ISOTHERM 2000 CALIBRATION PROCEDURE

Plug the ISOTHERM 2000 into the Calibration Tool 2000

The plug is located in the ISOTHERM's handle or calibration compartment(Reel)

NOTE: The Isotherm 2000 MUST remain plugged into the Calibration

Tool during the calibration process. Unplugging the Isotherm

when moving from the cold bath to the hot bath will cause

wrong temperature readings after calibration.

Pick a low calibration temperature

The ice-point (32°F or 0°C) is a good "low" calibration point (it's what we do the

factory calibration at). Any other convenient point can be used however, the

accuracy of the ISOTHERM can be adversely affected by a badly chosen

calibration point. It is suggested that you do the low calibration at the ice-point

and then do the high calibration at (or just above) the maximum temperature that

will normally be measured by the ISOTHERM being calibrated (or at the

maximum temperature less than or equal to 325°F (450°F if you have a high-

temperature probe assembly) that you can attain for calibration).

Set the probe into a bath set to the low temperature

This could be a properly prepared ice-bath. You will need a certified Liquid-In-

Glass thermometer positioned very close to the probe tip to get the exact

temperature of the bath.

Wait for the bath and the probe to settle to the temperature

If you don't wait 5 minutes or more, you won't get a good calibration.

Adjust the ISOTHERM's temperature until it matches the bath temperature

See Using The Calibration Tool 2000(above) to find out how to adjust the shown

temp.

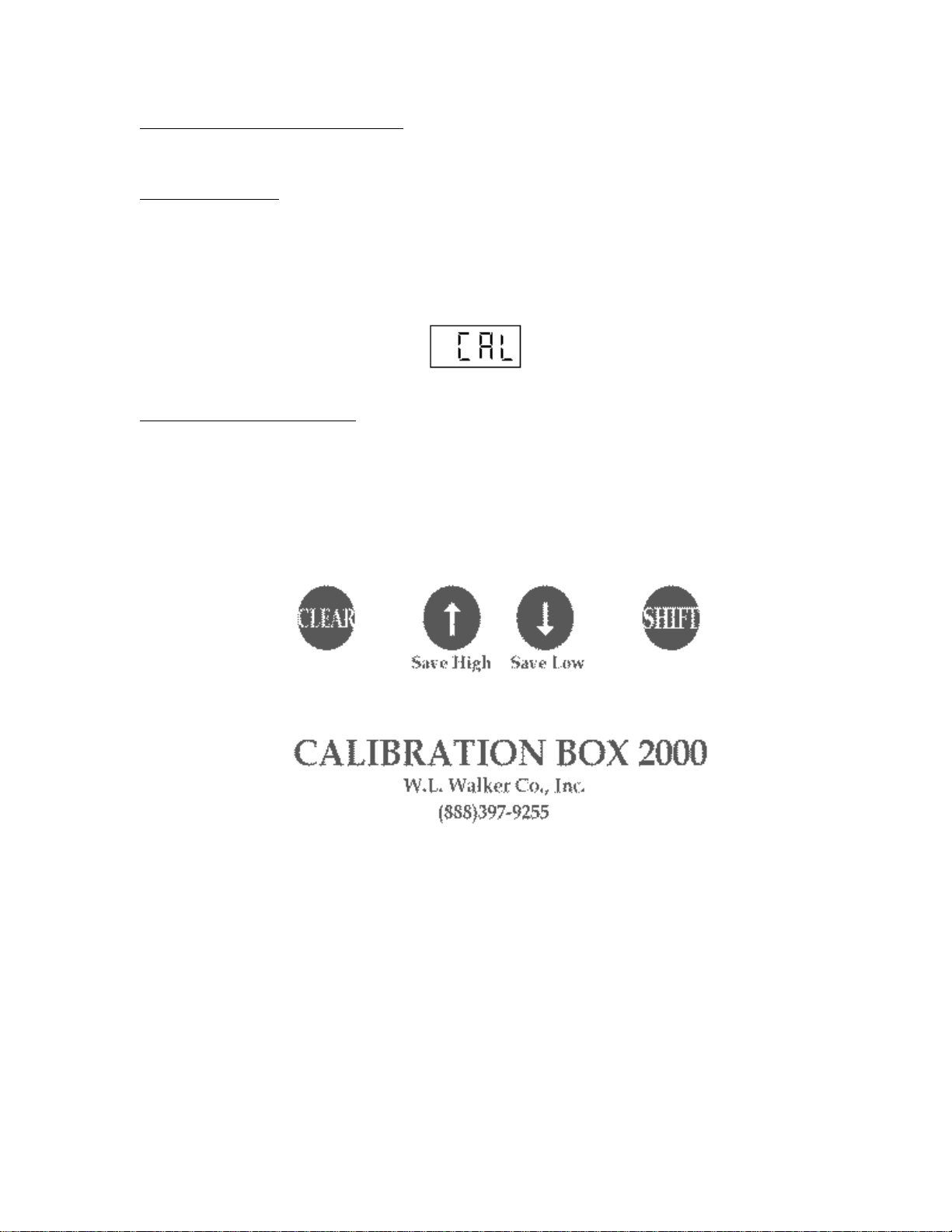

Store the Low calibration temperature

While holding down the SHIFT button, depress the button marked SAVE LOW,

you'll see:

Pick a high calibration temperature

The boiling point of water (212°F or 100°C) is a good "high" point. Any other

convenient point can be used however, the accuracy of the ISOTHERM can be

adversely affected by a badly chosen calibration point. It is suggested that you do

the high calibration at (or just above) the maximum temperature that will normally

be measured by the ISOTHERM being calibrated (or at the maximum

temperature less than or equal to 325°F (450°F if you have a high-temperature

probe assembly) that you can attain for calibration).

Set the probe into a bath set to the high temperature

This could be a pot of boiling water. You will need a certified Liquid-In-Glass

thermometer positioned very close to the probe tip to get the exact temperature

Wait for the bath and the probe to settle to the temperature

If you don't wait 5 minutes or more, you won't get a good calibration.

Adjust the ISOTHERM's temperature until it matches the bath temperature

See Using The Calibration Tool 2000(above) to find out how to adjust the shown

temp.

Store the High calibration temperature

While holding down the SHIFT button, depress the button marked SAVE HIGH,

you'll see: