2

Contents

W&H Symbols .......................................................................................................3 – 5

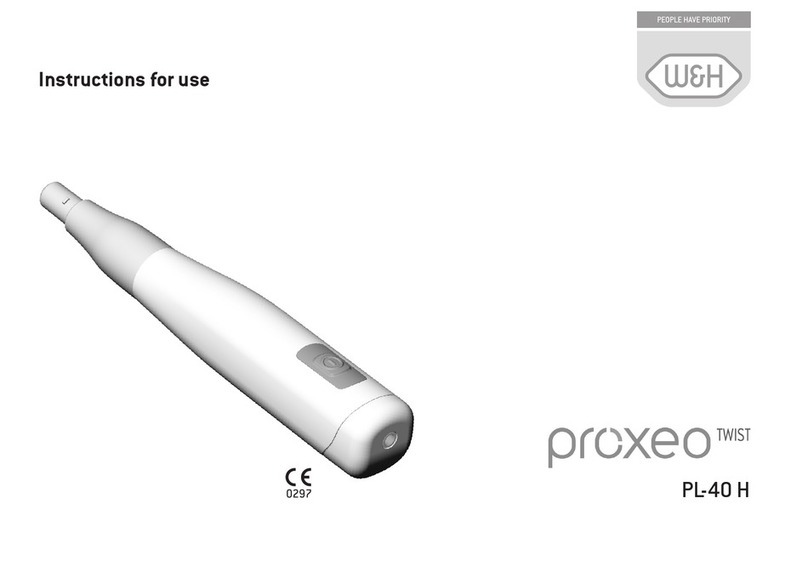

1. Introduction ...................................................................................................6 – 7

2. Unpacking.........................................................................................................8

3. Equipment supplied...........................................................................................9 – 10

4. Safety notes ................................................................................................11 – 12

5. Description / Assembly / Starting operation – Knee control unit.................................................13 – 15

6. Description / Starting operation – Table control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 – 18

7. General starting operation – Filling of the coolant tank / Regulating coolant .....................................19 – 20

8. Description of the motor handpiece LA-9 /

LA-66 (optional)

/ Adaptor for milling device (optional) ................21 – 22

9. General operation – Motor handpiece / Blow out function............................................................23

10. Description of the operating controls / Assemble support (optional) ............................................24 – 25

11. Operating the operating controls – Reverse operation / Changing the speed / Changing motor handpiece /

Coolant spray / Bistable operation / Speed control operation ...................................................26 – 30

12. Removing and assembling the motor handpiece ....................................................................31

13. Changing the rotary tools ....................................................................................32 – 33

14. Cleaning .........................................................................................................34

15. Cleaning / changing the chuck ................................................................................35 – 36

16. Error messages...................................................................................................37

17. W&H Accessories .................................................................................................38

18. Servicing .........................................................................................................39

19. Technical Data...............................................................................................40 – 41

20. Recycling and Disposal ...........................................................................................42

Letter of indemnity .....................................................................................................43

CE-Declaration of conformity ............................................................................................44

Authorized W&H service partners ........................................................................................45