4 | Page

TABLE OF CONTENTS

INTRODUCTION........................................................................................................................................... 5

Read this Manual ...................................................................................................................................... 5

Safety Considerations and Requirements ................................................................................................ 5

Contacting Assistance............................................................................................................................... 6

Engineering Improvements ....................................................................................................................... 6

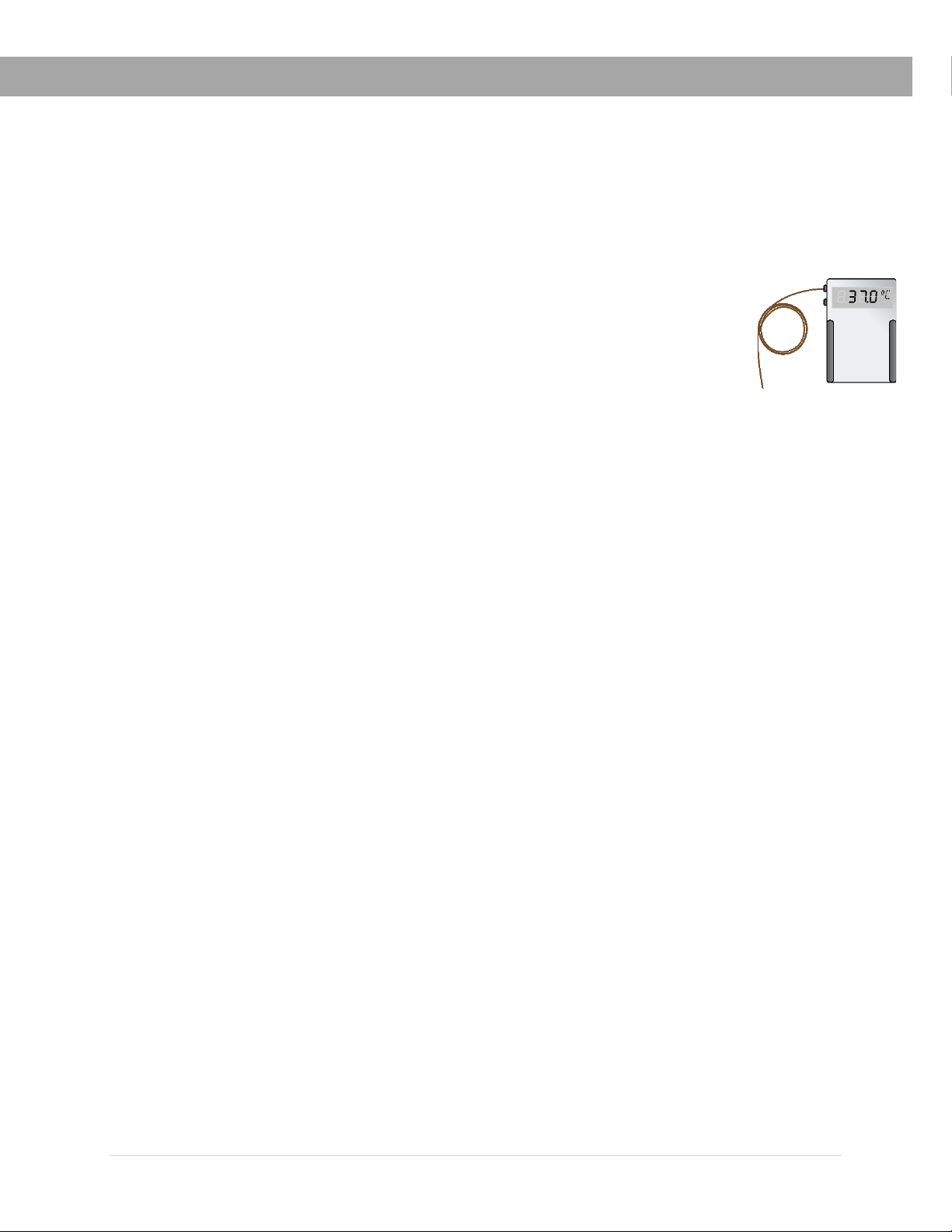

Reference Sensor Device ......................................................................................................................... 7

RECEIVING YOUR UNIT.............................................................................................................................. 9

Inspect the Shipment ................................................................................................................................ 9

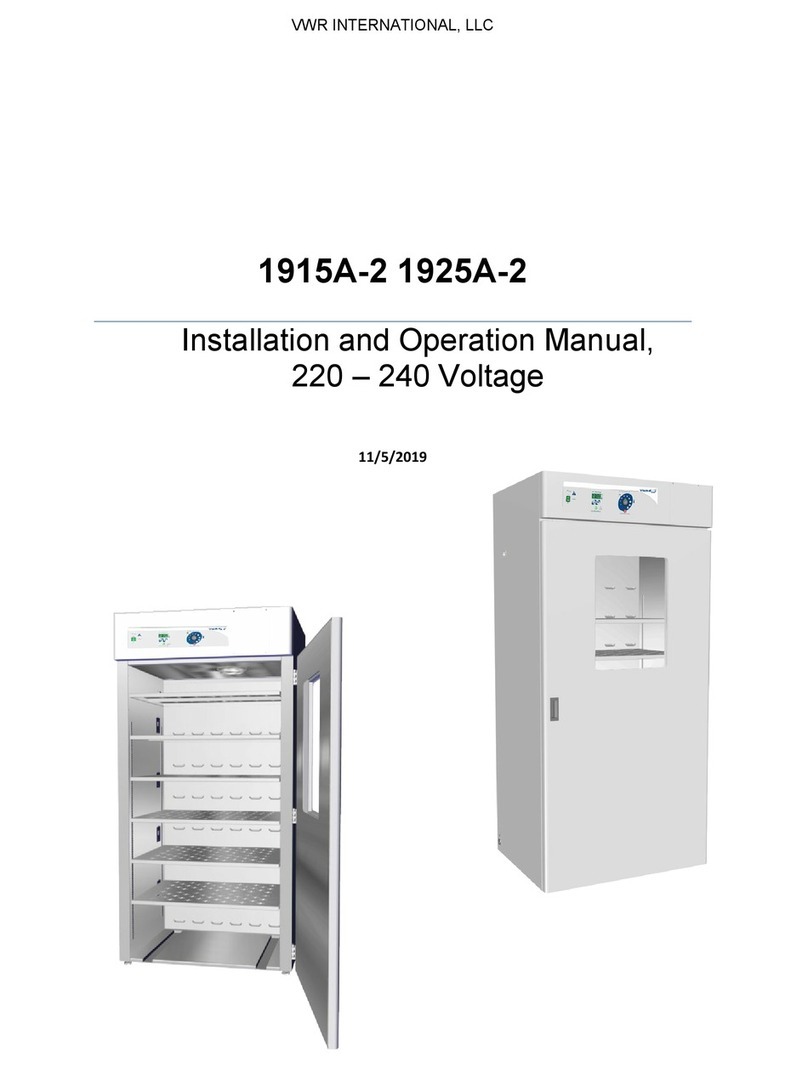

Orientation Images .................................................................................................................................. 10

Record Data Plate Information................................................................................................................ 13

INSTALLATION .......................................................................................................................................... 15

Installation Procedure Checklist.............................................................................................................. 15

Required Ambient Conditions ................................................................................................................. 16

Required Clearances .............................................................................................................................. 16

Power Source Requirements .................................................................................................................. 17

Lifting and Handling ................................................................................................................................ 18

Leveling ................................................................................................................................................... 18

Install the Incubator ................................................................................................................................. 19

Deionized and Distilled Water ................................................................................................................. 19

Installation Cleaning and Disinfecting ..................................................................................................... 19

Shelving Installation ................................................................................................................................ 20

Access Port ............................................................................................................................................. 20

GRAPHIC SYMBOLS................................................................................................................................. 21

CONTROL PANEL OVERVIEW................................................................................................................. 23

OPERATION ............................................................................................................................................... 25

Theory of Operation ................................................................................................................................ 25

Put the Incubator into Operation ............................................................................................................. 26

Set the Temperature Set Point................................................................................................................ 27

Set the Over Temperature Limit (OTL) ................................................................................................... 28

Loading Samples..................................................................................................................................... 29

Chamber Accessory Power Outlets ........................................................................................................ 29

Humidifying the Incubator ....................................................................................................................... 29

Condensation and the Dew Point............................................................................................................ 30

USER MAINTENANCE............................................................................................................................... 31

Cleaning and Disinfecting ....................................................................................................................... 31

Minimizing Contamination Exposure....................................................................................................... 32

Door Components ................................................................................................................................... 33

Electrical Components ............................................................................................................................ 33

Storing the Incubator ............................................................................................................................... 33

Calibrate the Temperature Display ......................................................................................................... 34

UNIT SPECIFICATIONS............................................................................................................................. 39

Weight ..................................................................................................................................................... 39

Dimensions.............................................................................................................................................. 39

Chamber Volume .................................................................................................................................... 40

Shelf Capacity ......................................................................................................................................... 40

Temperature............................................................................................................................................ 40

Power ...................................................................................................................................................... 40

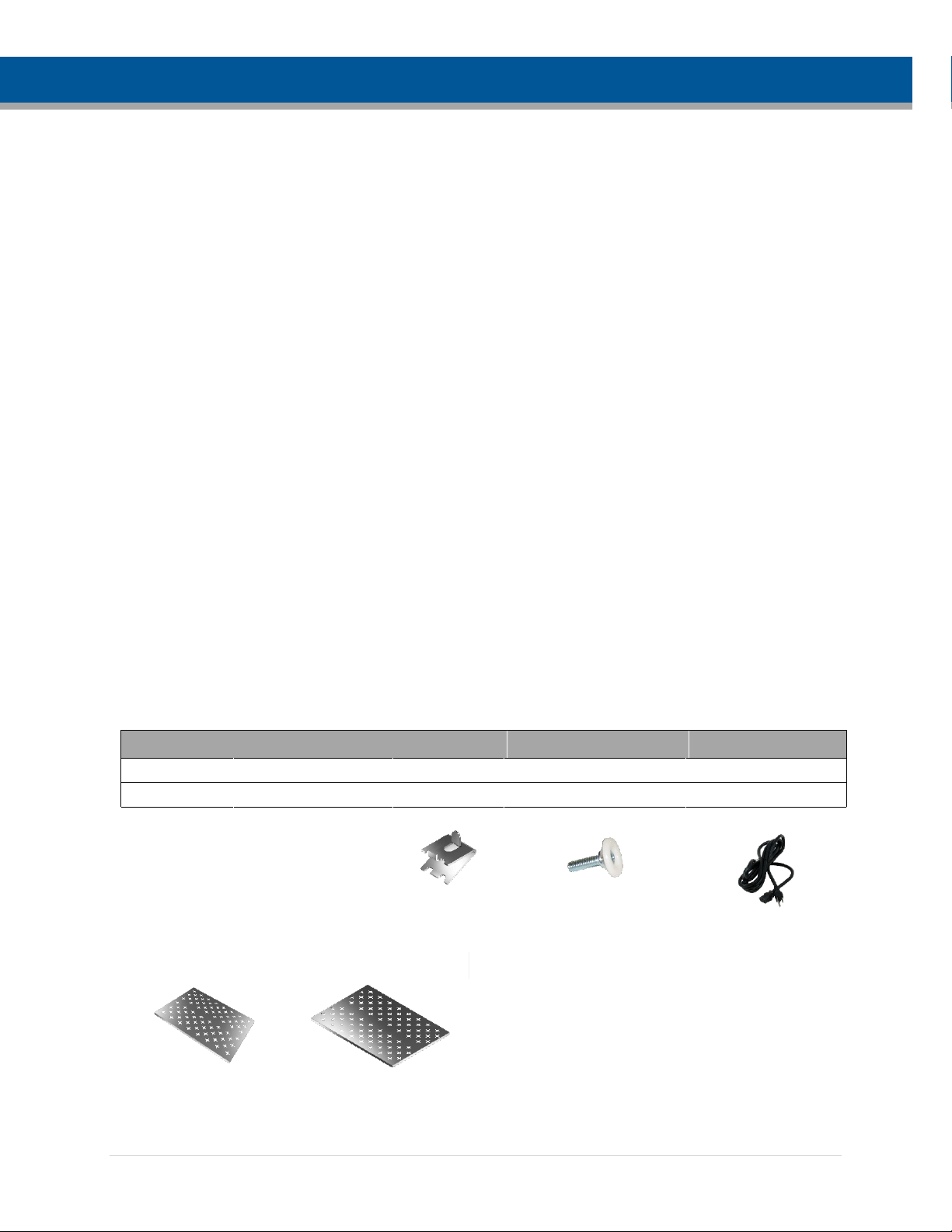

PARTS LIST ............................................................................................................................................... 41