Instructions condensing Air heaters type HR version HR-GB-4001-a

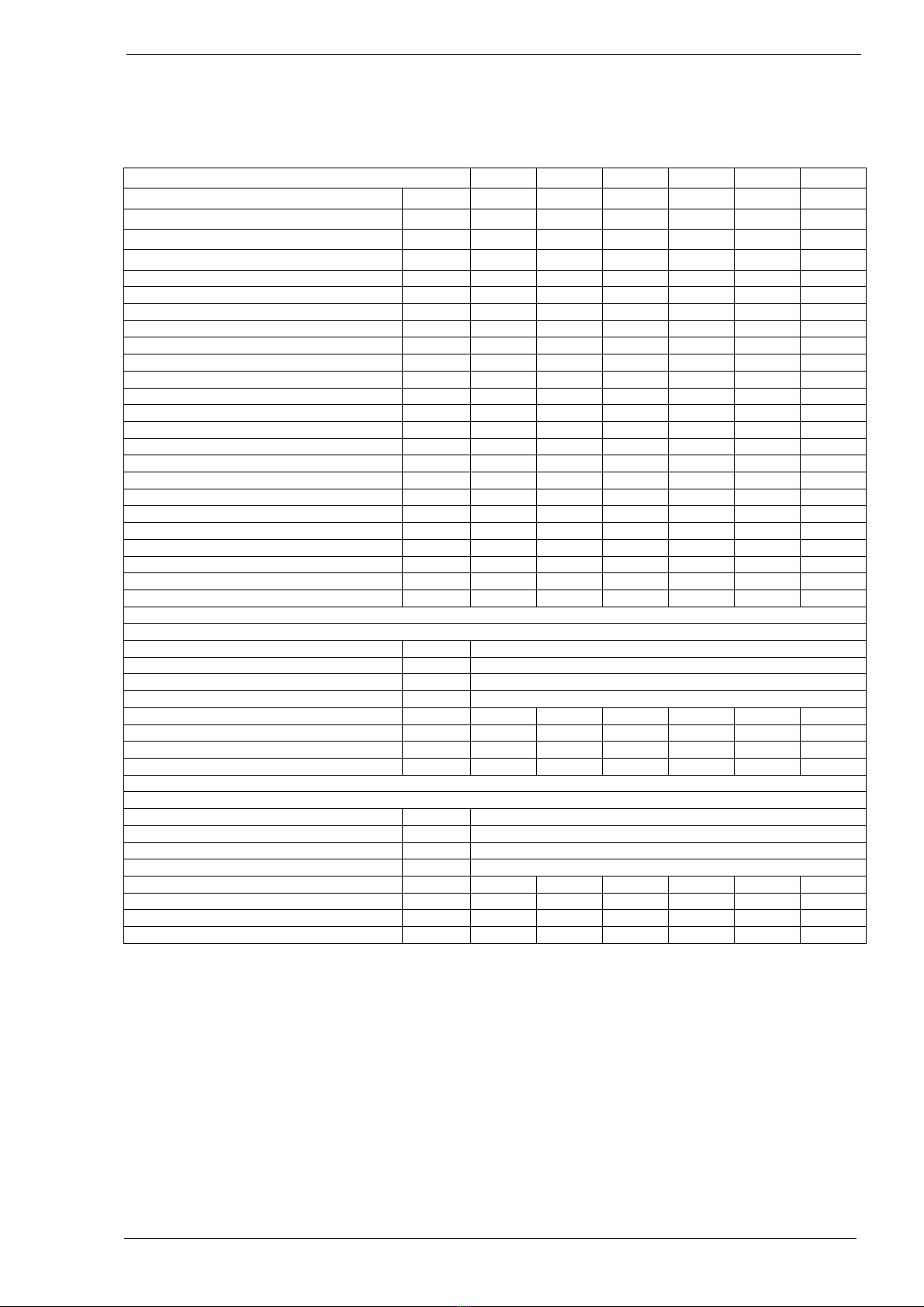

3Technica detai s:

Type HR 10 20 30 40 50 60

Maximum nominal heat input (H.I.) kW 12,5 20,0 30,0 40,0 50,0 60,0

Minimum nominal heat input (H.I.) kW 4,0 6,0 9,0 12,0 15,0 18,0

Efficiency max. power % 96,0 96,0 96,5 97,0 96,5 96,6

Efficiency 30% power % 106,0 106,0 106,0 106,5 106,0 106,0

Maximum heat output kW 12,0 19,2 29,0 38,8 48,3 58,0

Minimum heat output kW 4,2 6,4 9,5 12,8 15,9 19,1

Max air output (warm) m3/hr 2.000 2.600 3.000 4.500 5.000 6.000

Throw horizontal (max) m 15 20 23 26 28 30

Gas connection G” ½” bin ½” bin ¾” bui ¾” bui ¾” bui ¾” bui

Electrical Voltage [50 Hz] V 230 230 230 230 230 230

Electrical power max. kW 0,250 0,250 0,250 0,450 0,450 0,600

Electrical power min.

kW 0,250 0,250 0,250 0,450 0,450 0,600

Electrical power standby

kW 0,004 0,004 0,004 0,004 0,004 0,004

Electrical current A 1,1 1,1 1,2 2,0 2,6 2,6

Emission efficiency, (ηs,flow) % 97,6 96,4 94,6 95,0 94,8 94,6

Seas. space heating efficiency % 90,4 90,1 88,7 89,9 89,2 89,4

NOx emission (GCV) mg/kWh 30 21 33 40 31 44

NOX class 5 5 5 5 5 5

Flue amount max. kg/hr 19,4 31,1 48,3 64,2 80,2 96,2

Thermostat bus system (low voltage) Yes Yes Yes Yes Yes Yes

Sound level (average @ 4 meter) dBA 45 45 45 47 48 49

Suspension height horizontal throw min. m 1,7 1,7 1,7 1,7 1,7 1,7

Flue length max. m 9 9 9 9 9 9

Weight m 45 50 75 85 105 110

Nominal supply pressure G20 mbar. 20

Supply pressure (min-max) G20 mbar. 17-25

Gas category Cat. I2H

Class Class. B23, C13, C33

Max gas consumption G20 m3/hr 1,3 2,1 3,2 4,2 5,3 6,3

CO2 High G20 % 9,5 9,5 9,2 9,2 9,2 9,2

CO2 Low G20 % 9,0 9,0 8,8 8,8 8,8 8,8

CO (@ 0%O2) mg/kWh 4 5 1 1 3 3

Propane, G31, heater version 3.4

Nominal supply pressure G31 mbar. 30-50

Supply pressure (min-max) G31 mbar. 25-50

Gas category Cat. I3P

Class Class. B23, C13, C33

Max gas consumption G31 kg/hr 1,0 1,6 2,4 3,2 4,0 4,8

CO2 High G31 % 10,7 10,7 11,0 11,0 11,0 11,0

CO2 Low G31 % 10,3 10,3 10,5 10,5 10,5 10,5

CO (@ 0%O2) mg/kWh 13 8 3 1 1 1