MP sava3 User manual

Technical Manual

V700 –11/2017

MTMECMPsava3_700_EN

Installation • Assembly • Start-Up

Use • Maintenance • Repair

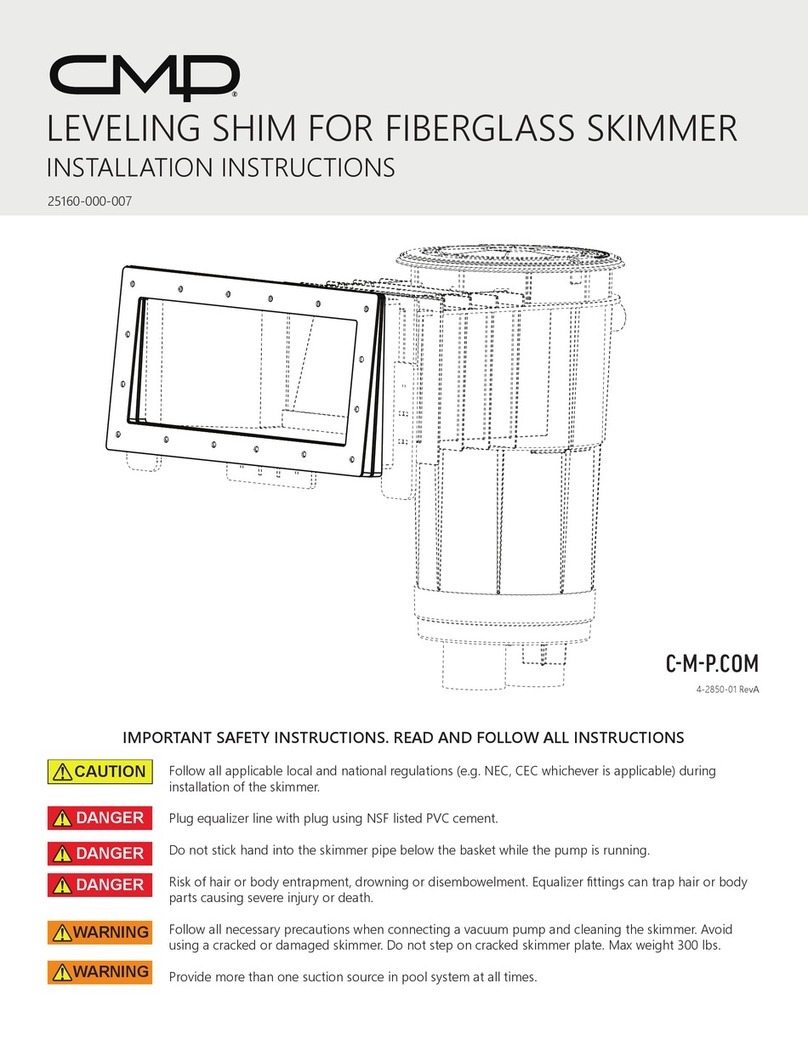

HYDRAULIC POWER UNIT 1 ¼” 1 ½”

MP sava3

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

2/40

MTMECMPsava3_700_EN

SUMMARY OF MODIFICATIONS IN REGARD WITH THE PREVIOUS VERSION:

INDEX

SECTION

DESCRIPTION OF THE

MODIFICATION

MODIFICATION CONCERNING

Physical

Product

Functions

Features

Figures

Writing

8.

The “Pressure test” for

commissioning as per

standards

EN 81-2 and EN 81-20 has

been inserted

MTHDsava3_600

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

3/40

MTMECMPsava3_700_EN

TABLE OF CONTENTS

0 •INDIVIDUAL PROTECTION EQUIPMENT ....................................................................................................................................................................................4

1 •HYDRAULIC POWER UNIT...........................................................................................................................................................................................................4

1.1. Mechanical assembly..................................................................................................................................................................................................................4

1.2. Types of pipe couplings...............................................................................................................................................................................................................5

1.3. Process for joining steel pipes ....................................................................................................................................................................................................5

1.4. Steel pipes and flexible hoses.....................................................................................................................................................................................................6

1.5. Rupture valve ..............................................................................................................................................................................................................................6

1.6. Electrical connections for 3-phase motors ¡Error! Marcador no definido. ..................................................................................................................................7

1.7. Sart-up.........................................................................................................................................................................................................................................8

2 •BLOCK OF VALVES .....................................................................................................................................................................................................................8

2.1. MP sava3 Valve Block according to 2014/33/EU European Standard.......................................................................................................................................9

2.1.1. Description of valves.............................................................................................................................................................................................................9

2.1.2. Unit operation .......................................................................................................................................................................................................................9

2.1.3. Hydraulic circuit MP sava3 Valve Block with Soft-Stop according to European Directive 2014/33/EU ............................................................................10

2.1.4. Adjustment of Valves..........................................................................................................................................................................................................11

2.1.5. Testings ..............................................................................................................................................................................................................................12

2.2. MP sava3 Valve Block...............................................................................................................................................................................................................14

2.2.1. Description of Valves..........................................................................................................................................................................................................14

2.2.2. Unit operation .....................................................................................................................................................................................................................14

2.2.3. Hydraulic circuit (Valid for Standard and Y- D configurations).........................................................................................................................................15

2.2.4. Valve adjustment................................................................................................................................................................................................................15

2.3. MP sava3 Valve Block SOFT-STOP.........................................................................................................................................................................................16

2.3.1. Description of Valves..........................................................................................................................................................................................................16

2.3.2. Unit operation .....................................................................................................................................................................................................................16

2.3.3. Hydraulic circuit MP sava3 + Soft-Stop..............................................................................................................................................................................17

2.3.4. Valve adjustment................................................................................................................................................................................................................17

3 •OIL COOLING DEVICE ...............................................................................................................................................................................................................18

3.1 Oil cooling device connections - Hydraulic power unit...............................................................................................................................................................18

3.2. Oil cooler and thermal switch wiring..........................................................................................................................................................................................19

4 •TANK OIL HEATER.....................................................................................................................................................................................................................19

5 •MAINTENANCE...........................................................................................................................................................................................................................19

5.1. Cleaning of the reutrn oil filter...................................................................................................................................................................................................20

5.2. General checks..........................................................................................................................................................................................................................20

6 •CONTROLS ..................................................................................................................................................................................................................................21

7 •COMMISSIONING TEST RELATED TO UNINTENDED CAR MOVEMENT (UCM) AS PER EN 81-2 & EN 81-20 .................................................................22

7.1. Preliminary requirements ..........................................................................................................................................................................................................22

7.2. Failure simulation of the VB valve (Descent valve operated by the YD Electrovalve).............................................................................................................22

7.2.1. Failure simulation of the VB valve in ascent ......................................................................................................................................................................22

7.2.2. Failure simulation of the VB valve in descent ....................................................................................................................................................................22

7.3. Failure simulation of the VD valve (Bypass valve operated by the YS Electrovalve)...............................................................................................................23

7.4. Test of the monitoring system...................................................................................................................................................................................................23

8 •COMMISSIONING WITH A PRESSURE OF 200% FULL LOAD, AS PER EN 81-2 AND EN 81-20.......................................................................................24

A. APPENDIX •ACTIONS TO FACE MALFUNCTIONS................................................................................................................................................................25

A1. Introduction ................................................................................................................................................................................................................................25

A2. Ascent ........................................................................................................................................................................................................................................27

A2.1. Start-up (the lift does not start)............................................................................................................................................................................................27

A2.2. Nominal speed (a slower speed than usual).......................................................................................................................................................................29

A2.3. Levelling speed (does not function correctly) .....................................................................................................................................................................30

A3. Descent......................................................................................................................................................................................................................................31

A3.1. Start-up (the lift does not start) .....................................................................................................................................................................................31

A3.2. Nominal speed ....................................................................................................................................................................................................................31

A3.2.1. Speed slower than usual..............................................................................................................................................................................................31

A3.2.2. Speed higher than usual...............................................................................................................................................................................................32

A3.3. Levelling speed (does not work or does not reach the correct speed)...............................................................................................................................32

4. At floor ..........................................................................................................................................................................................................................................33

A4.1.The lift descends continuously.............................................................................................................................................................................................33

A4.2.The lift descends when loaded.............................................................................................................................................................................................34

A5. Miscellany ..................................................................................................................................................................................................................................34

A6. Electric Motors, Operating Instructions......................................................................................................................................................................................36

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

4/40

MTMECMPsava3_700_EN

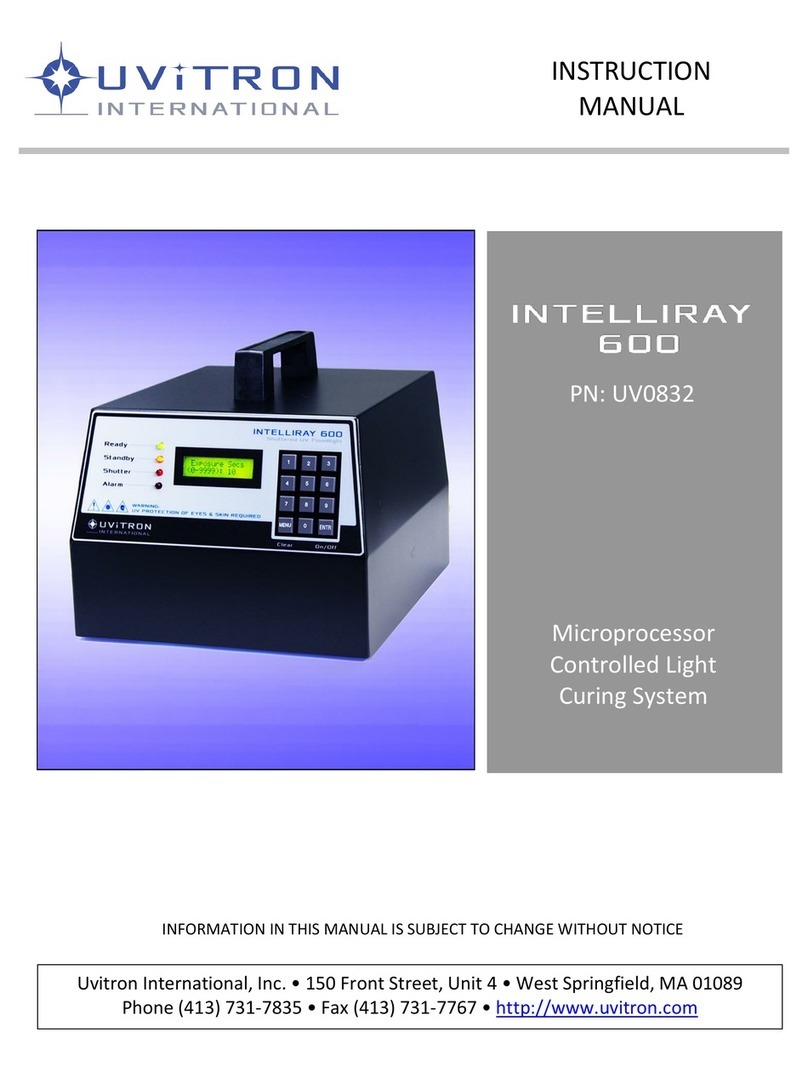

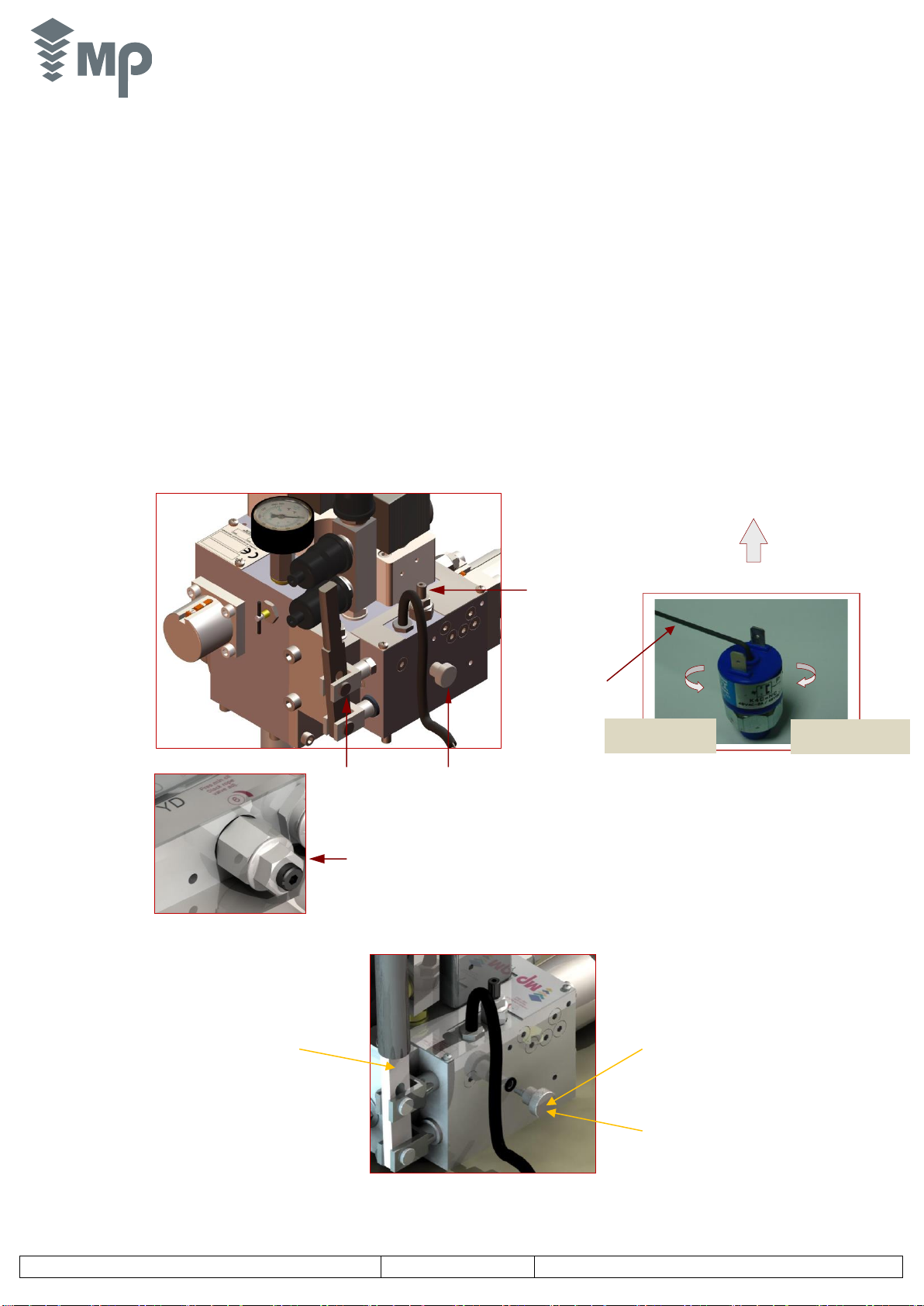

1. The power unit packaging contents the fitting box. Unpack all the assembly and place the

power unit at the final position at the installation correctly supports on its four anti-vibration rubber

feet.

2. Fit the lever of the hand pump and connect the

shut-off valve to the input of the power unit

(cylinder and power unit fitting boxes).

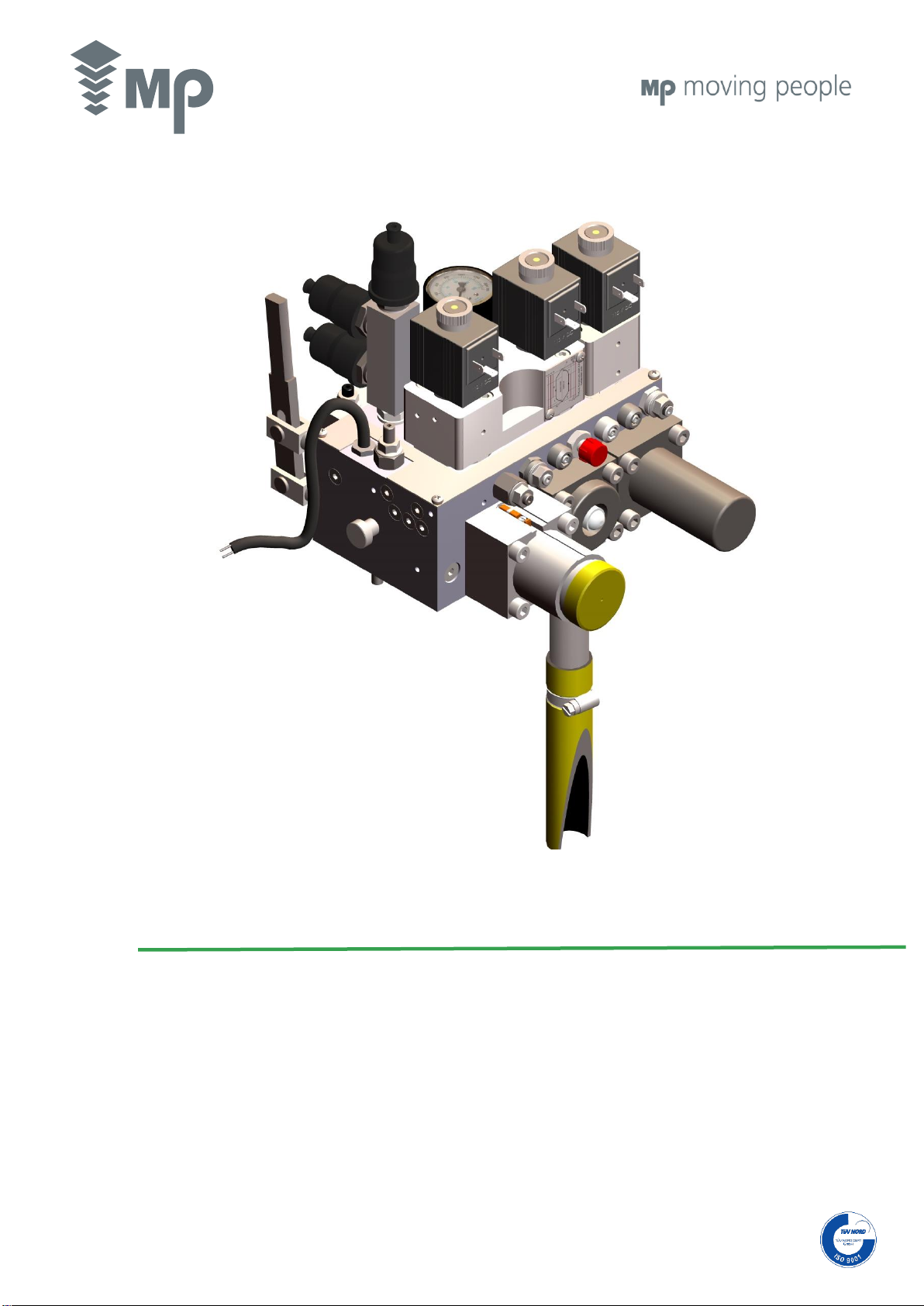

0 •INDIVIDUAL PROTECTION EQUIPMENT

Neither the tools nor the individual protection equipment are included in the pack.

Individual Protection Equipment

Helmet

Anti-cut gloves

Reinforced boots

Safety belt

Goggles or shield

Back belt

1 •HYDRAULIC POWER UNIT

1.1. Mechanical assembly

3. Take the hydraulic hose from the hole to connect to

the power unit and to the rupture valve on the cylinder.

4. Fill the tank

STEPS TO FOLLOW

a) Remove the tank cover and check the

cleaning of the tank (dry and no dust)

b) Fill the tank with hydraulic oil avoiding making

bubbles.

c) The oil level must be at least 10 cm higher

than the motor surface level at the moment of

maximum expansion of the cylinder.

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

5/40

MTMECMPsava3_700_EN

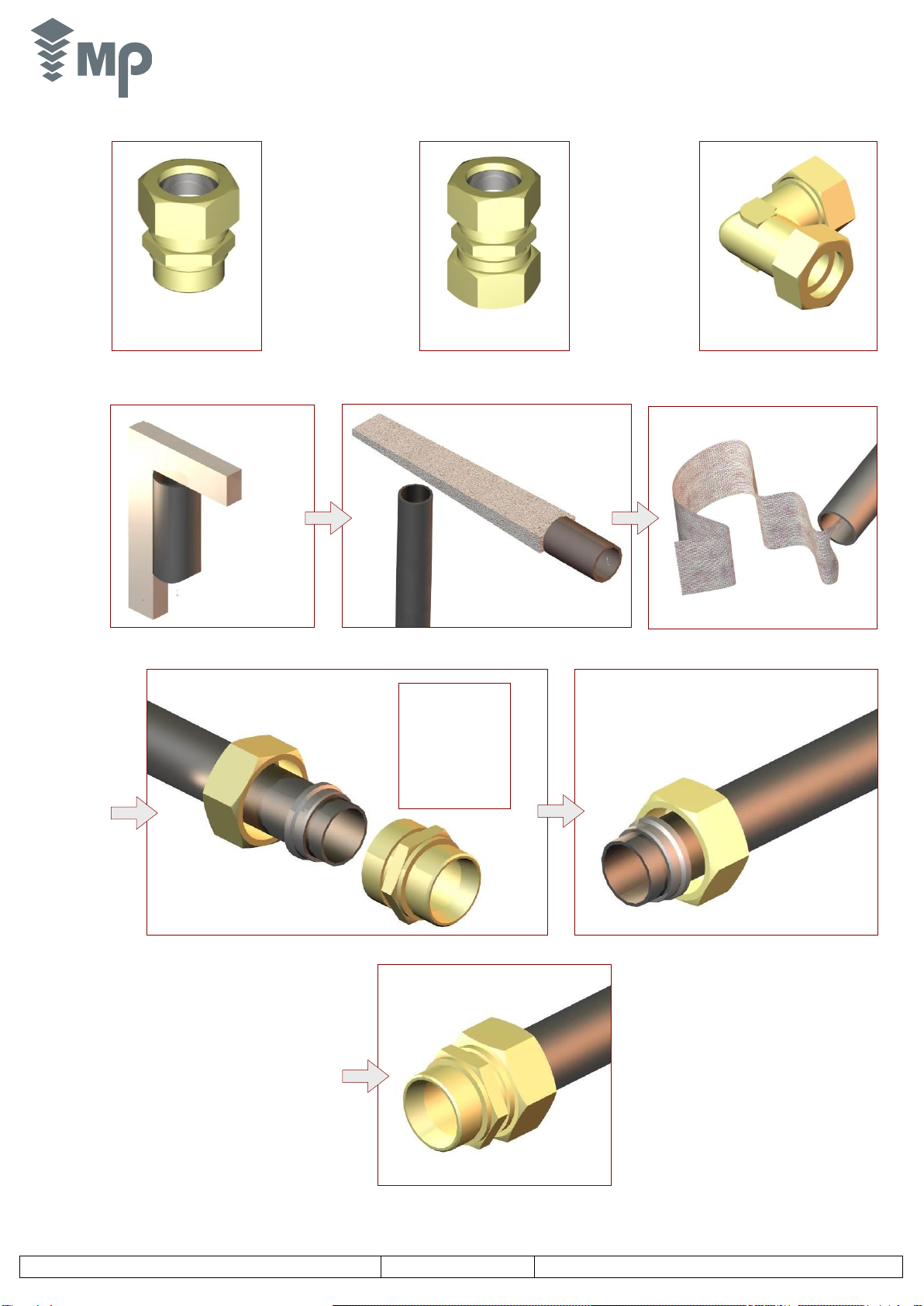

1.2. Types of pipe couplings

1.3. Process for joining steel pipes

UDA (double clasp)

To join pipe to valve block

(end coupling)

USA (single clasp)

To join pipe to valve block

(end coupling)

CODO (double clasp elbow at 90º)

To join a steel pipe and a hose

Cut hose perfectly square

Use a saw; do not use

a hose cutter

Remove burrs inside and outside

Clean the hose inside

with a non-fray cloth

Fit nut and ring to the

pipe in the shown order

- Screw on the cap

nut by hand as much

as possible

- Push the pipe up

against the bottom of

the coupling.

- Tighten the nut with

a spanner 1,5 turns;

the pipe must not be

able to rotate.

Oil the cutting ring

Cutting edge of the ring

towards the end of the pipe

Unscrew the cap nut

and check that the ring

is firmly gripping the

hose

Fully tighten

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

6/40

MTMECMPsava3_700_EN

1.4. Steel pipes and flexible hoses

1.5. Rupture valve

FLEXIBLE HOSE ONLY

FLEXIBLE HOSE AND

STEEL PIPE

Avoid up and down

curves in the course of

the hose

IMPORTANT:

Use for lengths > 10 m.

Assemble a piece of Flexible Pipe

behind the Rupture Valve as well as

between the Rigid Pipe and Power

Unit.

Recommended for lengths ≤ 10 m

Avoid leaving the hose completely straight

Remove the protective plate and seal paper

Check the o-ring seal

is properly placed in

its housing

In case of double cylinder installation,

connect the rupture valves each other

by using a Ø6mm steel pipe (fitting

box).

Fix steel or flexible pipe.

Use the cap nut and cutting ring

for steel pipe or flexible hose

with steel tube end

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

7/40

MTMECMPsava3_700_EN

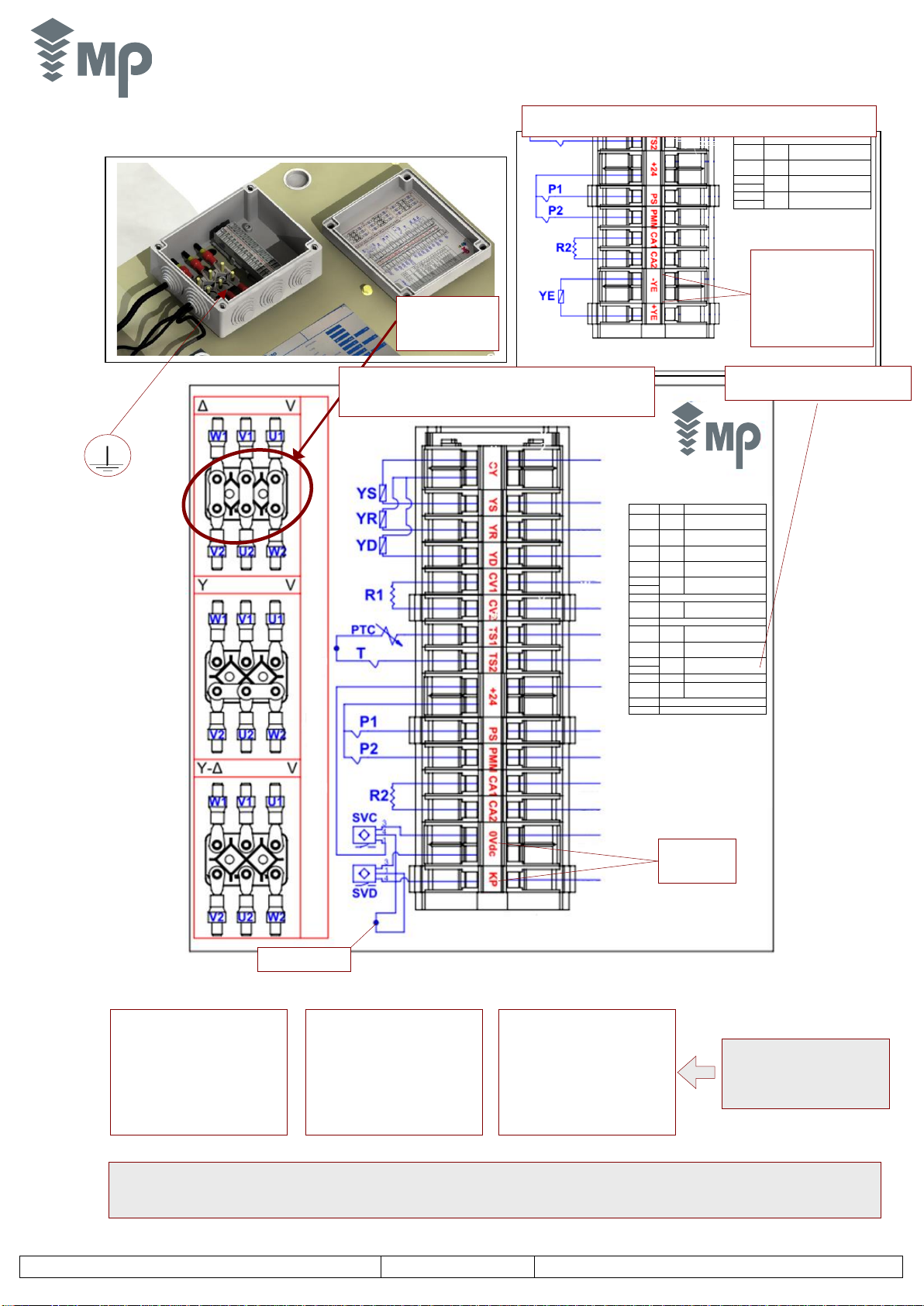

NOTE:

Once the installation is finished, check the motor turns to the ‘right’; should it turn to the left, the pump is very noisy. In this case, reverse the polarity of the

motor wiring (change two of the phases).

1.6. Electrical connections for 3-phase motors ¡Error! Marcador no definido.

CY

Común electroválvula

Common Electrovalve

YS

Electroválvula YS

Electrovalve YS

YR

Electroválvula YR

Electrovalve YR

YD

Electroválvula YD

Electrovalve YD

CV1

R1

R. Calentamiento Valv.

V.Block Heater

CV2

TS1

PTC

TS2

T

Termosonda

T.Switch

+24

VDC

PS

P1

Presostato

P.Switch

PMM

P2

Presostato.Pmax/Pmin

P.Swith. Pmax/Pmin

CA1

R2

Resistencia. Depósito

Tank Oil Heater

CA2

0Vdc

0Vdc

KP

Salida sensores

Output Sensors

SVC

SVC Sensor

SVD

SVD Sensor

Y- D Connection

Motors star-delta connected:

50 Hz

- 230/400 (mains 230 V).

- 400/690 (mains 400 V).

- 415/720 (mains 415 V).

60 Hz

- 220/380 (mains 220 V)

- 380/660 (mains 380 V)

Submerge the heater resistance into

the oil (Optional component)

Motor is supplied

according to the

customer

specifications.

U

2

W

1

V

1

U

1

D Connection

Motors delta connected:

50 Hz

- 230/400 (mains 230 V)

- 400/690 (mains 400 V)

- 415/720 (mains 415 V)

60 Hz

- 220/380 (mains 220 V)

- 380/660 (mains 380 V)

Y Connection

Motors star connected:

50 Hz

- 230/400 (mains 400 V).

60 Hz

- 220/380 (mains 380 V).

Warning:

Y-Dstarting is possible only if the

motors are wound for the voltages

shown in these diagrams.

EN 81-2+A3

EN 81-20

2014/33/EU

CONNECTION

THE EMERGENCY

VALVE WILL NOT BE

INCLUDED IN POWER

UNITS THAT SHOULD

BE IN ACCORDANCE

WITH THE EN 81-2+A3

AND EN 81-20

STANDARD

Connection according to EN 81-2+A3

and EN 81-20/50

+24

VDC

PS

P1

Presostato

P.Switch

PMM

P2

Presostato.Pmax/Pmin

P.Swith. Pmax/Pmin

CA1

R2

Resistencia. Depósito

Tank Oil Heater

CA2

-YE

Electroválvula YE

Electrovalve YE

+YE

Connection considering Emergency Valve

1: Marrón/Brown

4: Negro/Black

3: Azul/Blue

VIOLETA

VIOLET

NEGRO

BLACK

AMARILLO

YELLOW

AMARILLO

YELLOW

MARRÓN

BROWN

BLANCO/AZUL

WHITE/BLUE

ROJO

RED

BLANCO

WHITE

BLANCO

WHITE

VERDE

GREEN

VERDE

GREEN

AZUL

BLUE

NARANJA

ORANGE

ROSA

PINK

GRIS

GREY

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

8/40

MTMECMPsava3_700_EN

1.7. Sart-up

1. The oil supply line (flexible hose or steel pipe) should be as short as possible and without sharp bends.

2. Make sure the pipe is in line with the connection and the joints are made as indicated in the technical manual.

3. Before assembling the pipe line, make sure the pipes are smooth and deburred. Clean the inside of the pipes with a lint free rag.

4. Loosen the air bleeder screw in the cylinder head.

5. Rotate the pump at low speed until oil comes out of the air bleeder hole. Then close and tighten the oil bleeder screw.

6. During the installation, repeat the bleeding operation to remove any accumulated air.

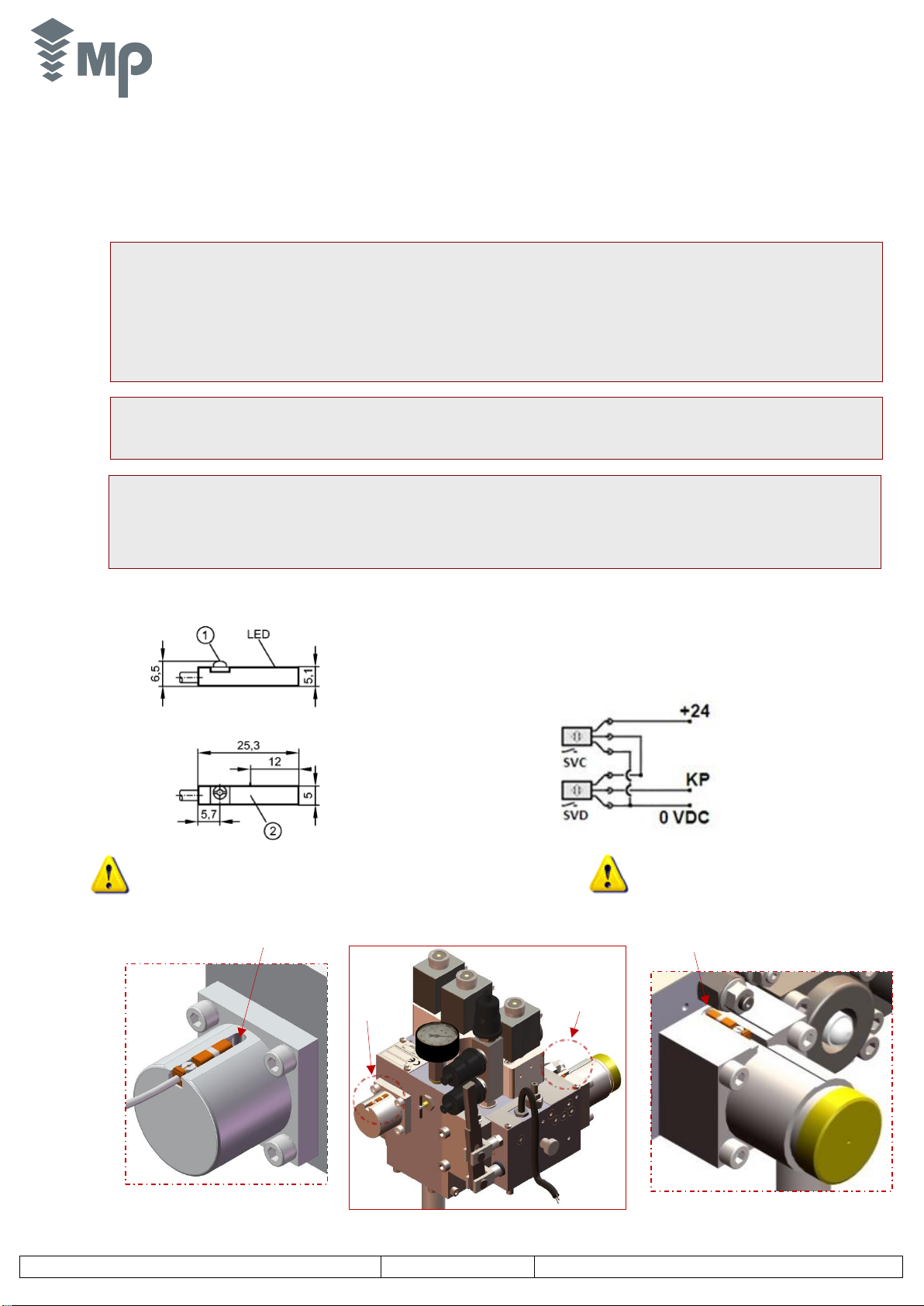

1.8 Wiring of Magnetic Sensors.

NOTE:

•Before pouring oil into a tank which may have been exposed to excessive humidity or opened to the air, remove the cover and check there are no trace of

moisture. Dry out the tank if necessary.

•Switch on the motor to check the turning direction. If the noise coming from the unit is excessive, the motor may be turning in the opposite direction.

•If the temperature of the machine room is very cold or very wet, the oil has to be heated.

•The manometer should be connected only when used by the installer.

•Check the rupture valve.

•After all adjustments have been made, seal the caps of all the valves.

NOTE:

•YS the name of this valve is defined by the chosen configuration equipment. Then it will be:

-Y-D Electrovalve. - Soft-Stop Electrovalve.

VERY IMPORTANT

The factor service of our motors is 40%. Consequently, in inspection speed, you have to remember that, during one minute time, the lift will be working for

20 seconds and resting for 40 seconds.

In the same way, during any t time period, it will be working for 0,4 t and resting for 0,6 t.

1 Brown

2 Black

3 Blue

1: Eccentric fixing

2: Active area

MAGNETIC

SENSOR

DESCENT VALVE

SVD

MAGNETIC

SENSOR

BYPASS VALVE

SVC

3

3

2

2

1

1

SENSOR STOP

SVC

SENSOR STOP

SVD

Proper position of Sensor SVC:

The lift being in idle state, the sensor

SVC shall be located as far as possible

to the limit and its led shall be lit

Proper position of Sensor SVD:

The lift being in idle state, the sensor

SVC shall be located as close as

possible to the limit and its led shall be lit

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

9/40

MTMECMPsava3_700_EN

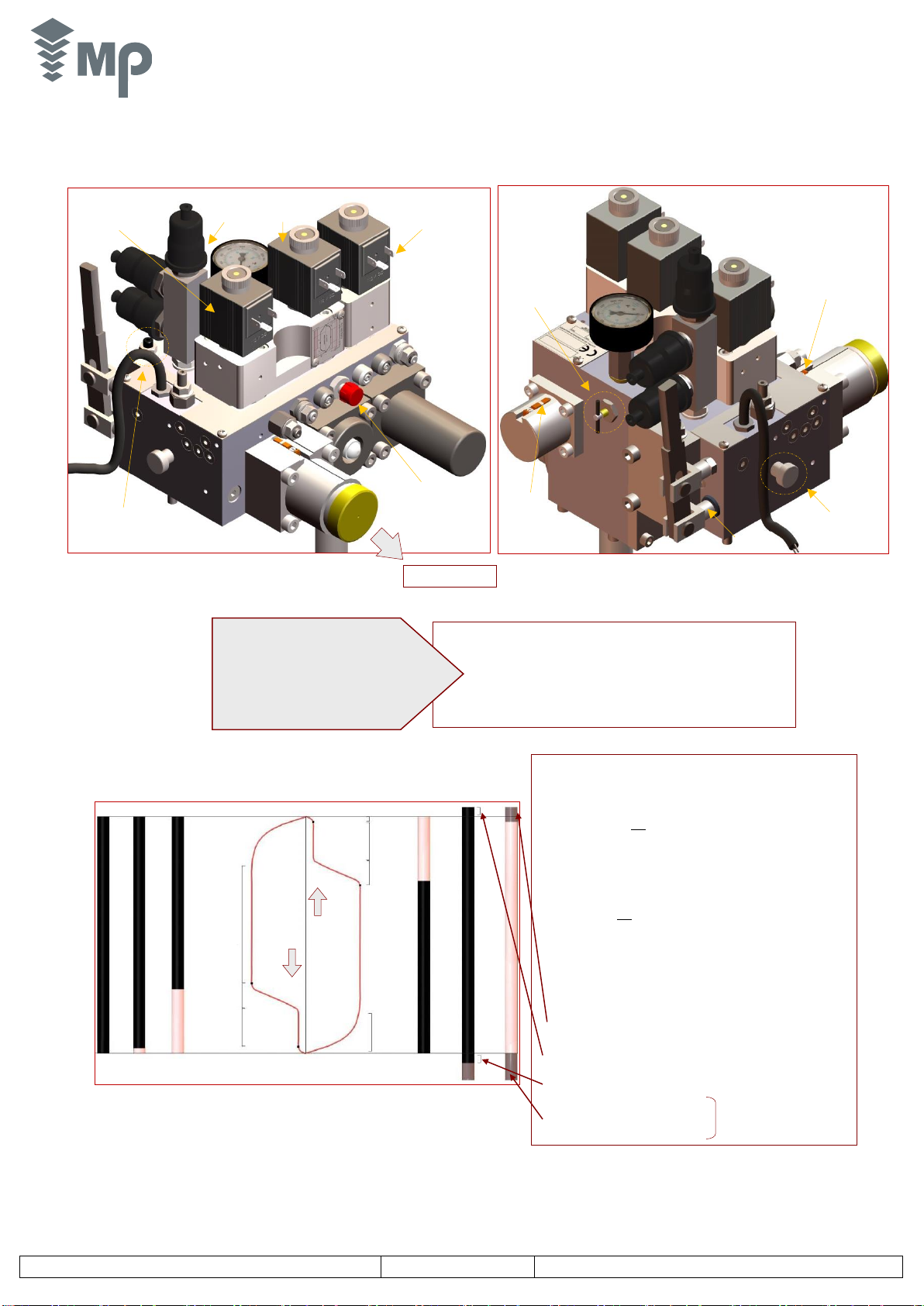

A Point Upwards deceleration signal.

Place at an S distance from the floor level equal to

B Point Disconnected motor signal.

C Point Downwards deceleration signal.

Place at an S distance from the floor level equal to

D Point YD Electrovalve disconnection signal

Connected

Adjustment

FLOOR

Adjustment

YR

FLOOR

MOTOR

YR

YS-A3

4

3

2

5

3

4

A

B

C

D

YD

Connected

Change to D

Connect in Y for 2 seconds approx.

Y- D

Starting

UPWARDS

DOWNWARDS

YS Electrovalve will be connected just before getting to the floor

Motor will remain connected for 2 seconds after the lift stops

For direct starting, motor idle time approx. 0,5 seconds

YS-A3

2 •BLOCK OF VALVES

2.1. MP sava3 Valve Block according to 2014/33/EU European Standard

2.1.1. Description of valves

2.1.2. Unit operation

1: Pressure relief valve adjustment

2: Upwards acceleration adjustment

3: Upwards/downwards acceleration adjustment

4: Levelling speed adjustment

5: Down speed adjustment

6: Cylinder minimum pressure adjustment.

7: Relief valve adjustment into hand pump.

Names of adjusting screws

YD Electrovalve

(descent)

+ YE (emergency)

YR Electrovalve

(for speed

change)

Pressure switch

with adjustment

screw

Testing screw

of the rupture

valve

Manual lowering

pushbutton

Hand pump

bleeding

Manometer

protection key

1

6

TO CYLINDER

Starting

Electrovalve YS

(-A3 optional)

Hand

pump

lever

5

4

3

2

7

Magnetic Sensor

Descent Valve

SVD

Magnetic Sensor

Bypass Valve

SVC

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

10/40

MTMECMPsava3_700_EN

VR. Non return valve Screw 1: Pressure relief valve adjustment (maximum pressure)

VA. Starting valve Screw 2: Upwards acceleration adjustment.

VD. Bypass valve Screw 3: Upwards/downwards deceleration adjustment.

VC. Flow regulator valve Screw 4: Levelling speed adjustment.

VB. Descent valve Screw 5: Down speed adjustment.

YR. Electrovalve for changing speed Screw 6: Hand pump relief valve adjustment.

YD. Descent Electrovalve Screw 7: Cylinder minimum pressure adjustment.

YS. Y- ΔStarting Electrov. (YS-A3 2014/33/EU) Integrated Soft-Stop SVC: YS-A3 Valve magnetic Sensor.

VP. Balancing down pressure switch SVD: Descent Valve YD magnetic Sensor

VL. Pressure relief valve

CP. Maximum pressure switch (optional)

VM. Manual descent valve

VG. Valve to control the minimum pressure in cylinder

Return filter-Shut-off valve

MP sava3 Valve Block

Rupture valve

Hand pump

2.1.3. Hydraulic circuit MP sava3 Valve Block with Soft-Stop according to European Directive 2014/33/EU

svc

SVD

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

11/40

MTMECMPsava3_700_EN

NOTE: If the lift does not go up, check the pressure relief valve or the

maximum pressure switch are not operating; see points 1 and 2 of section 4.5

Adjustment screws with seal-locks:

- Loosen the nut before adjusting

- Tighten the nut after adjusting

NOTE: The power unit

information plate shows,

beside every adjustment

screw, the quantity increase

or decrease direction of the

parameter that controls this

adjuster and its name as well.

2.1.4. Adjustment of Valves

1. Upwards acceleration adjustment. Screw 2

1. Load the lift car with half the rated load.

2. Tightening screw 1 makes starting gentler (- accelerated). If screw 1 is tightened fully, the lift will not start-up.

3. Loosening screw 1 makes the lift starts up more quickly and therefore abrupter (+ accelerated).

2. Down speed adjustment. Screw 5

1. Load the lift car with half the rated load. Time how long it takes the lift car to travel down.

2. If the speed is higher than required, loosen screw 5 until desired speed is obtained (- speed).

3. If the speed is lower than required, tighten screw 5 so that down speed increases (+ speed).

3. Upwards and downwards deceleration adjustment. Screw 3

1. Load the lift car with half the rated load.

2. Tightening screw 3 makes the change smoother (- accelerated); it also reduces the time at the levelling speed for a distance of the change signal.

3. Loosening screw 3 makes the change more abrupt (+ accelerated); it also increases the time at the levelling speed for a distance of the change signal.

4. Levelling speed adjustment. Screw 4

1. Load the lift car with half the rated load.

2. Tightening screw 4 reduces the speed, the lift stops smoothly (- speed). ‘If the speed is too low, it could jerk’.

3. Loosening screw 4 increases the speed; the lift stops abruptly (+ speeds).

4. Time at levelling speed depends on the position of contacts in the lift shaft and the adjustment of screw 3.

5. Soft-Stop adjustment. Screw 8. Available in 1 ½” Hydraulic Equipment

1. Load the lift car with half the rated load.

2. Tightening Soft-Stop screw, the lift stops smoothly.

3. Loosening Soft-Stop screw, the lift stops abruptly.

NOTE: All the blocks are adjusted prior to delivery; this information must only be used if a re-adjustment of a valve block is required.

Hand pump pressure

relief valve

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

12/40

MTMECMPsava3_700_EN

2.1.5. Testings

1. Pressure relief valve. Screw 1

1. Load the lift car with 100% of the rated load.

2. Open the manometer protection key and take the pressure reading (full load pressure).

3. Close the shut-off valve and disconnect the maximum pressure reading switch from the circuit if any.

4. Send the lift up and make a note of the manometer reading once it is stabilized (tripping pressure).

5. This pressure should be 1,4 times the full load pressure.

6. If the pressure is not correct, tighten screw 1 to increase the tripping pressure (+ pressure) or loosen to reduce it (- pressure).

2. Maximum or minimum pressure switch (optional)

1. Close the shut-off valve and send the lift up.

2. Note the cut-off pressure; it should be between 1,1 and 1,2 times the full load pressure.

3. If it is not correct, adjust the pressure switch using an appropriate screwdriver; see figure below.

3. Hand pump. Screw 7

1. Pump the lever and check the lift goes up.

2. If not, the hand pump needs priming. To do this, pump the lever while loosening and tightening the bleeding screw several times, until an opposition in

movement is observed. Then tighten the screw.

3. To check the tripping pressure of the relief valve:

-Close the shut-off valve and cut off the power.

-Pump the lever and note the manometer reading after it is stabilized.

-Pressure should be 2,3 times the full load pressure.

-Should it not be correct, tighten the relief valve screw to increase the tripping pressure, or loosen to reduce it.

Bleeding Hand Pump

Hand pump

lever

Relief valve screw (7)

Bleeding

screw

Cylinder minimum

pressure adjustment (6)

Allen Wrench hex.

2 mm

Unscrew a few turns the

Bleeding Screw. It is not

necessary unscrew it

completely

Repeat the pump

several times to ensure

the bleeding of the

hydraulic circuit.

Turn left to decrease

the acting pressure

Turn right to increase

the acting pressure

Remove the cap

Open and close several

times the Bleeding Screw

and, at the same time, start

to pump by acting on the

lever of the Hand-Pump.

Pump with the hand pump and close the bleeding Screw

when the hand pump is loaded.

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

13/40

MTMECMPsava3_700_EN

4. Pipe joints and couplings (Pressure test)

1. Raise the piston up to the end of the run.

2. Work the hand pump until the pressure is stabilized.

3. Keep the pipes under pressure for 5 min. and observe the possible pressure fall because of leaks (note the pressure might decrease due to cooling of oil).

4. Check the pipe joints and couplings are correct.

5. Overload pressure switch, low hysteresis

1. Close the shut-off valve. Connect the terminals to a multimeter (if digital, in a continuity position; if analogical, in low resistance position).

2. Operating the pump would cause a pressure of 1 bar above the Maximum Static Pressure.

3. Adjust the pressure switch using a screwdriver until the contact is energized, thus receiving the appropriate signal from the multimeter.

6. Minimum pressure in cylinder (for indirect acting lifts 2:1). Screw 6

1. Wedge the lift car using the safety gear.

2. Press the manual lowering pushbutton and check the piston does not go down.

3. If it does, tighten the cylinder minimum pressure screw until it does no longer go down.

4. Free the lift car using hand pump.

7. Excluding the manometer from the circuit

1. Turning the manometer protecting key anticlockwise enables working pressure to be read at any time.

2. Protecting key must remain locked (fully tightened) to ensure the correct operation of the manometer.

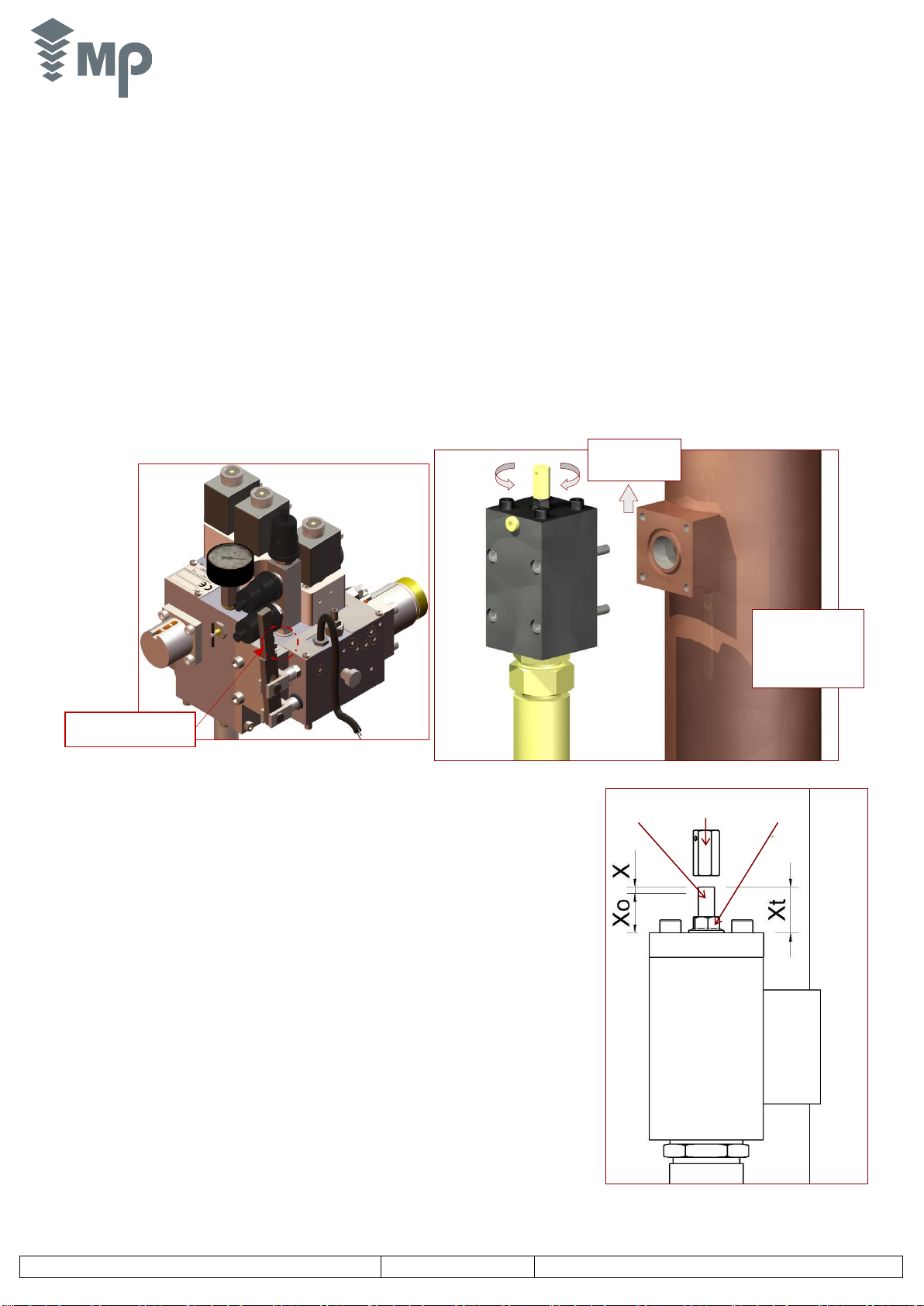

8. Rupture valve

DESCRIPTION

This device consists of a valve that stops the flow of oil when the downward speed of the lift

exceeds a preset value.

The Rupture Valve Test must be done with the FULL LOAD in the lift according to EN 81-2 and EN

81-20 standard.

1. Testing the rupture valve at free fall speed.

- Run the car with full load to the highest floor.

- Fully tighten the screw to test the rupture valve.

- Run the car to the lowest floor.

- The car should descend at a higher speed than the rated speed.

- The pipe rupture valve should trip at 130% of the rated speed.

When this happens, the flow of oil from the cylinder is cut off and the lift stops.

- Fully loosen the testing crew. This will allow the lift to operate normally in descent

but the lift will stop if the oil line breaks.

- Move the lift up to reset the rupture valve.

2. Valve adjustment (if the valve does not trip).

- This operation will only be done if the valve is not adjusted from the factory.

- Run the car to the highest floor.

- Unscrew the locknut.

- Move the car down.

- Tighten the adjusting screw according to the formula Xt=X+Xo, obtained from the

curves of the rupture valve certificate of conformity.

- Screw the locknut

Remove

protective cap

Testing screw of rupture

valve

Protective cap

Adjusting

rod

Lock nut

Turn clockwise the

adjusting rod to

reduce the tripping

flow. Turn

anticlockwise to

increase this value

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

14/40

MTMECMPsava3_700_EN

A Point Upwards deceleration signal.

Place at an S distance from the floor level equal to

B Point Motor disconnected signal.

C Point Downwards deceleration signal.

Place at an S distance from the floor level equal to

D Point YD Electrovalve disconnection signal

Connected

Adjustment

FLOOR

Adjustment

YR

FLOOR

MOTOR

YR

Y- D

4

3

2

5

3

4

A

B

C

D

YD

Connected

For direct starting, motor idle time approx. 0,5 seconds

Change to D

Connect in Y for 2 seconds approx

Y- Dstarting

UPWARDS

DOWNWARDS

YS -

2.2. MP sava3 Valve Block

2.2.1. Description of Valves

2.2.2. Unit operation

1: Pressure relief valve adjustment

2: Upwards acceleration adjustment

3: Upwards/downwards deceleration adjustment

4: Levelling speed adjustment

5: Down speed adjustment

6: Cylinder minimum pressure adjustment.

7: Hand pump relief valve adjustment.

Adjusting screws names

YD Electrovalve

(descent)

+ YE (emergency)

YR Electrovalve

(for speed

change)

Pressure switch

with adjustment

screw

Testing screw

of the rupture

valve

Manual lowering

pushbutton

Hand pump

bleeding

Manometer

protection key

1

6

TO CYLINDER

Starting

Electrovalve YS

(-A3 optional)

Hand

pump

lever

5

4

3

2

7

Magnetic Sensor

Descent Valve

SVD

Magnetic Sensor

Bypass Valve

SVC

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

15/40

MTMECMPsava3_700_EN

VR. Non return valve Screw 1: Pressure relief valve adjustment (maximum pressure)

VA. Starting valve Screw 2: Upwards acceleration adjustment.

VD. Bypass valve Screw 3: Upwards/downwards deceleration adjustment.

VC. Flow regulator valve Screw 4: Levelling speed adjustment.

VB. Descent valve Screw 5: Down speed adjustment.

YR. Electrovalve for changing speed Screw 6: Hand pump relief valve adjustment.

YD. Descent Electrovalve Screw 7: Cylinder minimum pressure adjustment.

YS. Y- Δstarting Electrovalve (optional)

VP. Balancing down pressure switch

VL. Pressure relief valve

CP. Maximum pressure switch (optional)

VM. Manual descent valve

VG. Valve to control the minimum pressure in cylinder

MP sava3 MP Valve Block

Return filter –Shut-off valve

Rupture valve

Hand pump

2.2.3. Hydraulic circuit (Valid for Standard and Y- D configurations)

2.2.4. Valve adjustment

See pages 10-14.

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

16/40

MTMECMPsava3_700_EN

A Point Upwards deceleration signal.

Place at an S distance from the floor level equal to

B Point Disconnected motor signal.

C Point Downwards deceleration signal.

Place at an S distance from the floor level equal to

D Point YD Electrovalve disconnection signal

Connected

Adjustment

FLOOR

Adjustment

YR

FLOOR

MOTOR

YR

YS

4

3

2

5

3

4

A

B

C

D

YD

Connected

Change to D

Connect in Y for 2 seconds approx.

Y- D

Starting

UPWARDS

DOWNWARDS

YS E

lectrovalve will be connected just before getting to the floor

Motor will remain connected for 2 seconds after the lift stops

For direct starting, motor idle time approx. 0,5 seconds

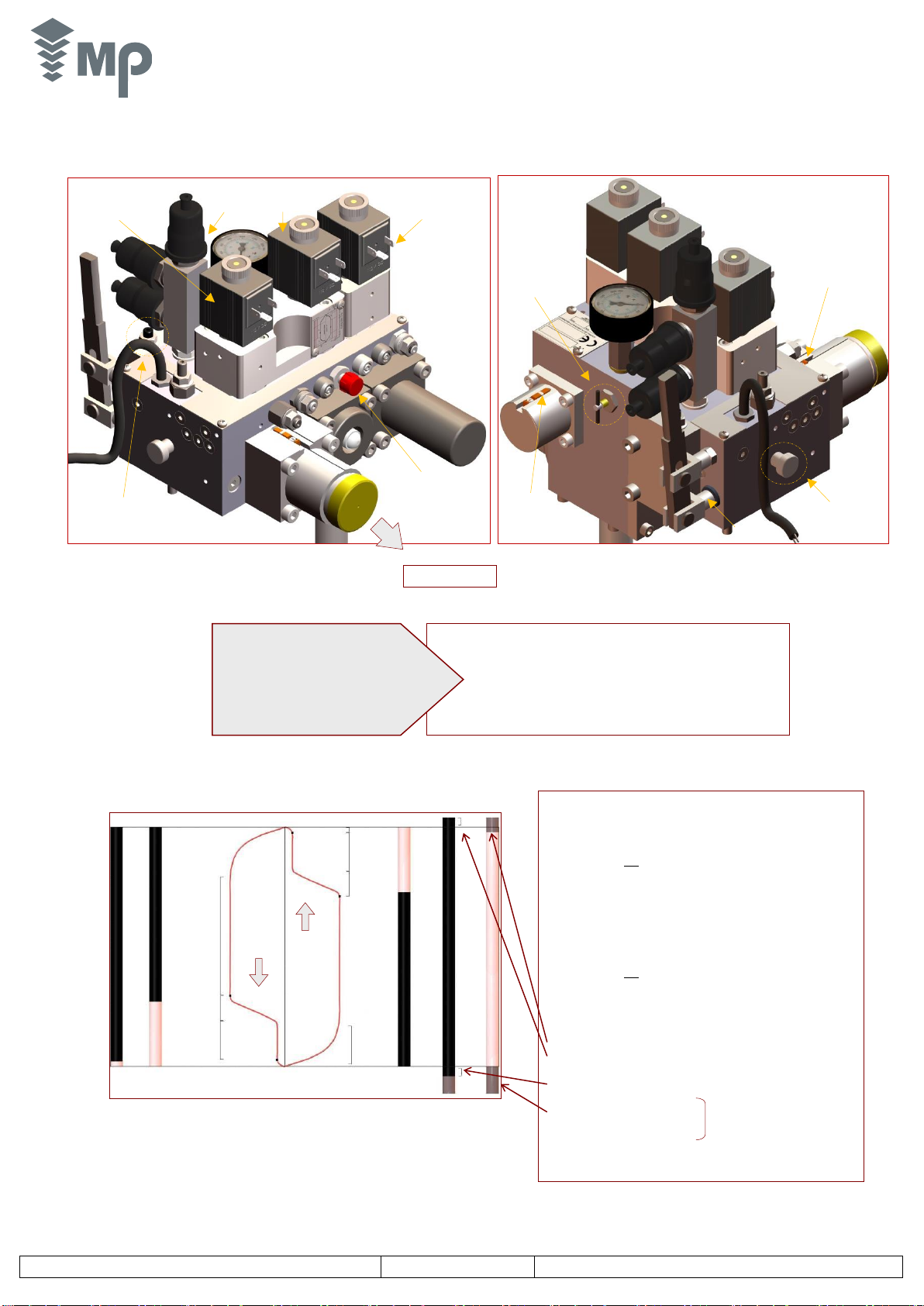

2.3. MP sava3 Valve Block SOFT-STOP

2.3.1. Description of Valves

2.3.2. Unit operation

1: Pressure relief valve adjustment

2: Upwards acceleration adjustment

3: Upwards/downwards acceleration adjustment

4: Levelling speed adjustment

5: Down speed adjustment

6: Cylinder minimum pressure adjustment.

7: Hand pump relief valve adjustment.

Adjusting screw names

YD Electrovalve

(descent)

+ YE (emergency)

YR Electrovalve

(for speed

change)

Pressure switch

with adjustment

screw

Testing screw

of the rupture

valve

Manual lowering

pushbutton

Hand pump

bleeding

Manometer

protection key

1

6

TO CYLINDER

Starting

Electrovalve YS

(-A3 optional)

Hand

pump

lever

5

4

3

2

7

Magnetic Sensor

Descent Valve

SVD

Magnetic Sensor

Bypass Valve

SVC

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

17/40

MTMECMPsava3_700_EN

VR. Non return valve Screw 1: Pressure relief valve adjustment (maximum pressure)

VA. Starting valve Screw 2: Upwards acceleration adjustment.

VD. Bypass valve Screw 3: Upwards/downwards deceleration adjustment.

VC. Flow regulator valve Screw 4: Levelling speed adjustment.

VB. Descent valve Screw 5: Down speed adjustment.

YR. Electrovalve for changing speed Screw 6: Hand pump relief valve adjustment.

YD. Descent electrovalve Screw 7: Cylinder minimum pressure adjustment.

YS. Y- Δstarting electrovalve (optional) Soft-Stop integrated.

VP. Balancing down pressure switch

VL. Pressure relief valve

CP. Maximum pressure switch (optional)

VM. Manual descent valve

VG. Valve to control the minimum pressure in cylinder

Return filter-Shut-off valve

MP sava3 block of valves

Rupture valve

Hand pump

2.3.3. Hydraulic circuit MP sava3 + Soft-Stop

2.3.4. Valve adjustment

See pages 10-14.

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

18/40

MTMECMPsava3_700_EN

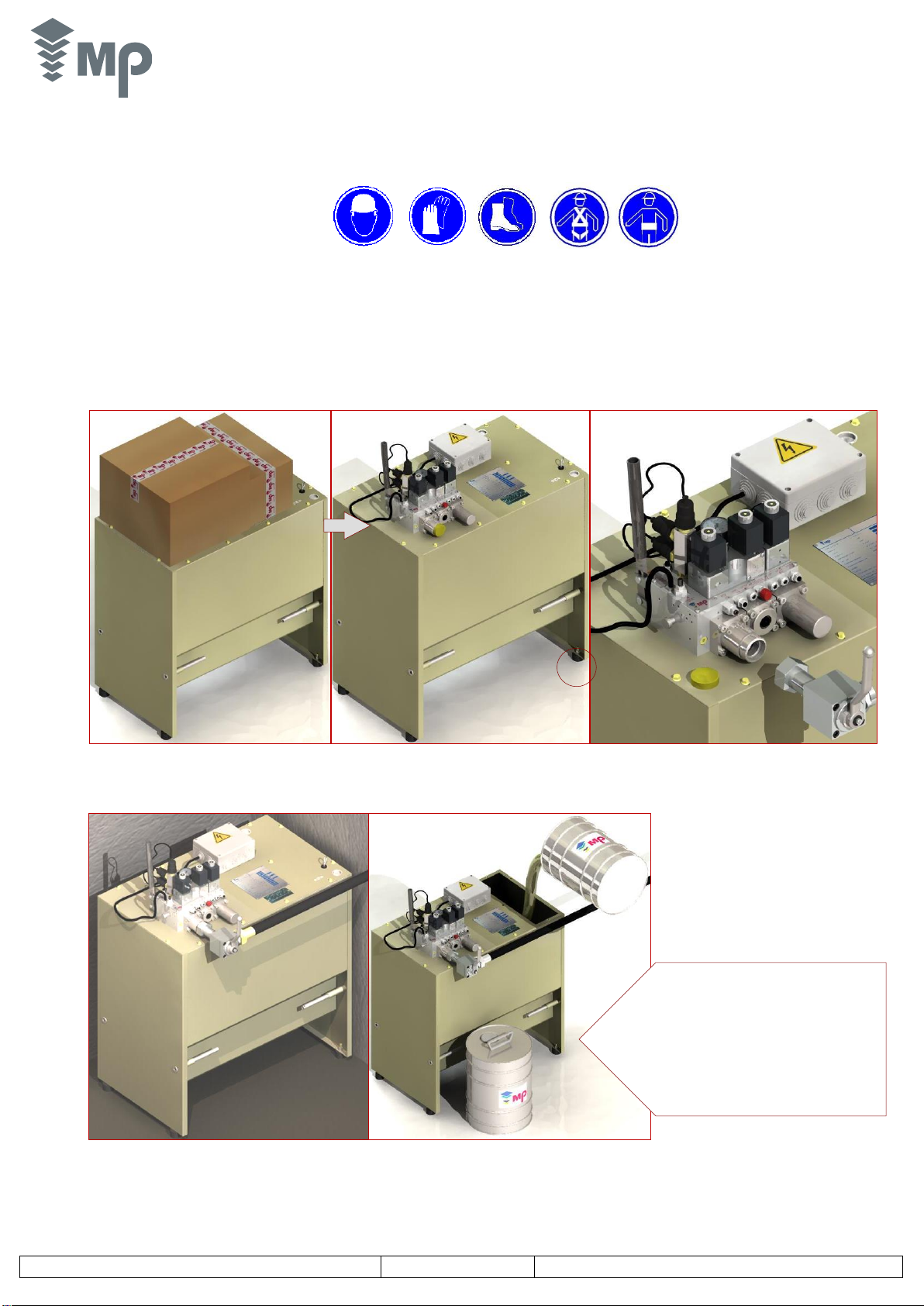

COOLER ASSEMBLY

1. Assemble as many hoses as required to enable the

oil input and output from the cooler (see attached table).

2. Insert the IN and OUT hoses of the cooler into the

holes of the tank cover.

3. To assemble the thermostat, see picture here below.

THERMOSTAT

ASSEMBLY DETAIL

The power unit has a dust protection on

the tank identification cover. Remove this

protection before installing the cooler.

REQUIRED ACCESSORIES NOT INCLUDED

INPUT

- SAE 100 Elbow 90º Hydraulic hose

- M G 1”–M G ¾” Connector

- 1” hydraulic joint.

OUTPUT

- SAE 100 Elbow 90º Hydraulic hose

- M G ¾” - M G ¾” Connector

- ¾” Hydraulic joint

ASSEMBLY ON TANK COVER

- 4 T 25-30 Silent-blocks

- 4 DIN 934 M6 nuts

- 4 DIN 7980 Ø6 Grower

- 4 DIN 9021 M6 Washers

.

IMPORTANT:

The oil cooler must not be placed at a height of more than 1100 mm

with regard to the ground where the hydraulic power unit stands.

3 •OIL COOLING DEVICE

3.1 Oil cooling device connections - Hydraulic power unit

INPUT

OUT

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

19/40

MTMECMPsava3_700_EN

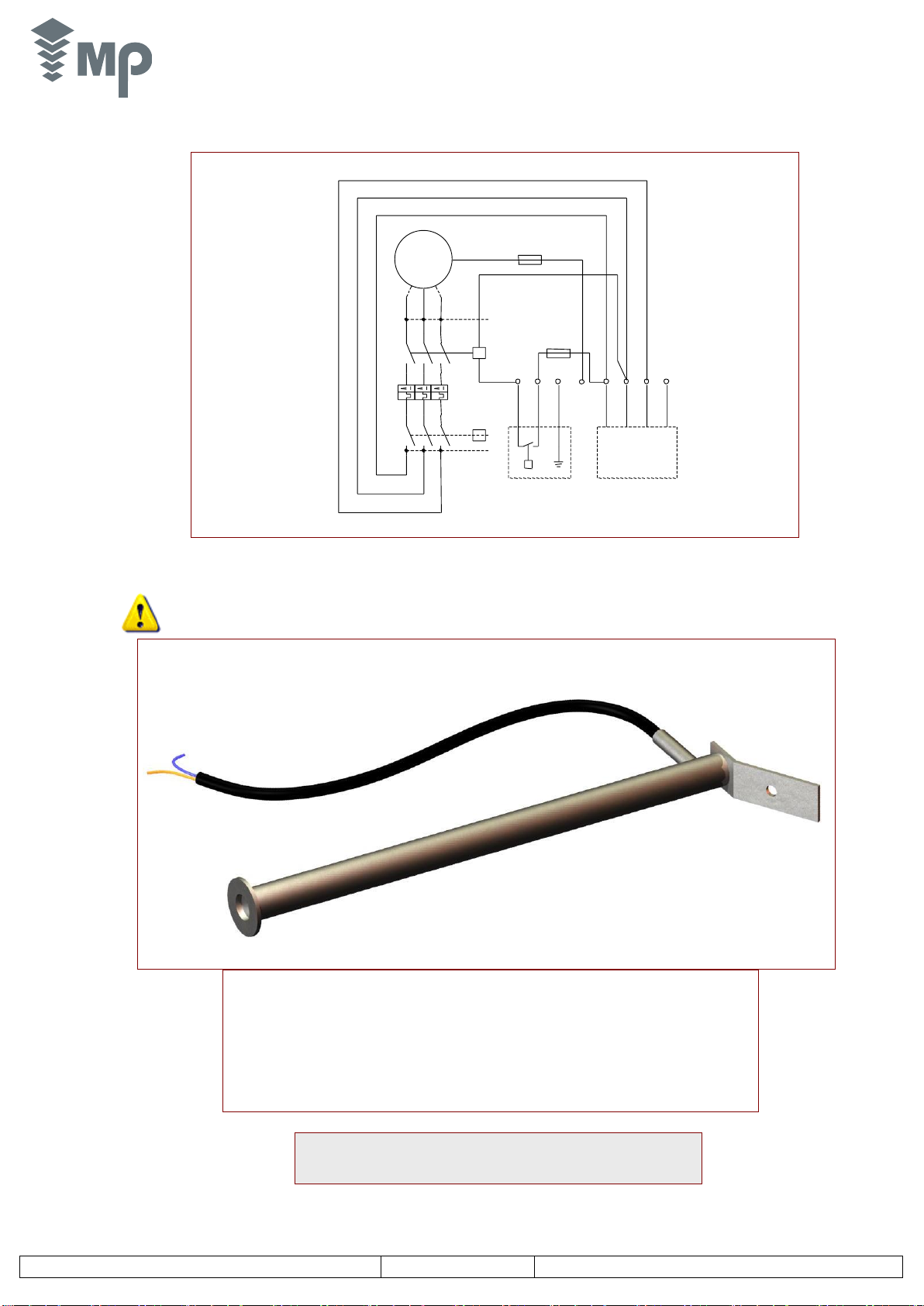

ADJUSTING

THERMOSTAT

GENERAL

CONNECTION

THERMOSTAT OPENING 30º C ± 3º C

CLOSING 20º C ± 4º C

POWER 500 W +5/-10%

HEAT FLOW SUPPLIED 2 W/cm2

SUPPLY VOLTAGE 380 V

220 V

THREE-PHASE

COOLER

IMPORTANT: Do not connect the resistance without drowning it into oil

NOTE: The resistance does not work over an oil temperature of 15ºC

3~

TT

TT

TT

R

S

T

2A

2A

3.2. Oil cooler and thermal switch wiring

4 •TANK OIL HEATER

- To make a correct connection between the power unit and the oil heater, see page number 6 of this technical manual.

MP sava3 Hidraulic Power Unit 1 ¼” 1 ½”

V700 - 11/2017

20/40

MTMECMPsava3_700_EN

5•MAINTENANCE

5.1. Cleaning of the reutrn oil filter

5.2. General checks

•Once every 5 to 10 years and depending on the lift general conditions, it is recommended to make a general inspection of all the hydraulic components.

Any worn or old component must be replaced.

•We recommend to filter the oil (the filter should be between 30 and 40 μm) .Clean the tank.

•Change the fitting set (seals and rings) of the cylinder.

•Once the inspection operations have been performed, check all the points as if it was a new installation.

Close the shut-off valve so the power unit and the cylinder are isolated.

Remove the four connection screws of the valve body and open it. Take

out the return filter and clean it correctly. It is very important to set properly

this filter in its housing before the cleaning. Repeat these operations once

per year.

Table of contents

Other MP Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB J2007003L301CB quick start guide

Eaton

Eaton NZM1-XDTV Series Instruction leaflet

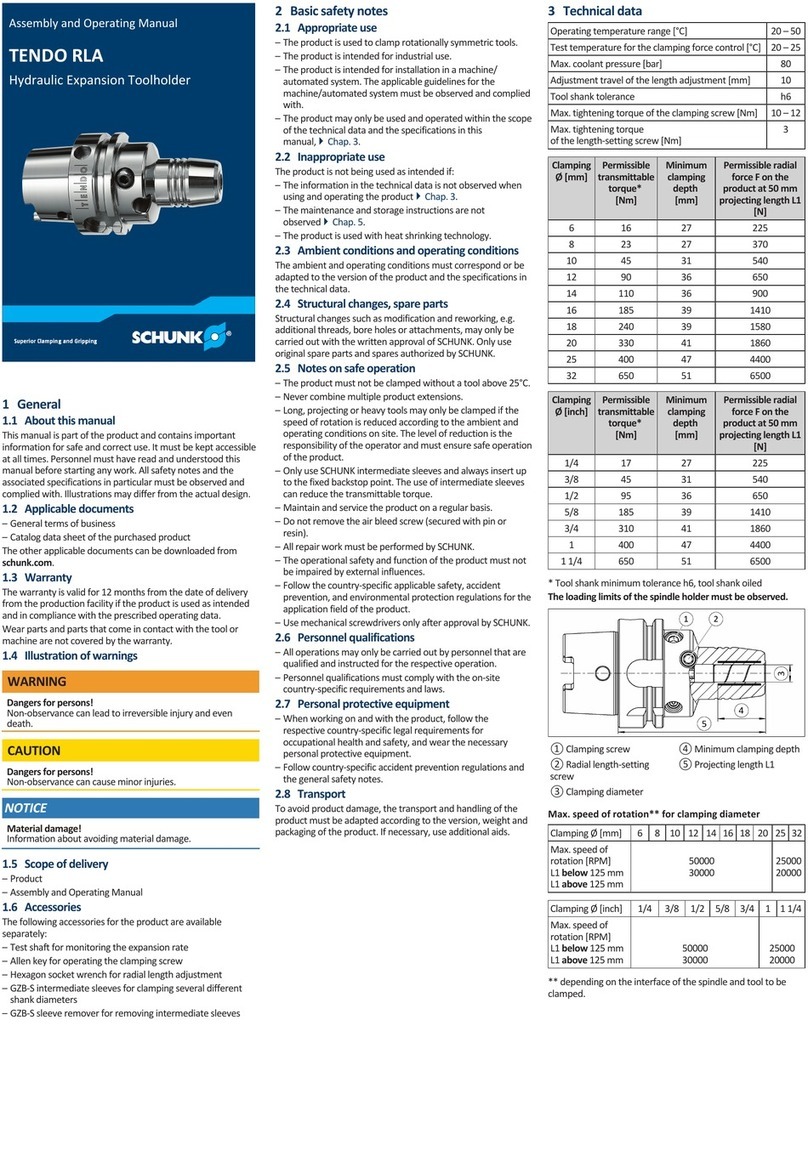

SCHUNK

SCHUNK TENDO RLA Assembly and operating manual

Regulus

Regulus BIO 55 MIX-BP G75 1F Installation and operation manual

Trooper

Trooper ADVANTAGE TR-100 instruction manual

Phoenix Mecano

Phoenix Mecano LD1000C Assembly instructions