LF-210 Manual P/N 24154 5 April, 2003

DRAIN CONNECTION

- See Rough-In Dimensions

Bottom Discharge Models: Center on floor flange

12" (standard) from finished wall with wax ring

(provided). If floor is uneven a second standard wax

ring may be added. If bottom ring of toilet hits

flange, it should be ground down for added

clearance, as any contact will break seal on hopper.

Rest toilet on its back on a padded surface (e.g.

packing from shipping box). Center wax ring on

toilet discharge flange. Turn toilet over, lifting up,

and center the horn of the wax ring into the toilet

floor flange. Compress the wax ring by applying

weight to the toilet.

REAR DISCHARGE MODELS: Discharge line

should be connections at hopper with a No-Hub

Coupling (P/N 33324, provided). Do not glue or

connect fittings until fitting alignment has been

checked. Toilet discharge line must have a rise

(trap) (see ROUGH-IN DIMENSIONS) in order to

provided water trap seal when flapper is open.

CAUTION: do not apply stress to align outlet to

waste line. This will result in eventual seal damage.

DOWNWARD DISCHARGE MODELS: Toilet

mounts to floor with 1/4" closet bolts. Install screws

with a 3/8" nut driver. Screw on bolt caps to

mounting screws.

INSTALLATION AND START UP

1. Position and mount

the Toilet to floor.

See Rough-In

Dimensions.

2. For units with

Remote Flush,

position and mount

Remote Flush

Assembly to wall with Vacuum Breaker at least

6" above the rim of the toilet bowl. The

maximum water line distance between the toilet

and the Remote Flush Assembly is 4'.

3. Position and mount the Flush Activator to wall.

The maximum distance between the Flush

Activator and the Remote Flush Assembly is

72".

4. Connect the incoming water supply to the 3/4"

I.D. Hose Barb on the Remote Flush Assembly.

5. Connect the water line from Remote Flush

Assembly to the toilet spud assembly.

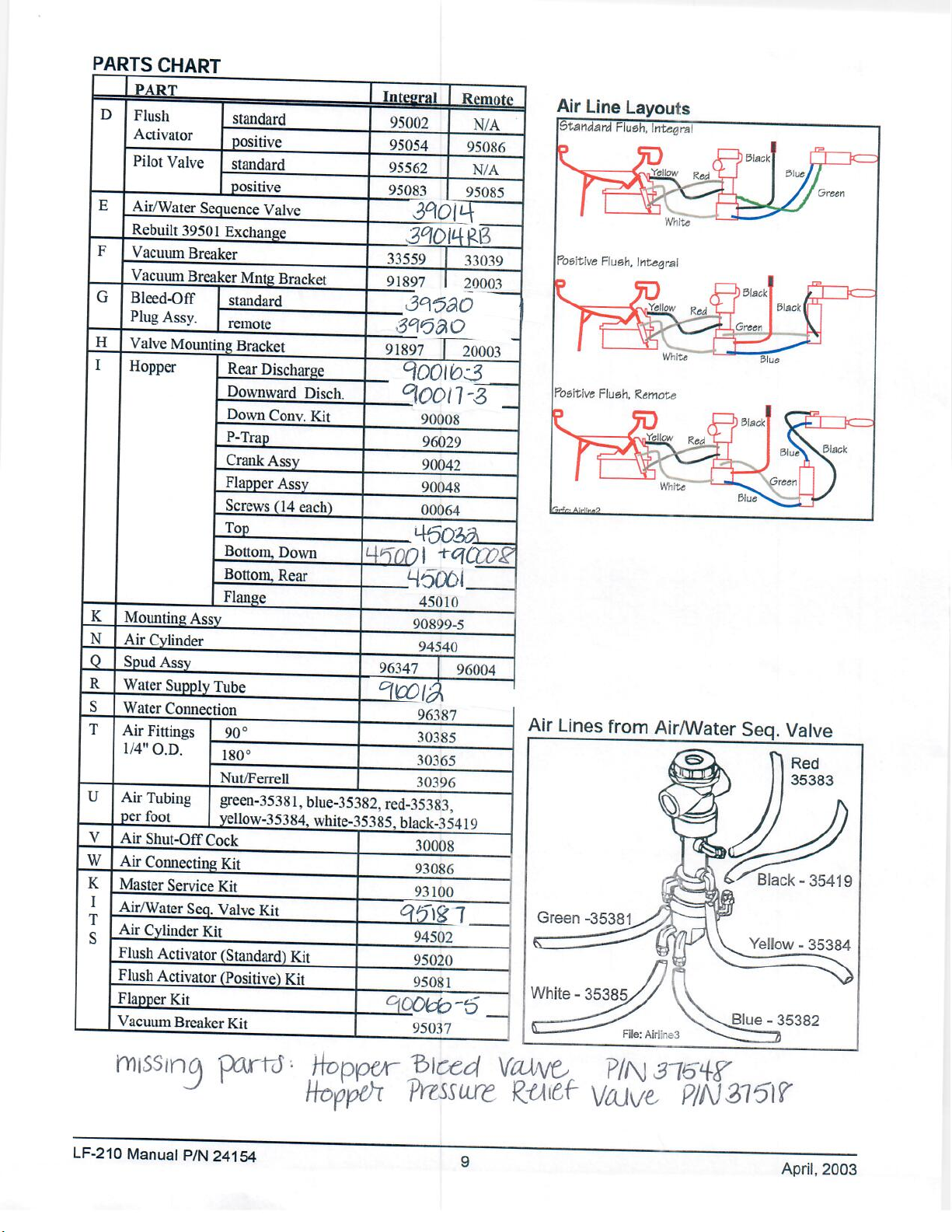

6. Assemble the Air Connecting Kit (P/N 93086)

provided and connect to incoming air supply.

Do not connect to flush Activator.

7. Turn OFF air shut-off cock at toilet.

8. Turn ON air supply at compressor.

9. Turn ON air shut-off cock at toilet to blow out

airlines for a few seconds. This procedure

should remove any debris or contaminants from

the airline. Turn OFF air shut-off cock.

10. Now connect airline to the top of the Flush

Activator. Turn ON air shut-off cock. Check

total installation for air leaks using soapy water.

11. Turn ON water. Check for water leaks.

12. Flush toilet four times, waiting twenty seconds

between flushes to get water through toilet and

operating regularly. To flush properly, hold

down handle until flapper opens.

13. Water level in bowl should be at top edge of

flapper opening.

14. If the toilet does not operate correctly or have

the proper water level in bowl, refer to adjusting

Toilet or Troubleshooting sections of this

manual.