Waters ACQUITY UPLC I-Class Series Parts list manual

ACQUITY UPLC I-Class Series

System Guide

715005704

Revision A

Copyright © Waters Corporation 2018

All rights reserved

General information

Copyright notice

© 2018 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF AMERICA AND IN

IRELAND. ALL RIGHTS RESERVED. THIS DOCUMENT OR PARTS THEREOF MAY NOT BE

REPRODUCED IN ANY FORM WITHOUT THE WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and should not be construed

as a commitment by Waters Corporation. Waters Corporation assumes no responsibility for any

errors that may appear in this document. This document is believed to be complete and accurate

at the time of publication. In no event shall Waters Corporation be liable for incidental or

consequential damages in connection with, or arising from, its use. For the most recent revision

of this document, consult the Waters website (waters.com).

Trademarks

ACQUITY® is a registered trademark of Waters Corporation.

ACQUITY UPLC® is a registered trademark of Waters Corporation.

Analyst® is a registered trademark of Applied Biosystems/MDS Analytical Technologies.

Auto•Blend PlusTM is a trademark of Waters Corporation.

Connections INSIGHT® is a registered trademark of Waters Corporation.

eCordTM is a trademark of Waters Corporation.

Empower® is a registered trademark of Waters Corporation.

KEL-F® is a registered trademark of 3M.

Keps® is a registered trademark of Illinois Tool Works Inc.

LAC/ETM is a trademark of Waters Corporation.

MassLynx® is a registered trademark of Waters Corporation.

Millennium® is a registered trademark of Waters Corporation.

MP35NTM is a trademark of SPS Technologies Inc.

PharMed® is a registered trademark of Saint-Gobain Performance Plastics Corporation.

PHILLIPS® is a registered trademark of Phillips Screw Company.

April 4, 2018, 715005704 Rev. A

Page ii

PEEKTM is a trademark of Victrex PLC.

PEEKsilTM is a trademark of SGE Analytical Science Pty Ltd.

PIC® is a registered trademark of Waters Corporation.

Teflon® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates.

THE SCIENCE OF WHAT'S POSSIBLE® is a registered trademark of Waters Corporation.

TORX® is a registered trademark of Acument Intellectual Properties, LLC in the United States or

other countries.

TritonTM X-100 is a trademark of The Dow Chemical Company or an affiliated company of Dow.

TWEENTM is a trademark of ICI Americas Inc.

Tygon® is a registered trademark of Saint-Gobain Performance Plastics Corporation.

UPLC® is a registered trademark of Waters Corporation.

XBridge® is a registered trademark of Waters Corporation.

Waters® is a registered trademark of Waters Corporation.

All other trademarks are property of their respective owners.

Customer comments

Waters’ Customer Experience and Knowledge Management organization invites you to report any

errors that you encounter in this document or to suggest ideas for otherwise improving it. Help us

better understand what you expect from our documentation so that we can continuously improve

its accuracy and usability.

We seriously consider every customer comment we receive. You can reach us at

Contacting Waters

Contact Waters with enhancement requests or technical questions regarding the use,

transportation, removal, or disposal of any Waters product. You can reach us via the Internet,

telephone, fax, or conventional mail.

April 4, 2018, 715005704 Rev. A

Page iii

Waters contact information

Contacting medium Information

Internet The Waters Web site includes contact information for Waters locations

worldwide.

Visit www.waters.com

Telephone and fax From the USA or Canada, phone 800-252-4752, or fax 508-872-1990.

For other locations worldwide, phone and fax numbers appear in the

Waters Web site.

Conventional mail Waters Corporation

Global Support Services

34 Maple Street

Milford, MA 01757

USA

Safety considerations

Some reagents and samples used with Waters instruments and devices can pose chemical,

biological, or radiological hazards (or any combination thereof). You must know the potentially

hazardous effects of all substances you work with. Always follow Good Laboratory Practice

(GLP), and consult your organization’s standard operating procedures as well as your local

requirements for safety.

System height

Warning: To avoid injury, do not stack modules, including the solvent tray and rails,

higher than one meter (39.4 inches) above the bench top.

Warning: To avoid spinal and muscular injury, do not attempt to lift a system module

without assistance.

Warning: To avoid crushing your fingers beneath or between modules, use extreme

care when installing a module in the system stack.

Safety hazard symbol notice

Documentation needs to be consulted in all cases where the symbol is used to find out the

nature of the potential hazard and any actions which have to be taken.

April 4, 2018, 715005704 Rev. A

Page iv

Power cord replacement hazard

Warning: To avoid electric shock, use SVT-type power cords in the United States and

HAR-type (or better) cords in Europe. The power cords must be replaced only with ones

of adequate rating. For information regarding which cord to use in other countries,

contact your local Waters distributor.

Hand crush hazard

Warning: To avoid hazards associated with the reciprocating or rotating parts in the

source, keep hands clear of the regions marked with yellow and gray labels.

High voltage hazard

Warning: To avoid electric shock, do not remove protective panels from system

modules. The components within are not user-serviceable.

Bottle placement prohibition

Warning: To avoid injury from electrical shock or fire, and damage to the equipment, follow

these guidelines:

• Do not expose the workstation or ancillary equipment to dripping or splashing liquids.

• Do not place objects filled with liquid, such as solvent bottles, on top of the workstation or

ancillary equipment.

FCC radiation emissions notice

Changes or modifications not expressly approved by the party responsible for compliance, could

void the user's authority to operate the equipment. This device complies with Part 15 of the FCC

Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

Electrical power safety notice

Do not position the device so that it is difficult to disconnect the power cord.

April 4, 2018, 715005704 Rev. A

Page v

Equipment misuse notice

If equipment is used in a manner not specified by its manufacturer, protections against personal

injury inherent in the equipment’s design can be rendered ineffective.

Safety advisories

Consult the "Safety advisories" appendix in this publication for a comprehensive list of warning

advisories and notices.

Operating the system

When operating the system, follow standard quality-control (QC) procedures and the guidelines

presented in this section.

Applicable symbols

The following symbols can be present on the device, system, or packaging.

Symbol Definition

Manufacturer

Date of manufacture

Authorized representative of the European Community

Confirms that a manufactured product complies with all applicable

European Community directives

or

Australia EMC compliant

Confirms that a manufactured product complies with all applicable United

States and Canadian safety requirements

Consult instructions for use

Alternating current

April 4, 2018, 715005704 Rev. A

Page vi

Symbol Definition

Electrical and electronic equipment with this symbol may contain

hazardous substances and should not be disposed of as general waste.

For compliance with the Waste Electrical and Electronic Equipment

Directive (WEEE) 2012/19/EU, contact Waters Corporation for the correct

disposal and recycling instructions.

Serial number

REF

Part number, catalog number

Audience and purpose

This guide is intended for personnel who operate and maintain the ACQUITY UPLC I-Class

Series system. The term "Series" refers to both the latest generation ("PLUS") and previous

generations of I-Class systems. It gives an overview of the system’s technology and operation.

Intended use of the ACQUITY UPLC I-Class Series system

Waters designed the ACQUITY UPLC I-Class Series system to perform chromatographic

separations. The system is for research use only and is not intended for use in diagnostic

applications.

Calibrating

To calibrate LC systems, adopt acceptable calibration methods using at least five standards to

generate a standard curve. The concentration range for standards must include the entire range

of QC samples, typical specimens, and atypical specimens.

When calibrating mass spectrometers, consult the calibration section of the operator’s guide for

the instrument you are calibrating. In cases where an overview and maintenance guide, not an

operator’s guide, accompanies the instrument, consult the system guide or the instrument’s

online Help system for calibration instructions.

Quality control

Routinely run three QC samples that represent subnormal, normal, and above-normal levels of a

compound. If sample trays are the same or very similar, vary the location of the QC samples in

the trays. Ensure that QC sample results fall within an acceptable range, and evaluate precision

April 4, 2018, 715005704 Rev. A

Page vii

from day to day and run to run. Data collected when QC samples are out of range might not be

valid. Do not report these data until you are certain that the instrument performs satisfactorily.

ISM classification: ISM group 1 class B

This classification has been assigned in accordance with CISPR 11 Industrial Scientific and

Medical (ISM) instrument requirements.

Group 1 products apply to intentionally generated and/or used conductively coupled radio-

frequency energy that is necessary for the internal functioning of the equipment.

Class B products are suitable for use in both commercial and residential locations and can be

directly connected to a low voltage, power-supply network.

EC authorized representative

Address Waters Corporation

Stamford Avenue

Altrincham Road

Wilmslow SK9 4AX UK

Telephone +44-161-946-2400

Fax +44-161-946-2480

Contact Quality manager

April 4, 2018, 715005704 Rev. A

Page viii

Table of contents

General information .......................................................................................................ii

Copyright notice ..................................................................................................................................... ii

Trademarks............................................................................................................................................ ii

Customer comments..............................................................................................................................iii

Contacting Waters .................................................................................................................................iii

Safety considerations............................................................................................................................ iv

System height................................................................................................................................. iv

Safety hazard symbol notice .......................................................................................................... iv

Power cord replacement hazard...................................................................................................... v

Hand crush hazard .......................................................................................................................... v

High voltage hazard......................................................................................................................... v

Bottle placement prohibition ............................................................................................................ v

FCC radiation emissions notice....................................................................................................... v

Electrical power safety notice.......................................................................................................... v

Equipment misuse notice ............................................................................................................... vi

Safety advisories ............................................................................................................................ vi

Operating the system............................................................................................................................ vi

Applicable symbols......................................................................................................................... vi

Audience and purpose....................................................................................................................vii

Intended use of the ACQUITY UPLC I-Class Series system .........................................................vii

Calibrating ......................................................................................................................................vii

Quality control.................................................................................................................................vii

ISM classification: ISM group 1 class B ...............................................................................................viii

EC authorized representative ..............................................................................................................viii

1 ACQUITY UPLC I-Class Series System ..................................................................13

1.1 UPLC technology ..........................................................................................................................13

1.2 Features of the ACQUITY UPLC I-Class Series system...............................................................15

1.3 Binary solvent manager ................................................................................................................16

1.4 Column compartments ..................................................................................................................16

1.5 Injector mechanisms .....................................................................................................................16

April 4, 2018, 715005704 Rev. A

Page ix

1.6 Mass spectrometry........................................................................................................................17

1.7 System components......................................................................................................................17

1.7.1 Binary solvent manager (BSM)............................................................................................18

1.7.2 Sample manager-FTN (SM-FTN) ........................................................................................18

1.7.3 Sample manager-FL (SM-FL)..............................................................................................19

1.7.4 Column heater (CH-A).........................................................................................................19

1.7.5 30-cm Column heater (optional) ..........................................................................................19

1.7.6 Column manager (optional) .................................................................................................20

1.7.7 Column heater/cooler (optional) ..........................................................................................20

1.7.8 Column Module Switch Box (optional).................................................................................20

1.7.9 Sample organizer (optional).................................................................................................21

1.7.10 FlexCart (optional) .............................................................................................................21

1.7.11 Column technology............................................................................................................21

1.7.12 Detection............................................................................................................................22

1.8 For additional information..............................................................................................................22

2 Performance optimization........................................................................................24

2.1 General guidelines ........................................................................................................................24

2.2 Dispersion .....................................................................................................................................25

2.3 Carryover ......................................................................................................................................26

2.4 Contamination ...............................................................................................................................26

2.5 Reproducibility...............................................................................................................................26

2.6 Cycle time (between injections) ....................................................................................................27

2.7 Preventing leaks............................................................................................................................27

2.7.1 Installation recommendations for fittings .............................................................................27

2.8 Sample preparation.......................................................................................................................41

2.8.1 Particulates..........................................................................................................................41

2.8.2 Matching sample diluents ....................................................................................................41

2.9 Solvent recommendations.............................................................................................................41

3 System preparation ..................................................................................................42

3.1 Powering-on the system................................................................................................................42

3.2 Opening the console .....................................................................................................................43

April 4, 2018, 715005704 Rev. A

Page x

3.2.1 To open the console from Empower software .....................................................................43

3.2.2 To open the console from MassLynx software ....................................................................43

3.2.3 To open the console from UNIFI software...........................................................................43

3.3 Preparing system hardware ..........................................................................................................44

3.3.1 Powering-on the system ......................................................................................................44

3.3.2 Monitoring module LEDs .....................................................................................................45

3.3.3 Power LED...........................................................................................................................45

3.3.4 Status LEDs.........................................................................................................................45

3.3.5 Enabling the leak sensors....................................................................................................47

3.3.6 Priming a wetted binary solvent manager ...........................................................................47

3.4 Priming the system........................................................................................................................48

3.5 Monitoring from control panels......................................................................................................48

3.5.1 Binary solvent manager control panel .................................................................................49

3.5.2 Sample manager control panel............................................................................................50

3.5.3 TUV control panel................................................................................................................51

3.5.4 Column manager control panel............................................................................................52

A External connections...............................................................................................54

A.1 Ethernet connections ....................................................................................................................54

A.2 Column heater connection............................................................................................................54

A.3 External cable connections...........................................................................................................56

A.4 Plumbing connections...................................................................................................................57

A.5 Waste-tubing connections ............................................................................................................59

A.6 Connecting to a wall electricity source..........................................................................................60

A.7 Connecting signal cables..............................................................................................................61

A.7.1 Binary solvent manager I/O signal connectors....................................................................63

A.7.2 Sample manager I/O signal connectors ..............................................................................65

A.7.3 TUV detector signal connectors ..........................................................................................66

A.7.4 PDA detector signal connectors..........................................................................................66

A.8 Connecting to a column module ...................................................................................................67

B Safety advisories .....................................................................................................68

B.1 Warning symbols ..........................................................................................................................68

B.1.1 Specific warnings ................................................................................................................69

April 4, 2018, 715005704 Rev. A

Page xi

B.2 Caution advisory ...........................................................................................................................71

B.3 Warnings that apply to all Waters instruments and devices ......................................................... 71

B.4 Electrical and handling symbols ...................................................................................................76

B.4.1 Electrical symbols................................................................................................................76

B.4.2 Handling symbols................................................................................................................76

B.5 Stacking system modules with interlocking features ....................................................................77

B.6 Stacking system modules without interlocking features ...............................................................78

April 4, 2018, 715005704 Rev. A

Page xii

1ACQUITY UPLC I-Class Series

System

Waters designed the ACQUITY UPLC I-Class Series system for optimum performance when

running difficult assays. Configure it with a mass spectrometer to take full advantage of the

system’s design enhancements.

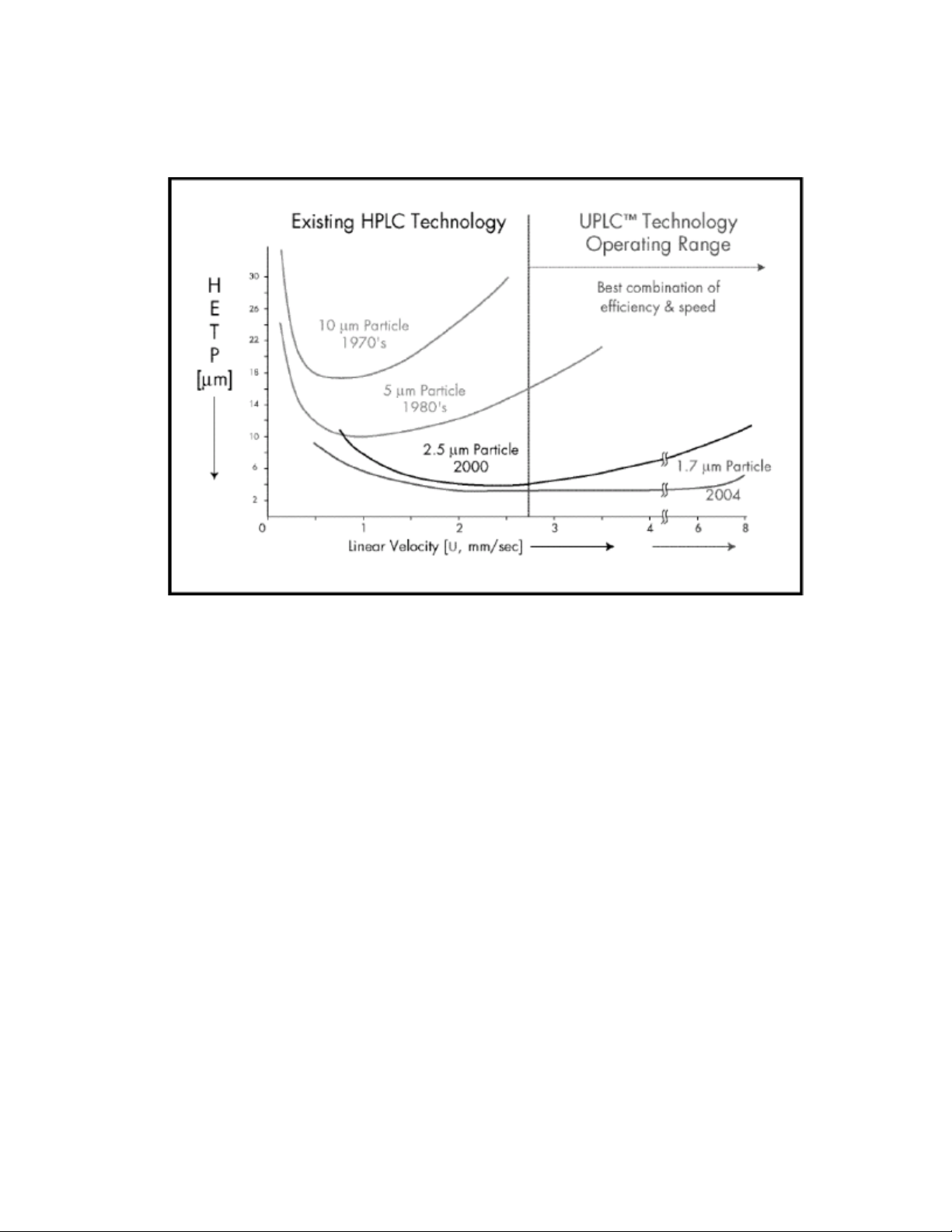

1.1 UPLC technology

In 2004, Waters made significant advances in instrumentation and column design to introduce

UPLC technology to the field of separation science. By employing this technology, Waters’

ACQUITY UPLC systems achieve a marked increase in resolution, speed and sensitivity in liquid

chromatography when compared to conventional systems.

UPLC technology is based on columns packed with 1.7 µm-diameter, spherical particles coupled

with low dispersion systems, allowing you to realize the full separation potential of these highly

efficient columns.

April 4, 2018, 715005704 Rev. A

Page 13

Figure 1–1: Evolution of particle size in liquid chromatography and the impact on

separation efficiency

It is apparent from the figure, above, that using 1.7-µm particles achieves higher efficiency that

persists as flow rate increases (lower HETP indicates higher efficiency). When operating in this

area of the plot, the peak capacity and the speed of a separation can set limits well beyond those

of conventional HPLC technology.

April 4, 2018, 715005704 Rev. A

Page 14

Figure 1–2: Comparison of chromatographic separations using 5.0-µm and 1.7-µm

particles

The figure above compares two separations, one using HPLC with a column packed with 5 µm

particles, and the other using UPLC with a column packed with 1.7 µm particles. The

improvements in both resolution and the speed of analysis are apparent in the UPLC

chromatogram. Each separation was performed on a 2.1 × 50 mm column. Chromatographic

conditions for the separations were identical, except for the flow rate, which was scaled based on

particle size.

1.2 Features of the ACQUITY UPLC I-Class Series system

The ACQUITY UPLC I-Class Series system significantly improves the results of traditionally

challenging separations.

When compared to systems typically used for difficult assays, the I-Class Series system offers

these advantages:

• Significantly decreased system dispersion

• Rapid injection cycles and sample throughput

• Greatly reduced carryover

These advantages provide the following benefits over traditional systems:

April 4, 2018, 715005704 Rev. A

Page 15

• Superior peak capacity

• Higher sensitivity

• Faster data acquisition

• Consistent, reproducible results

The I-Class Series system is an effective tool for analyzing complex or dilute samples, providing

high resolution and reproducible results for chromatographic separations.

1.3 Binary solvent manager

The ACQUITY UPLC I-Class Series system employs a binary solvent manager that, like the

system, is optimized for sub-2-μm particle liquid chromatography and uses reduced fluid

volumes. New pressure management capabilities extend the flow rate envelope for the system to

support ballistic gradients. This support enables you to run higher flow rates and faster cycle

times to accelerate your chromatography, while maintaining the integrity of the separation.

1.4 Column compartments

Column compartments configured with ACQUITY UPLC I-Class Series systems ensure reliable

and robust separations. This is especially important when you transfer methods to other systems.

UPLC applications can benefit from pre-column, mobile-phase heating to improve

chromatographic separations.

The ACQUITY UPLC I-Class Series column compartments use an active preheater to condition

solvent as it enters the column. The preheater is a heat source that raises the temperature of the

incoming mobile phase and injected sample to the same set point as that of the column

compartment. Active solvent preheaters provide precise thermal performance with low dispersion

for exact control of chromatographic conditions that remain consistent between systems.

1.5 Injector mechanisms

ACQUITY UPLC I-Class Series system configurations include a sample manager with either a

fixed-loop or flow through needle injector mechanism. This flexibility allows you to choose the

optimum injector mechanism for your application. Both mechanisms provide high precision with

low dispersion and efficient sample recovery. The low carryover performance of the injector

mechanisms, which enables you to use a wider sample concentration range, is also beneficial for

mass spectrometry applications.

April 4, 2018, 715005704 Rev. A

Page 16

1.6 Mass spectrometry

When you configure an ACQUITY UPLC I-Class Series system with a mass spectrometer, the

system’s design enhancements enable you to separate more peaks with better peak shapes to

aid quantitation. You also benefit from improvements in sensitivity and flexibility.

See also: Waters.com for more information on compatible Waters mass spectrometers.

1.7 System components

The following illustration depicts a system stack that includes four core modules and the solvent

bottle tray.

Figure 1–3: Example of an I-Class Series system core stack

Solvent bottle tray

Detector

April 4, 2018, 715005704 Rev. A

Page 17

Column heater

Sample manager

Binary solvent manager

The ACQUITY UPLC I-Class Series core system includes a binary solvent manager, a sample

manager - flow through needle or sample manager - fixed loop (SM-FTN or SM-FL), a column

heater (CH-A), detectors (tunable ultraviolet, photodiode array, eλ photodiode array, or mass

spectrometry), and an ACQUITY UPLC column.

Waters Empower chromatography data software, MassLynx mass spectrometry software, stand-

alone ACQUITY UPLC Console software, or Analyst software controls the system.

1.7.1 Binary solvent manager (BSM)

The Waters ACQUITY UPLC I-Class Series binary solvent manager (BSM) delivers solvent

compositions for isocratic and binary gradient methods at flow rates of 0.01 to 2.0 mL per minute.

Its features include in-line filters upstream of a primary check valve, the Waters Intelligent Intake

Valve (i2Valve), automated priming functions, and daily system-setup routines.

The design of the binary solvent manager is optimized for sub-2-μm particle liquid

chromatography. The upper pressure limit is set at 124,106 kPa (1241 bar, 18,000 psi) per pump.

A maximum flow rate of 1 mL/min is permitted at system backpressures to 124,106 kPa (1241

bar, 18,000 psi), which falls within the range of optimal linear velocity for sub-2-μm particle

columns of ID 1.0 mm to 3.0 mm.

See also: ACQUITY UPLC Binary Solvent Manager PLUS Overview and Maintenance Guide on

your documentation media, or at Waters.com, for more details.

Note: An optional degasser vent line extension exists for applications requiring longer tubing

lengths. For more information, contact your local Waters distributor.

1.7.2 Sample manager-FTN (SM-FTN)

The ACQUITY UPLC I-Class Series sample manager - flow through needle (SM-FTN) differs

from a loop-based injector. The mechanism aspirates a sample from plates and vials and holds it

in the sample needle in preparation for injecting the sample onto the column. The needle serves

as part of the injection flow path when the sample is pushed onto the column.

Optional extension loops (installed between the sample needle and the injection valve) can

increase the injection volume beyond that of the sample needle. The SM-FTN can also dilute

samples using the auto-dilution option.

Using the flow through needle (FTN) mechanism, the system operates similarly to most traditional

HPLC systems, which facilitate the transfer of HPLC methods. The FTN mechanism also does

not require you to learn new injection modes. Also, it achieves injection accuracy and decreases

April 4, 2018, 715005704 Rev. A

Page 18

cycle time for small volume injections. Gradients pass through the needle during injection,

ensuring complete sample recovery.

1.7.3 Sample manager-FL (SM-FL)

The sample manager - fixed loop (SM-FL) uses a loop-based mechanism to inject samples. After

a puncture needle pierces the well or vial covering, a sample needle emerges from within the

puncture needle to aspirate the sample. In the partial loop needle overfill injection mode (default),

the sample needle is then removed from the vial and the sample syringe continues to pull the

sample aliquot through the sample needle and through the injection valve until any pre-sample

and the sample injection volume pass through the injection valve. The valve actuates, switching

the sample loop to the load position. The sample is pushed back toward the needle and the

sample volume is then pushed into the sample loop. The sample loop is moved to the injection

position and flow from the pump pushes the sample onto the column.

See also: ACQUITY UPLC Sample Manager - Fixed Loop PLUS Overview and Maintenance

Guide on your documentation media, or at Waters.com, for more information on other injection

modes.

1.7.4 Column heater (CH-A)

Column temperature variations can shift peak retention times and alter peak shapes, increasing

the difficulty of achieving precise results. The ACQUITY UPLC I-Class Series system’s column

heater (CH-A) helps to ensure precise, reproducible separations by controlling the column

temperature. The CH-A heats the column compartment to any temperature from 20 ºC to 90 ºC,

that is at least 5 °C above the ambient temperature. A low dispersion, active preheating device

heats the incoming solvent before it enters the column. The column compartment can

accommodate columns of up to 4.6-mm I.D. and up to 150-mm length.

1.7.5 30-cm Column heater (optional)

The optional 30-cm column heater (CH-30A) heats the column compartment to any temperature,

from 20 ºC to 90 ºC, that is at least 5 ºC above the ambient temperature. The CH-30A mounts on

the side of the system stack.

The CH-30A can accommodate UPLC columns of 4.6 mm, or less, ID and 150 mm, or less,

length and HPLC columns of 4.6 mm, or less, ID and 300 mm, or less, length. For columns that

exceed 4.6 mm ID, use the ACQUITY UPLC 30-cm column heater/cooler (30cm CHC) with the

appropriate compatibility kit.

Note: The ACQUITY UPLC 30cm CHC is compatible with ACQUITY UPLC I-Class Series

systems. See ACQUITY UPLC Column Compartments Operator's Overview and Maintenance

Information on your documentation media, or at Waters.com, for details.

April 4, 2018, 715005704 Rev. A

Page 19

1.7.6 Column manager (optional)

The ACQUITY UPLC I-Class Series column manager (CM-A) is an option for helping to ensure

precise, reproducible separations. The CM-A can regulate the temperature of columns from 4 °C

to 90 °C. Its troughs can accommodate columns of up to 4.6-mm I.D. and up to 150-mm length,

depending on the configuration. Each of the two column troughs can hold one column, up to 150

mm in length (with filter or guard column). The CM-A also offers a bypass channel and

automated, programmable switching between columns (for methods development), and is

installed with two column switching valves.

Restriction: The minimum achievable column compartment temperature set point must not be

greater than 25 °C below the ambient temperature.

Tip: You can use the CM-A for column switching and two-dimensional chromatography

applications. For information about two-dimensional applications, consult the ACQUITY UPLC

Systems with 2D Technology Capabilities Guide.

1.7.7 Column heater/cooler (optional)

The 30-cm column heater/cooler (CHC) module compartment temperature is settable from 4.0 to

65.0 ºC, in 0.1 ºC increments. Compartment controllable temperatures range from 15 ºC below

ambient to 65.0 ºC.

The 30-cm CHC module shares many of the same components with the 30-cm CH module,

except for a thermoelectric engine for heating and cooling, and an additional fan for exhausting

engine heat. In addition, the 30-cm CHC module incorporates an internal onboard power supply,

external power-entry module, and power on/off switch. The power supply is necessary for

additional power required to operate the thermoelectric heater/cooler engine circuit. Additionally,

the 30-cm CHC module is fitted with a standard, passive preheater module and supports the

optional 3-position column-selection valve.

Restriction: You cannot use the 30-cm CHC module's passive preheater simultaneously with

the optional column-selection valve.

1.7.8 Column Module Switch Box (optional)

With the optional Waters Column Module Switch Box, you can physically connect a column

heater (CH-A) and a 30-cm column module (either a CH-30A or a 30-cm CHC) to the sample

manager - flow-through-needle (SM-FTN) and switch the electrical control of the column modules

via the SM-FTN console.

The switch box is mounted to the rear of the SM-FTN. The SM-FTN interconnect cable is

connected to the sample manager (SM) port of the switch box, the CH-A interconnect cable is

connected to the CH-A port, and either the CH-30A or the 30-cm CHC interconnect cable is

connected to the 30-cm port.

April 4, 2018, 715005704 Rev. A

Page 20

Table of contents

Other Waters Water System manuals

Popular Water System manuals by other brands

Wilo

Wilo Stratos PICO Installation and operating instructions

Sears

Sears 390.250095 owner's manual

Cetetherm

Cetetherm Midi Compact SR144 Installation, service and operating instruction

Halsey Taylor

Halsey Taylor HVRGRN8WSNF 1B Series Installation, care & use manual

Hellenbrand

Hellenbrand ProMate 6.5 brochure

Grundfos

Grundfos UPSe instructions

salmson

salmson C1000N Installation and starting instructions

WaterLogic

WaterLogic 12-WL200CT manual

Barnstead International

Barnstead International NANOpure DIamond 1192 Series Operation manual

SIGELOCK

SIGELOCK SPARTAN Operation and maintenance guide

Cuno

Cuno SQC Series owner's manual

Istore

Istore 180L installation manual