Solar thermal / Collectors EN-USA_SECUSOL_TI-MA-111013-1121R800 1

TECHNICAL INFORMATION / INSTALLATION INSTRUCTIONS

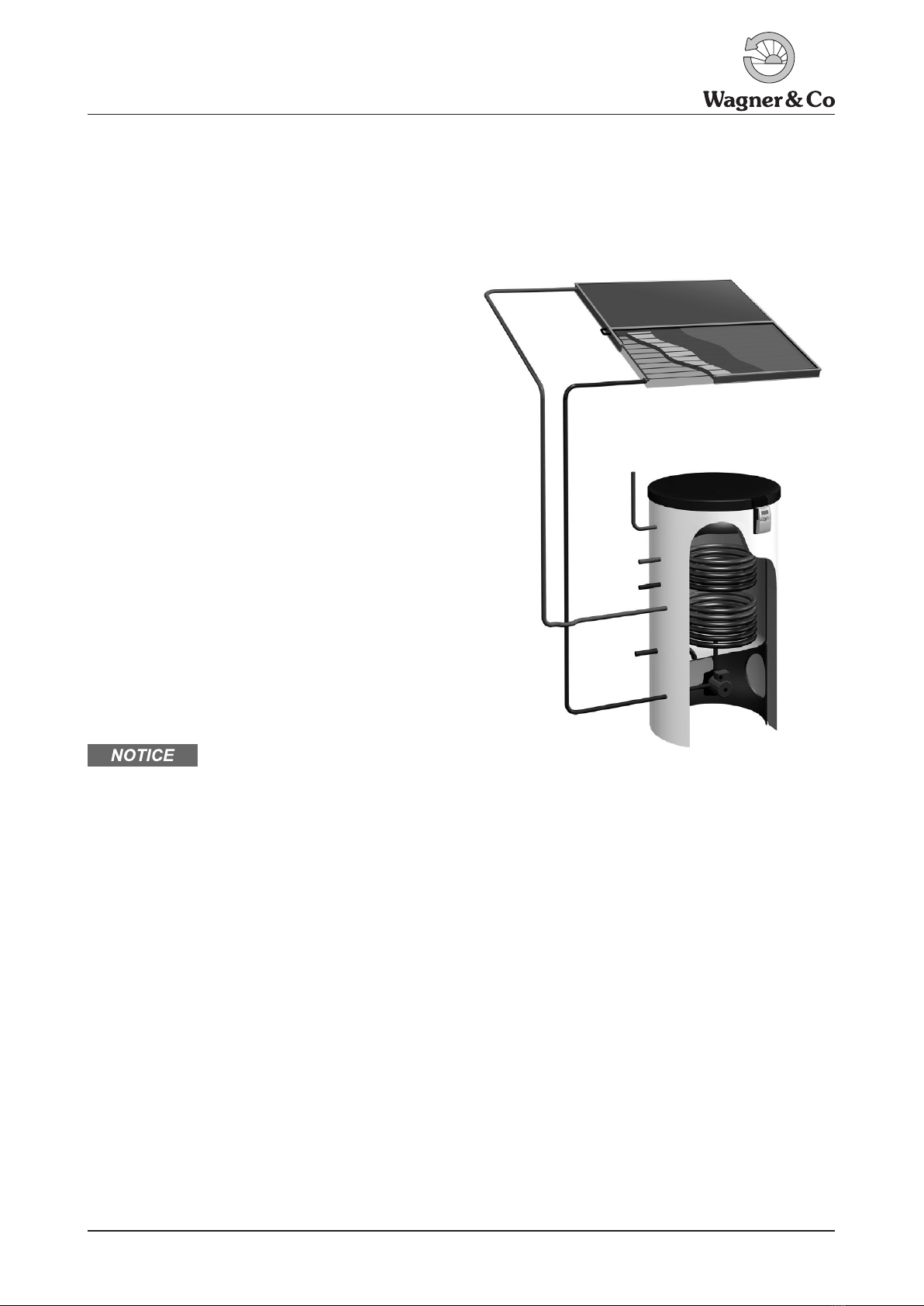

Compact Solar Drainback System SECUSOL

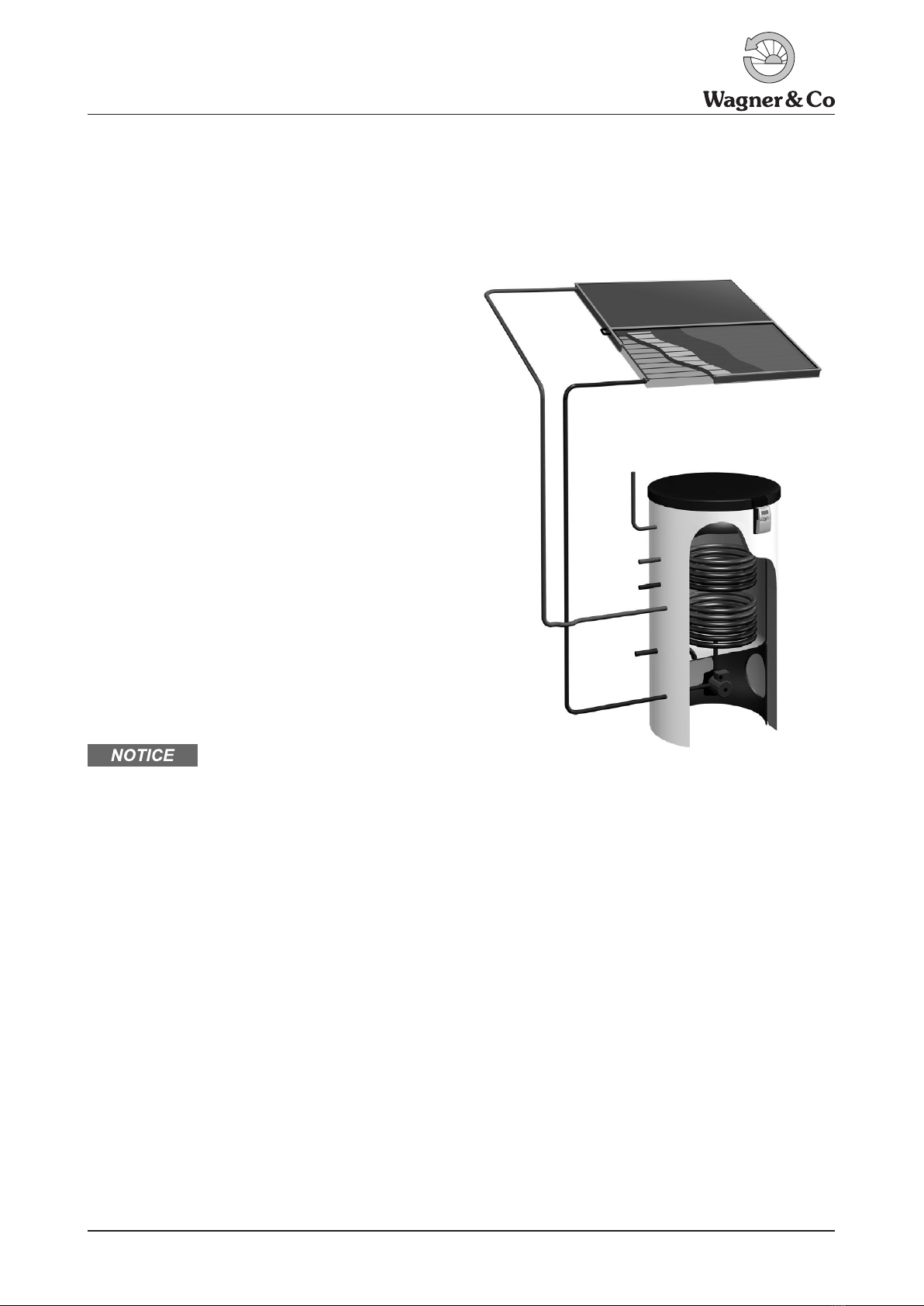

Figure 1 SECUSOL-System

Operational Safety and Low Maintenance

When the pump is not operating, there is no solar fluid

present in the collectors. Therefore the solar fluid and any

downstream system components are protected against

detrimental effects from overheat. Unwanted gravitational

forces as well as operational faults due to air pockets are

eliminated. A service intensive membrane expansion ves-

sel, air bleeds and check valves are not required. Operati-

on with common anti-freeze solar fluid prevents potential

frost damage.

High Yield Thanks To:

●High transparency anti reflection glass

●Single surface absorber with selective vacuum coating

●Solid insulation of individual components

Simplified Installation and Start-Up

●Pre-assembled unit of storage tank, solar controller and

solar circulator, including all safety components.

●Flexible copper double-pipe with only 12mm cross

section, for simple and time saving piping (supplied by

Wagner & Co).

●No expansion vessel and hence no setting of pre-pres-

sure required.

●Very simple flushing and filling

●No venting of solar circuit required

Installation, startup and maintenance of the SECUSOL

solar thermal installation are intended to be carried out

by trained professionals only, e.g. in line with SRCC Stan-

dard OG-300 installation guidelines or NABCEP certifica-

tion. They have to be licensed, must be familiar with the

IAPMO Uniform Solar Energy Code and must conform

to applicable federal, state and local regulations, codes,

standards and meet all legal requirements related to the

installation of solar hot water systems as well as plumbing,

electrical wiring and roof works.

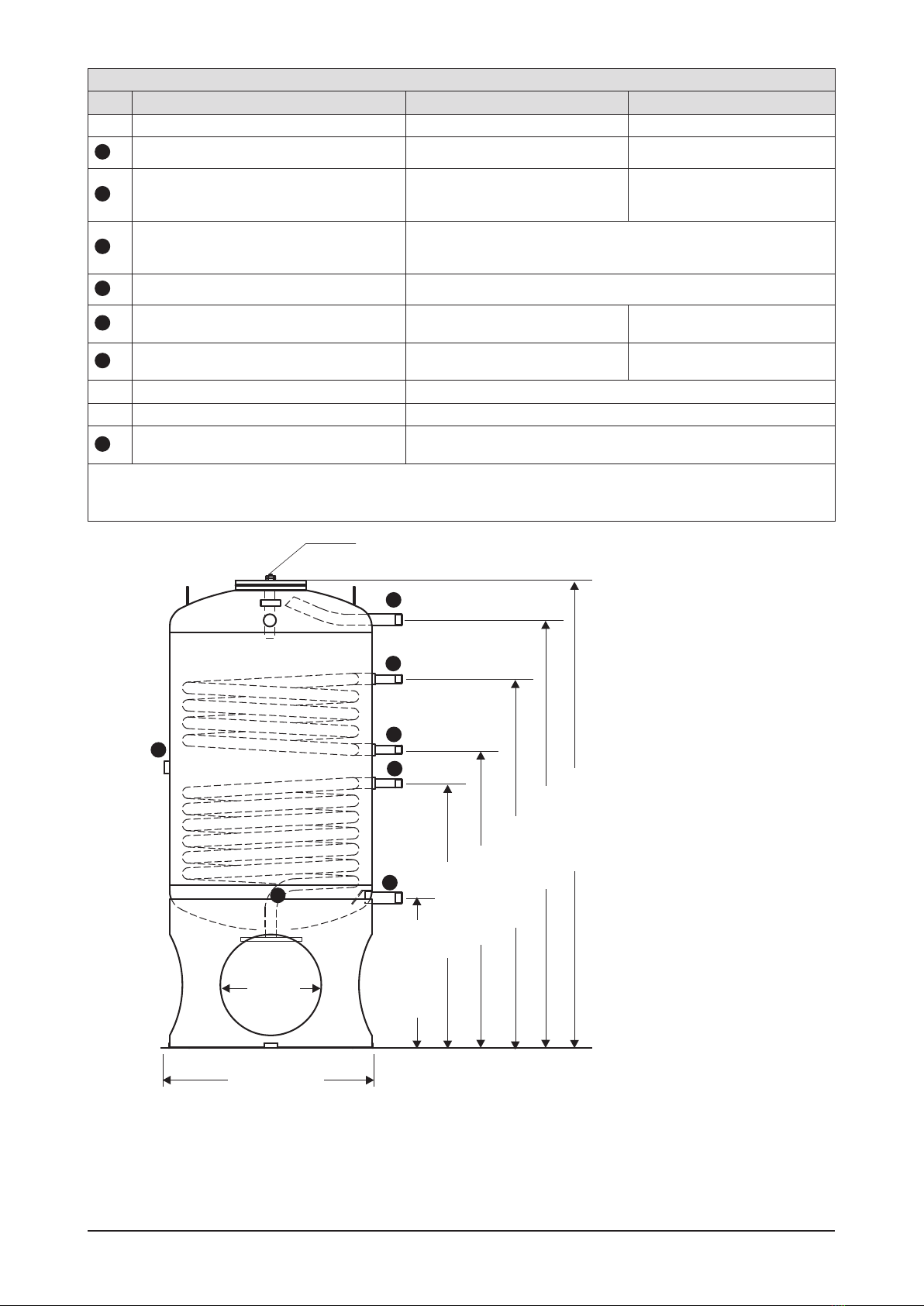

Content

1 Technical Information 2

1.1 Technical Data 2

1.2 Scope of Supply 8

1.3 Accessories 14

2 General Safety Notes 16

2.1 Symbols 16

2.2 Standards and Codes 16

2.3 Qualification of the Installer 17

2.4 Intended Use and Application 17

2.5 Pre Installation Notes 18

2.6 Function of the SECUSOL system 18

3 Installation 19

3.1 Preparation 19

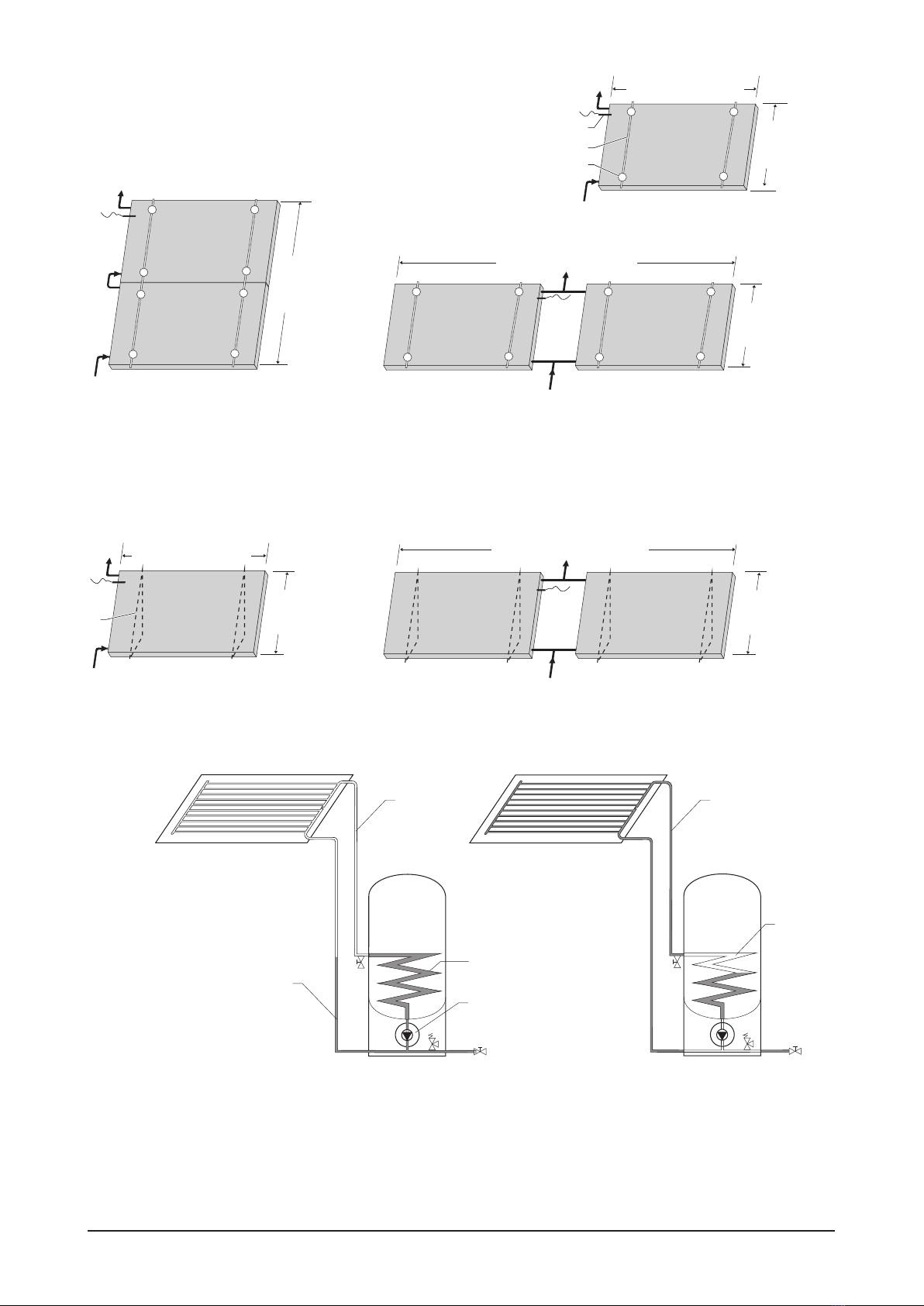

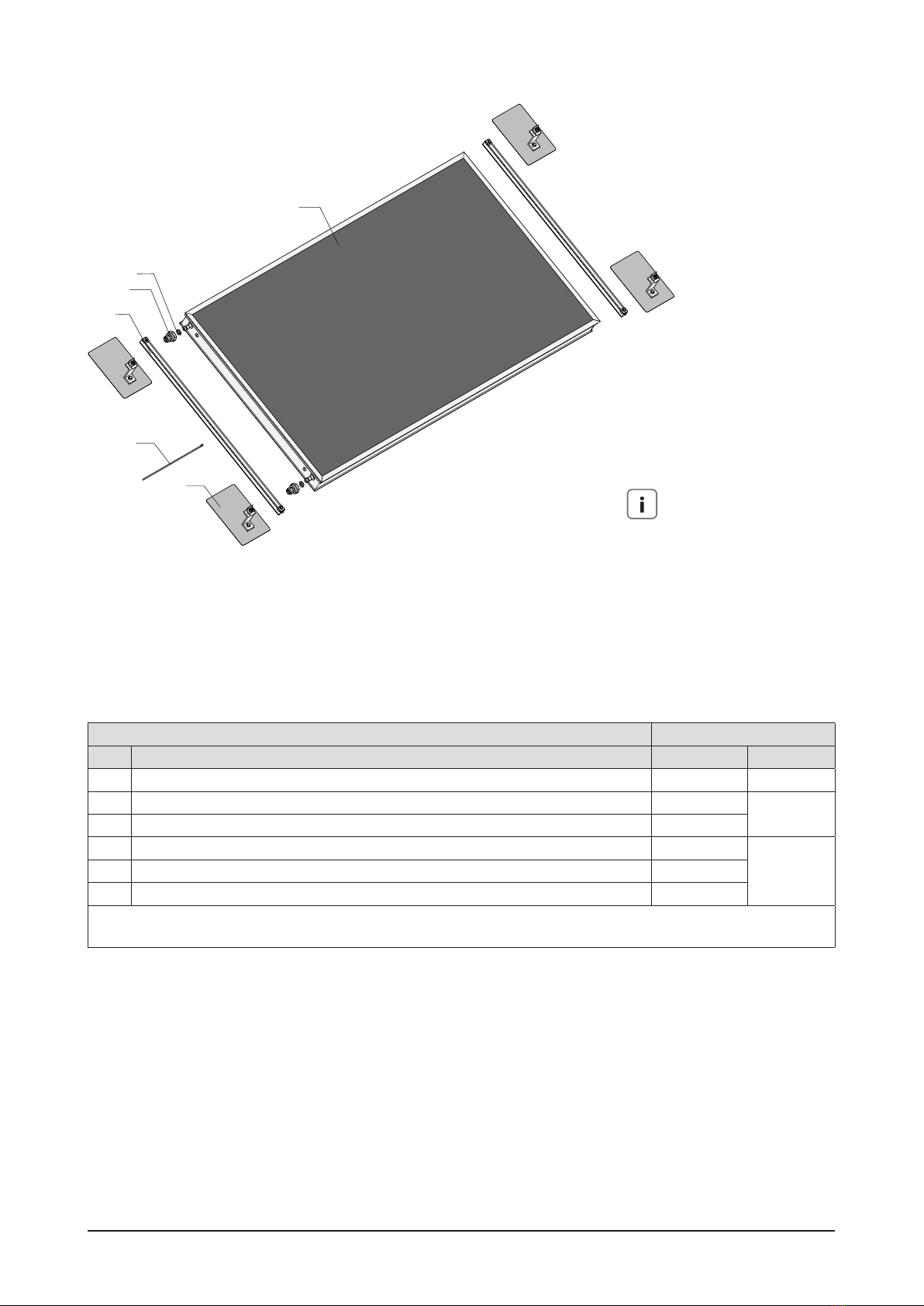

3.2 On-Roof Installation 20

3.3 Free Standing Installation 24

3.4 General Notes about Storage Installation 29

3.5 Setting up the Storage Tank 29

3.6 Connection to Domestic Water Supply 29

3.7 Laying the Solar Circuit 31

3.8 Installing the Controller 35

4 Startup 36

4.1 DHW System 36

4.2 Backup Heating Circuit 36

4.3 Solar Circuit 36

5 Connecting the storage Insulation 38

6 Advice for the User 38

7 Maintenance and Care 39

8 Troubleshooting 40