Table of Contents

INTRODUCTION..........................................................................................................................................3

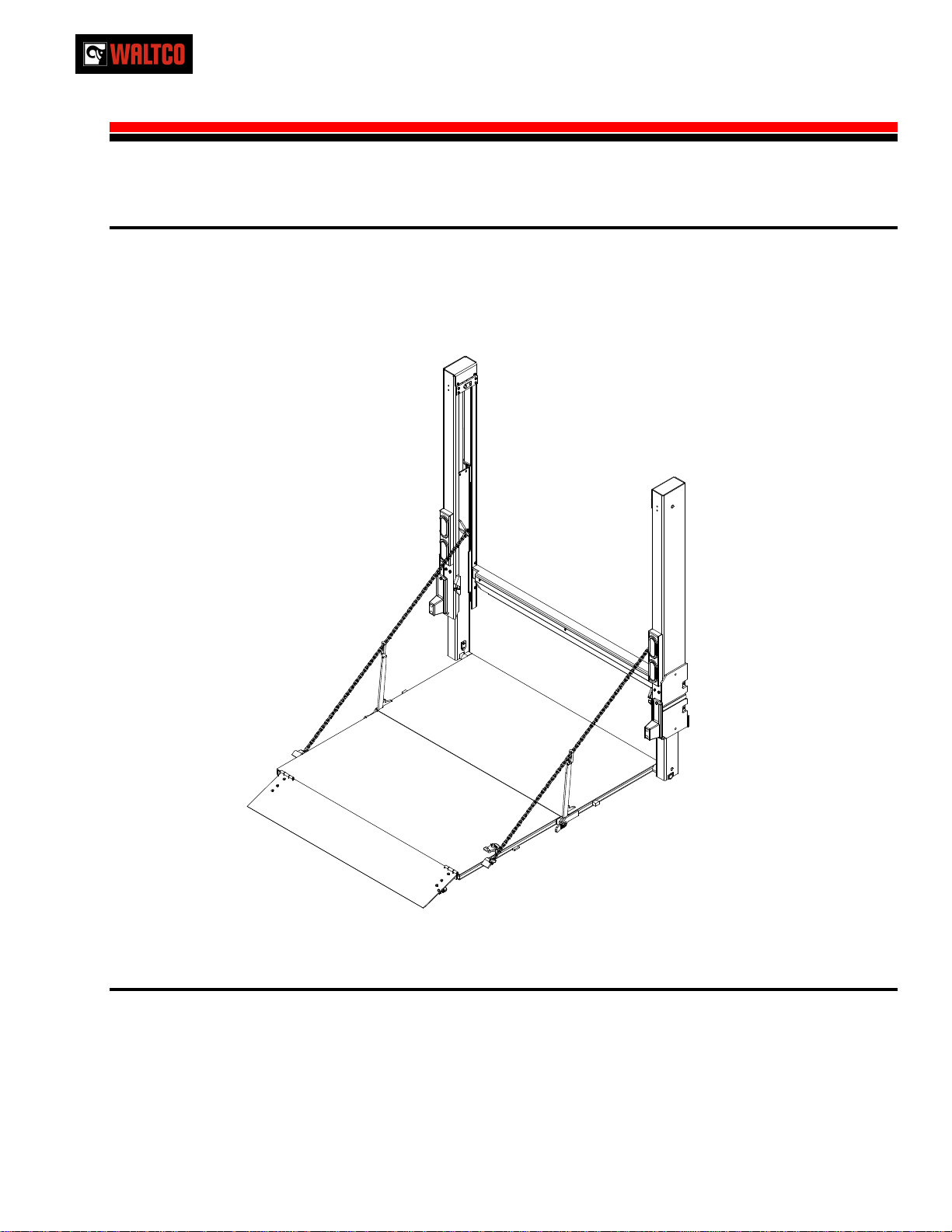

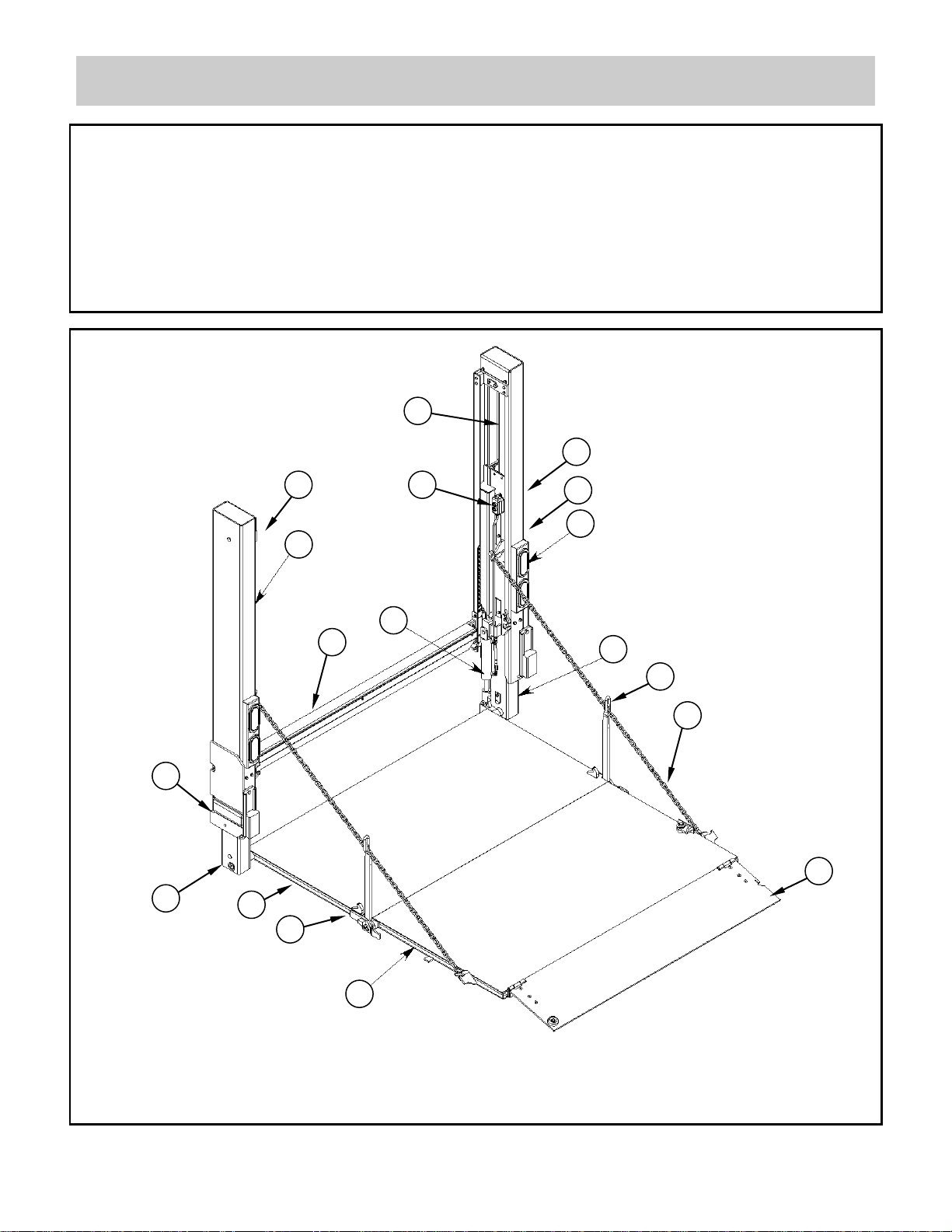

LIFTGATE TERMINOLOGY........................................................................................................................4-7

HYDRAULIC CIRCUIT DIAGRAM ..............................................................................................................8

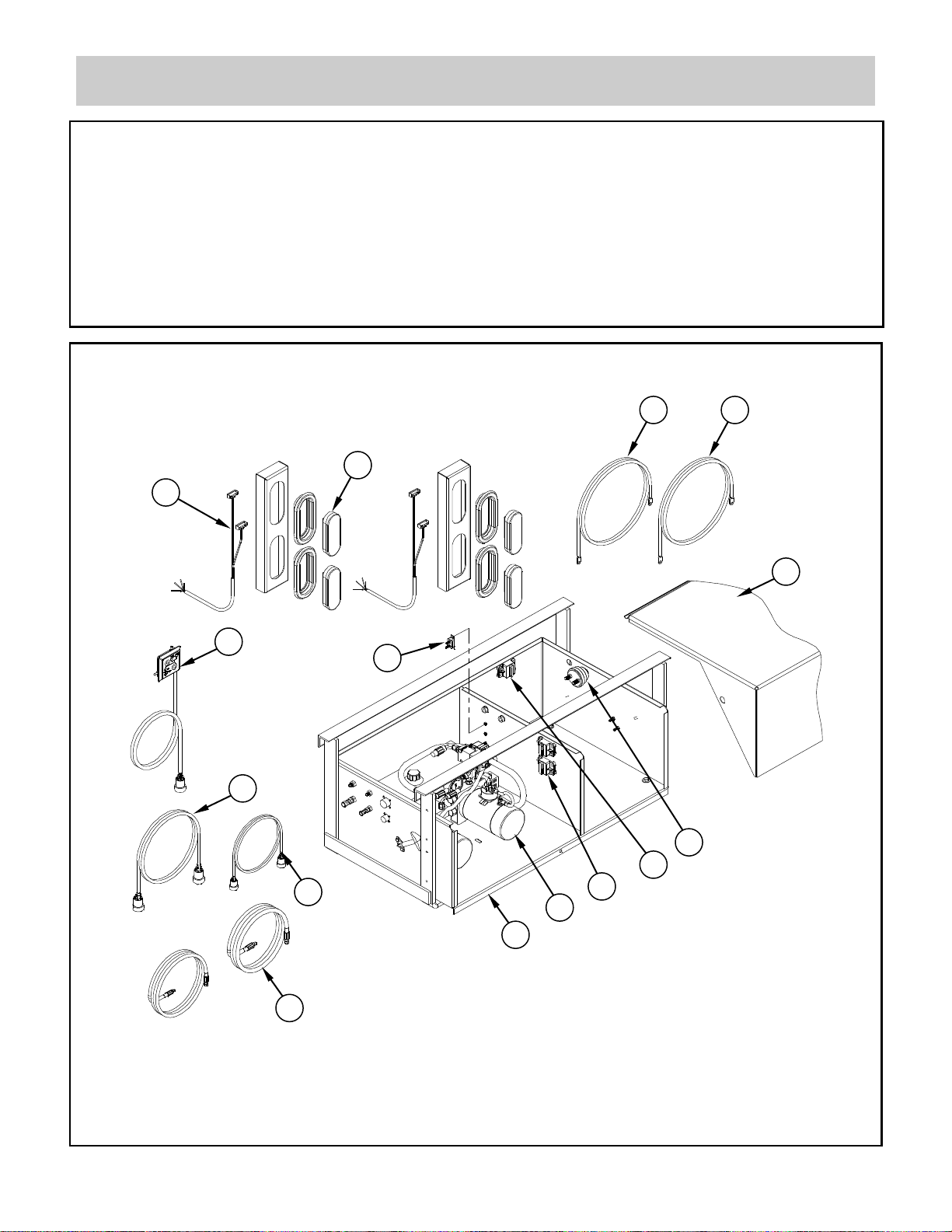

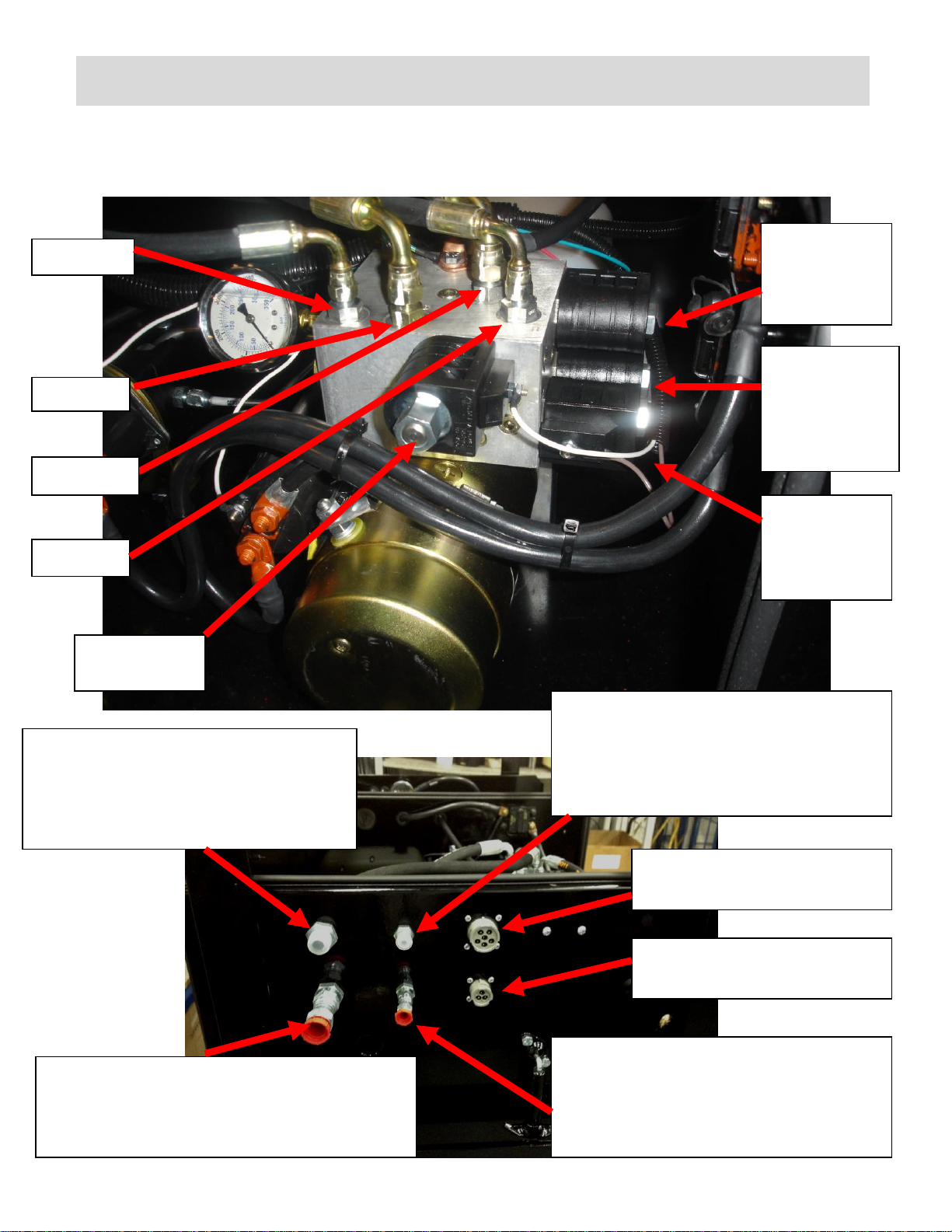

POWER UNIT KEY COMPONENTS ...........................................................................................................9-14

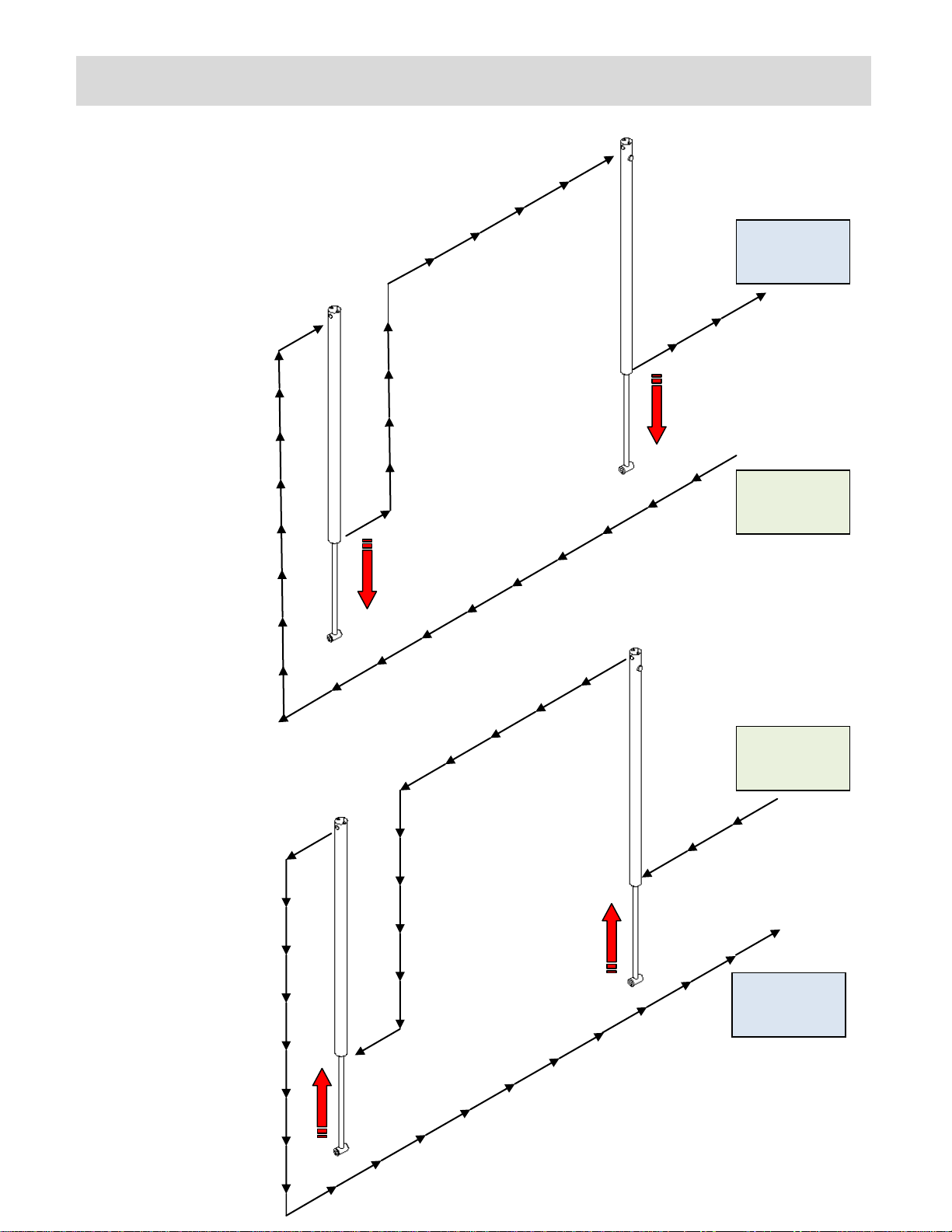

ELECTRICAL & HYDRAULIC FLOW SCHEMATICS ................................................................................15-18

HYDRAULIC & ELECTRICAL SCHEMATICS BUILT FROM 4/09 THRU 10/11 .......................................19-20

HYDRAULIC & ELECTRICAL SCHEMATICS BUILT FROM 10/11 ..........................................................21-22

HYDRAULIC & ELECTRICAL SCHEMATIC - WORK LIGHT....................................................................23

HYDRAULIC & ELECTRICAL SCHEMATICS – CYCLE COUNTER.........................................................24-25

HYDRAULIC & ELECTRICAL SCHEMATIC- GRAVITY DOWN ON DEMAND ........................................26-27

HYDRAULIC & ELECTRICAL SCHEMATIC ..............................................................................................28-31

TROUBLESHOOTING GUIDE ....................................................................................................................32-36

LIFT CYLINDER REPLACEMENT INSTRUCTION....................................................................................37-38

CLOSING CYLINDER BLEEDING PROCEDURE......................................................................................39

HYDRAULIC OIL CHANGING PROCEDURE ............................................................................................40

HIGH PITCH NOISE REPAIR......................................................................................................................41

REPLACING SWITCH AND POWER CLOSE HOSES ..............................................................................42-43

TRAVEL LATCH ENGAGMENT .................................................................................................................44

PREVENTIVE MAINTENANCE...................................................................................................................45-46

HOW TO ORDER PARTS............................................................................................................................47