2

GENERAL INFO & ID

Table Of Contents

GENERAL INFO & ID

HOW TO ORDER PARTS ................................................. 1

UNIT WARRANTY............................................................. 1

Safety Precautions, Hazard Seriousness Level ................ 4

Introduction................................................................... 5

Reporting Safety Defects............................................ 5

Unit Nameplate or Certication Label......................... 5

Serial Number Data.................................................... 6

Trailer Capacity Data.................................................. 6

Tire and Rim Data....................................................... 6

Care and Maintenance ............................................... 6

Decals And Warnings................................................... 7

Webb Hubs........................................................................ 9

OPERATION

Operation Instructions............................................... 10

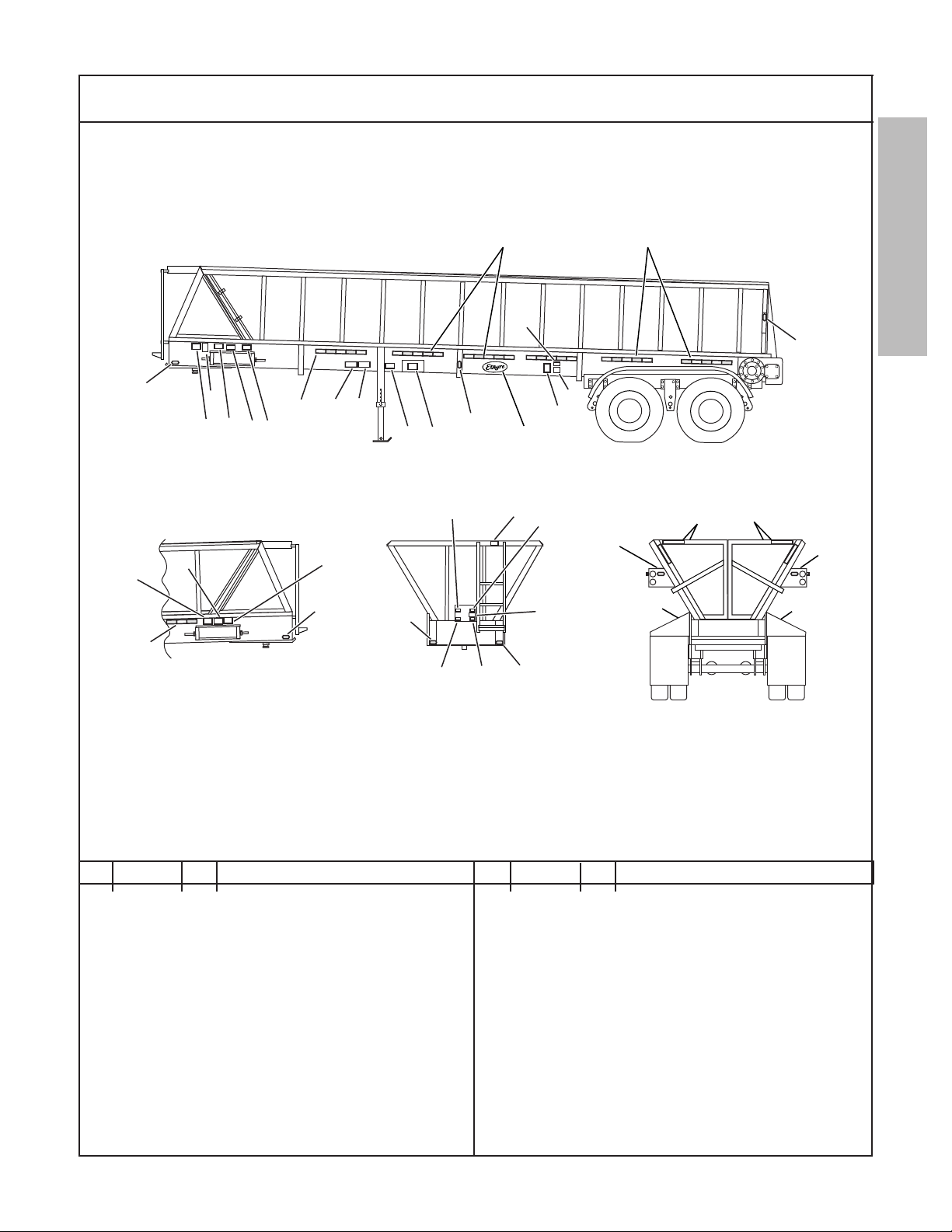

General Description of Operation............................ 10

Pump Performance Recommendations................... 10

General.................................................................... 10

Trailer to Tractor Connecting Procedures.................10

Unloading Without Flow Control Valve .................... 11

Trailer Loading General Information........................ 11

Operating the Manual Tarp (optional)...................... 11

Lift Axle Operation ................................................... 12

Hendrickson Air Lift Control Decal L402.................. 13

Hendrickson Air Lift Control Kit AK-163 Schematic.... 15

MAINTENANCE

Maintenance Instructions .......................................... 16

General.................................................................... 16

Maintenance Schedule ............................................ 16

Maintenance Procedures......................................... 18

Frame Inspection..................................................... 18

Weld Repairs ........................................................... 18

Wheel Bearings ....................................................... 18

Undercarriage.......................................................... 18

Suspension Alignment & Fastener Torque .............. 19

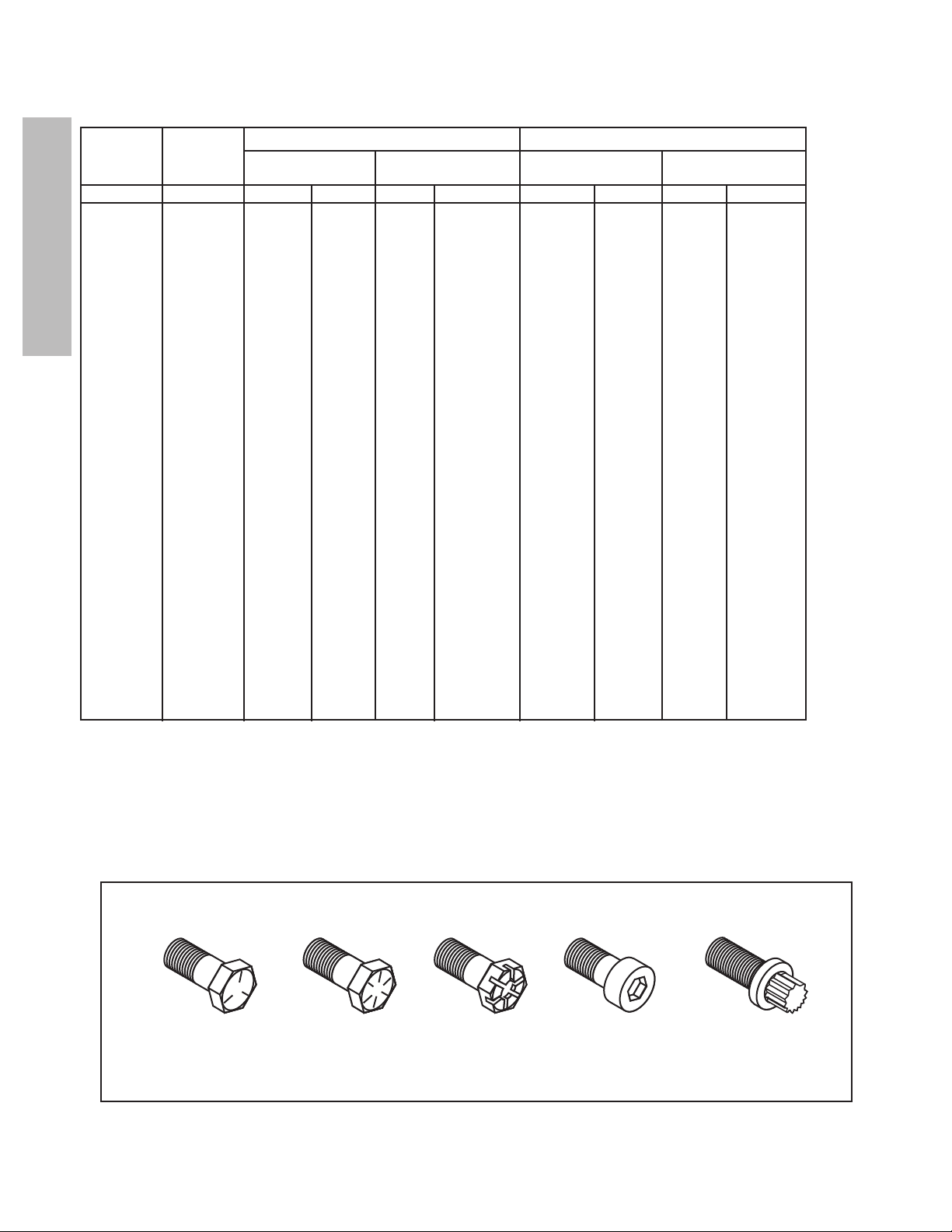

Torque Specications .............................................. 19

Alignment Adjustment.............................................. 19

Tires, Rims and Disc Wheels................................... 20

Tire Ination .......................................................... 20

Tire Overination .................................................. 20

Tire Underination ................................................ 20

Matching Dual Tires.............................................. 20

Removing Tire and Rim Assemblies..................... 20

Removing Tire and Disc Wheel Assemblies ......... 20

Mounting and Demounting Tires

on Rims or Disc Wheels ...................................... 22

Mounting Tire and Rim Assemblies ...................... 22

Mounting Tire and Hub Piloted Type

Disc Wheels......................................................... 22

Mounting Tire and Ball Seat Type

Disc Wheel Assemblies ....................................... 22

Checking Tightness on Mounted Disc Wheels .... 23

Wheels and Hubs................................................ 23

General.............................................................. 23

Cast Wheel or Hub Removal............................. 23

Inspection and Cleaning.................................... 23

Cast Wheel or Hub Installation.......................... 23

Rim Mounting Instructions................................. 23

Careless Mounting is the Major Cause of

Tire and Rim Problems ...................................... 23

Mounting Procedure .......................................... 23

Check Wheel Alignment .................................... 24

Special Note on Aluminum Wheels ................... 24

Examine Wheels at Frequent Intervals.............. 24

Air Systems and Brakes ............................................ 25

Air Systems and Brakes - General .......................... 25

Air System Tests ...................................................... 25

Air Reservoir ............................................................ 25

Air Hoses and Tubing .............................................. 25

Brake Relay Emergency Valve ................................ 25

Air Brake Chambers ................................................ 25

Brake Air Supply System Description...................... 25

Relay Emergency Valve .......................................... 26

Brake Chambers ................................................. 26

Brake Chamber Servicing.................................. 26

Brake Chamber Removal .................................. 27

Brake Chamber Disassembly............................ 27

Brake Chamber Assembly................................. 27

Trailer ABS......................................................... 27

Installation ......................................................... 27

Air Brakes............................................................... 28

Air Brakes - General ............................................. 28

Operating Checks................................................. 28

Brake Assembly.................................................... 28

Slack Adjuster................................................... 29

Crewson Brunner Automatic Slack Adjuster.... 29

Recommended Preventive Maintenance......... 29

Every Three Months or 25,000 Miles............... 29

Every Six Months or 50,000 Miles................... 29

Testing Adjuster Function ................................ 29

Slack Adjuster Replacement............................ 31

Conveyor System Maintenance....................................... 32

TROUBLE ANALYSIS

Trouble Analysis for Hydraulic Systems .......................... 33

Trouble Analysis for Air Brakes........................................ 34

CONVEYOR / TARP MAINTENANCE

Conveyor System Maintenance....................................... 37

Cover Tarp Maintenance ................................................. 40

COMMENT / SUGGESTION FORM.................................41