- 2 -

TABLE OF CONTENTS

1.General Information....................................................................................4

1.1. INTENDED USE......................................................................................4

1.2. INAPPROPRIATE USE ..............................................................................4

1.3. WARRANTY............................................................................................4

2. UNPACKING AND INSTALLATION ................................................................4

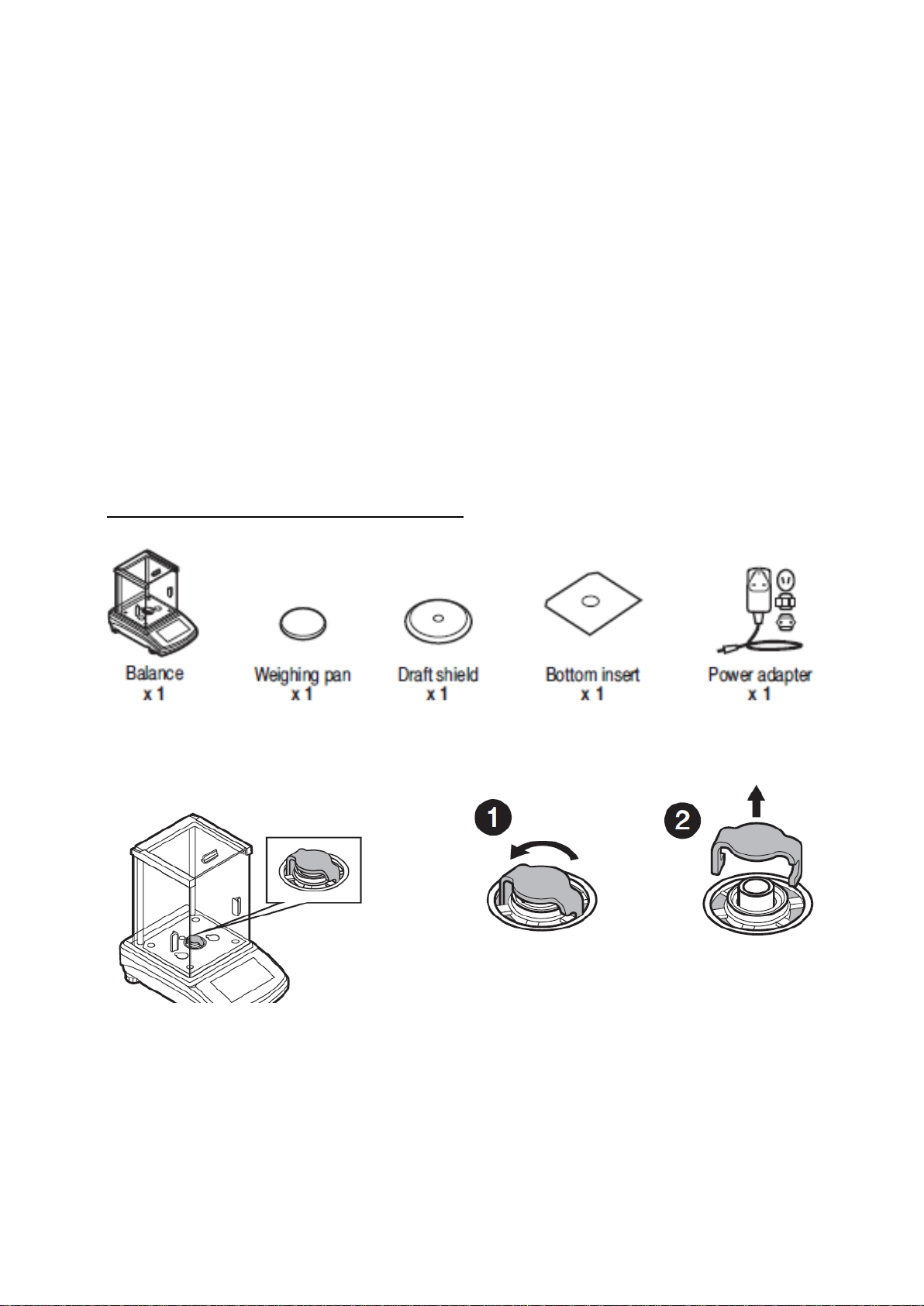

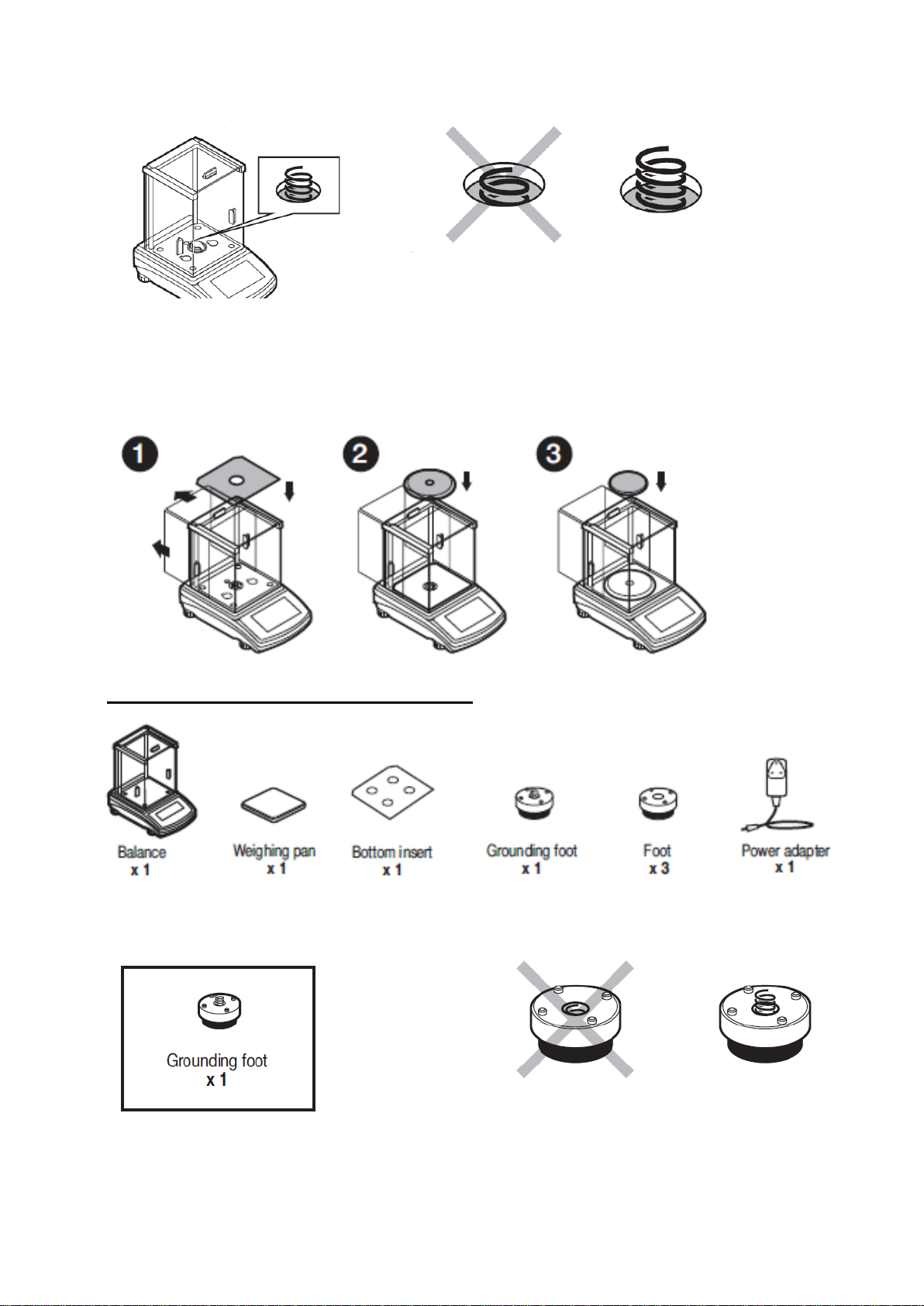

2.1. STANDARD DELIVERY COMPONETS LIST...................................................4

2.2. UNPACKING...........................................................................................4

2.3. PLACE OF USE AND ASSEMBLY ................................................................5

2.4. BALANCE ASSEMBLY...............................................................................5

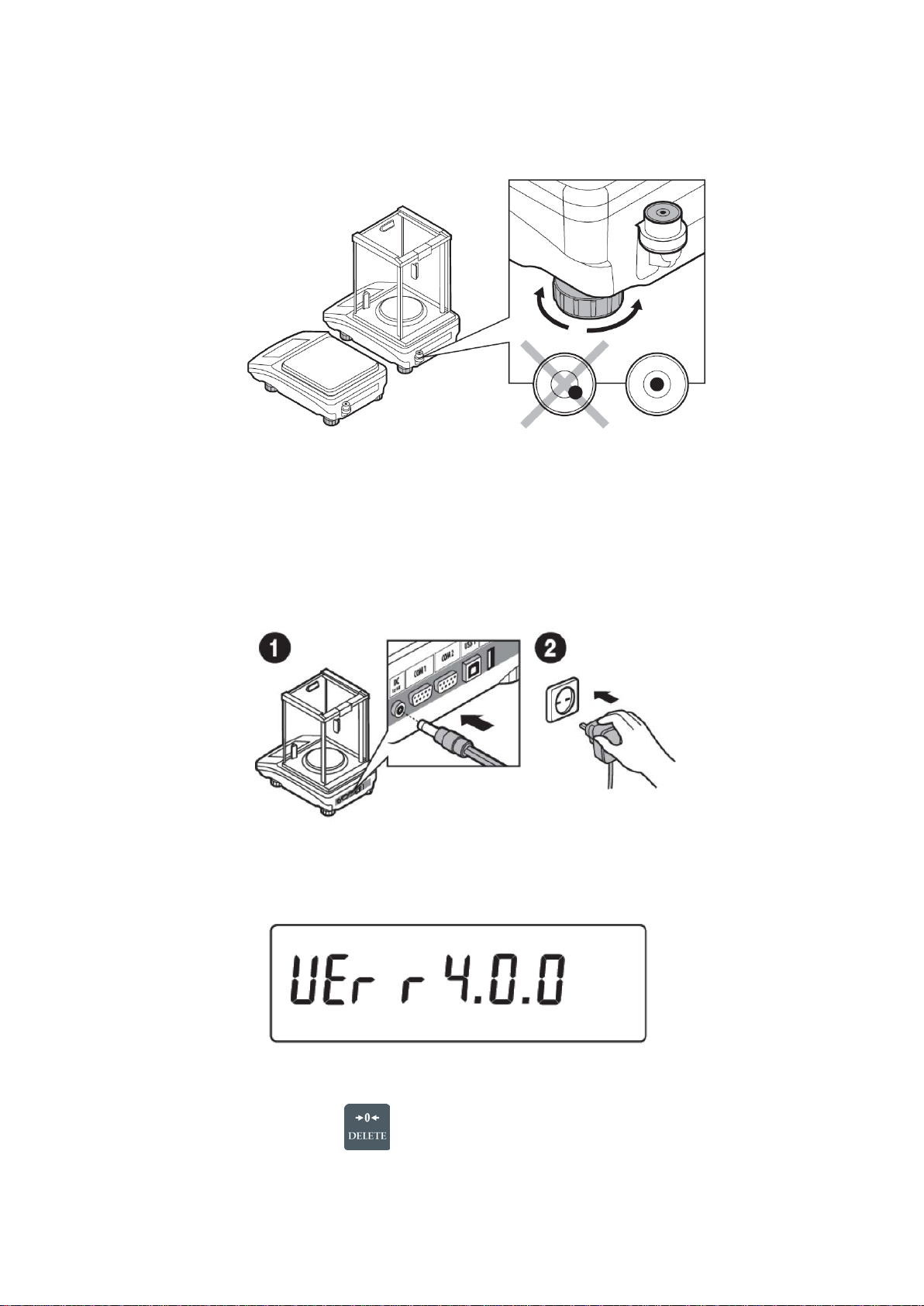

2.5. BALANCE LEVELING................................................................................8

2.6. POWERING THE DEVICE..........................................................................8

3. KEYBOARD – BUTTON FUNCTIONS ..............................................................9

4. START-UP..................................................................................................10

4.1. TEMPERATURE STABILIZATION PERIOD.................................................. 10

4.2. USER MENU......................................................................................... 10

5. BALANCE OPERATION – GENERAL INFORMATION.....................................12

5.1. BALANCE ZEROING .............................................................................. 12

5.2. BALANCE TARING................................................................................. 12

5.2.1. MANUAL TARE DETERMINATION.............................................................12

5.2.2. DELETING TARE ...................................................................................12

5.3. UNITS................................................................................................. 13

5.4. TEMPORARY MEASURING UNIT .............................................................. 13

5.5. UNITS ACCESSIBILITY.......................................................................... 13

5.6. START UNIT SELECTION ....................................................................... 13

5.7. CUSTOM UNIT...................................................................................... 14

6. WORKING MODES- GENERAL INFORMATION.............................................14

6.1. RUNNING WORKING MODE.................................................................... 15

6.2. WORKING MODE ACCESSIBILITY ........................................................... 15

6.3. WORKING MODE PROFILE ..................................................................... 15

6.4. WORKING MODE SETTINGS- READING ................................................... 16

6.4.1. FILTER LEVEL SETTING.........................................................................16

6.4.2. VALUE RELEASE...................................................................................17

6.4.3. AUTOZERO..........................................................................................17

6.4.4. LAST DIGIT DISPLAY ............................................................................18

6.4.5. BALANCE AMBIENT CONDITIONS ...........................................................18

6.5. WORKING MODE SETTINGS- AUTOTARE ................................................. 18

6.6. WORKING MODE SETTINGS- PRINT MODE .............................................. 19

6.7. WORKING MODE SETTINGS- INFORMATION............................................ 21

6.8. WORKING MODE SETTINGS- Non-Standard INFORMATION........................ 21

6.9. WORKING MODE SETTINGS- F shortcut keys........................................... 22

7. CALIBRATION............................................................................................23

7.1. CALIBRATION MENU SETTINGS.............................................................. 23

7.2. EXTERNAL CALIBRATION....................................................................... 23

7.2.1. EXTERNAL CALIBRATION.......................................................................23

7.2.2. USER CALIBRATION..............................................................................23

7.3. CALIBRATION REPORT PRINTOUT........................................................... 24