WAFE Intelligent ventilation specialist | 7

Heat recovery story

Housing standards in the Western world are continually rising. It’s not only about comfort

anymore: ease of maintenance, ergonomics and low operating costs do matter, too. Above all

–we expect to live in a healthy and natural environment.

At first, we tried to solve this with better quality building materials, more efficient isolation and

airtight door and window systems. Some heat savings were achieved but it soon became ap-

parent that a sealed off indoor environment like this is far from healthy and natural. Levels of

CO2kept rising due to an accumulated exhaled stale air inducing weariness and a loss of focus.

Opening the window was the only solution. By doing so, however, we not only reversed any

previous heat saving benefits but allowed the city pollution and noise back into our homes.

Ventilation with heat recovery became the only suitable alternative.

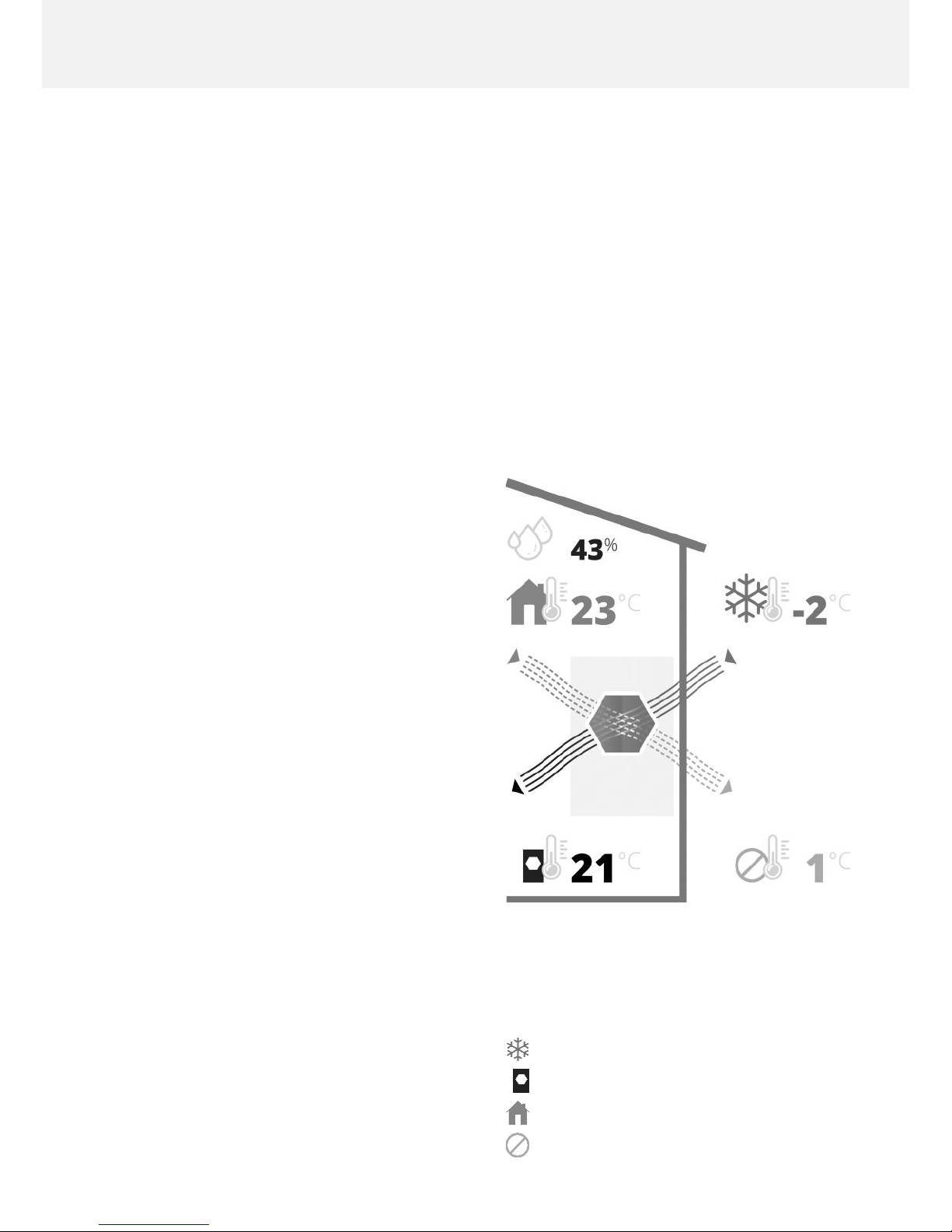

Heat recovery basics

Heat Recovery Ventilation (HRV) efficiently

uses energy of waste stale air ejected out of

the building (with high levels of CO2) to

warm up the fresh air coming from outside,

thus creating a healthier and more comfort-

able environment for all the residents. In

summer, on the contrary, the air flowing

into the building is pleasantly cooled.

In addition to filtering out dust, smog ele-

ments and various allergens, superior

forms of ventilation systems —like

WAFE 350—recover not only heat but hu-

midity, too. Devices like these —called

Energy Recovery Ventilation (ERV) units—

save us money on heating costs and, more

importantly, create healthy and balanced

home environment.

Energy recovery ventilation is the

new standard in the construction of

modern houses, apartments and

commercial properties.