a third ti e and the control goes back to the standard screen display

Place the part of the garment/article to be marked onto the silicone pressure pad.

Pull the handle forward into the locked position, ensuring the garment is firmly clamped between the heat plate and pressure pad. (Make sure that your

hands are away from the heated platen when using the heat press).

The timer display will now start a countdown.

After completion of the above the buzzer will sound when the pre-set time has elapsed and t.End (timer end) will be displayed, the handle

should then be lifted back to it full extent.

Before operating the machine at the start of each day carry out a sealing procedure without any garment or transfers this will remove any

moisture from the pad.

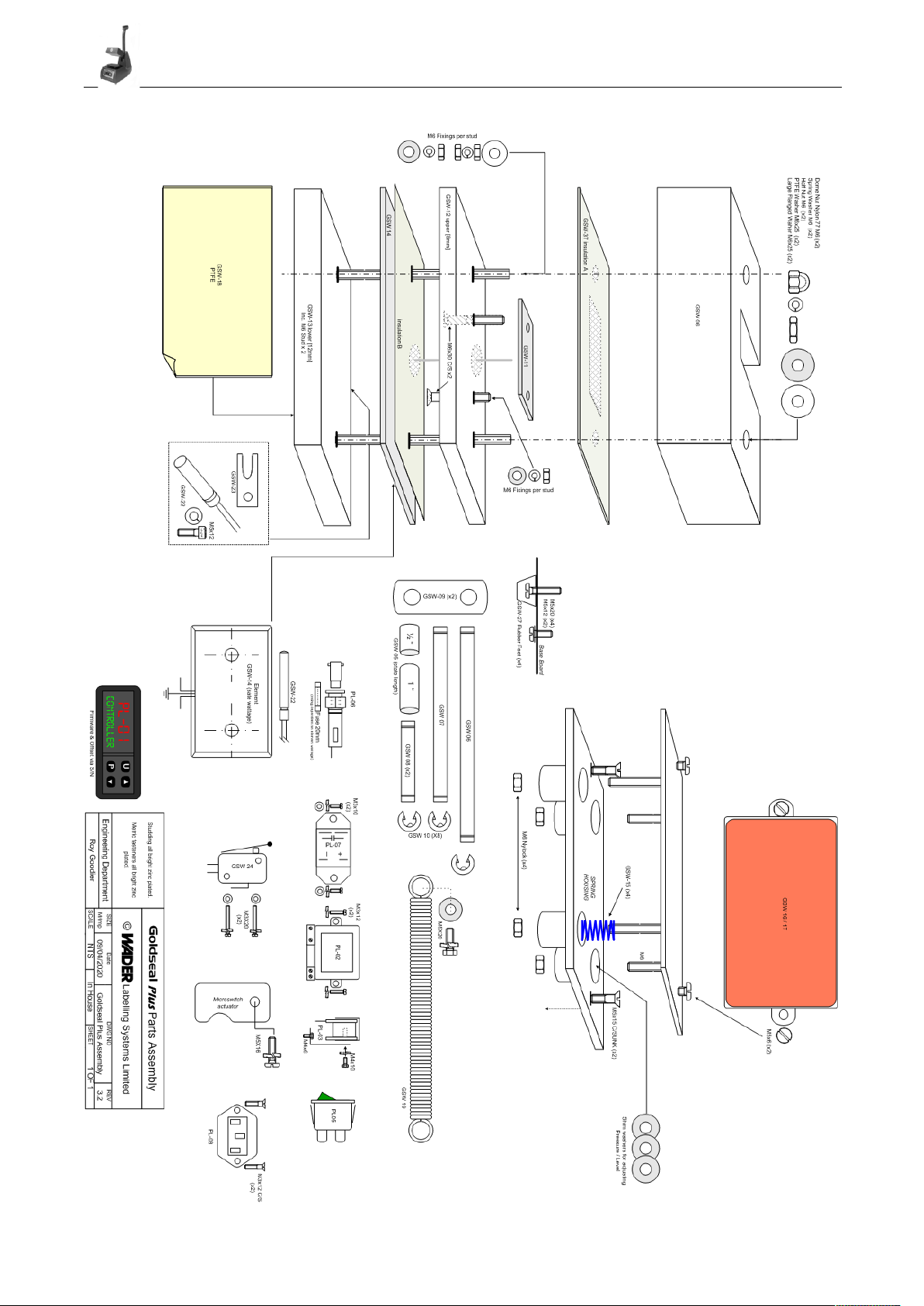

ressure ad Assembly

The silicone pressure pad and assembly should be maintained and kept in good condition at all times.

A worn silicone pressure pad will effect the quality of transfer marking / fusing and should be replaced when showing signs of wear. (See parts list).

After a long duration of time it may be found that there is a loss of pressure through the pressure pad assembly, this can be rectified by replacing the pressure springs

located under the pressure plate.

Never allow the heat plate to rest on the silicone pressure pad when the press is not in use.

TFE Heat late Cover

A PTFE cover is fitted to the heat plate, which allows the surface to be wiped clean should it become marked.

New PTFE covers may be fitted to the heat plate when ARM (not hot) and has been cleaned to remove residue of the old PTFE.

Design Change

With a policy of constant improvement and/or modifications to meet changing conditions, the right is reserved to change the design and/or specifications at any time

without prior notification, therefore no guarantee can be given as to the accuracy of the information contained in this instruction book.

Guarantee

This press is guaranteed to be free from defects in materials and workmanship ** for a period of 12 months from the proven date of delivery or installation.

hould, in our opinion, any part of this press be defective in materials or workmanship it will be replaced or repaired free of charge (excluding any travelling costs /

carriage costs which will be charged at our discretion) provided that the press has been installed and operated in the correct manner and not subjected to misuse.

A charge will be made for any costs incurred if a reported fault on the press is found to be due to incorrect installation, operation and/or incorrect materials being

used, as it is the responsibility of the press user to ensure the suitability of the materials operating through the press.

** Exclusions - Pressure Pad GSW-16, PTFE GSW-18

Application details for Wader roducts

Your press should have the following settings: -

Temperature: - 204 °C (application dependent)

Pressure: - 20 PSI

Time Dwell: - 8-10 seconds

The above is only a basic guideline you may need to change settings for special materials. To alter the settings see page 3.

e recommend that THERMAL materials / clothing are not used on this heat press.

It is also recommended not to apply heat seal labels to existing garment labels.

Contact Sales For Special Material Settings.

Specifications

upply Voltage 230 / 240 Volt AC. 500watt (8x6 - 700 Watt)., Microprocessor PID Temperature/Timer Control Unit.

Allowances should be ade when P.A.T. testing.

240v Mica plate heating element including 40" leads and integral earth.

Cast Aluminium construction. Dry weight of 14 kg (8x6 15 kg).

Maintenance

Lubricate toggle linkage at regular intervals with light machine oil, this will ensure a long life of the toggle assembly and also a smooth operation.

Keep top PTFE cover in good condition.

Ensure that the silicone pad is in good condition.

Never clean the machine with abrasive cleaners or solvents that may damage the product.

Check all fasteners are tightened to the correct torque. This is particularly important with the heat plate fixing as these are under extreme heat and strain.

This machine is designed for application of heat-seal transfers, tape, badges and patches only.

Please ensure the manufacturers operating instructions are adhered to.

A colour copy of this manual plus all the ader machinery can be downloaded from the website www.wader.co.uk

e recommend a qualified engineer inspect the machine at six Monthly intervals