PRODUCT SUPPORT 800.927.2120 8am - 6pm EST

UNIVERSAL

1/2" THERMOSTATIC VALVE INSTALLATION GUIDELINES

Page 1 of 3

6.13.2014

These guidelines have been prepared for the professional contractor to aid in the installation of:

UNIVERSAL 1/2" THERMOSTATIC VALVE STYLE NO. GUTH56, GU56TH (UK)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

Style No. GUTH56†

Code No. GUSV56R

SPECIFICATIONS:

Fitting Hole Diameter Ø4-1/2" (Ø 114mm)*

Inlet/Outlet Connection

Size & Type:

1/2" Female NPT†

Recommended Water

Pressure:

45 psi (3 Bar)

Unrestricted Maximum

Flow Rate:

7gpm @ 45 psi

(26 L/min @ 3 Bar)

Valve Material: Wax Element

Water Pressure: 20 psi MIN - 80psi MAX

(1.4 Bar Min - 5.5 Bar Max)

* Ø4-1/2" (Ø 114mm) hole is required for servicing.

†UK Style No. GU56TH supplied with 4 BSP Adapters,

assembly required.

IMPORTANT:

¾To ensure this product is installed properly, you

must read and follow these guidelines.

¾The owner/user of this product must keep this

information for future reference.

¾This valve includes integrated service stops. Make

sure the tile guard is in place.

¾This valve features anti-scald protection. The risk of

scalding exists until the installer had properly

calibrated/adjusted the temperature setting during

final trim installation.

¾This product must be installed by a professional

licensed contractor.

¾Check local building and plumbing codes to ensure

that your installation conforms to all applicable

requirements. In the State of Massachusetts, all

installations must comply with the rules and

regulations set forth within 248 CMR.

¾Supply fittings are designed in accordance with

pressure and temperature ratings specified in ASME

A112.18.1/B125.

¾DO NOT APPLY DIRECT HEAT TO THE VALVE. Pre-

solder any connections to prevent damage to the

cartridge and service stop seals.

¾The trim should be on-site prior to rough in and

allows the installer to visualize the installation.

¾This thermostatic valve only mixes hot and cold

water and does not have volume control or shut off

capability. A diverter or wall valves (SOLD

SEPARATELY) control on/off/volume and must be

installed for each fitting that will have water flowing

to it. This valve cannot be used with a diverting tub

spout.

¾Insure that the hot and cold supply lines are

connected to the valve according to the markings

on the valve body: NO INVERSE CARTRIDGE IS

AVAILABLE.

¾Inspect this product to assure you have all parts

shown that are required for proper installation.

¾Check incoming water pressure.

¾If valve is going to remain unused for an extended

period of time (over 3 months), then the water to

the valve should be shut off (via service stops or

system control valve) and the volume control valves

should be opened to allow the water in the

thermostatic valve to evaporate. This is to keep the

cartridge from being exposed to stagnant or hard

water, which can cause the valve to malfunction.

¾It is recommended to flush the supply lines prior to

valve installation.

ROUGH-IN:

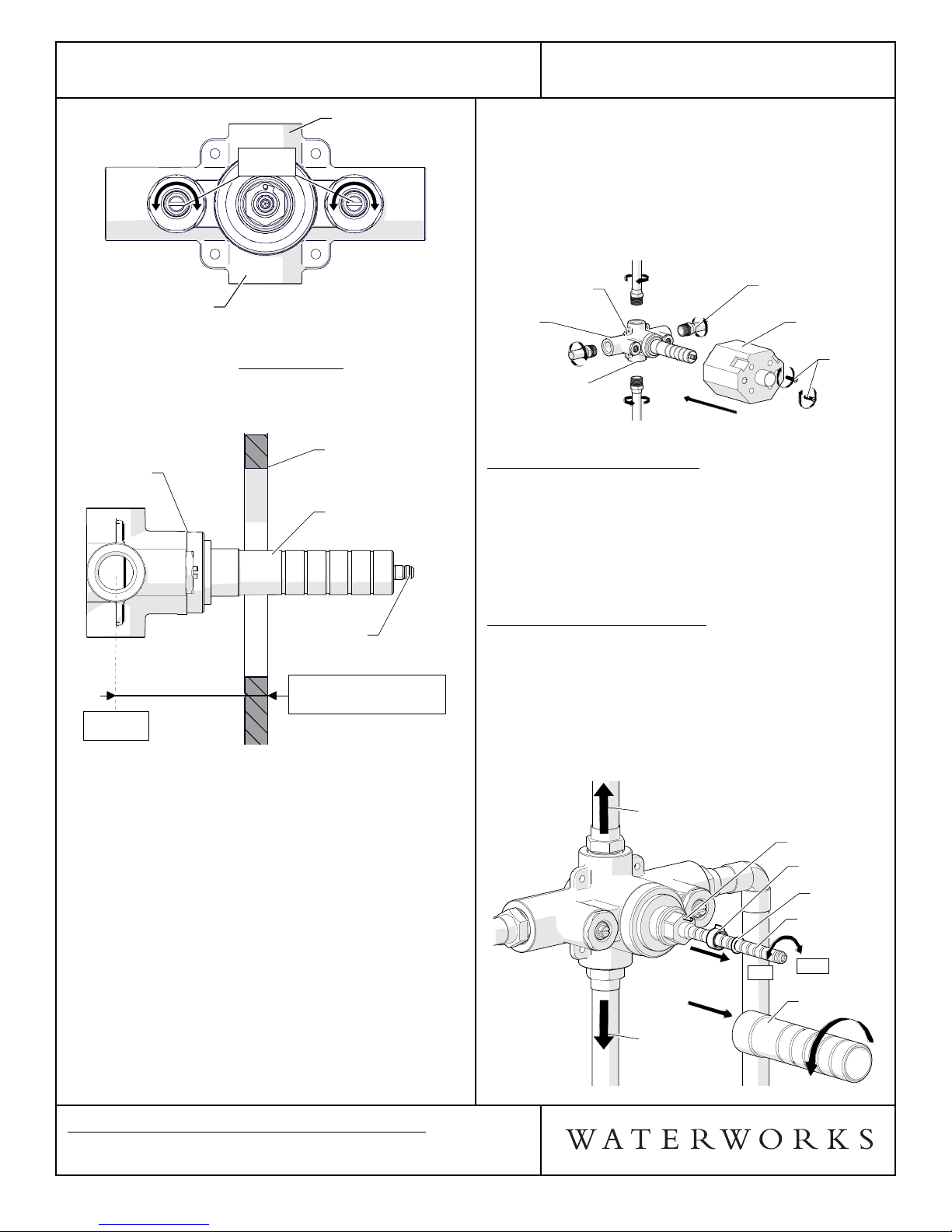

1. Remove TILE GUARD from VALVE BODY by

unthreading the SCREWS, as shown in Figure - 01.

VALVE

BODY

TILE

GUARD

SCREWS

VALVE

BODY

TILE

GUARD

SCREWS

FIGURE - 01

2. Make sure the valve body is positioned according to

valve markings so the inlets are situated with hot

piped on the left and cold piped on the right. Turn

the service stops to the right to close and to the left

to open. See Figure - 02.