®

ii

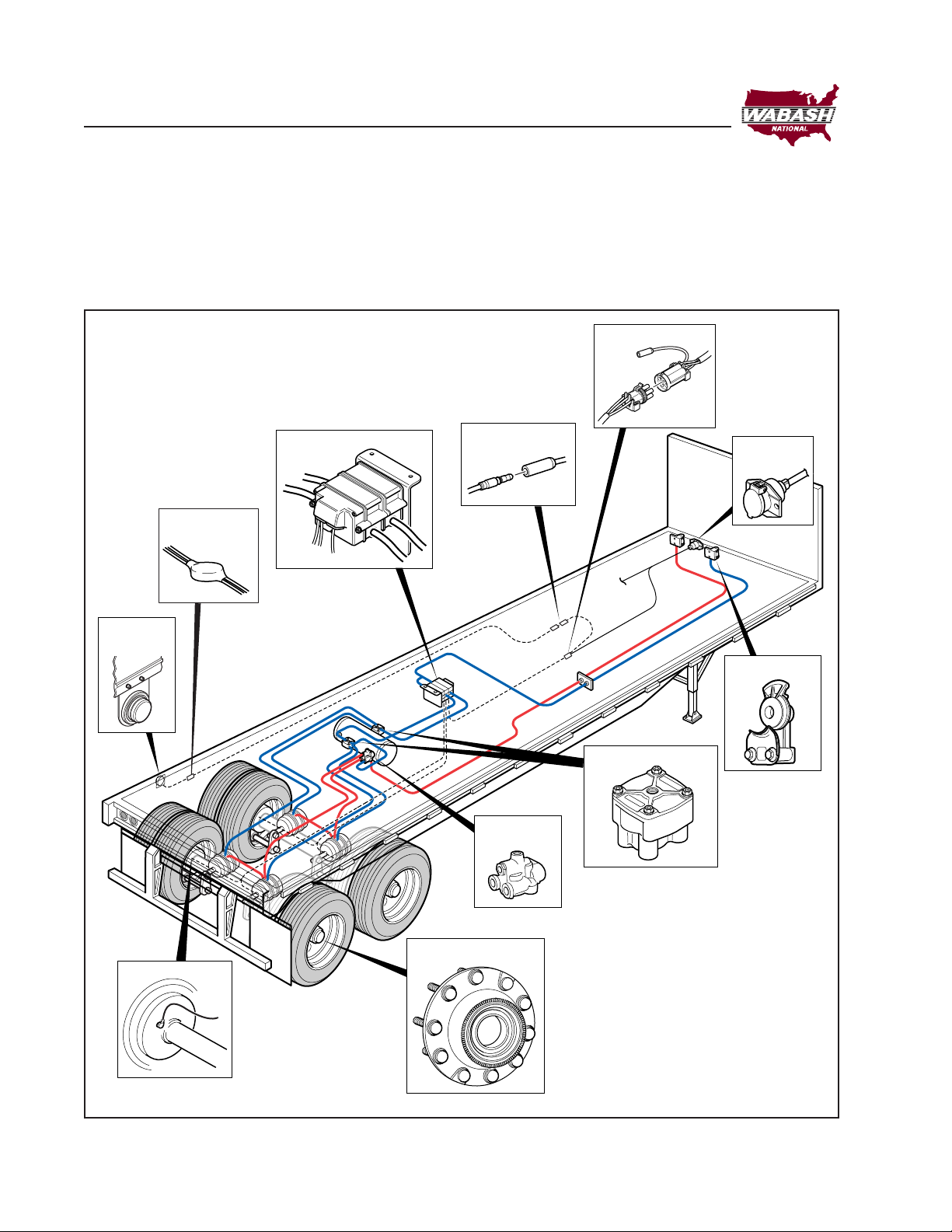

MBS-1P Installation

Contents

Wabash MBS-1P ABS Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

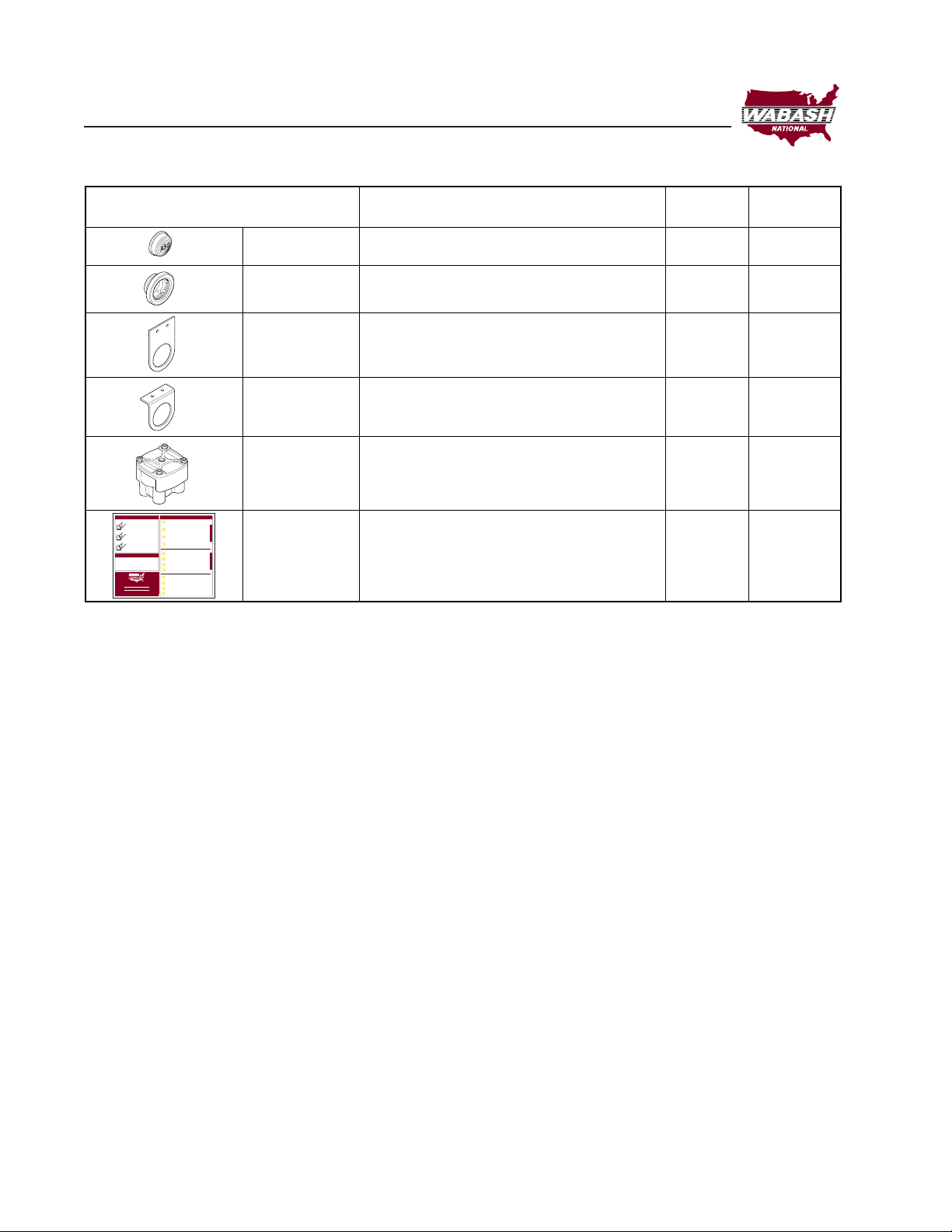

MBS-1P System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Air Brake Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Key Dates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

ABS Design Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Type of ABS Required for Trailers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Power Requirements for ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

ABS Malfunction Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Color and Labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Intensity and Photometric Requirements . . . . . . . . . . . . . . . . . . . . . . . . .8

Power Line Carrier (PLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Pneumatic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Installation of Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Power and Sensor Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

MBS-1P Cable Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Circuit Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Malfunction Lamp Diagnostic Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Pneumatic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

MBS-1P Location and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Plumbing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Relay Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Hub Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Initial System Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

ABS System Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Initial System Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Pneumatic Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Electrical Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Troubleshooting The System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Entering the Flash Code Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . .27

Suitable Light Tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Current Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Stored Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Clearing Stored Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Malfunction Lamp Diagnostic Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Sensor Signal Faults (Trace) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Malfunction Lamp Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

MBS-1P Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40