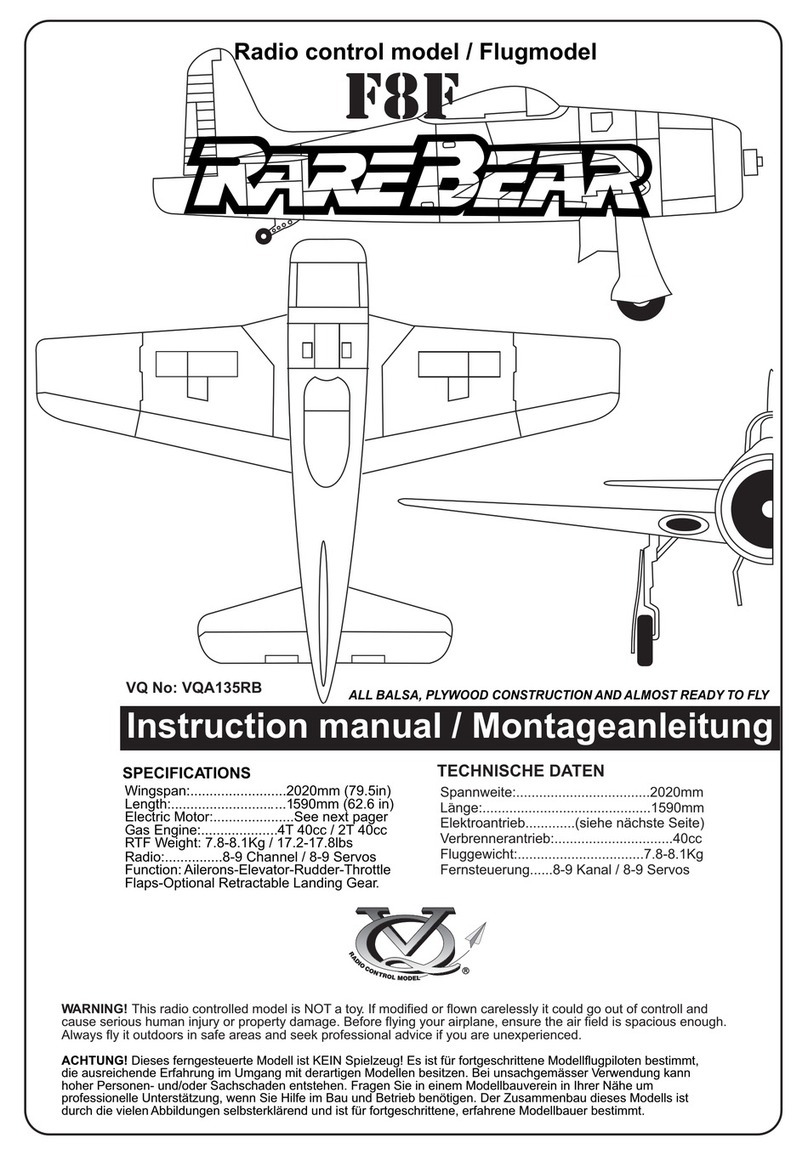

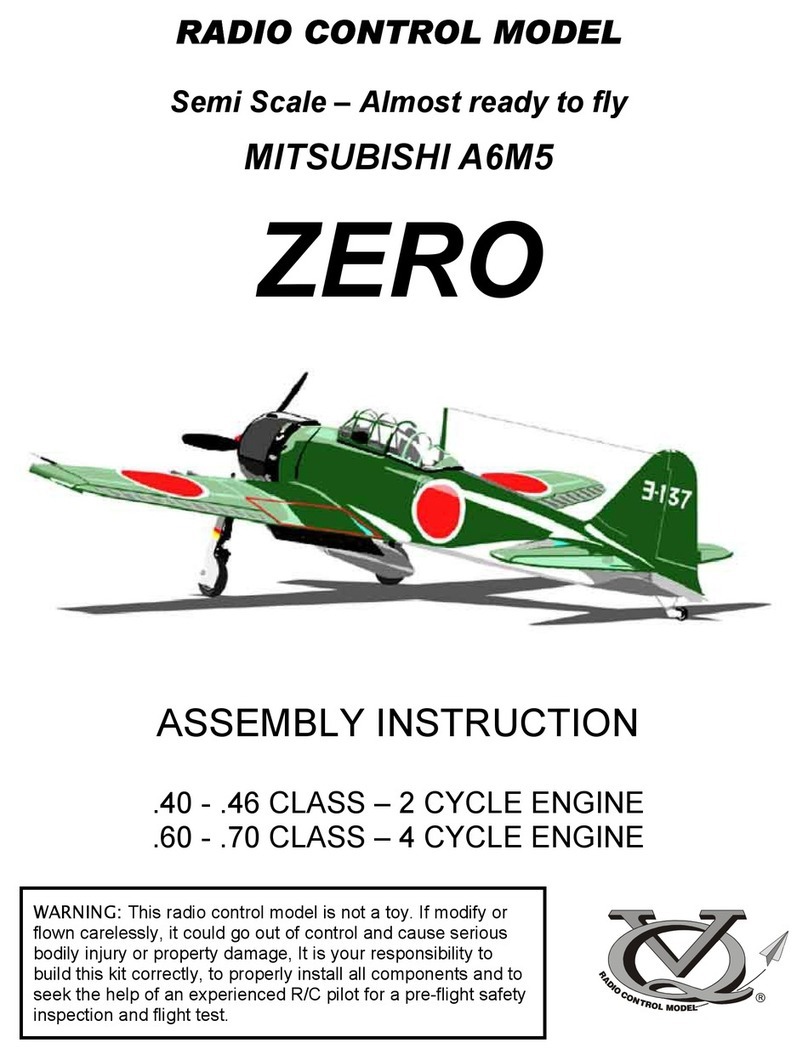

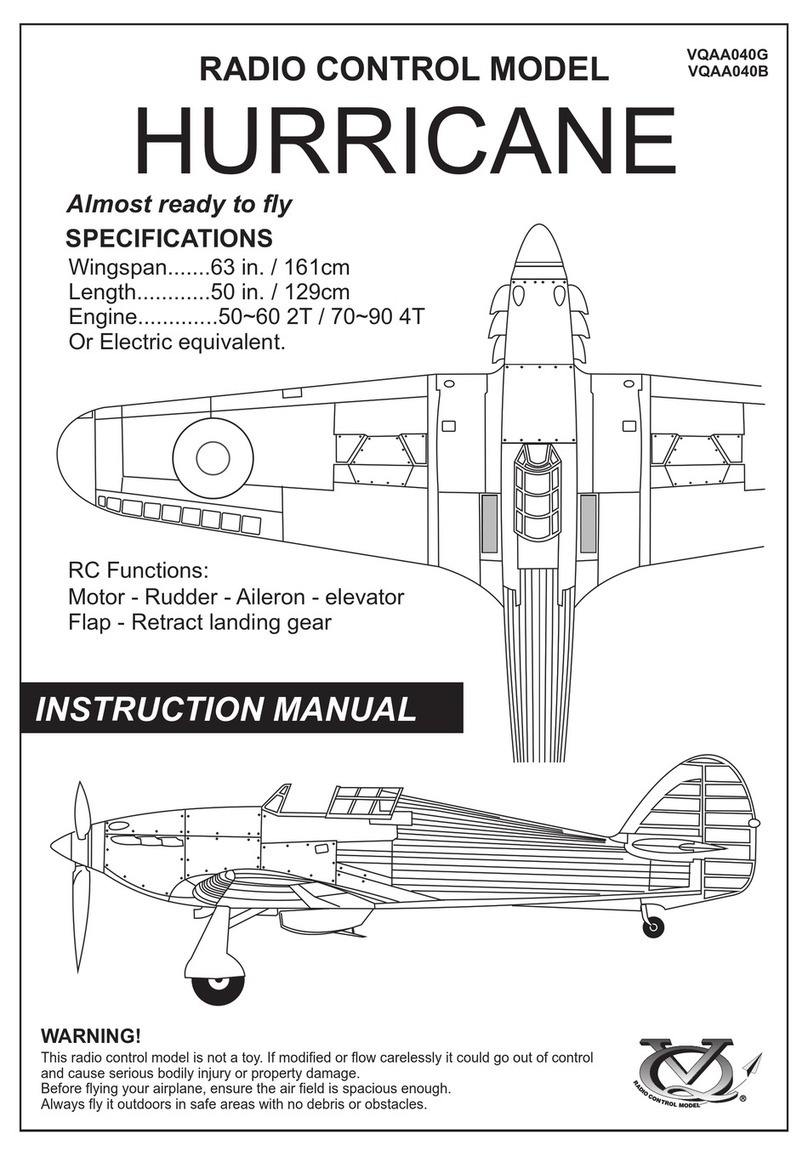

.60 ~.70 - 4 cycle

10.5x6 for .40 - 2 cycle engine

11x6 for .46 - 2 cycle engine

12x6 for .60 - 4 cycle engine

12x7 for .70 - 4 cycle engine

13x6 for Quantum 4120/05

Silicone tube

Extension for aileron

servo, retract servo.

.46 ~ .50 - 2 cycle

Linkage Stopper x2

(for retract servo)

Retract landing

gear VQAR08

Retract servo

x1

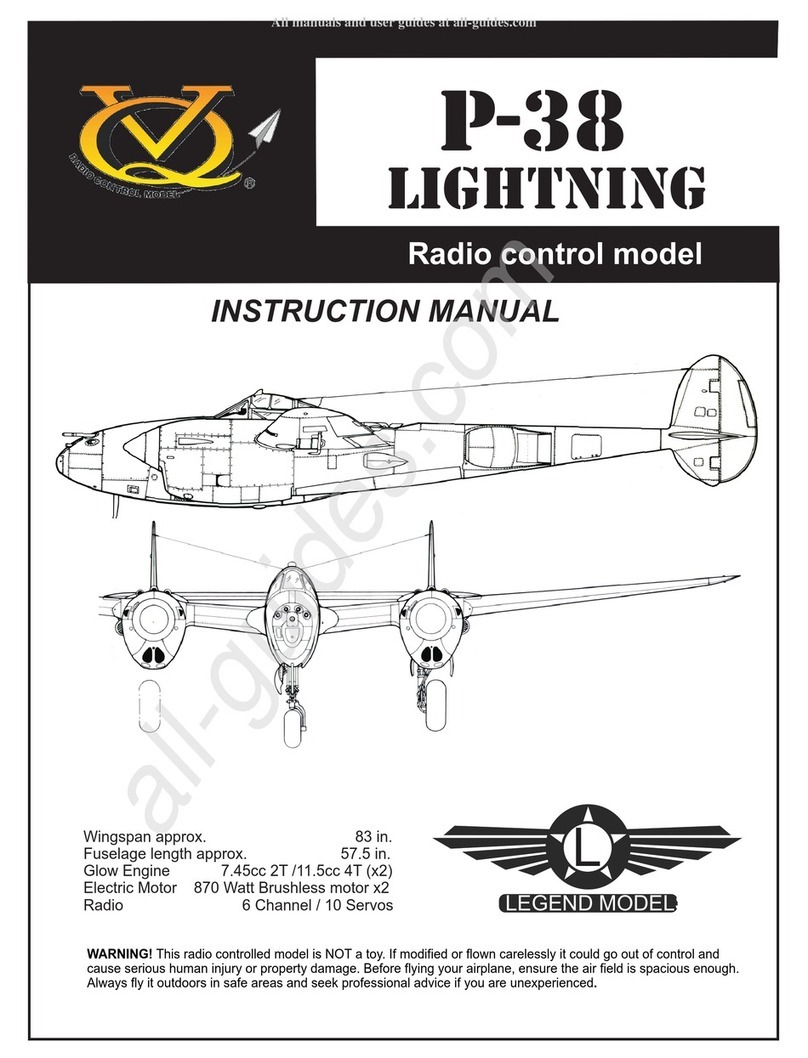

870Watt Brushless

Motor (PULSAR 60)

60A Brushless ESC

60A Brushless Regler

Li-Po Battery, 18.5V, 4500mAh (LEMONRC)

Minimum 5 channel radio

for airplane with 5 servos

Aileron servo x 2.

Throttle servo x 1.

Rudder servo x 1.

Elevator servo x 1.

REQUIRED ITEMS / Zum Betrieb wird benotigt

If exposed to direct sunlight and / or heat, wrinkles can appear. Storing the model in a coll

place will let the wrinkles disappear. Otherwise, remove wrinkles in covering film with a hair-

dryer, starting with low temperature. You can fix the corners by using a hot iron.

Bei Sonneneinstrahlung und / oder Warme kann die Folie erschlaffen bzw. Falten entstehen.

Verwenden Sie ein Warumluftgeblase (Haartrockner) um evtl. Falten aus der Folie zu

bekommen. Die Kanten konnen Sie mit einem Bugeleisen behandeln. Nicht zuviel Hitze

anwenden

Symbols used throughout this instruction manual, comprise / Selbsterklarende Symbole

CONVERSION TABLE

1.0mm = 3/64”

1.5mm = 1/16”

2.0mm = 5/64”

2.5mm = 3/32”

3.0mm = 1/8”

4.0mm = 5/32”

5.0mm = 13/64”

6.0mm = 15/64”

10mm = 13/32”

12mm = 15/32”

15mm = 19/32”

20mm = 51/64”

25mm = 1”

30mm = 1-3/16”

45mm = 1-51/64”