INDEX

WAMFLO® FN200X

2

FIL.WAMFLO_FN200.EX.M.A7.0522.EN Issue: A7

05.22

III

1.0 GENERAL INFORMATION ...................................................................................................................... 1

1.1 Scope of the Manual ......................................................................................................................... 1

1.2 Symbols ............................................................................................................................................ 2

1.3 Glossary and terminology ................................................................................................................. 4

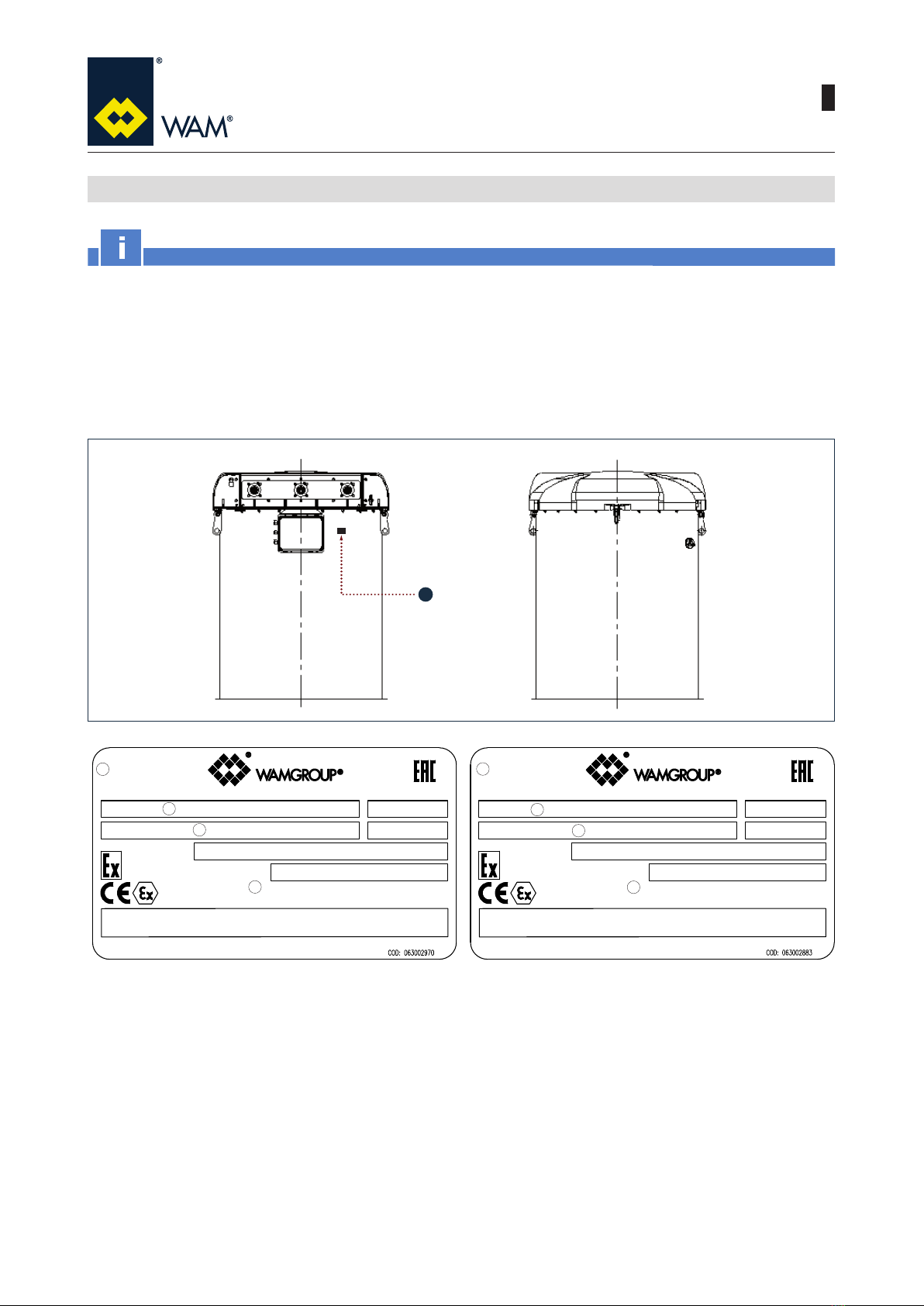

1.4 Manufacturer’s data and identication of equipment......................................................................... 5

1.5 Request for assistance...................................................................................................................... 6

1.6 Warranty............................................................................................................................................ 6

1.7 Exclusion of responsibility ................................................................................................................. 6

2.0 INFORMATION REGARDING SAFETY................................................................................................... 7

2.1 General safety prescriptions ............................................................................................................. 7

2.2 Safety prescriptions for transport and handling................................................................................. 7

2.3 Safety prescriptions for installation ................................................................................................... 8

2.4 Safety prescriptions for use and operation........................................................................................ 8

2.5 Safety prescriptions for maintenance and replacement of components ........................................... 8

2.6 Safety recommendations on biological risks ..................................................................................... 9

3.0 TECHNICAL INFORMATION ................................................................................................................. 10

3.1 General description of the equipment ............................................................................................. 10

3.2 Indications for use ........................................................................................................................... 10

3.3 Limits of use .....................................................................................................................................11

3.4 Compliance with the ATEX Directive ............................................................................................... 12

3.5 Notes on safety standards .............................................................................................................. 13

3.6 Residual risks.................................................................................................................................. 14

3.7 Personal protection equipment ....................................................................................................... 14

3.8 Main components............................................................................................................................ 15

3.9 Operating principle .......................................................................................................................... 16

3.10 Permitted use ................................................................................................................................ 16

3.11 Improper use not permitted ........................................................................................................... 16

3.12 Noise level..................................................................................................................................... 17

3.13 Environmental operating limits ...................................................................................................... 18

3.14 Options - Cleaning systems .......................................................................................................... 18

3.15 Options - Filter type....................................................................................................................... 19

3.16 Options: Coupling type.................................................................................................................. 21

3.17 Options: Filter outlet ..................................................................................................................... 22

3.18 Options: Rain cover....................................................................................................................... 23

3.19 Options - Upper anged connection for standard lters................................................................ 24

3.20 Options - Lateral anged connection for standard lters............................................................... 25

3.21 Options - Fans............................................................................................................................... 26

3.22 Fans - combinations ..................................................................................................................... 27

3.23 Options - Fan voltage / frequency ................................................................................................. 28

3.24 Options - Anti-explosion panel ...................................................................................................... 29

3.25 Motor absorption ........................................................................................................................... 30

3.26 Cleaning system voltage / frequency ............................................................................................ 31

3.27 Options: Board accessories .......................................................................................................... 31

3.28 Overall dimensions and technical features ................................................................................... 31

3.29 Safety and information signs......................................................................................................... 32

3.30 Safety devices............................................................................................................................... 32

TABLE OF CONTENTS