PRONAR T028ML User manual

Other PRONAR Utility Vehicle manuals

PRONAR

PRONAR T680 User manual

PRONAR

PRONAR T701HP User manual

PRONAR

PRONAR T046H User manual

PRONAR

PRONAR T285/1 User manual

PRONAR

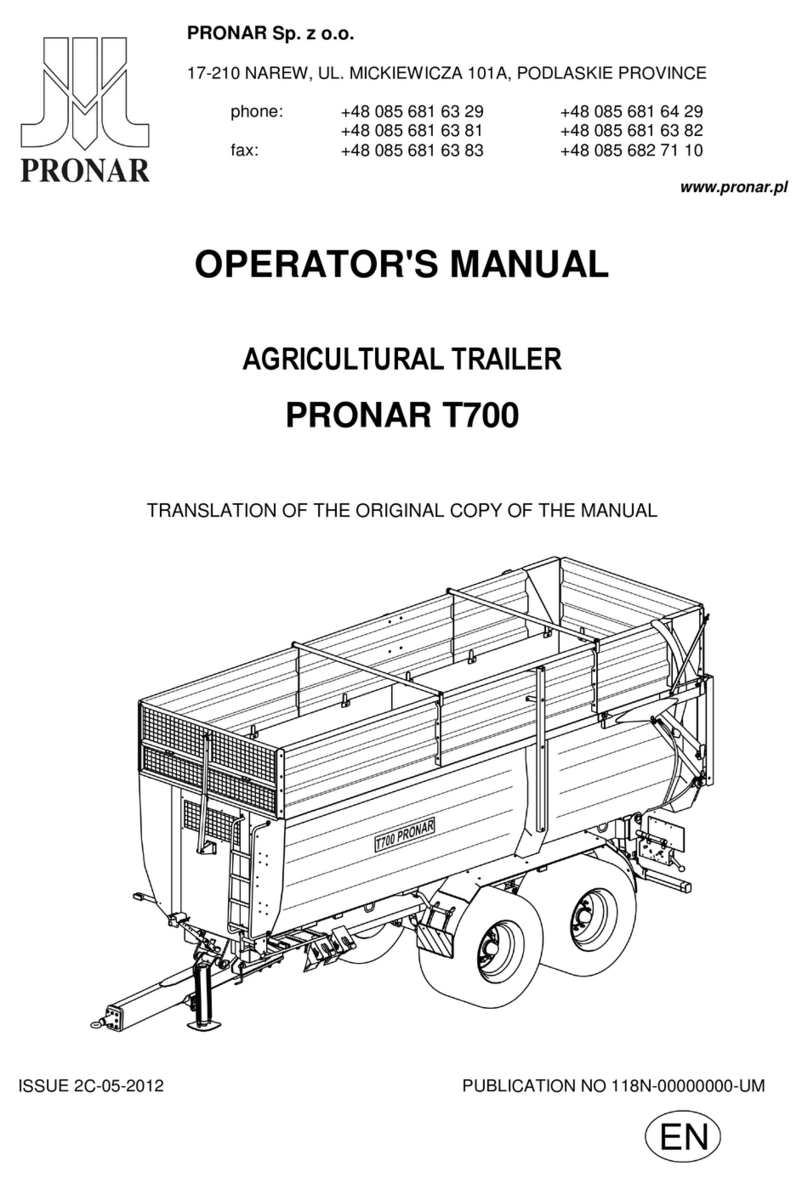

PRONAR PRONAR T700 User manual

PRONAR

PRONAR PT510 User manual

PRONAR

PRONAR T700M User manual

PRONAR

PRONAR T682/1 User manual

PRONAR

PRONAR PRONAR T400 User manual

PRONAR

PRONAR T683 User manual

PRONAR

PRONAR PT610 User manual

PRONAR

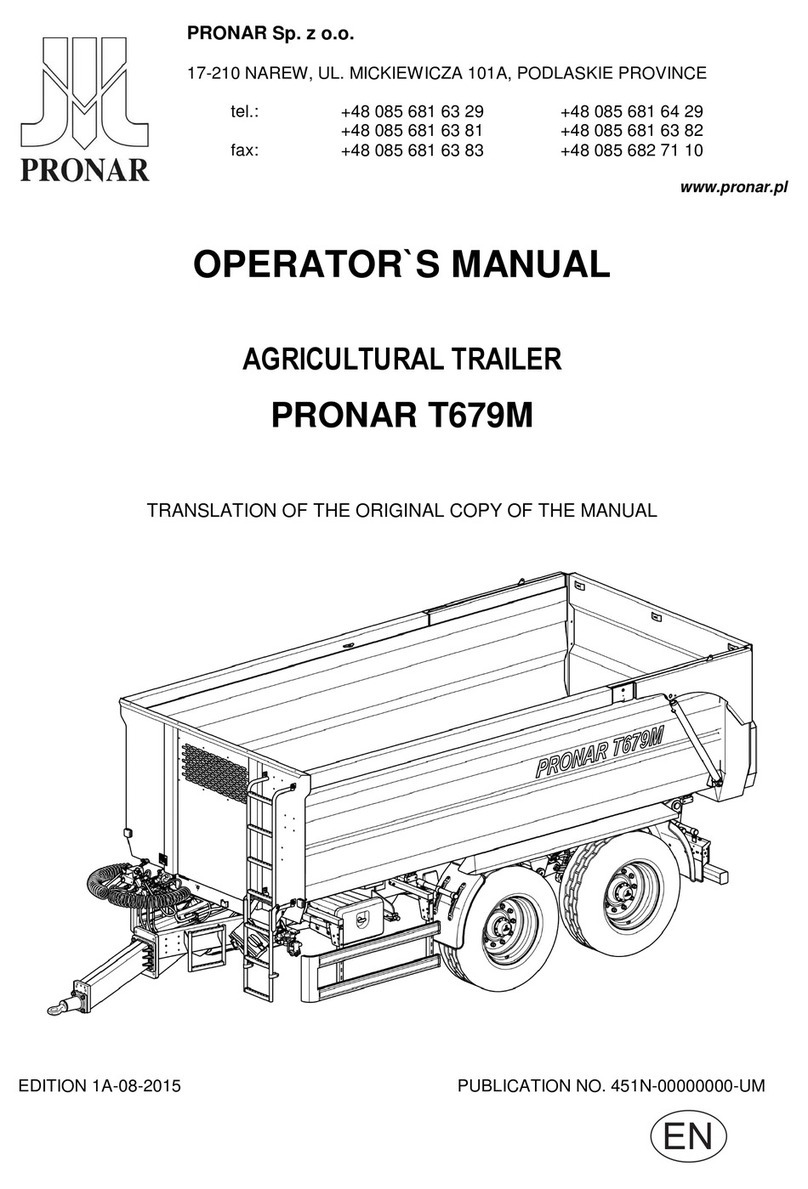

PRONAR T679M User manual

PRONAR

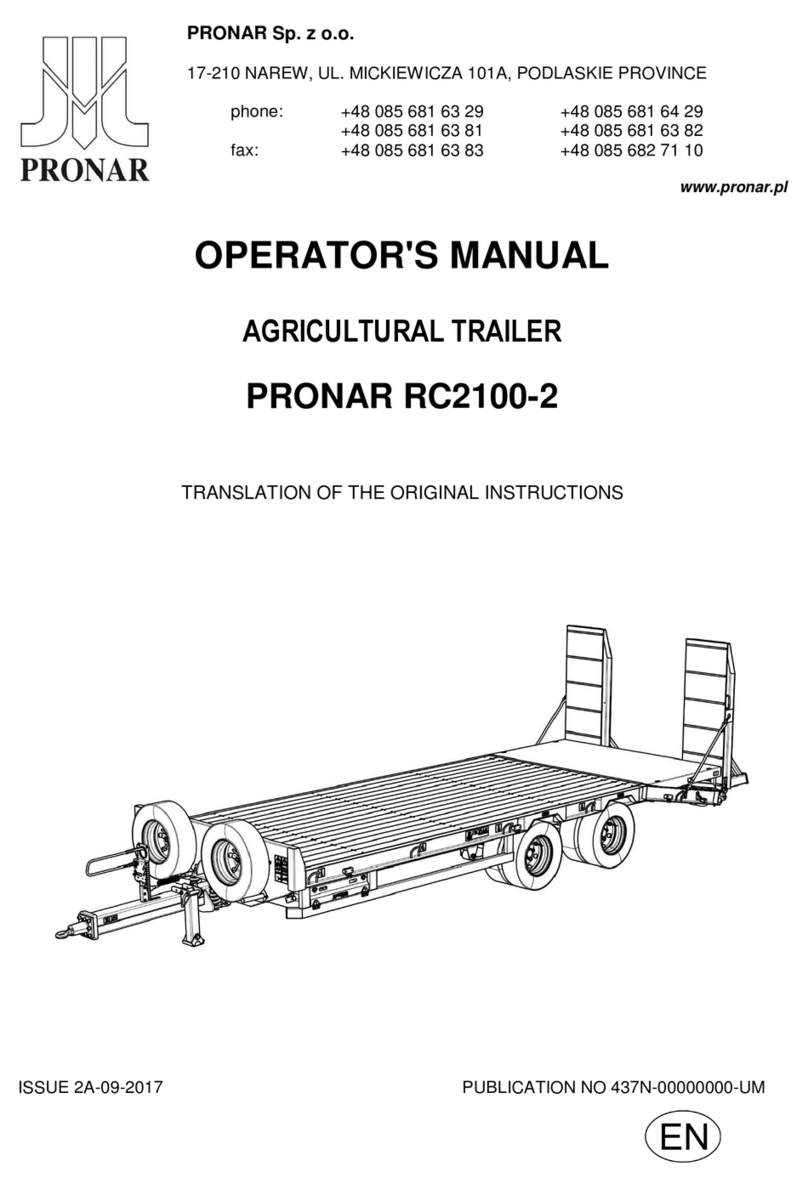

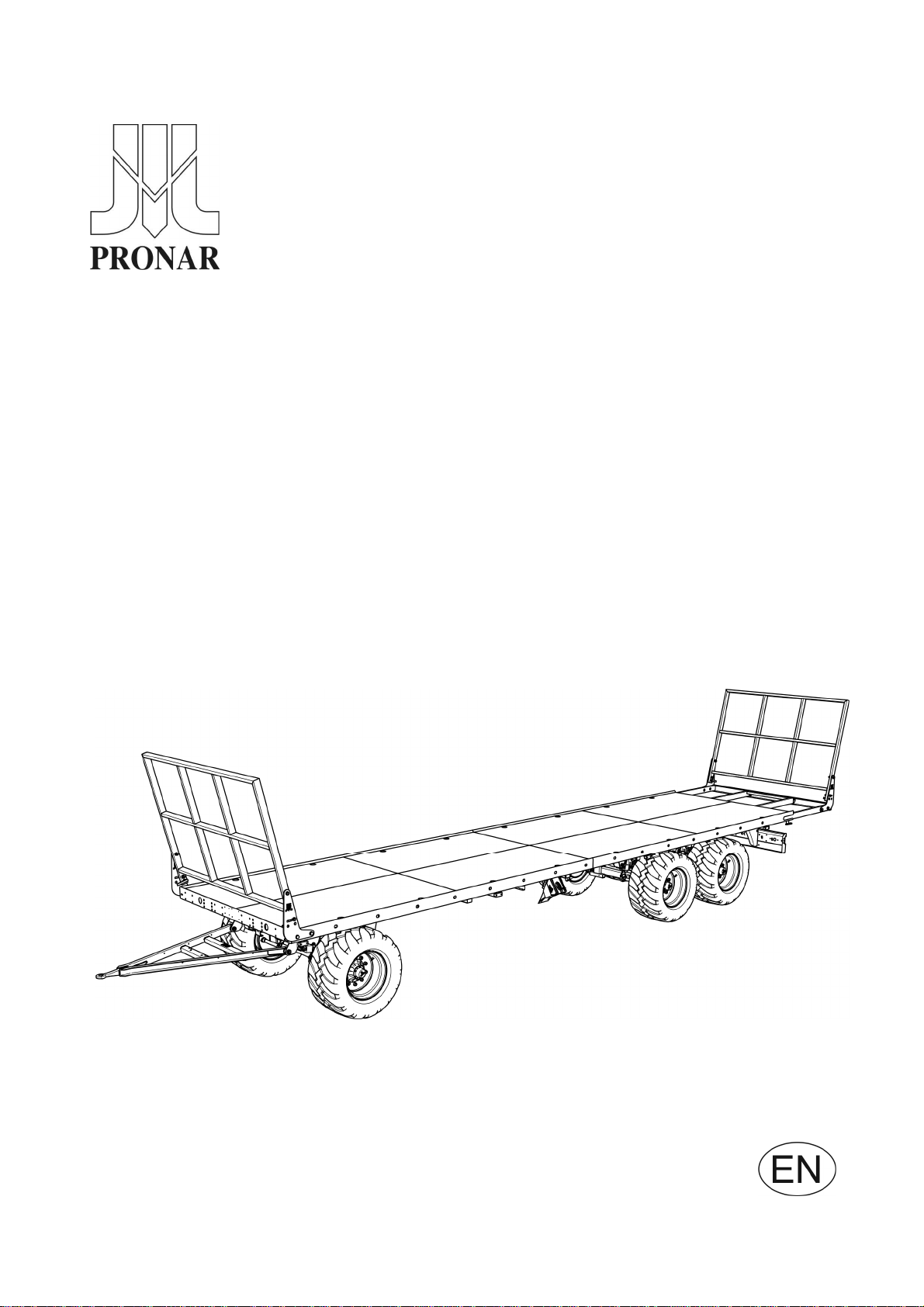

PRONAR RC2100 User manual

PRONAR

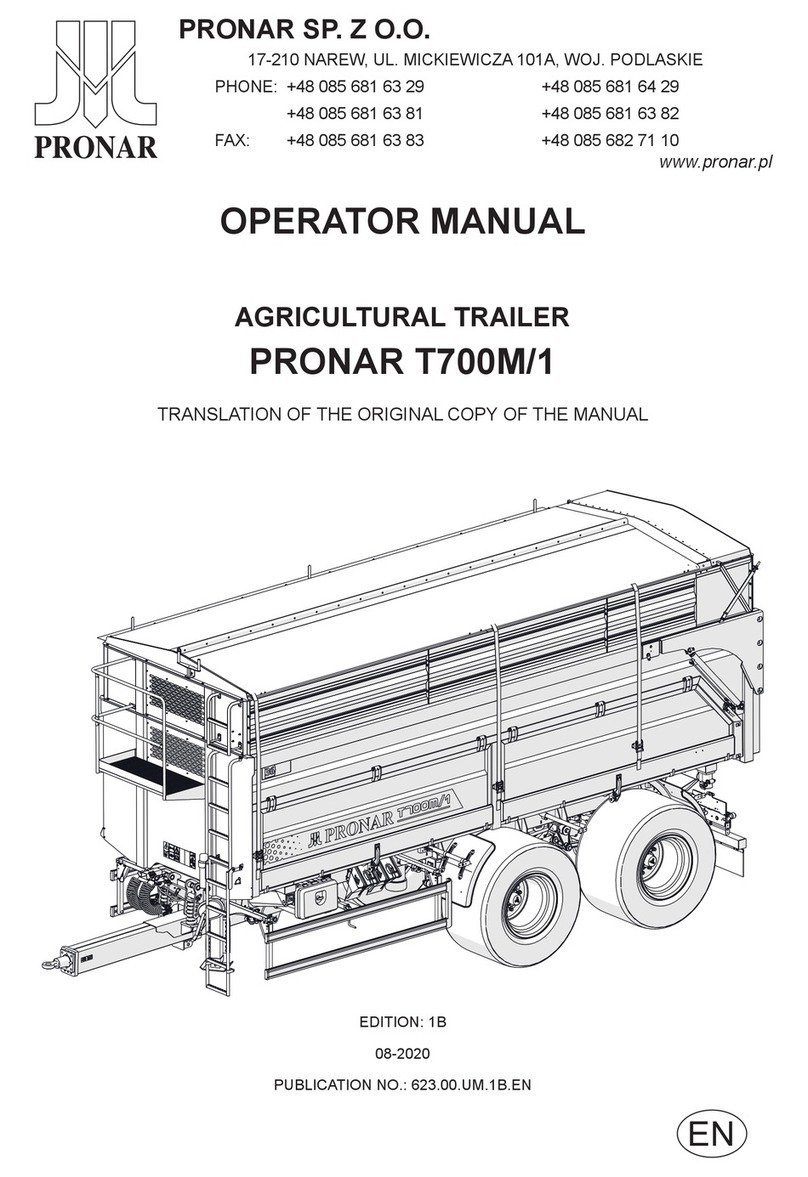

PRONAR T700M/1 User manual

PRONAR

PRONAR T679 User manual

PRONAR

PRONAR T663/1 User manual

PRONAR

PRONAR T780 User manual

PRONAR

PRONAR KURIER 10 User manual

PRONAR

PRONAR T672ECO User manual

PRONAR

PRONAR T683P User manual