MICROFLUSH Toilet Manual 2 March 2005

THANK YOU FOR PURCHASING A

MICROPHOR PRODUCT!

Your Microflush®toilet is designed to provide you with

years of reliable service while using only two quarts of

water per flush. Please read this Owner’s Manual com-

pletely prior to installation of your Microflush toilet. This

will familiarize you with all of the proper installation and

operation requirements.

CUSTOMER SERVICE

Please contact your local Microphor dealer for parts and

service. For a list of dealers, please contact Microphor at

1-800-358-8280 or visit our website at

www.microphor.com.

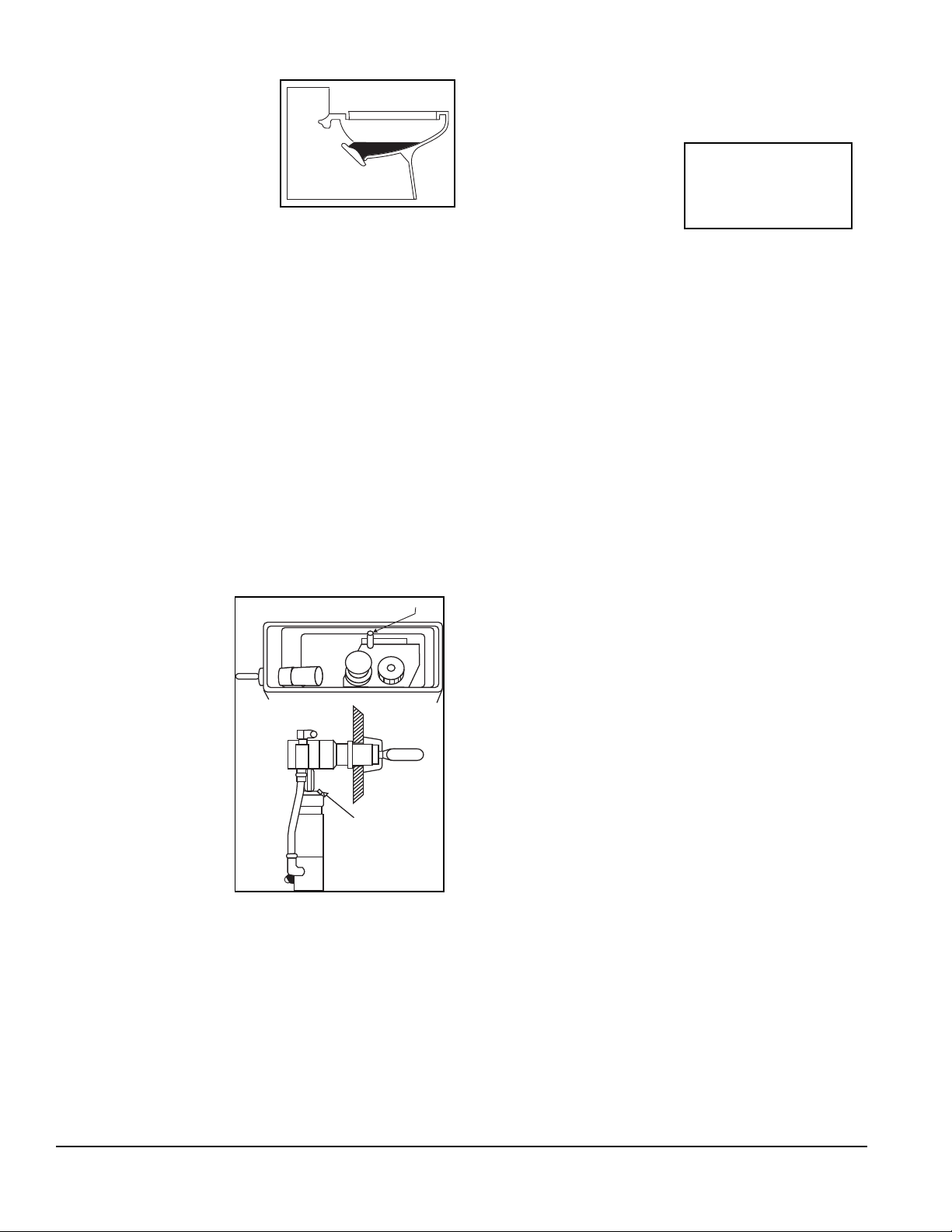

AIR SYSTEM

Filter-regulators are available

in a variety of sizes and types.

Their purpose is to remove

water, oil and other foreign

matter from the air line and to

maintain a constant pressure

at the toilet of 60-65 PSI.

The following steps must be

observed to assure moisture

will be removed from the

airline:

1.Drain air compressor receiver regularly. Most water

tends to accumulate at this point.

2.Install drip legs with condensate drains at all low

points in air piping.

3.Whenever possible, grade all airlines back to the air

receiver or drip leg assembly and drain regularly.

4.The air supply to your Microflush toilet must be taken

from the top of the main or branch air line.

AIR COMPRESSOR

Be certain compressor crankcase has proper oil levels.

Locate the compressor in a clean, dry, well ventilated

location. Size compressor according to separate Air

Compressor Specifications Sheet.

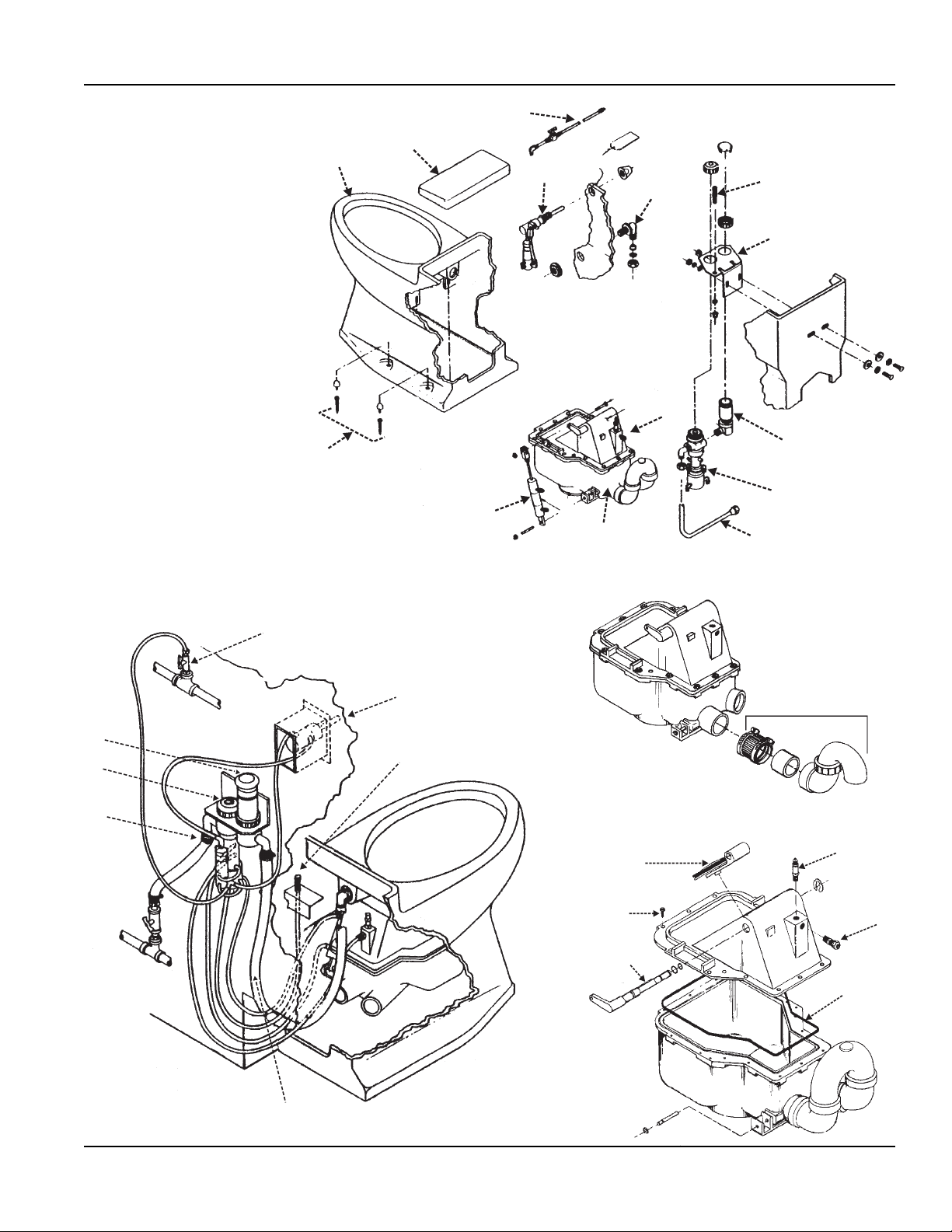

PRE-INSTALLATION

The following procedures apply to all Microflush models

unless otherwise noted. Remove your toilet from box

carefully. Integral Models - Install toilet seat and flush

handle before mounting Microflush to floor. Seat is not

included. Bolt caps and closet screws are provided.

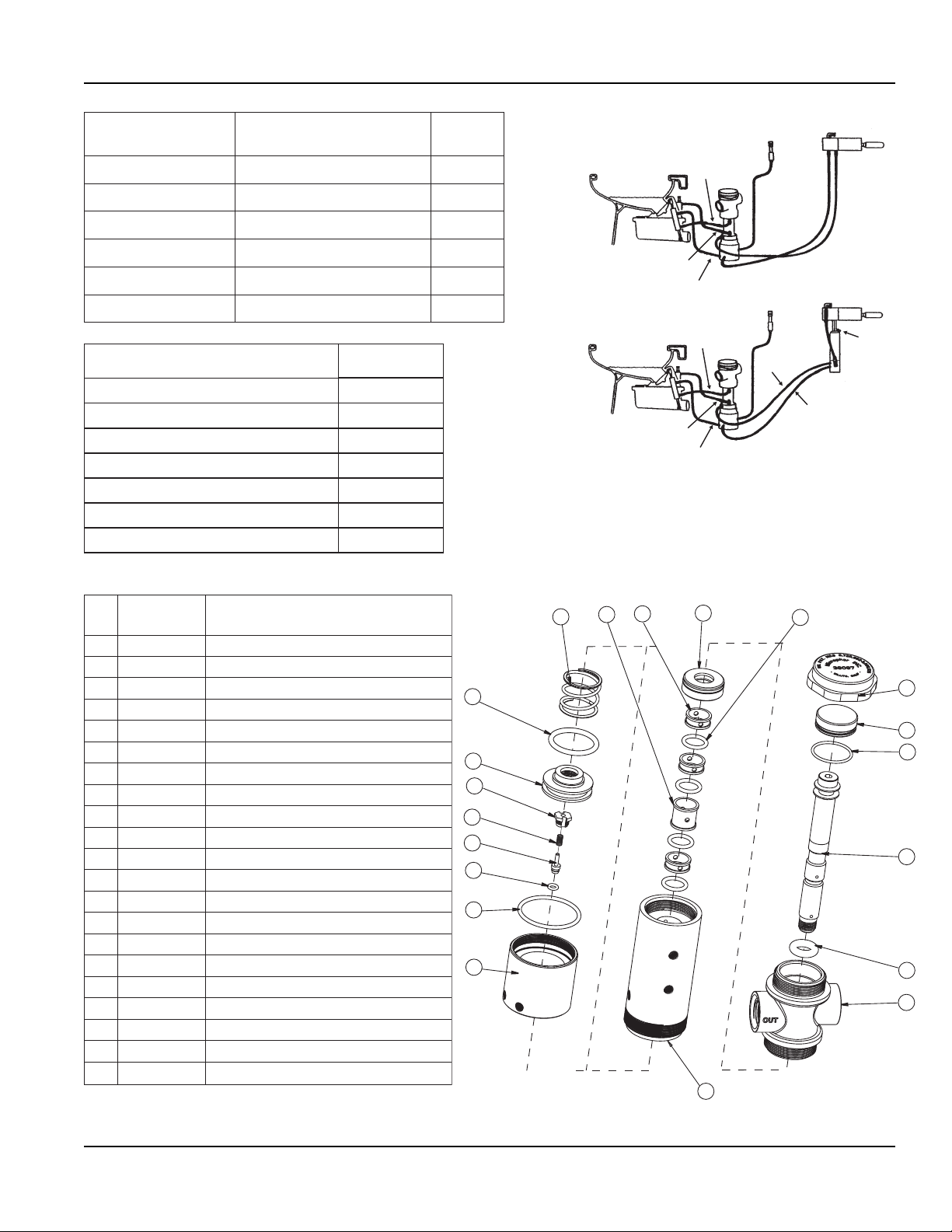

1. AIR LINES

If used in Marine applications, all piping supplied by

customer is to conform to U.S.C.G. requirements relating

to water tight decks and bulkhead (46CFR56.69)

Be sure airline from compressor is of sufficient size,

based on length of pipe run to head. We suggest 3/8" air

line up to 40', 1/2" air line up to 75', and 3/4" air line for

over 75'.

Install a filter-regulator assembly in incoming airline.

Place the filter-regulator as close as possible to the first

Microflush toilet and in an accessible location.

Set filter-regulator so that 60-65 PSI constant is avail-

able at the toilet. Install Microphor combination filter/

regulator/dryer, P/N 94036.

Assemble the Air Connecting Kit provided and connect to

incoming air line with shut-off valve between bulkhead

and toilet. For LF-210 Models, use Air Connecting Kit

P/N 93086, and for LF-219 Integral Models use Air

Connecting Kit P/N 95172. The plastic airline provided

goes from the air supply to the Flush Activator. On

integral models, the plastic air line enters the Microflush

through the back wall or up through the floor under the

unit. Make sure air is OFF at air compressor. DO NOT

CONNECT TO FLUSH ACTIVATOR YET!

2. WATER LINES

Use a 1/2" water line and install a water shut-off valve

(angle stop) between bulkhead and toilet. Water at the

toilet must be regulated at an even pressure between 20

to 50 PSI for Microflush to operate properly. Optimum

pressure is 35 PSI. DO NOT CONNECT WATER

LINE TO MICROFLUSH YET!

INSTALLATION PROCEDURES

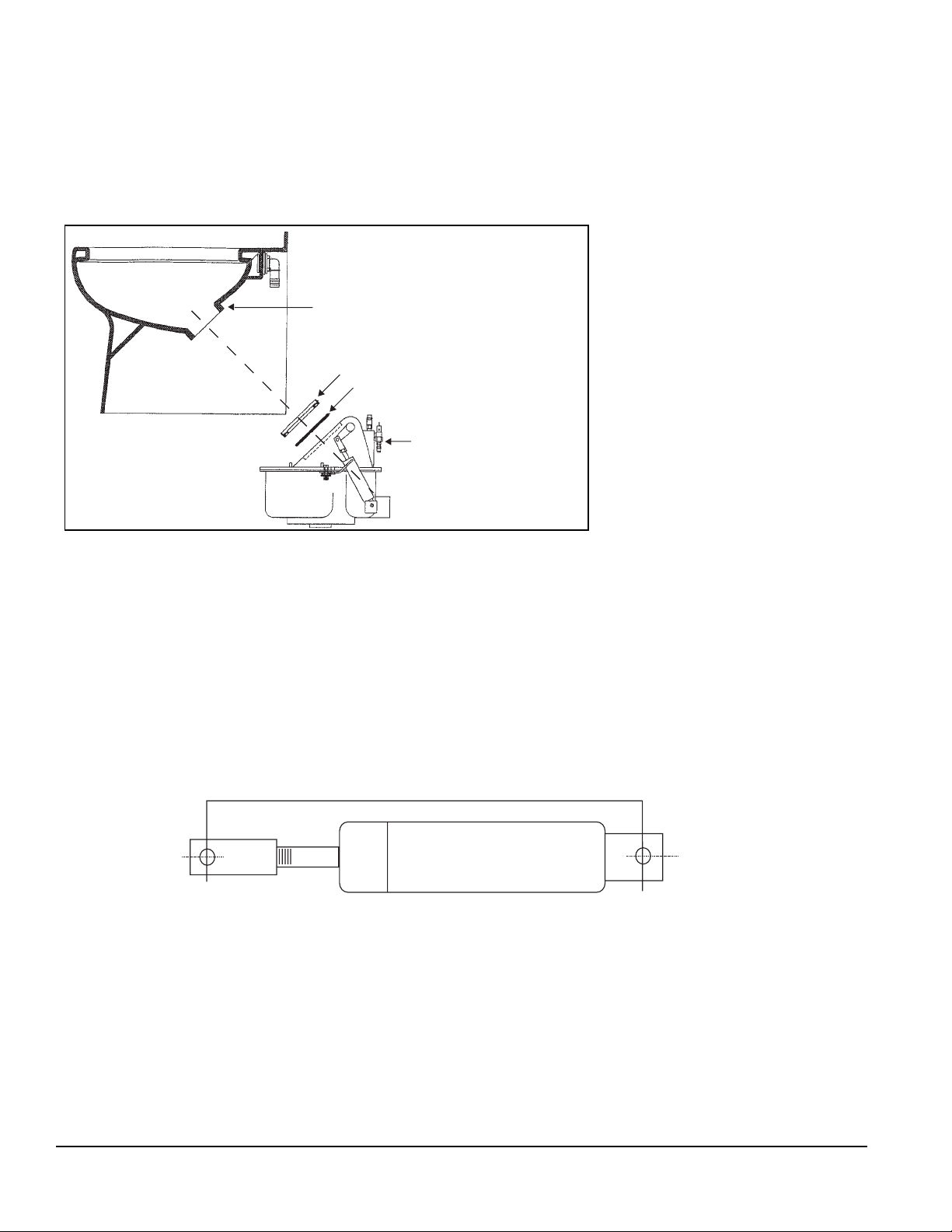

3. DRAIN CONNECTION - See Rough-In Dimensions

FOR ALL INSTALLATIONS:

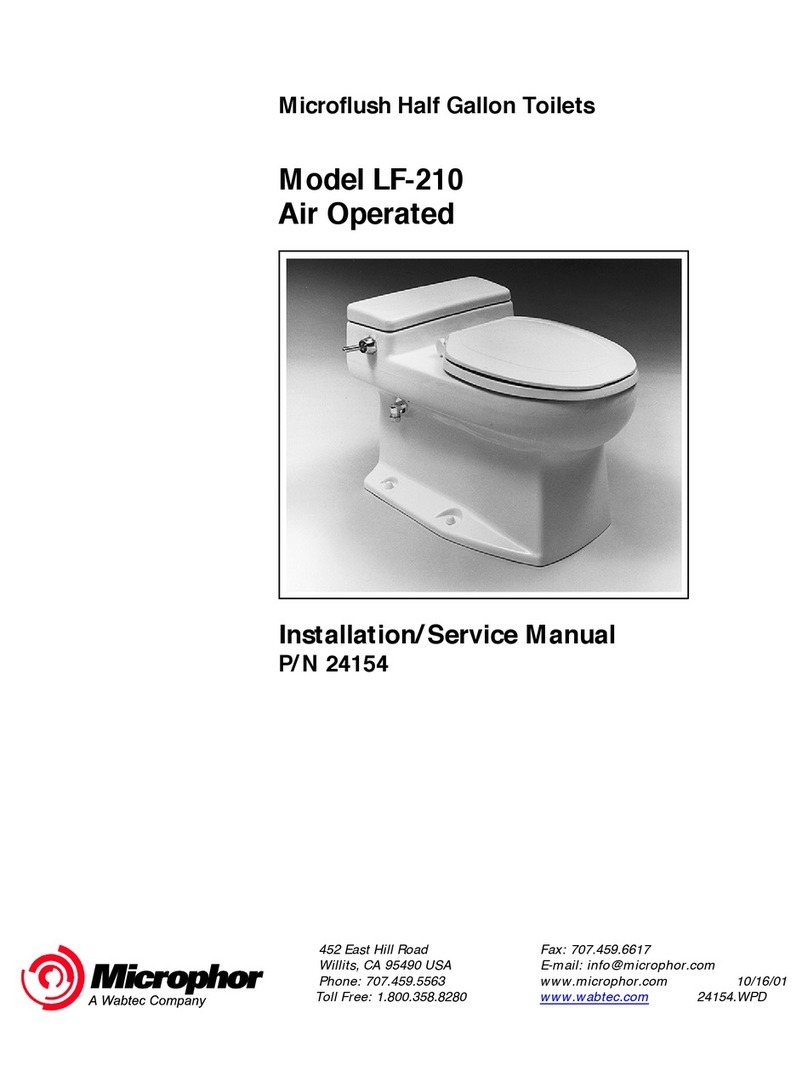

LF-210 Downward Discharge Model: Rest Microflush

on its back on a padded surface (e.g. shipping box).

Center wax ring over Hopper Flange. Turn Microflush

toilet over, lift up, and center it with the horn of the wax

ring into standard floor flange. Compress the wax ring by

applying weight to your Microflush toilet. A second

standard wax ring may be added if floor is uneven. If

Hopper Flange hits floor flange, grind it down for added

clearance, as any contact will break seal between Hopper

and Toilet Bowl and cause leaking.

Note: Discharge on toilet is 13.25 (+/- 0.5”) from

back. See rough in dimensions.

Condensate Drain

Drip Leg

Filter-Regulator

Air Connection

Slope

ile: airline