5

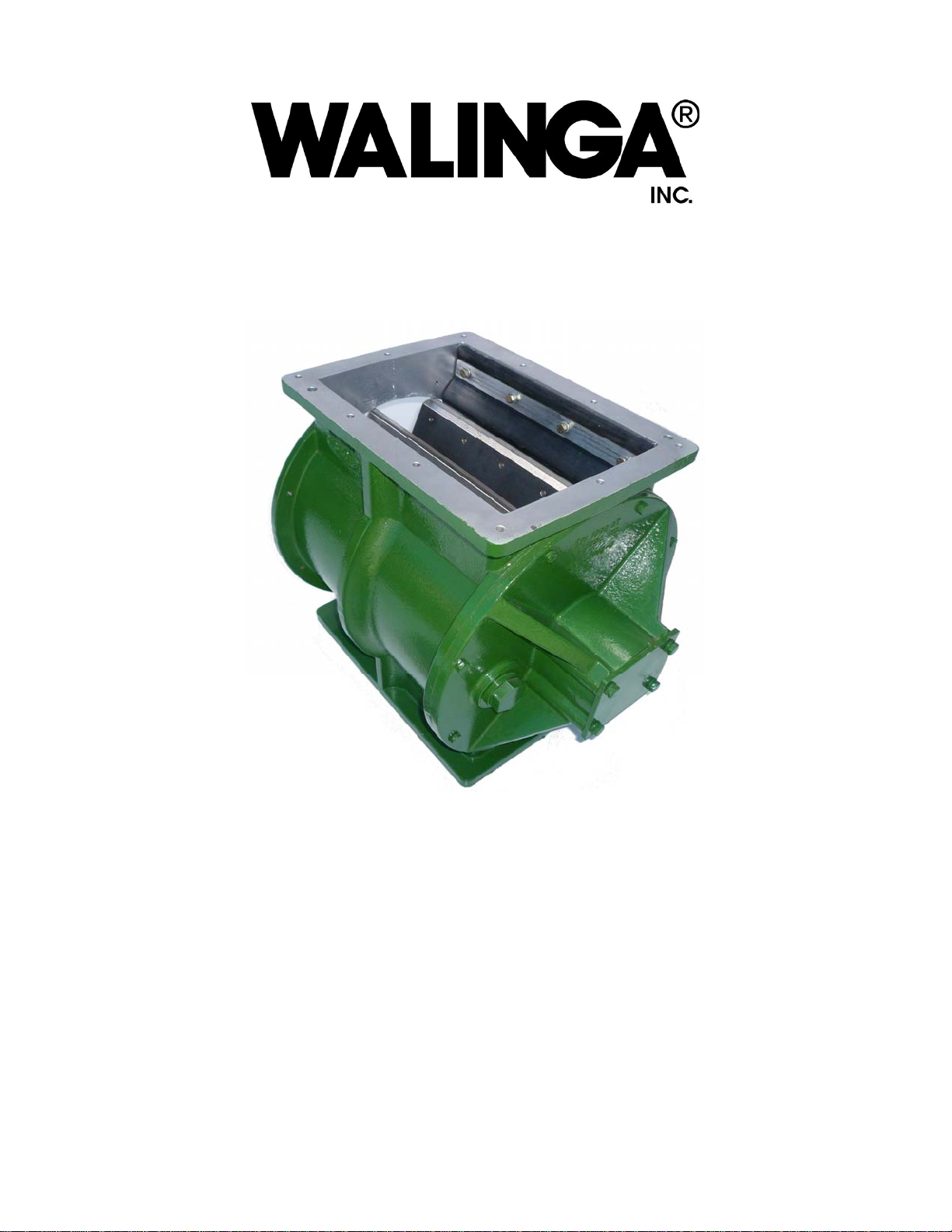

1 INTRODUCTION

1.1 Operating Principles

Walinga Rotary Airlocks use a multi-bladed

rotor to move material. The rotor picks up

material in the pocket between each 2 blades

as it rotates past the top feed inlet area. It

then transfers the feed through the airlock

casing to either a ‘blow-through’ or ‘drop-

through’ chamber at the bottom.The airlock

often features low clearance wear tips on

each rotor. These are both adjustable &

replaceable and usually made of high-wear

material. Other tip materials and designs may

be used for specialized applications. The tips

deliver a high degree of sealing between the

material supply chamber and the outlet

area.During operation the multi-bladed rotor

fills with material at the inlet (top) side of the

unit. This material moves with the rotating

blades and drops through to either the' blow-

through' or 'drop-through' chamber below.

‘Blow- Through’ designs use a pressurized

air-stream entering the inlet port to move

material through the chamber to a pneumatic

transfer line connected to the outlet port.

‘Drop- Through’ designs drop the product out

of the airlock under gravity through a large

rectangular discharge port under the unit.

1.2 Airlocks & Rotary Seals

The terms ‘airlock’ / ‘rotary valve’ and 'rotary

seal' are sometimes used to describe the

same item of equipment. In general an

‘airlock' provides a higher level of sealing and

is more easily adjusted than a 'rotary seal'.

Their heavy duty cast construction and high

level of sealing suit them well to commercial

applications - especially when using

pressurized delivery line.

2 KEY OPERATING GUIDELINES

2.1 Direction of Rotation

The airlock rotor MUST MOVE COUNTER -

CLOCKWISE WHEN VIEWED FROM THE

DRIVEN END.

Do not operate for extended periods in reverse

direction.

PROLONGED OPERATION IN REVERSE

DIRECTION OF ROTATION RESULTS IN HIGH

WEAR RATES IN THE CASING AND LOSS OF

PERFORMANCE.

Operating for short periods in reverse direction is

acceptable but only to assist in clearing objects

jammed between the blades and casing. Reverse

operation also increases product damage because

the flexible tip wiper is not effective when the rotor

moves in a clock-wise direction (viewed from the

driven end).

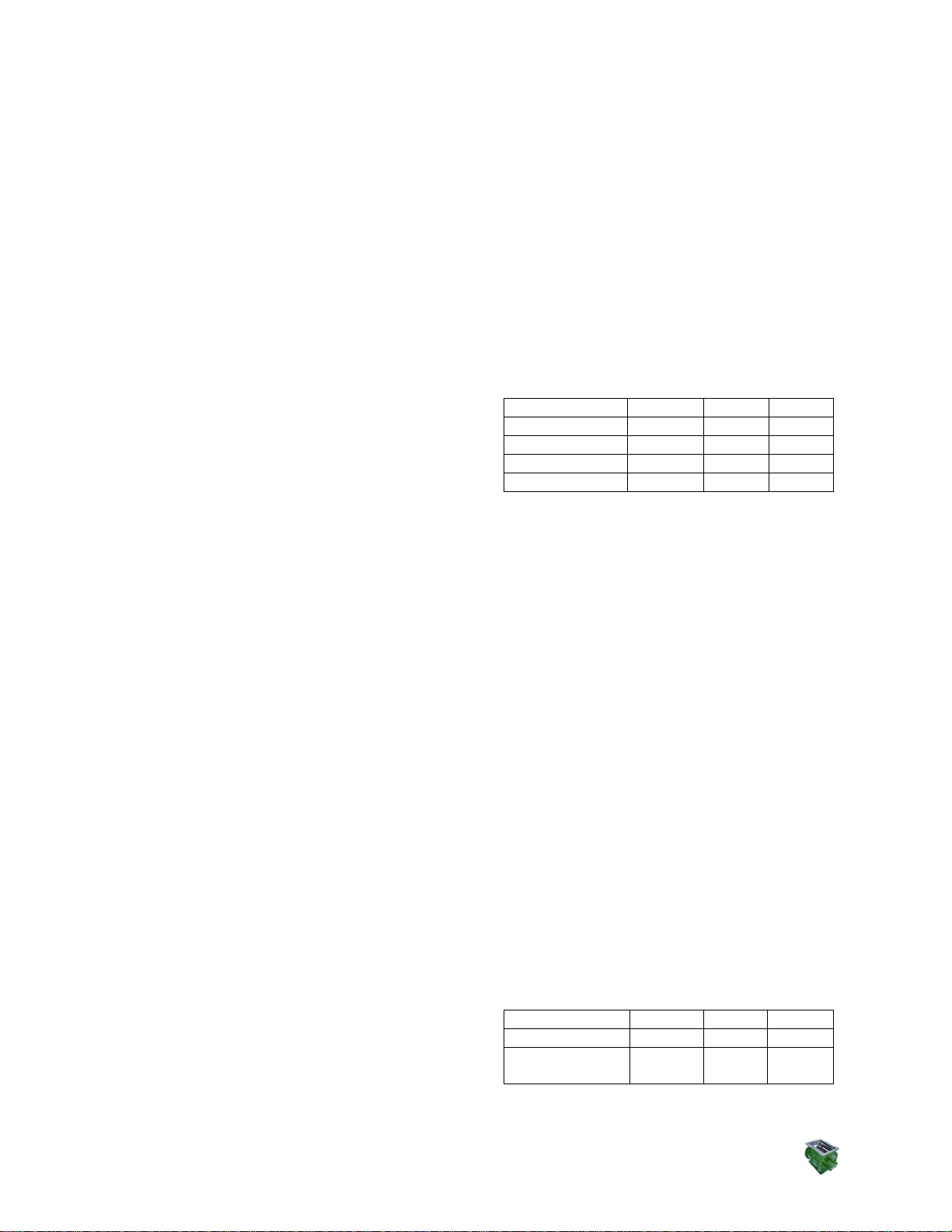

2.2 Tip Clearances

MODEL 1314 1618 2224

Maximum 0.014 0.016 .020

Minimum 0.005 0.006 .008

Preferred 0.006 0.007 .009

Max. Reset 0.009 0.010 .010

An adjustable tip fits at the outer edge of each rotor

blade. These tips provide a seal as the rotor

transfers material from the intake to the outlet area.

Efficient operation requires a close fit between the

top of each blade tip and the airlock casing.

Excessive clearance allows ‘blow-back' of air

through the airlock causing uneven flow and

reduced performance. Check and adjust airlock

blade tip clearances regularly as part of a scheduled

maintenance program. Routine maintenance of tip

clearances is especially important in materials with

high abrasion characteristics.

2.3 Rotor Clearances

Airlock rotors are not adjustable, so clearances can

not be changed. If the clearance between the rotor

and the endplate is too high, no amount of tip

adjustment will improve performance. If the

rotor/endplate clearance total is at or greater than

the total clearance in the chart below, the airlock

should be replaced.

Model 1314 1618 2224

Clearance/side 0.010 0.012 0.015

Total

Clearance 0.020 0.024 0.030