EN-CIRCO-5-MA-0701-11217300 5

3.1 Installation Preparations

●The entire layout of flow and return pipes should be

clear before mounting the CIRCO 5 solar circulation unit

(125 mm centres)!

In this context please also observe the operation instruc-

tions "Commissioning the System"

●If the solar system is installed for heating or if vacuum

tubes are used you must pay attention to the technical

documentation “Heat Protection”.

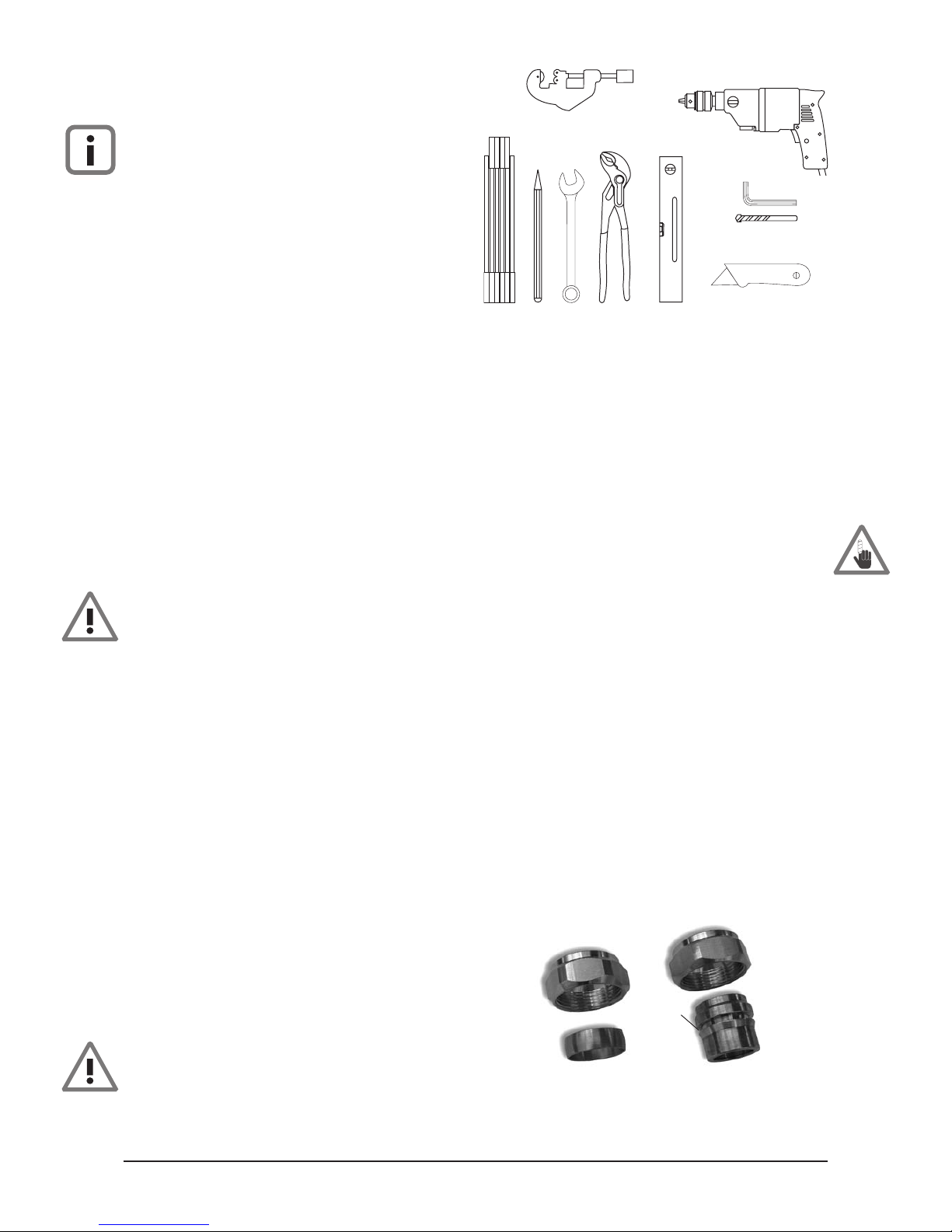

●These tools are required for the installation of the

CIRCO 5 solar circulation unit: Power drill, masonry bits,

pipe wrench, stilton etc. (figure 5).

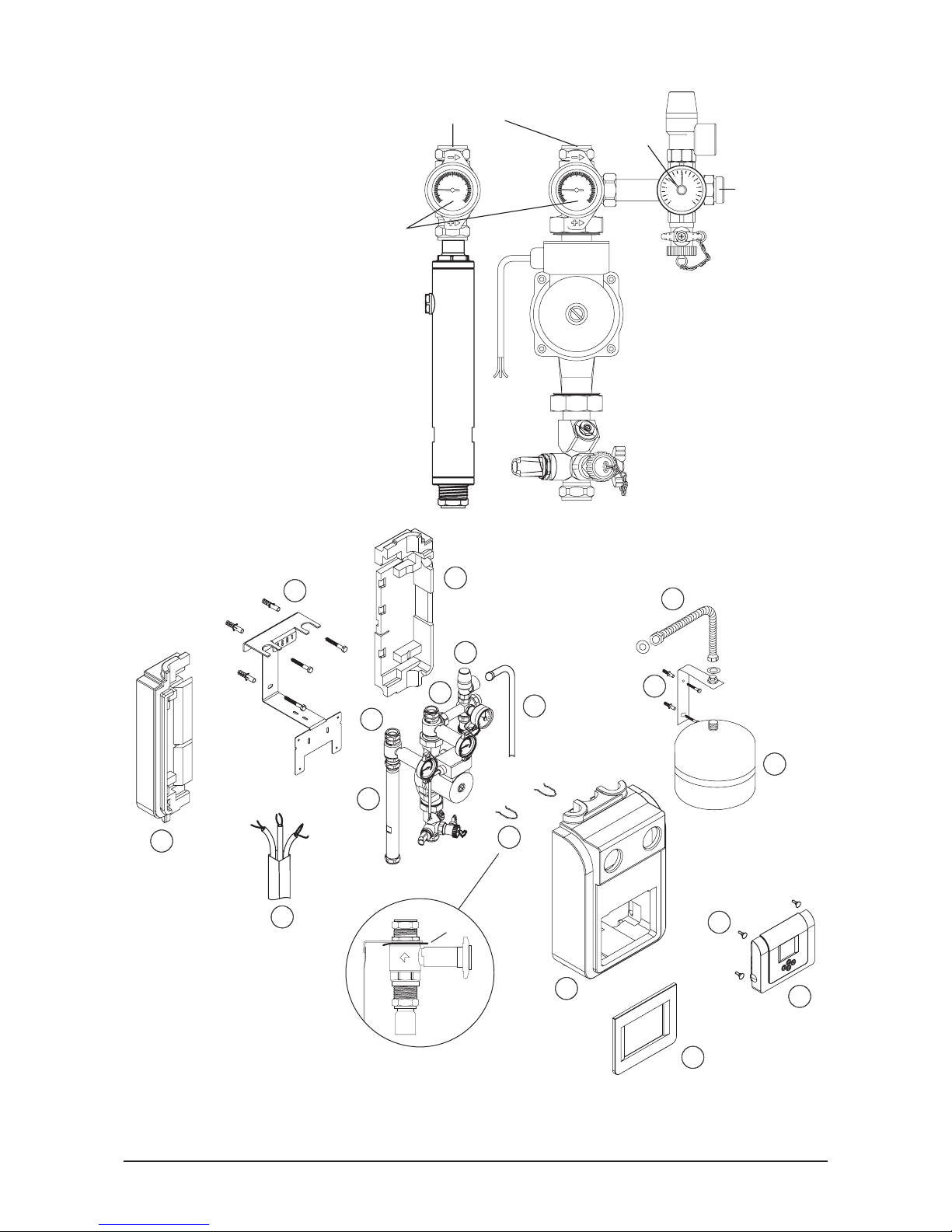

3.2 Wall Mounting

●Use spirit level to place the wall mounting bracket (1),

see figure 4, into the correct position, mark the three

holes, drill and fix with plugs and screws supplied.

●Place the two pieces of assembly (2+6) into the correct

holders of the wall mounting bracket and affix with the

two spring clips (3).

●Place the two halves of the back insulation (4) with the

recesses over the wall mounting bracket and push to-

gether.

●Connect the safety group (5) with the included ¾" gas-

ket to the free exit of the return unit (6) using an open

wrench SW30.

Make sure of proper clamping during the tightening of

the compression fittings to prevent damage or loosen-

ing of other parts of the assembly.

●Use the included wall anchors and screws to connect

wall-mount (7) for the expansion vessel (8) to the right of

the safety group. Observe length of the ¾" corrugated

tube (9). There are special wall mounting kits for 35 litre

and 50 litre vessels.

●Connect the flexible hose with the expansion vessel and

the pump station using supplied ¾ “ gaskets. It is recom-

mended to fit in a special cap check valve between flexi-

ble hose and vessel.

●Connect exhaust pipe (10) to the safety unit and put

empty container in place to collect any spills from the

pipe.

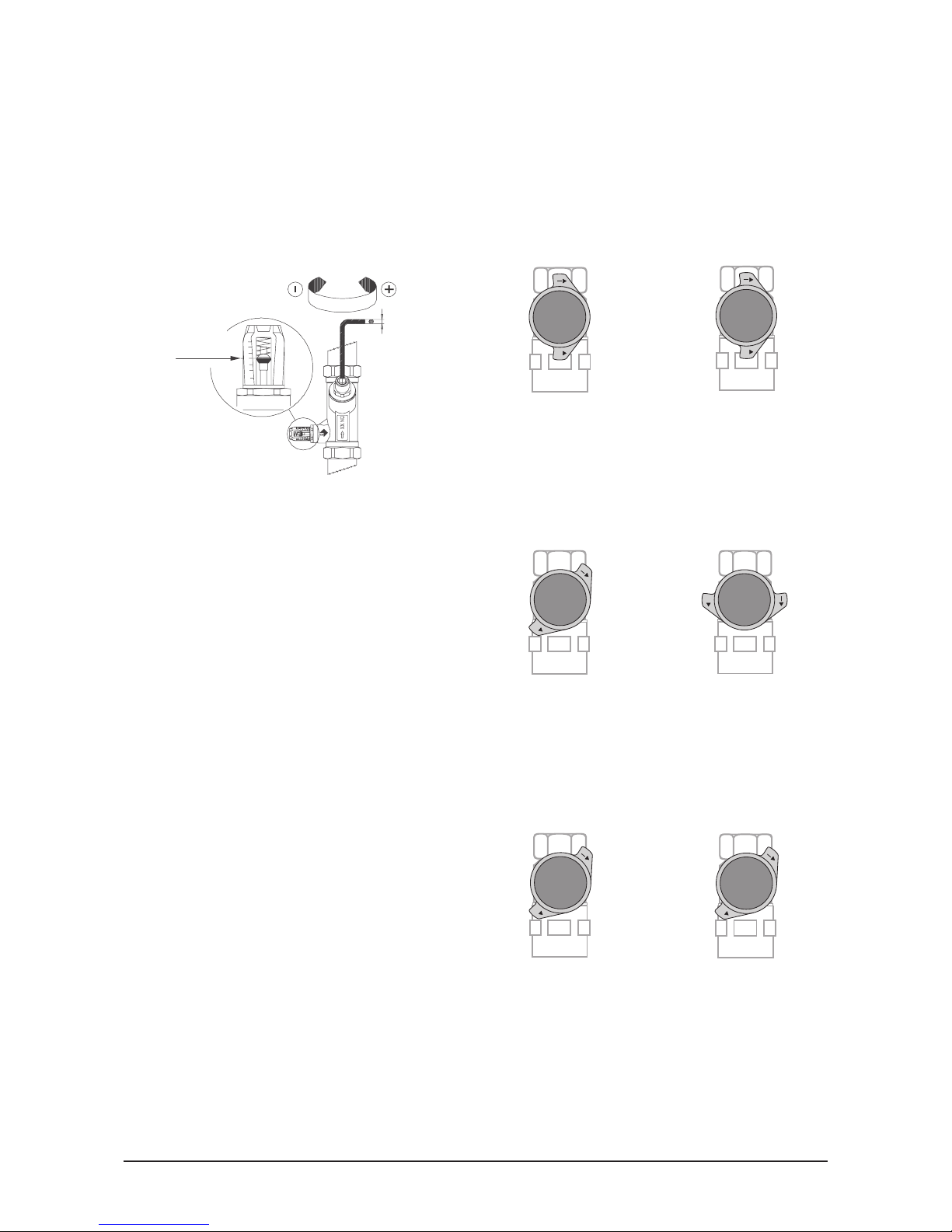

●The connections to the solar circuit (11) (distance of

pipes see figure 3) are made by compression fittings 18

or 22 mm (figure 6) .

Cut, burr pipes and push into fittings as far as possible,

then tighten nuts. Using the 18 mm compression fitting a

cracking sound will be heard, which is a sign of proper

tightening. Continue until fully tight.

Do not solder 18 mm compression fitting.

Here too, special care must be taken to ensure proper

clamping to prevent damage or loosening of other parts

of the assembly.

●Rinse solar pump station and solar circuit and check for

leaks. For this procedure a filler valve is fitted to the

safety unit (5) and the flow meter below the pump.

●Install electrical wiring, switching and sensor circuits

(12). Fix cables with cable ties to the prepared sections

(notches and long holes) to the wall mounting bracket

and ensure that there are no forces on the connectors of

the control unit and that there is no contact with hot pip-

ing. If required feeding holes can be enlarged with a

sharp knife.

Always disconnect mains when working with electrical

equipment!

●Remove frame (13) from the pump station in order to in-

stall the SUNGO control.

●Open SUNGO control (14) and affix with the four screws

(15) supplied to the wall mounting bracket. You will find

all required installation and operating instructions in the

manuals for SUNGO S, SUNGO SL and SUNGO SXL.

●Put front insulation (16) into place.

compression fitting

for 22 mm

compression fitting

for 18 mm

snapping

point

Figure 5 Tools required for the installation of the CIRCO 5 solar circula-

tion unit

Figure 6 Compression fittings 18 and 22mm