Installation and Maintenance •Rexnord®Thomas®Disc Couplings

(Page 2 of 4) Series 52 • Sizes 225-750 (Tpack)

538-212 Rexnord Industries, LLC, 5555 S. Moorland Rd., New Berlin, WI 53151-7953

November 2008 Telephone: 262-796-4060 Fax: 262-796-4064

Supersedes CP-Series 52-T, 8-06 e-mail: info@rexnord.com web: www.rexnord.com

Set the indicator to “0”. Remove the hub and

install the key(s). Heat the hub in an oil bath or

oven until the bore is sufficiently larger than the

shaft. 350°F is usually sufficient. An open flame

is not recommended. However, if flame heating is

necessary, use a very large rose bud tip to give

even heat distribution. A thermal heat stick will help

determine the hub temperature. DO NOT SPOT

HEAT THE HUB OR DISTORTION MAY OCCUR.

With the hub expanded, slide it quickly up the shaft

to the “0” set point. Continue to advance the hub

up the taper to the desired axial position. Use the

indicator as a guide only. A preset axial stop device

can be helpful. Check the final results with a depth

micrometer. Install the hub retention device to hold

the hub in place.

5. Shaft Alignment — Move equipment into place.

A. Soft Foot — The equipment must sit flat on its base.

Any soft foot must now be corrected.

B. Axial Spacing — The axial spacing of the shafts

should be positioned so that the disc packs (flexing

elements) are not distorted when the equipment

is running under normal operating conditions. This

means there is a minimal amount of waviness in the

disc pack when viewed from the side. This will result

in a flexing element that is centered and parallel

to its mating flange faces. Move the connected

equipment to accomplish the above. Refer to the

assembly drawing and the connected equipment

installation procedures for specific axial spacing

requirements.

NOTE: The disc pack is designed to an optimal

thickness and is not to be used for axial adjustments

by removing or adding individual discs.

As a guide, maximum and minimum values for

dimension “N” are given. These dimensions are

suggested for initial installation. Additional capacity

is available to compensate for thermal and structural

movement. Maximum axial capacity values for these

couplings are also given. See Table 1 and Figure 1.

NOTE: C=2N+Center Member Length.

C. Laser Alignment is an Option — If not available,

proceed with dial indicator method.

D. Angular Alignment — Rigidly mount a dial

indicator on one hub or shaft, reading the face of

the other hub flange, as shown in Figure 2. Rotate

both shafts together making sure the shaft axial

spacing remains constant. Adjust the equipment

by shimming and/or moving so that the indicator

reading is within the values shown in Table 1.

E. Parallel Offset — Rigidly mount a dial indicator

on one hub or shaft, reading the other hub flange

outside diameter, as shown in Figure 3. Compensate

for indicator set-up sag. Rotate both shafts together.

Adjust the equipment by shimming and/or moving so

that the indicator reading is within .001 inch per inch

of the axial length between flex elements.

NOTE: If the driver or driven equipment

alignment tolerances are more stringent than our

recommendations, the driver or driven equipment

tolerances should be used. Also, be sure to

compensate for thermal movement in the equipment.

The coupling is capable of approximately four times

above shaft alignment tolerances. However, close

alignment at installation will provide longer service

with smoother operation.

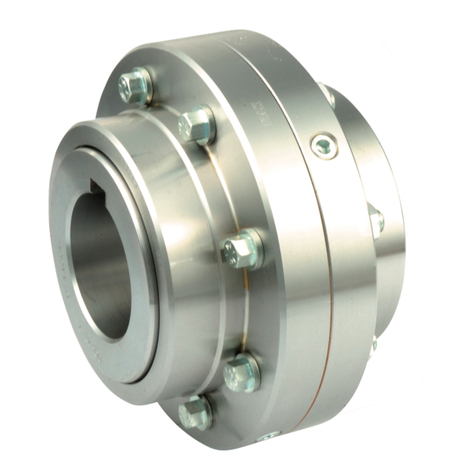

6. Final Assembly — With the coupling in good alignment,

the bolts should easily fit through the holes in the

flanges and the disc packs.

NOTE: All bolt threads should be lubricated. A clean

motor oil is recommended. Also, see Footnote below

Table 1.

A. If the coupling arrived assembled, the disc packs

are still attached to the center member assembly.

Remove the disc packs from the center member.

B. With the hubs mounted and the span length “C”

set, proceed to put the center member into place

between the two hubs. Care should be taken when

handling the center member as the tube can be

damaged. Support the center member at both ends

on wood blocks, with nylon straps from a hoist, or

some other convenient way. It may help to support

the end not being worked on with bolts through the

spool flange bolt holes. This will hold the parts in line

at that end.

C. Now install the disc pack. Rotate the hub or center

member so that the hub bolt holes line up with

the center member flange clearance holes. If the

coupling was assembly balanced, also align the

match marks. Start a bolt through a loose washer.

The radius side of the washer must always be

against the disc pack. Hold the disc pack in one

hand and slip it down between the two flanges so that

the bushing heads in the pack line up with the bolt

holes in the flanges as shown n Figure 1. Slide the

bolt and washer through the clearance hole in one

flange, into the bushing, and through the bolt hole of

the opposite flange. Make sure all parts pilot on the

body ground area of the bolt. Install a locknut onto

the bolt, but do not tighten it at this time.

Now pivot the pack around until it lines up the

bushing heads with the rest of the bolt holes. Place

a loose washer on each remaining bolt and install

the bolts through the clearance holes, into the

bushings, and through the bolt holes. The last bolt

may be tight and require some light tapping on the

head of the bolt to work it through the disc pack.

Install a locknut on each bolt. The locknuts can be

slightly tightened at this time. The disc pack, when

installed, should look centered and parallel with the

mating flanges.