TABLE OF CONTENT

1INTRODUCTION................................................................................................................................1

1.1 GENERAL ..................................................................................................................................... 1

1.2 DESCRIPTION.............................................................................................................................. 1

1.2.1 SENSOR UNIT........................................................................................................................ 1

1.2.2 TRANSMITTER UNIT ............................................................................................................ 1

2INSTALLATION ................................................................................................................................. 3

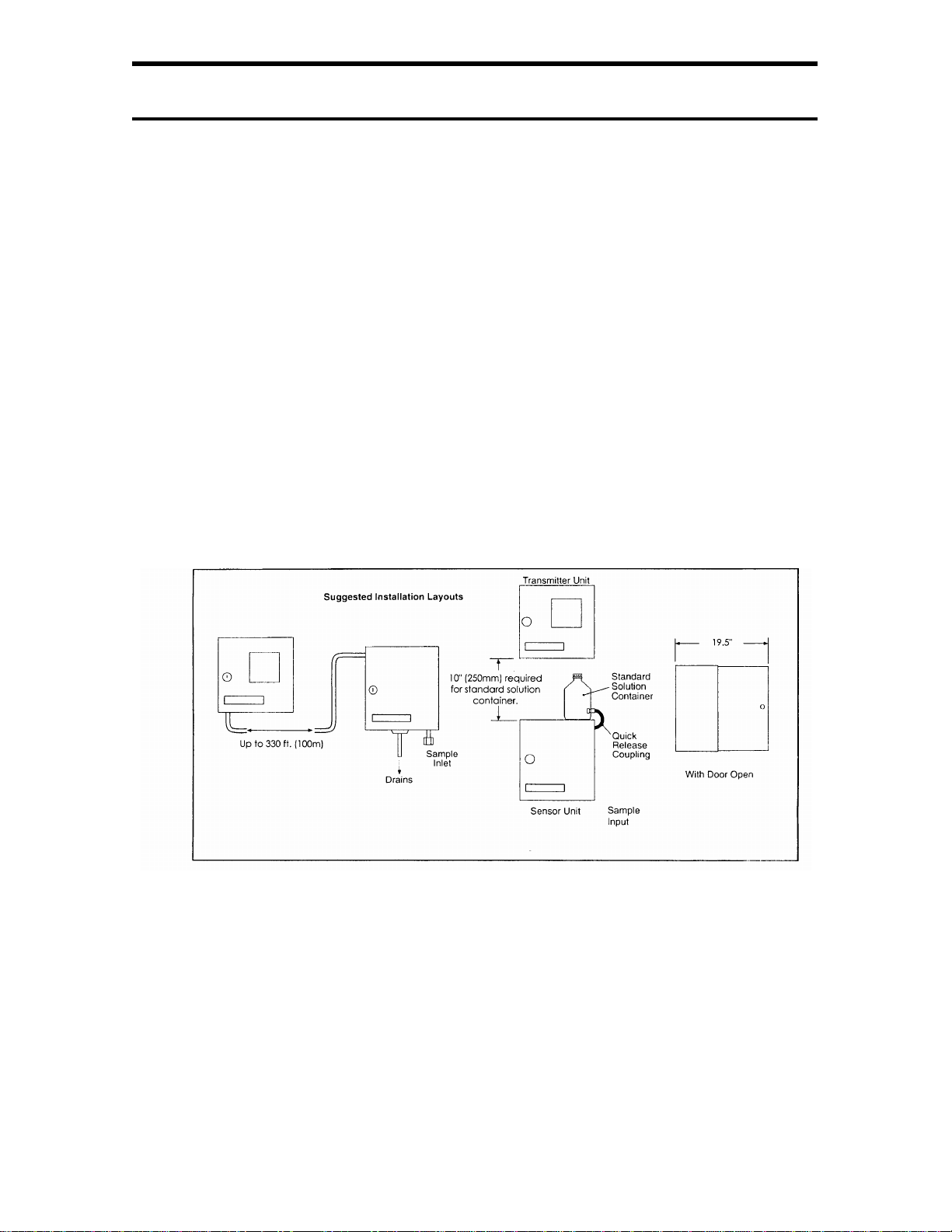

2.1 MOUNTING OF UNIT.................................................................................................................. 3

2.1.1 LOCATION AND LAYOUT.................................................................................................... 3

2.1.2 TRANSMITTER UNITS .......................................................................................................... 4

2.2 SAMPLE REQUIREMENTS......................................................................................................... 6

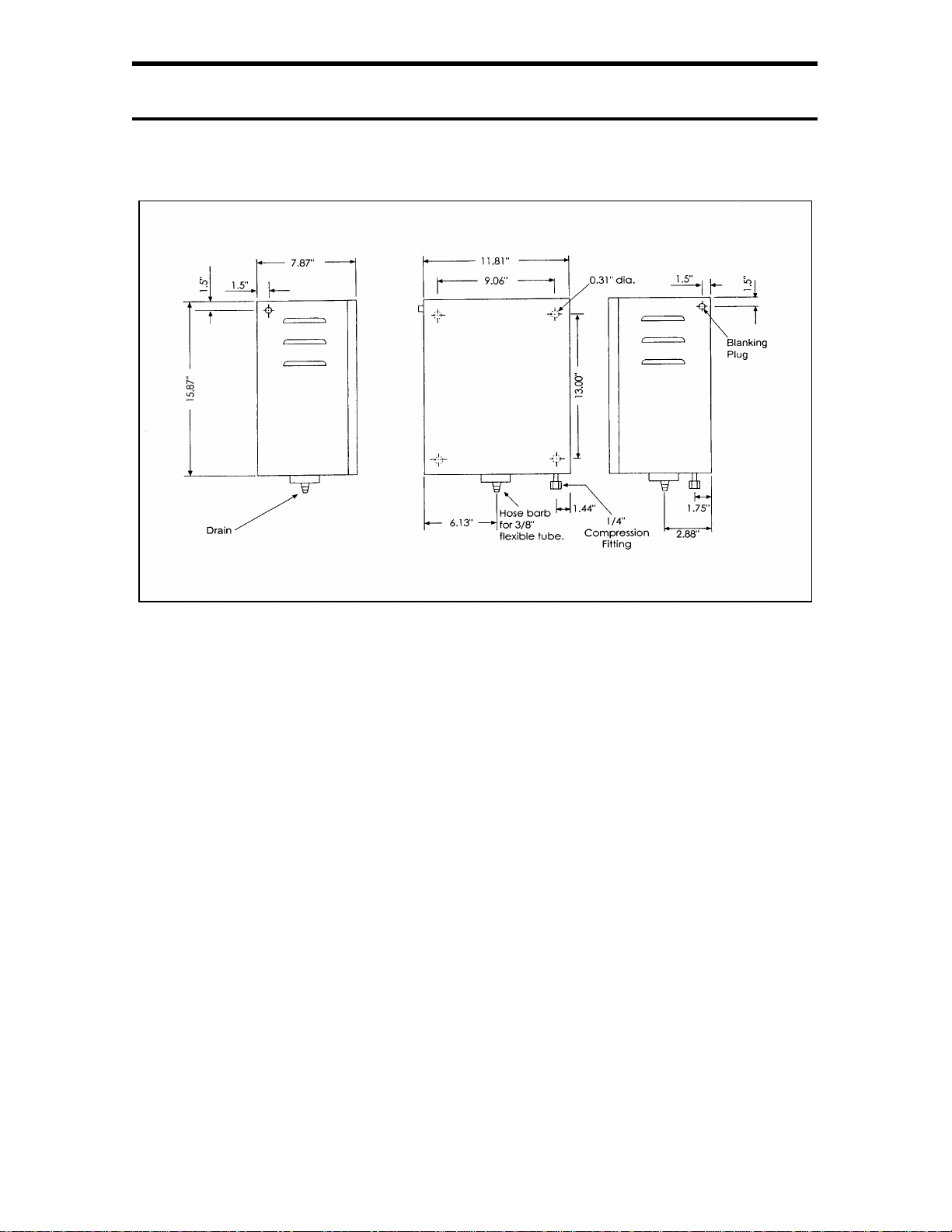

2.3 EXTERNAL PIPING CONNECTIONS......................................................................................... 6

2.3.1 INLET..................................................................................................................................... 6

2.3.2 DRAIN .................................................................................................................................... 6

2.4 ELECTRICAL CONNECTIONS................................................................................................... 7

2.5 SENSOR UNIT .............................................................................................................................. 7

2.5.1 TRANSMITTER UNIT ............................................................................................................ 7

2.5.2 WIRING OF BOARDS................................................................................................................ 8

Chassis.................................................................................................................................................. 10

2.6 REMOTE EQUIPMENT.............................................................................................................. 10

2.6.1

RECORDERS........................................................................................................................ 10

2.6.2

RANGE INDICATION.......................................................................................................... 10

3START UP .......................................................................................................................................... 12

4PRINCIPLE OF OPERATIONS...................................................................................................... 14

4.1 SENSOR UNIT ............................................................................................................................ 14

4.1.1 A flow schematic is shown in Fig. 4.1................................................................................... 14

4.2 QA/QC JUNCTION BOX SWITCH............................................................................................ 15

4.2.1 Normal Calibration .............................................................................................................. 15

4.2.2 Process Calibration.............................................................................................................. 15

4.2.3 QA/QC.................................................................................................................................. 15

4.3 TRANSMITTER UNIT................................................................................................................ 16

4.3.1 ELECTRONICS CHASSIS.................................................................................................... 16

4.3.2 CIRCUIT BOARD FUNCTION............................................................................................ 16

4.3.3 FRONT PANEL CONTROLS ............................................................................................... 17

4.3-4 ALARMS..................................................................................................................................... 20

4.4 ANALOG OUTPUTS................................................................................................................... 20

5CALIBRATION PROCEDURE....................................................................................................... 22

5.1 SINGLE POINT CALIBRATION USING STANDARD SOLUTION....................................... 22

5.2 CALIBRATION USING PROCESS SAMPLE AS ASTANDARD SOLUTION....................... 23

6MAINTENANCE ............................................................................................................................... 24

6.1 CHEMICAL SOLUTIONS .......................................................................................................... 24

6.1-1 BUFFER SOLUTION........................................................................................................... 24

6.1.1 Concentrated ammonia solution - 2 liters ............................................................................ 24

6.1-2 STANDARD SOLUTIONS........................................................................................................... 24

6.1-3 NITRIC ACID CLEANING SOLUTION............................................................................... 26

Note: Waltron L.L.C. offers Nitric Acid in a 2 ounce size part number H1234-556 ........................... 26

6.1-4 HYDRAZINE SENSOR RECHARGE GEL................................................................................. 26

6.2 SCHEDULED SERVICING ........................................................................................................ 26

i