Wadkin CK90 User manual

Other Wadkin Saw manuals

Wadkin

Wadkin AGS400 User manual

Wadkin

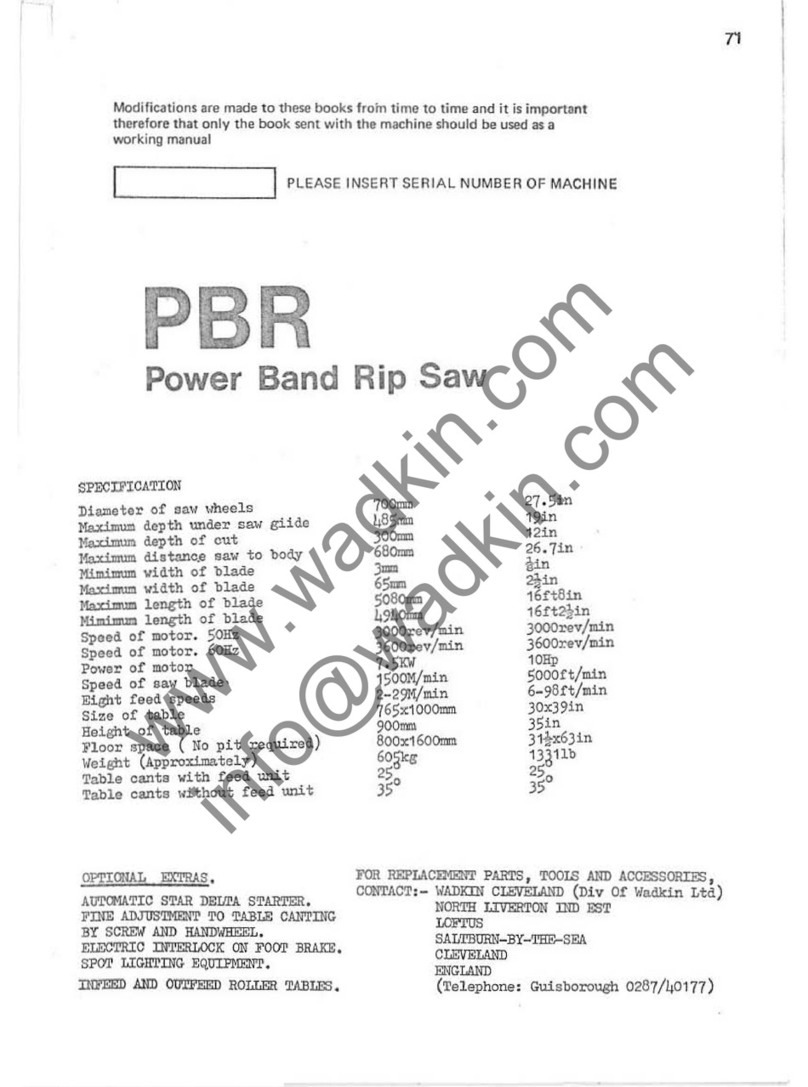

Wadkin PBR User manual

Wadkin

Wadkin BSW User manual

Wadkin

Wadkin 24BSW User manual

Wadkin

Wadkin CK90 User manual

Wadkin

Wadkin Ultracare DR User manual

Wadkin

Wadkin PP Series User manual

Wadkin

Wadkin BSW 26 inch User manual

Wadkin

Wadkin BSW 20 inch User manual

Wadkin

Wadkin AGS400 User manual