Table of Contents

Safety 4

Safety Precautions 4

Introduction 5

Using this Document 5

Viewing the Document Electronically 5

Printing the Document 5

Additional Documentation 5

Symbols 5

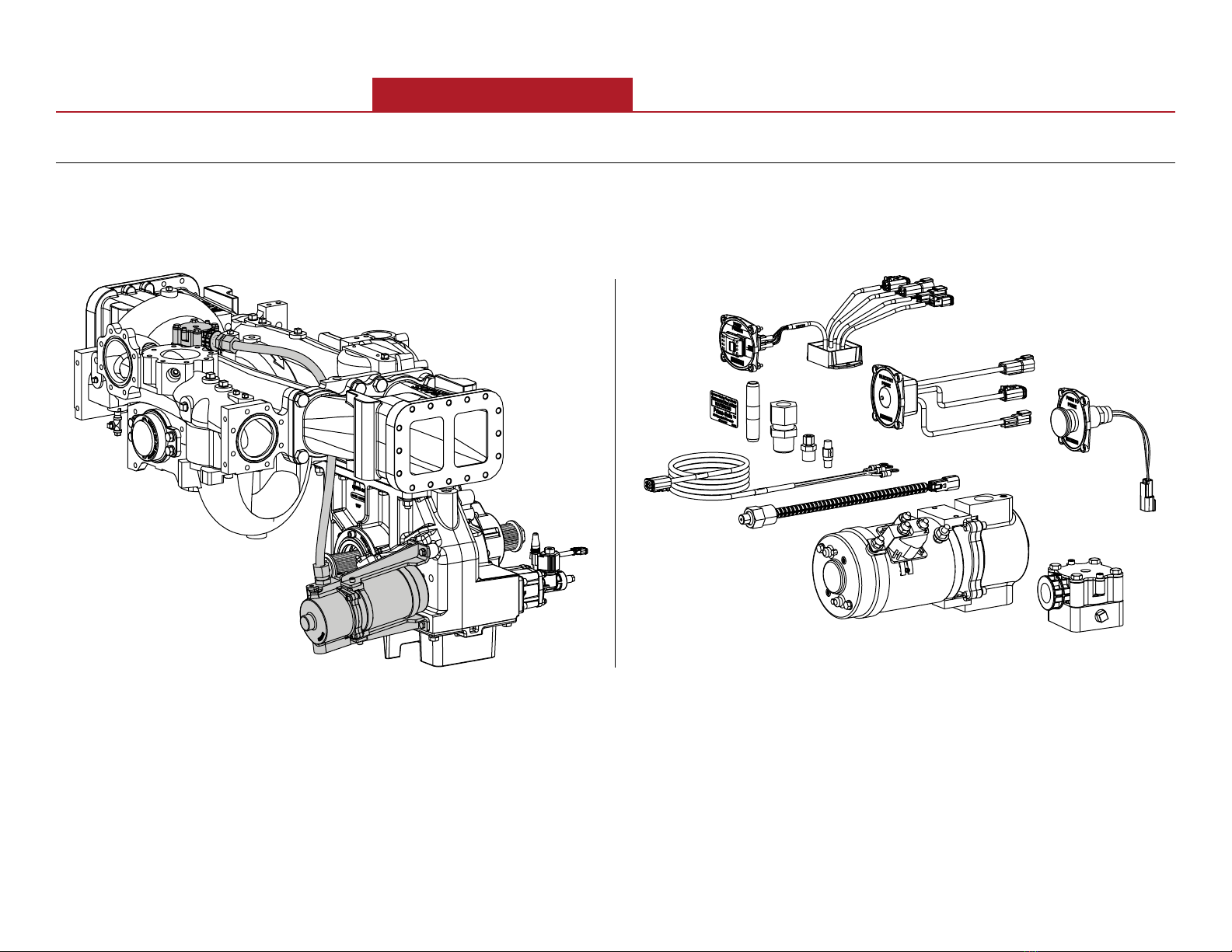

Product Overview 6

Congurations 6

Individually Installed Components 7

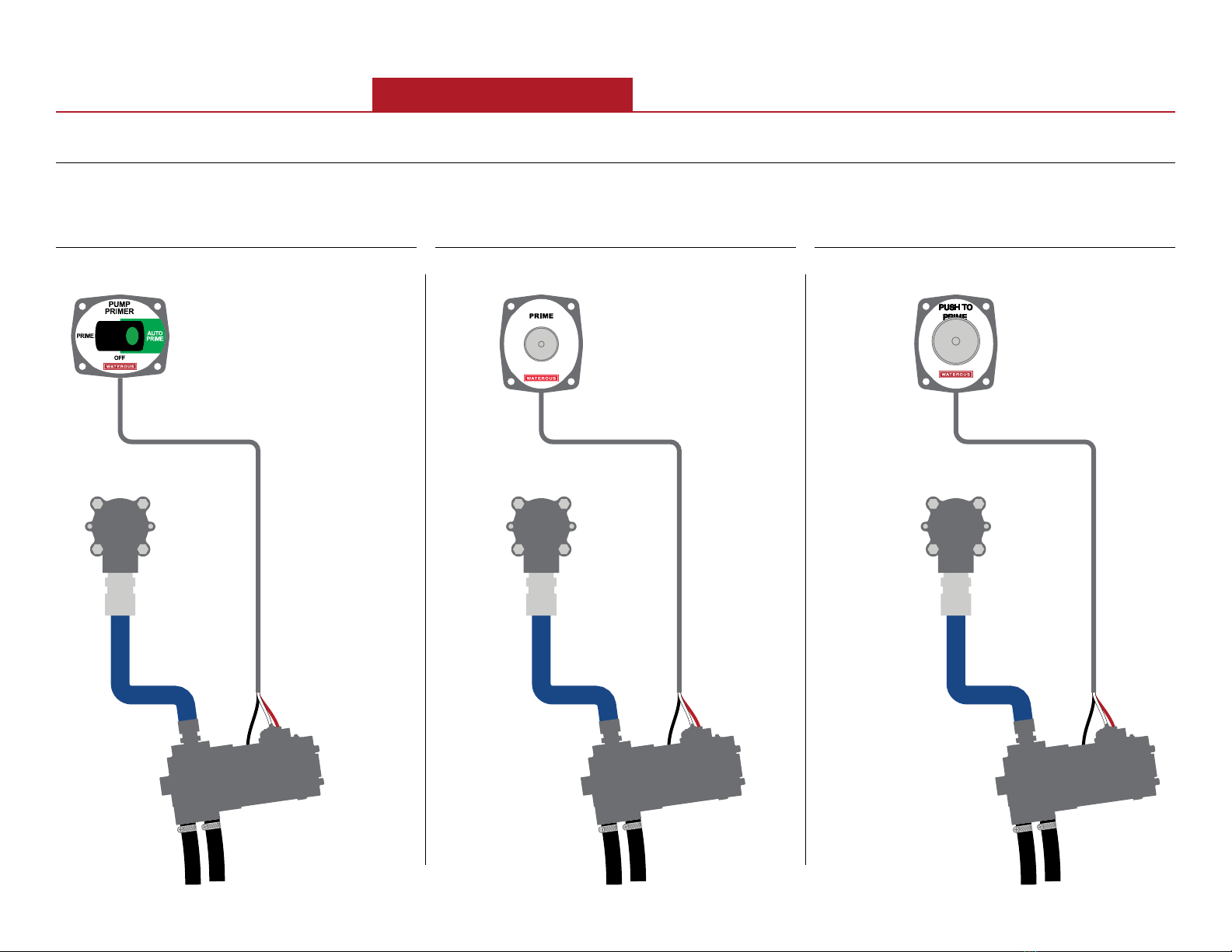

Panel Switch with Single Priming Pump

Overview 8

Auto-Prime Switch 8

Standard Push Button Switch 8

Oversized Push Button Switch 8

Multiple Priming Valve System Overview 9

Dual Priming Pump System Overview 10

Auto-Prime Switch 12

Standard Push Button Switch 14

Oversize Push Button Switch 15

Priming Pump—12V 16

Priming Pump—24V 17

Pressure Switch 18

Priming Valve Solenoid 19

Priming Valve 20

Priming Pump Cable 21

Priming Valve Solenoid Extension Cable 22

Extension Cable—Optional 23

Pressure Switch Extension Cable 24

Installation 25

Installation Overview 25

Determining Cable and Wire Routing 25

Preparing for the Installation 25

Optional Equipment 25

Hose and Tubing Requirements 25

Tubing 25

Hose 25

Determining the Installation Requirements 26

Installation Requirements 26

Auto-Prime Switch Cutout Dimensions 27

Standard Push Button Switch Dimensions 28

Oversized Push Button Switch Dimensions 29

Priming Pump Dimensions 30

Panel Cutout and Mounting Holes 31

Positioning the Switch 32

Mounting the Enclosure 33

Mounting the Panel 34

Installing the Standard Push Button Switch 35

Installing the Oversized Push Button Switch 36

Installing the Priming Pump 37

Installing the Priming Valve 38

Installing the Pressure Switch 39

Installing the Priming Valve Solenoid 40

Connecting to Apparatus Power 41

Priming Pump—12V 41

Priming Pump—24V 42

Dual Priming Pumps—12V 43

Dual Priming Pumps—24V 44

Connecting the Extension Cable 45

Priming Pump—12V 45

Priming Pump—24V 46

Dual Priming Pumps—12V 47

Dual Priming Pumps—24V 48

Connecting the Priming Components 49

Priming Pump and Priming Valve 49

Multiple Priming Valves 50

Dual Priming Pumps 51

Auto-Prime Push Button Switch 52

Standard Push Button Switch 53

Oversized Push Button Switch 54

Multiple Priming Valves 55

Multiple Priming Pumps 56

Priming the Pump—Auto-Prime Switch 57

Operation 58

Priming the Pump—Manual-Prime Switch 58

Maintenance 59

Maintenance Schedule 59

Vacuum Testing 59

Priming Valve 59

Priming Tank 59

Priming Pump 59