SAFETY INSTRUCTIONS

Carefully read instruction manual with particular reference to the following

instr.uctions:-

a)

Slinging,

ie,

safe lifting limits for slings, etc.

b)

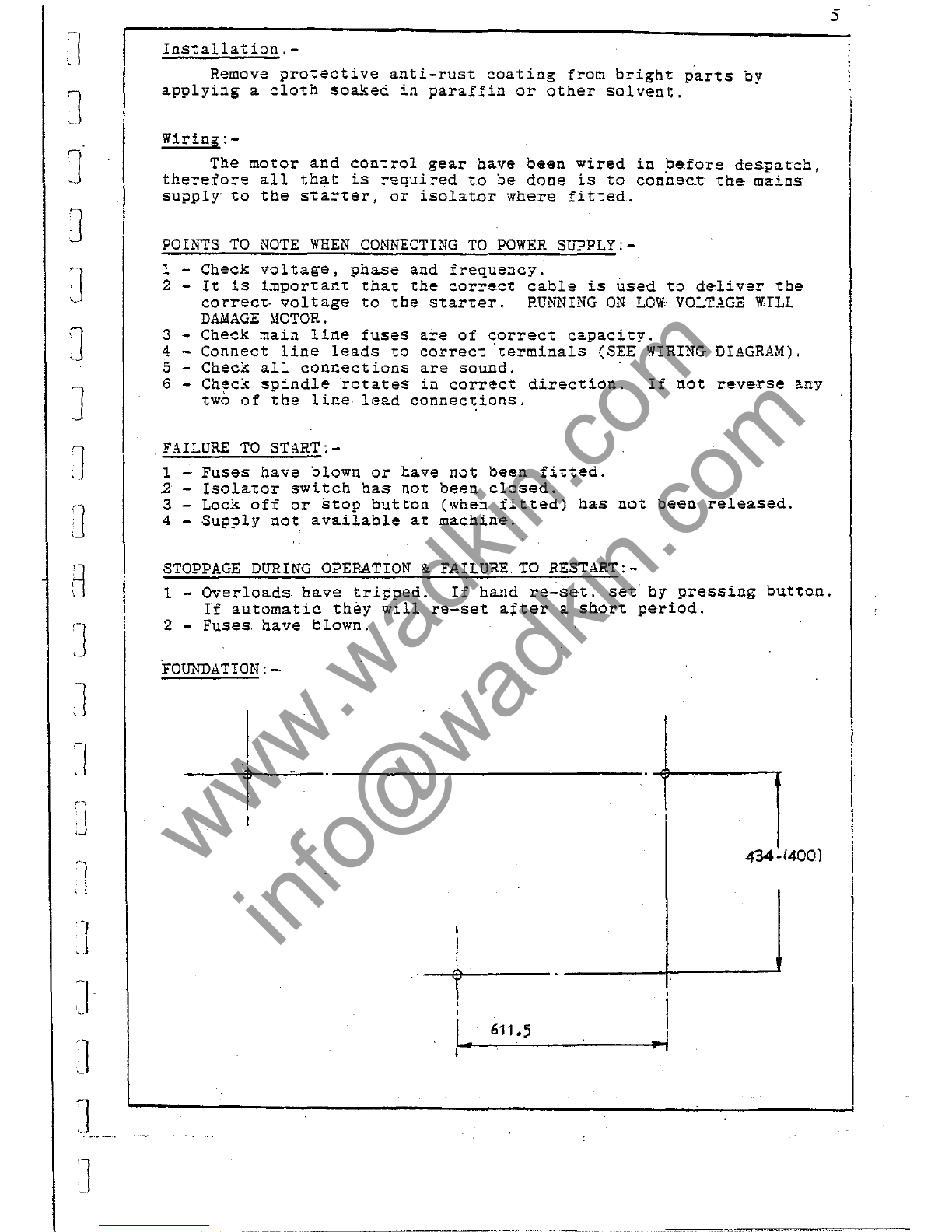

Installation and foundation,

ie,

safe working area of machine,bolt positions,

etc.

c)

Wiring details, ie, connection

of

machine to mains supply, fuse details, etc.

d) Machine controls and operating instructions.

Ensure tooling

is

of

the

correct type for use with

the

machine and cutters are

securely fixed in position.

Select correct spindle speed and feed rate relevant to the tooling being used.

Set all guards correctly

and

ensure they are securely fixed

in

accordance with the

current regulations.

Use suitable jigs, fixtures and feeding devices etc., (push stick, etc.,) where

appropriate.

Referto .8S.6854, Part 1, "Safeguarding Woodworking Machines'

UK

market and

subsequent parts for specific machines for safe working practices.

During Machining

Wear suitable protective equipment, where necessary, eg, goggles, ear defenders

and dust mask.

Ensure

all

moving

parts

of

the machine are stationary before setting, cleaning

or

making any adjustments.

Report immediately

to

a person in authority any machine malfunction

or

operator

hazard. Do not attempt

to

repair the machine unless authorised

to

do

so.

Ensure machine

is

electrically isolated before any maintenance/cleaning

work

commences.

NOISE

lEVELS

This

machine,

undercertain conditions,

will

em~

noise

levels

in

excess

of

85d8(a).

Noise

levels

will

be

affected

by

the

environment

in

which

the

machine

operates

the

timber

being

machined,

tooling,

machine

setting

and

dust

extraction.

Further

information

available

from

Wadkin

on

request.

As

a

manufacturer

~

is

Wadkin's

policy

to

reduce

the

noise

level

as

far

as

it

is

practicable.

In

[1

o

o

o

[l

[l

'--'

o

o

lJ

o

o

]

o

•

iJ

J