Warner Electric • 800-825-9050 P-1177-WE • 819-0457 3

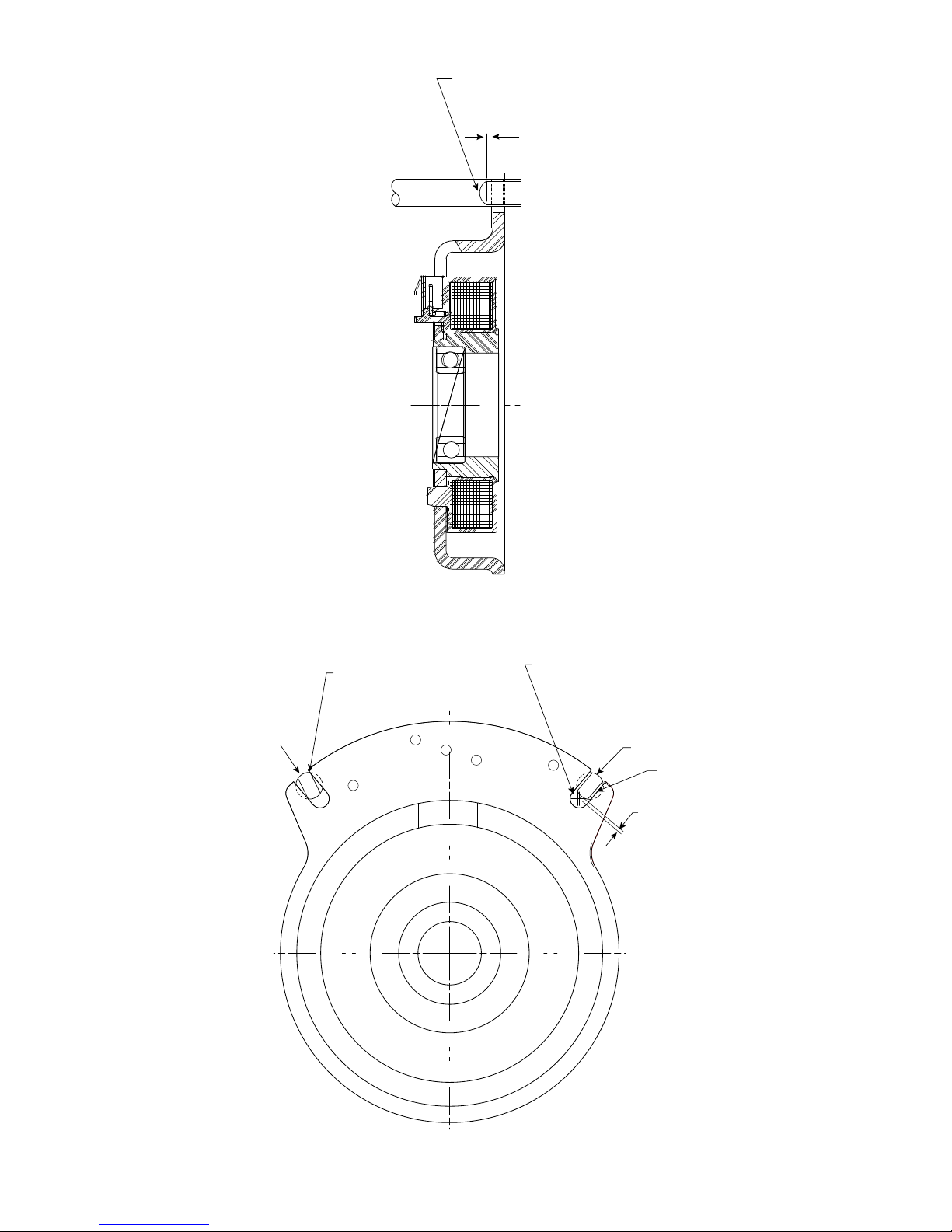

Optional Washer

A single .250 inch (6.35 mm) minimum thick steel

washer must be used between the clutch and the

crank shaft retaining bolt if the D-drive spacer is

not used.

A washer less than .250 inch

(6.35 mm) thick will deform and allow the

clamping load to be lost, resulting in damage

to the clutch and/or the crankshaft and

possible personal injury due to clutch

separating from the shaft. Multiple thinner

washers are not acceptable.

Components: (See Figure 1 on page 4.)

1. Rotor Assembly

Generally, the input of the clutch. Includes

a keyed hub which mates with the keyway

in the crank shaft. The rotor transmits the

torque from the crankshaft (driving shaft) to the

armature assembly (output).

2. Armature Assembly

Generally, the output of the clutch. Consists

of a disk, springs and pulley (or output flange).

With power applied the armature transmits

torque from the rotor to the driven load. Power

from the armature disk is transmitted to the

pulley or flange by means of the leaf springs.

3. Field Assembly

The clutch “power” source contains the coil

which generates magnetic attractive force.

4. Brake Poles

The two permanent magnets and plates ffixed

to the field shell provide the brake torque when

the clutch is disengaged. Brake poles are not

present if the assembly is a clutch only.

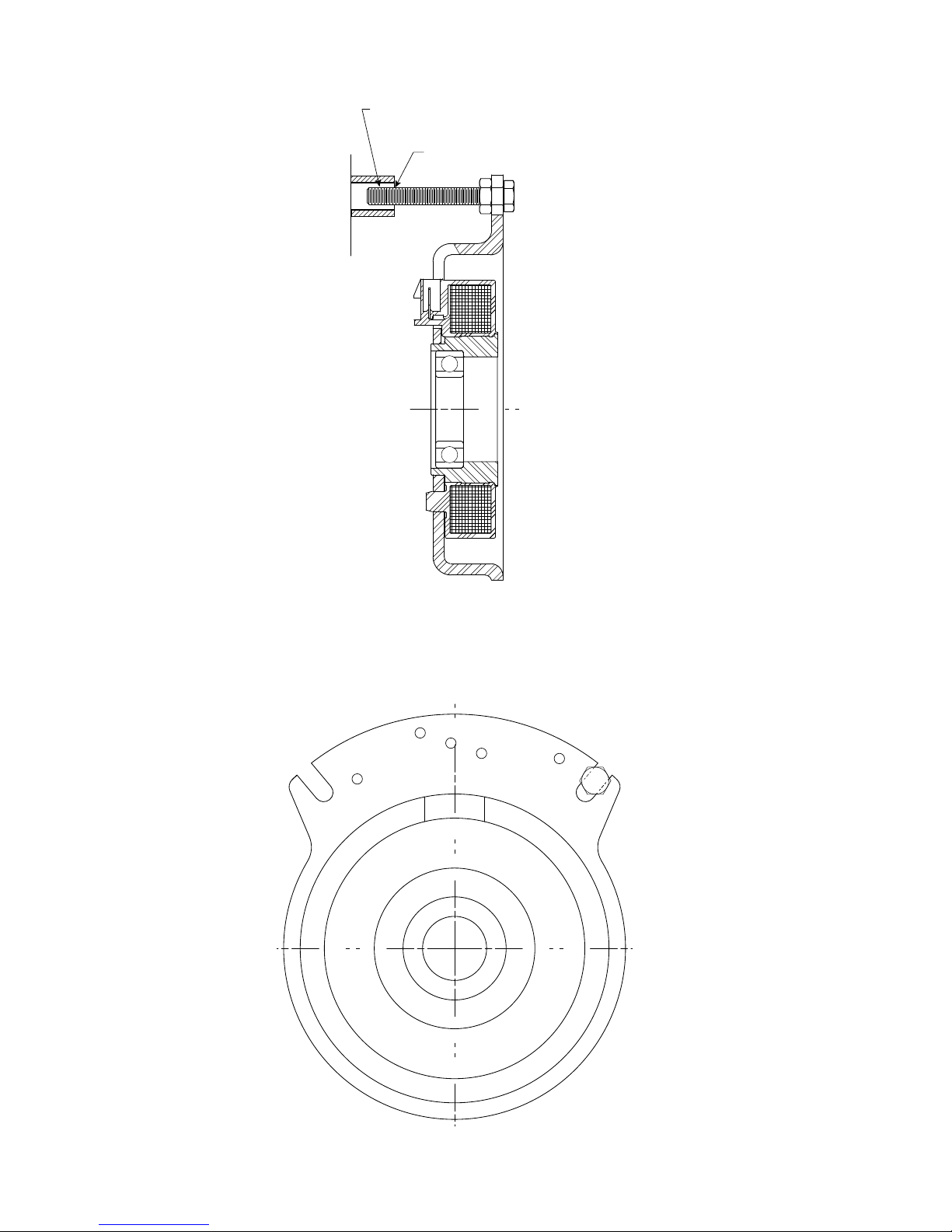

5. D-drive Spacer

A hub that is inserted into either armature or

field bearing (see Figure 2). The head has flats

that can be held with a wrench to prevent

rotation of the crankshaft when tightening

the mounting bolt (see Figure 5). This hub

also takes the place of the standard retaining

washer.

6. Anti-rotation Slot

Anti-rotation Slot (used with OEM’s anti-

rotation device) prevents MagStop from

rotation with crankshaft. If the field is bolted

rigidly or if its axial movement is restricted the

bearing in the field assembly will be improperly

loaded and may fail. Use OEM supplied anti-

rotation.

MagStop®Bearing Mounted Electric Clutch and Clutch/Brake Assemblies and Operation