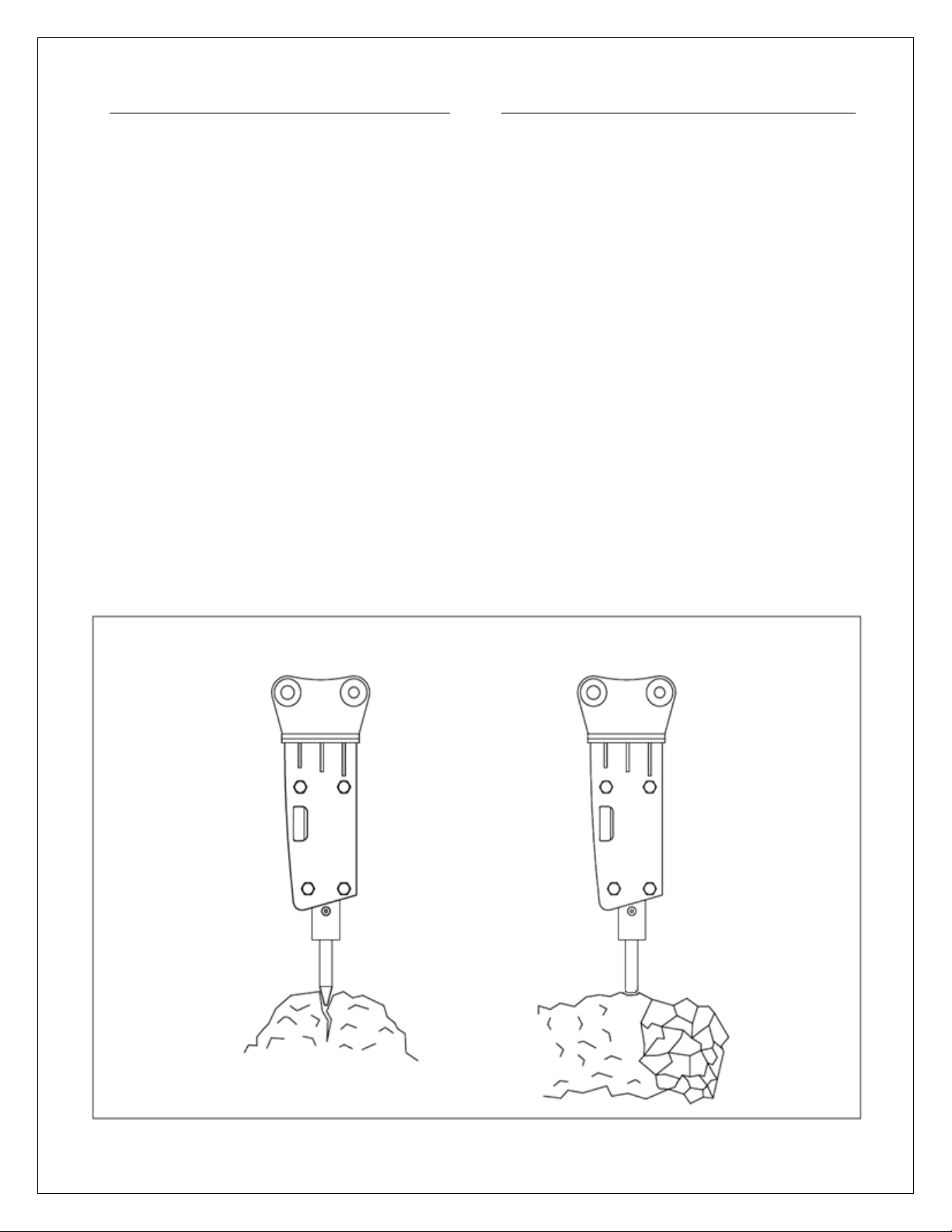

8) Stop the breaker quickly.

a. Do not allow the breaker to fall off the

object or make idle strokes when the object

breaks. Constant idle strokes have a

deteriorating effect on the breaker.

b. If the breaker falls off the object ,side

pressure could occur, and side plates will

be worn down more quickly

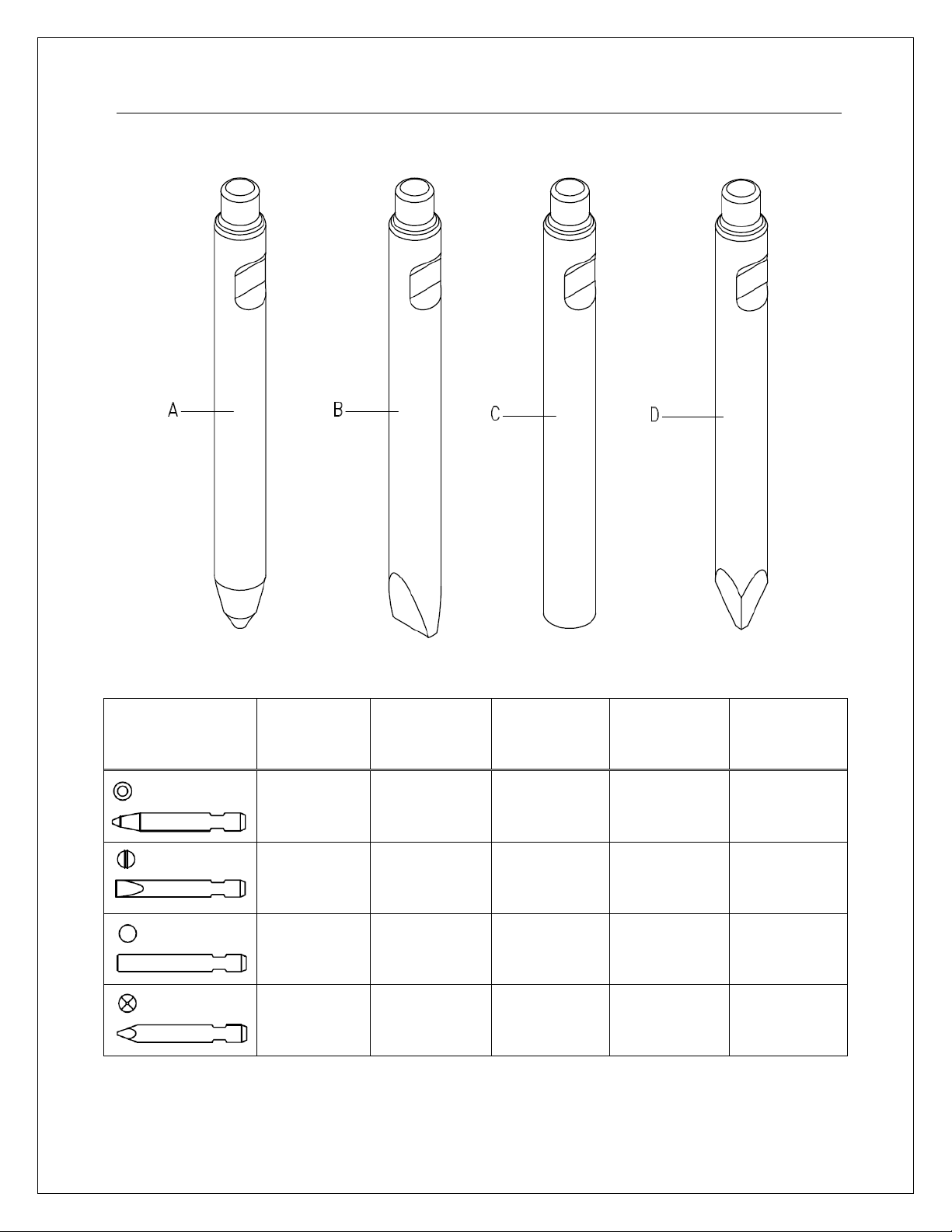

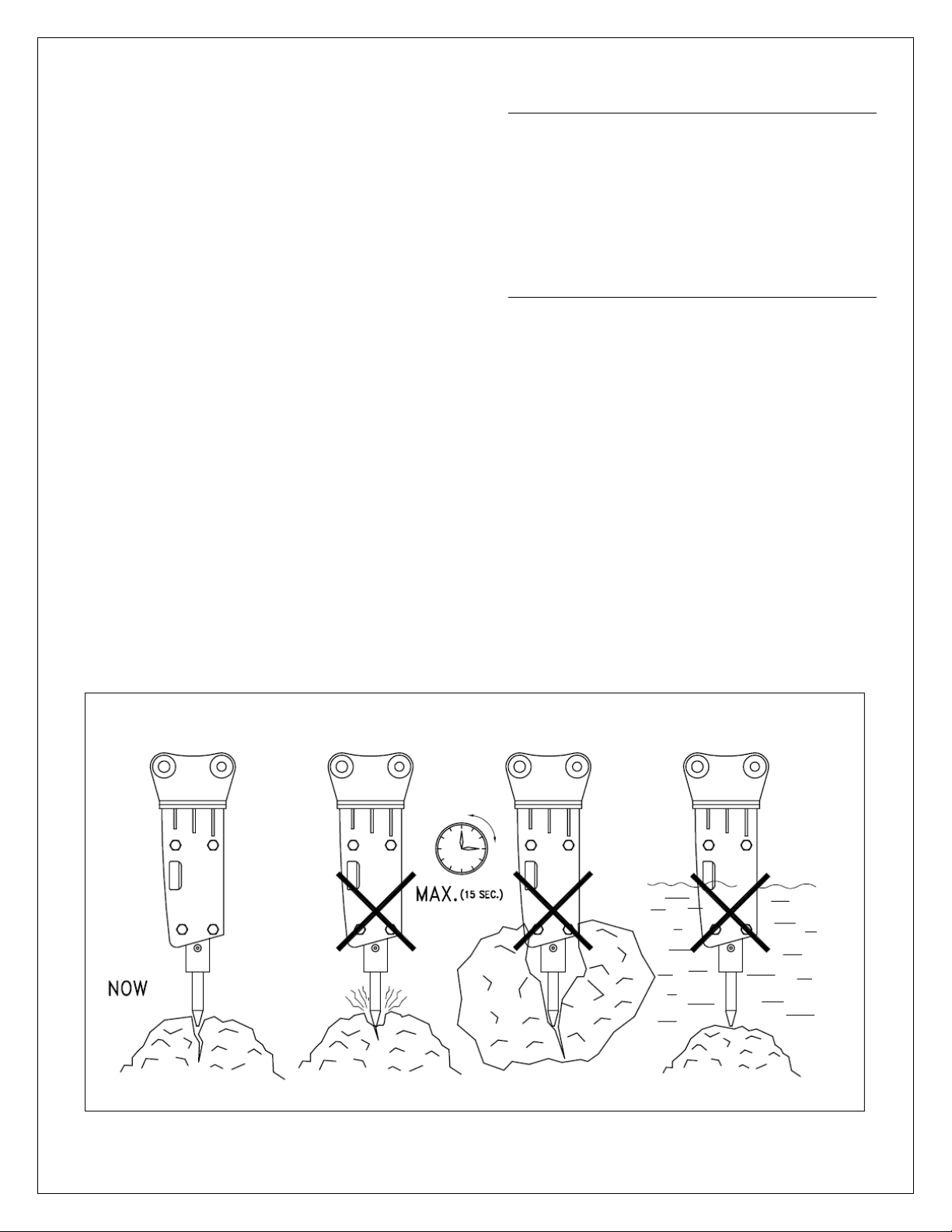

9) Chisel, cone, and moil

If the object does not break after fifteen

seconds, stop the beaker and change the

position of the tool. Leaving the tool in the

same position for more that fifteen seconds

will only make an indentation, which will fill

with dust and dampen the impact effect. This

will cause the tool to overheat.

10) When breaking concrete, hard ground, frozen

ground, or any similar material, never strike and

pry with the tool at the same time. This could

break the tool.

2.5 Operating Temperature

The operating temperature is -20°C~80⁰C. If the

temperature is lower than -20°C (-4°F), the

breaker and tool must be preheated before

starting to operate, in order to avoid breakage of

the accumulator membrane and the tool.

During operation they will remain warm.

2.6 Important Operation Points

a. Listen to the breaker‟s sound while you are

working.

If the sound becomes thinner and the impact

is less efficient, the tool is misaligned with

the material and/or there is not enough

“pressing” force on the tool.

Realign the tool and press the tool firmly

against the material.

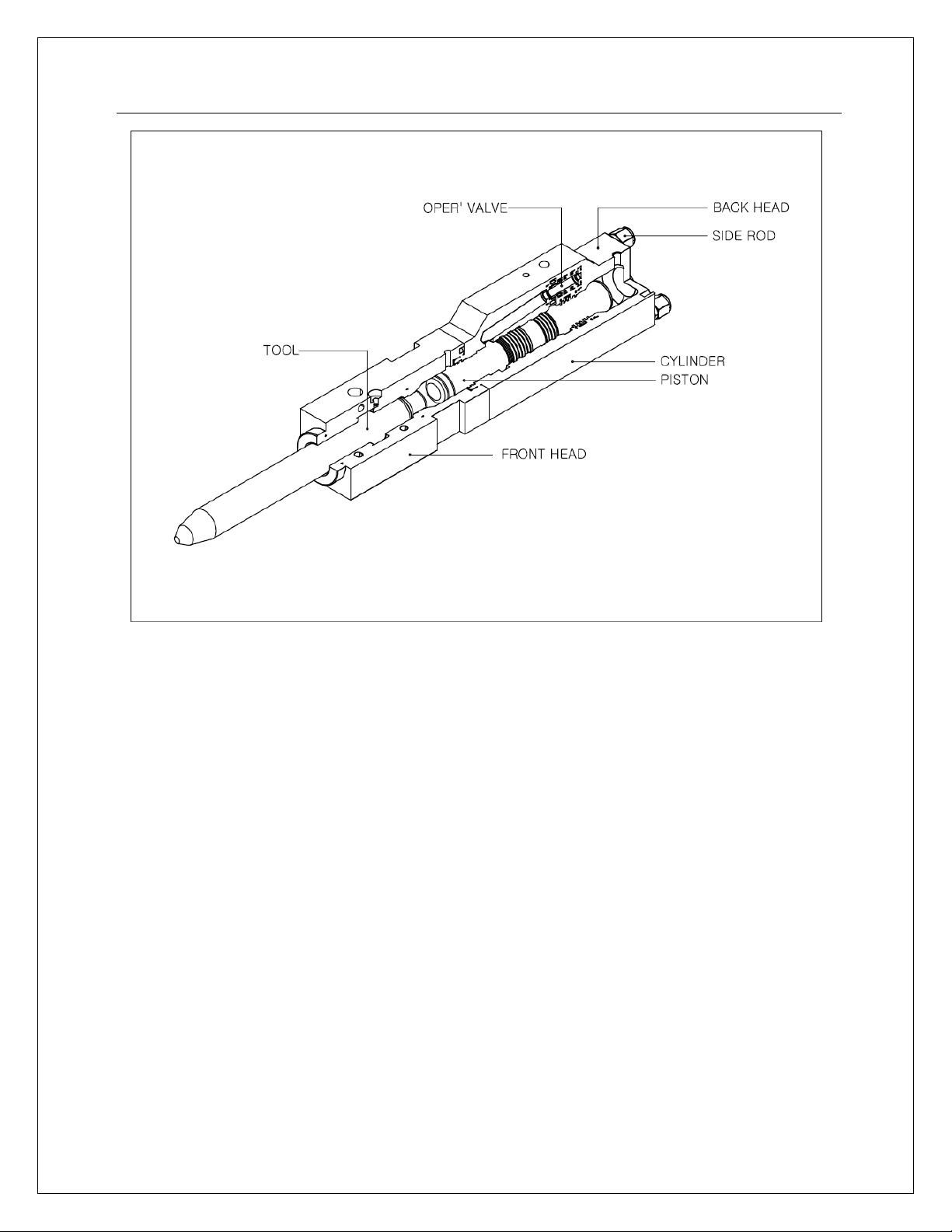

b. The breaker, as a standard assembly must

not be used underwater.

If water fills the space where the piston

strikes the tool, a strong pressure wave is

generated and the breaker could be

damaged.