INDEX

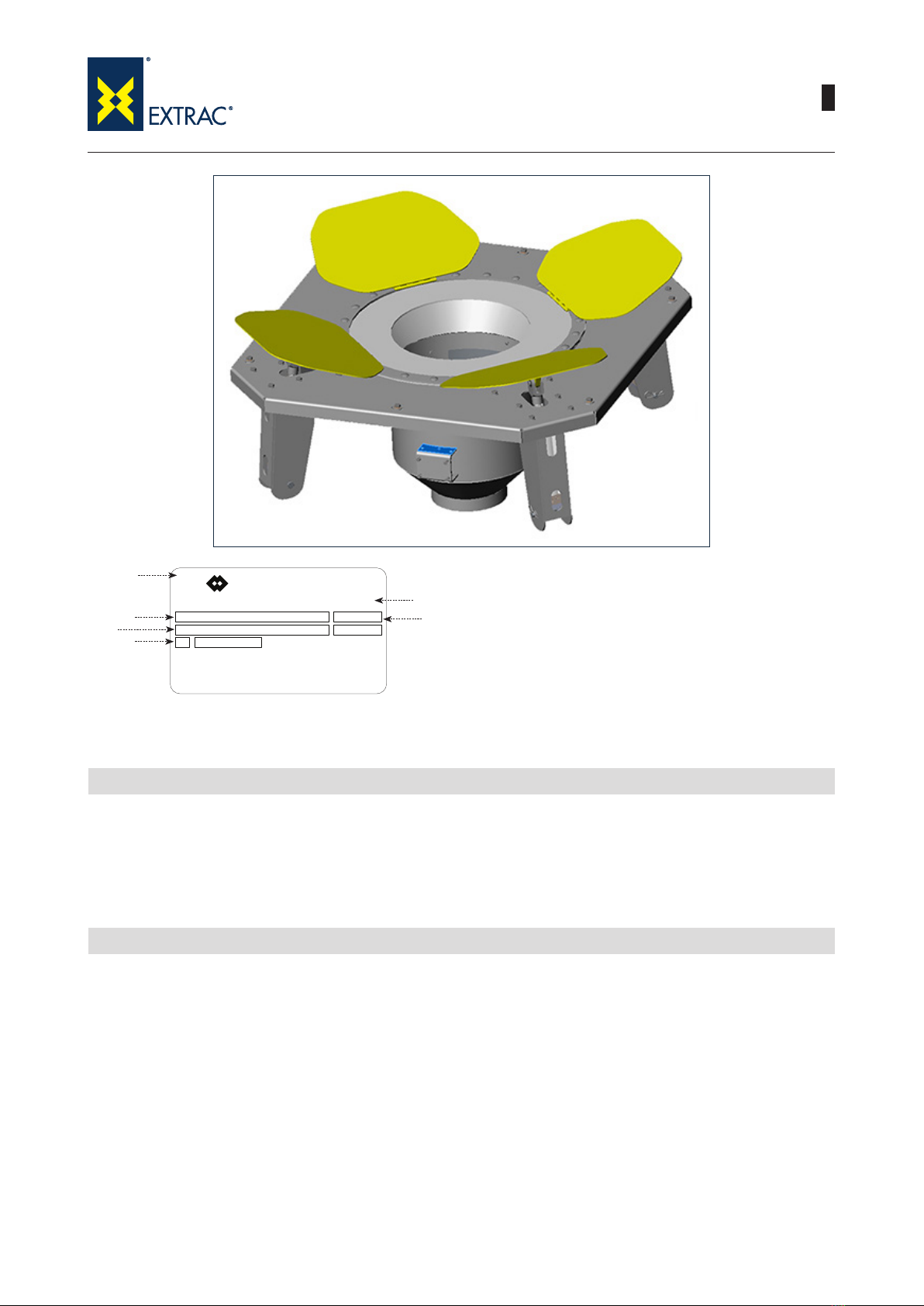

SBB-HFF

2

EXT.SBB-HFF.--.M.A.0219.EN Issue: A

02.19

III

SUMMARY

1.0 GENERAL INFORMATION .......................................................................................................................1

1.1 Scope of the Manual ..........................................................................................................................1

1.2 Symbols .............................................................................................................................................2

1.3 Glossary and terminology ..................................................................................................................4

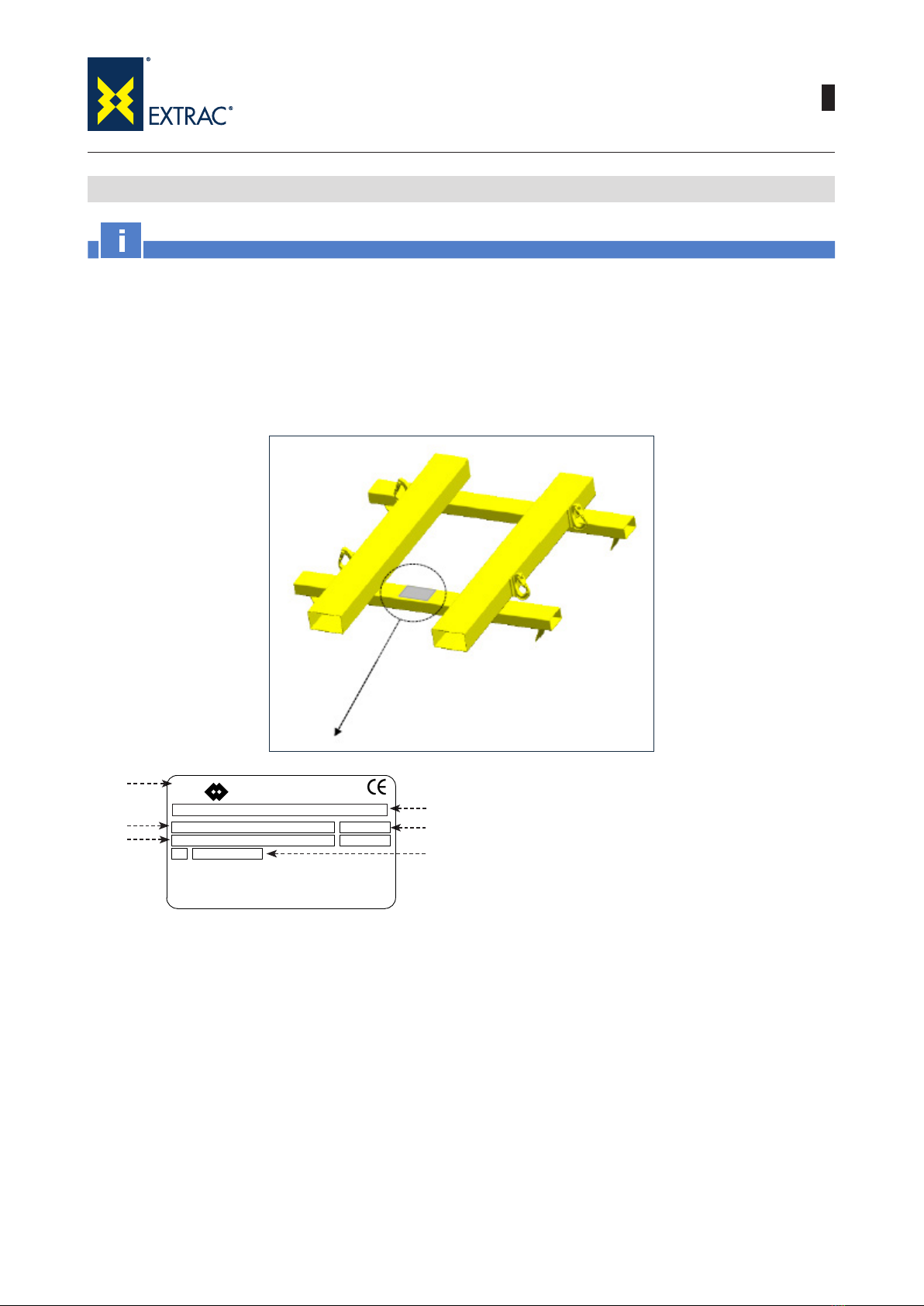

1.4 Manufacturer’s data and identication of equipment..........................................................................5

1.5 Request for assistance.......................................................................................................................6

1.6 Warranty.............................................................................................................................................6

1.7 Exclusion of responsibility ..................................................................................................................7

2.0 INFORMATION REGARDING SAFETY....................................................................................................8

2.1 General safety prescriptions ..............................................................................................................8

2.2 Safety prescriptions for transport and handling..................................................................................8

2.3 Safety prescriptions for installation ....................................................................................................9

2.4 Safety prescriptions for use and operation.........................................................................................9

2.5 Safety prescriptions for maintenance and replacement of components ............................................9

3.0 TECHNICAL INFORMATION ..................................................................................................................11

3.1 General description of the equipment ..............................................................................................11

3.2 Main components.............................................................................................................................14

3.3 Operating principle ...........................................................................................................................17

3.4 Permitted use ...................................................................................................................................17

3.5 Improper use not permitted ..............................................................................................................17

3.6 Noise level........................................................................................................................................18

3.7 Environmental operating limits .........................................................................................................18

3.8 Overall dimensions and technical features ......................................................................................18

3.9 Safety and information signs............................................................................................................19

4.0 INFORMATION REGARDING HANDLING AND TRANSPORT..............................................................20

4.1 Type of packaging ............................................................................................................................20

4.2 Reception of goods ..........................................................................................................................21

4.3 Lifting and unloading methods .........................................................................................................22

5.0 INSTALLATION AND FIXING..................................................................................................................23

5.1 Recommendations for installation ....................................................................................................23

5.2 Positioning........................................................................................................................................23

5.3 Installation ........................................................................................................................................25

5.4 Connecting the electric - pneumatic actuators .................................................................................35

5.5 Commissioning.................................................................................................................................37

5.6 Installing the accessories ................................................................................................................37

6.0 INFORMATION REGARDING USE ........................................................................................................42

6.1 Production Start-up ..........................................................................................................................42

6.2 Long shutdowns of the equipment ...................................................................................................46

6.3 Reuse...............................................................................................................................................46