Waltron User Manual 101-046-B.3

9096 Degassed Cation Conductivity Analyzer

TABLE OF CONTENTS

Waltron Customer Commitment.........................................................................1

Safety .................................................................................................................2

Warranty Agreement..........................................................................................3

Checklist of Materials .........................................................................................4

Table of Contents................................................................................................5

1Overview ......................................................................................................7

1.1 Specifications ................................................................................................................................ 7

1.1.1 Performance.......................................................................................................................... 7

1.1.2 Operating Conditions ............................................................................................................ 7

1.1.3 Communications & Signal Outputs ....................................................................................... 7

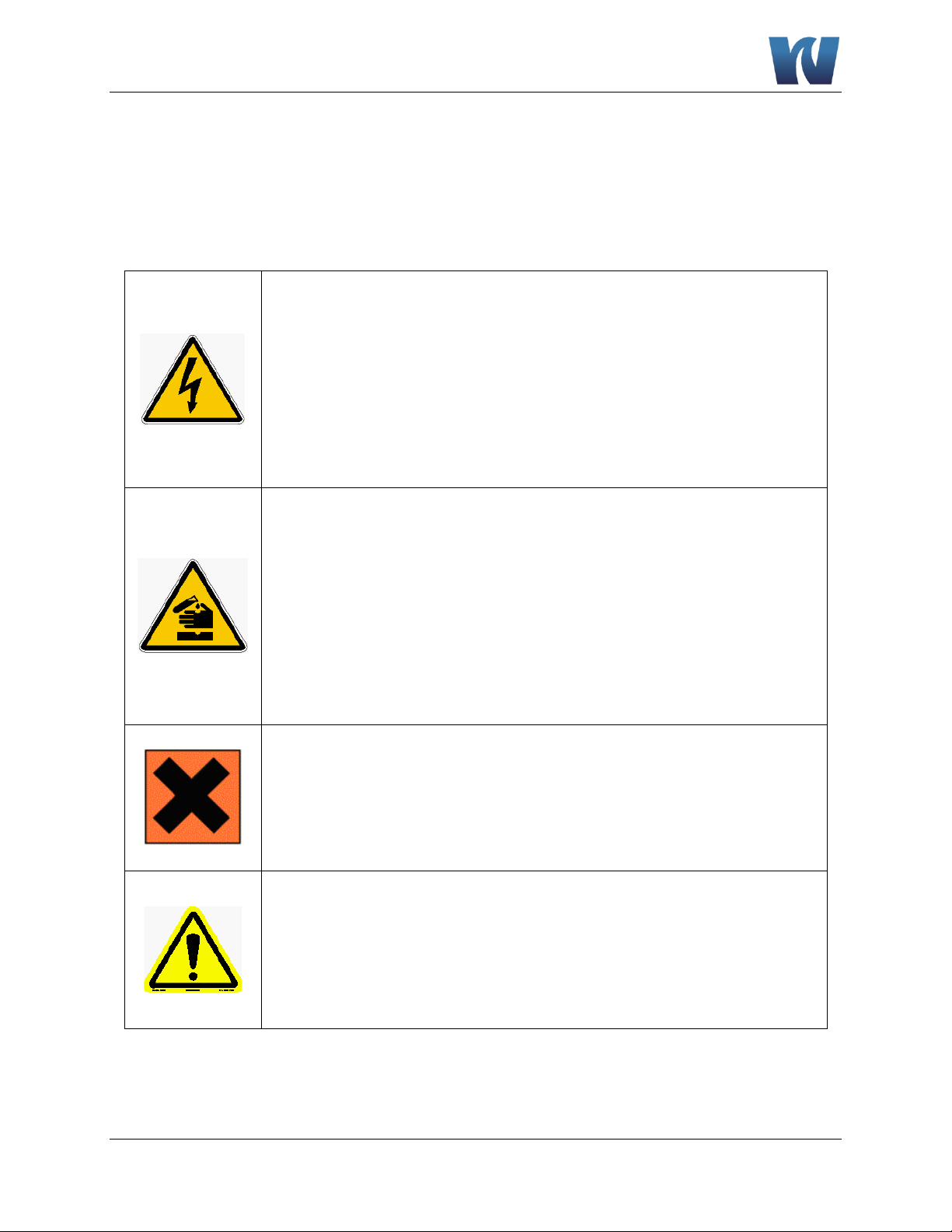

1.2 Safety Precautions, Instructions, and Hazards.............................................................................. 8

1.2.1 General Information ............................................................................................................. 8

1.2.2 List of Warnings and Potential Dangers................................................................................ 9

1.2.3 Sample................................................................................................................................. 10

1.2.4 Analyzer General Hazards ................................................................................................... 10

2Introduction................................................................................................11

2.1 Preliminary Remarks ...................................................................................................................11

2.2 Working Principle........................................................................................................................ 11

2.3 Flow & Component Diagram....................................................................................................... 13

2.4 Wet-Section ................................................................................................................................ 14

2.5 Electronics...................................................................................................................................14

3Installation .................................................................................................15

3.1 Receiving .....................................................................................................................................15

3.2 Analyzer Handling .......................................................................................................................15

3.3 Location and Mounting...............................................................................................................15

3.4 Mounting Schematics .................................................................................................................16

3.5 Sample Connections....................................................................................................................17

3.6 Electrical Connections................................................................................................................. 18

3.6.1 Transmitter Enclosure......................................................................................................... 19

3.6.2 Terminal Block Connections................................................................................................ 20

3.6.3 AC Power Connection .........................................................................................................21

3.6.4 User Signal Connections...................................................................................................... 22

4Analyzer Initial Start-Up..............................................................................23

4.1 Preparing the Analyzer for Start-Up ...........................................................................................23

4.1.1 Installing Cation Resin Bottle ..............................................................................................23

4.1.2 Installing Decarbonization Column .....................................................................................25

4.2 Putting the Analyzer Online ........................................................................................................ 25