Scarifier Control Lever, Item 4. Used

to raise and lower scarifier.

Circle Reverse Lever, Item 5. Use for

rotating moldboard clockwise or counter-

clockwise for correct positioning of mold-

board for type of work being done.

Lateral Shift Lever, Item 6. Use for

moving moldboard and circle right or left to

desired position for type of work being done.

Leaning Wheel Lever, Item 7. Use for

leaning front wheels to offset side thrust

caused by position of moldboard. For most

operations the top of the front wheels are

leaned away from the leading edge of mold-

board.

Right Hand Blade Lift Lever, Item 8.

Use for raising or lowering the right hand

end of moldboard.

Moldboard Power Shift Lever, Item 9.

e for shifting moldboard right or left for

extended reach or to clear obstructions such

bridge abutments, etc.

Moldboard Tilt Lever, Item 10. Use for

tilting moldboard to correct position for type

of work and material.

Ground Speed Selector Lever, Item 11.

Use for hand control of engine RPM.

Horn Button, Item 12.

Key Switch, Item 13, turns on the elec-

trical system. When turned clockwise to its

extreme position, it acts as starter switch.

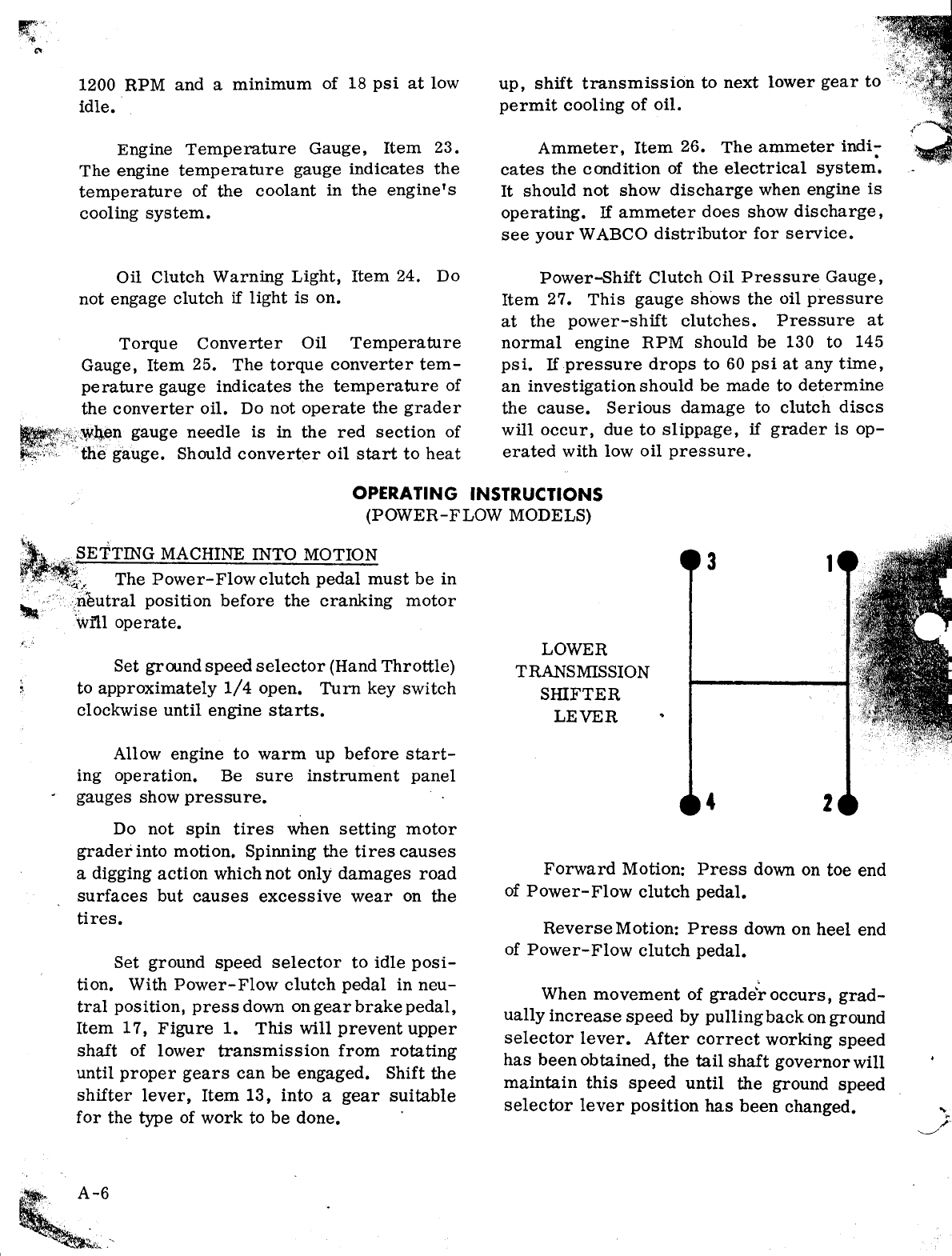

Gear Shift Lever, Item 14. Use to shift

lower transmission gears through the four

gear ranges.

Parking Brake Lever, Item 15. Use to

set parking brake when machine is parked.

The parking brake is located on front end of

lower shaft of lower transmission.

Accelerator-Decelerator Pedal, Item 16.

Use as a foot throttle by pressing down on

forward pad to increase engine RPM. Or use

to decelerate engine RPM when working with

ground speed selector lever in a set posttton.

By pressing down on the rear pad, engine

RPM will be reduced. Remove foot from pad

and engine RPMwill increase to that as pre-

set with ground speed selector lever.

Wheel Brake Foot Pedal, Item 17. Use

to apply wheel brakes for bringing grader to

a halt. Each of the four tandem wheels are

equipped with a hydraulic actuated, shoe-

type brake.

Power Shift Clutch Pedal, Item 18. Use

to engage Power-Shift transmission clutches

(upper transmission). Depress toe of pedal

for forward motion. Depress heel of pedal

for reverse motion. Clutch pedal-must be in

neutral positionbefore starting motor circuit

will work.

,.r

Transmission Gear Brake Pedal, Item

19. To be used only when shifting transmis-

sion gears while grader is at halt. Do not

use when grader is moving. The gear brake

stops transmission gears from rotating while

shift is being made. Permits easier shifting

without clashing of gears.

Light Switch, Item 20. Controls light

circuits.

Engine Shut Down Button (GM Engine),

Item 21. Pressing button actuates solenoid

at engine governor to shut downengine. Hold

button in until engine stops.

If

grader is

equipped with lever instead of solenoid, the

pull knob will be located just under R.H.

side,

of the operator's seat. Pull lever and hold

until engine stops. NOTE:' Do not use the

emergency engine shut down to stop engine

except in case of an emergency.

Engine Oil Pressure Gauge, Item 22.

Registers engine oil pressure. Gauge should

read 40 to 60 psi at high idle, 30 to 60 psi at