Installation

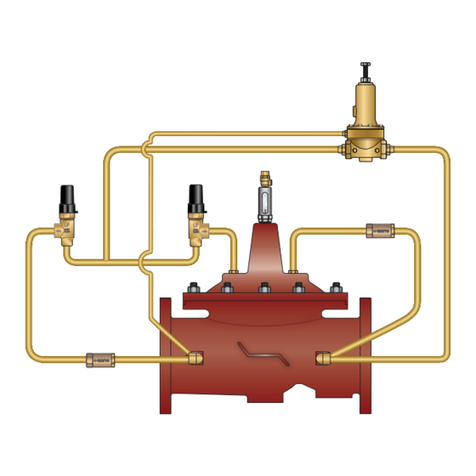

1. Install valve on return line of equipment to be balanced or as

shown on the plans.

2. For maximum accuracy, the flow measurement/balancing

valve should be located in an unrestricted straight pipe run

so that no fittings (elbow, valve, tee, etc.) is closer to the

flow measurement/balancing valve than 5 pipe diameters

upstream and 2 pipe diameter downstream. If a balancing

valve is located downstream from a circulation pump, allow a

distance of ten (10) diameters between the pump and balanc-

ing valves.

3. Series CSM-81-F flow measurement/balancing valves are

bidirectional and should be installed to insure ease of hooking

up meter and adjusting setting

Flow Measurement Instruction

1. With wrench, turn indicator to open position on indicator

plate.

2. Connect, vent and prepare the differential gauge. Refer to

instructions furnished with the gauge.

3. After initial pressure differential reading is taken, refer to flow

rate charts to obtain flow rate based on pressure differential

and valve setting. If flow rate is in excess of that specified,

turn indicator towards closed position, noting pressure drop

and valve setting and determining new flow rates from flow

rate chart. The unit or system has now been balanced.

4. Disconnect differential gauge.

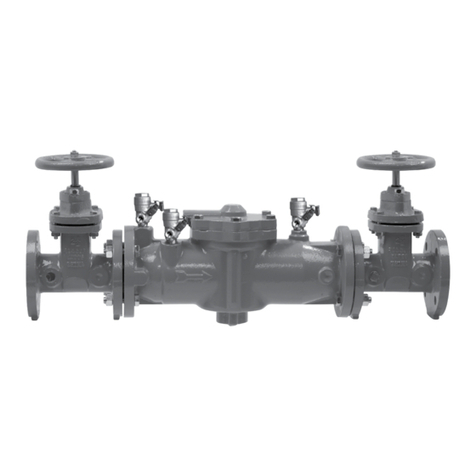

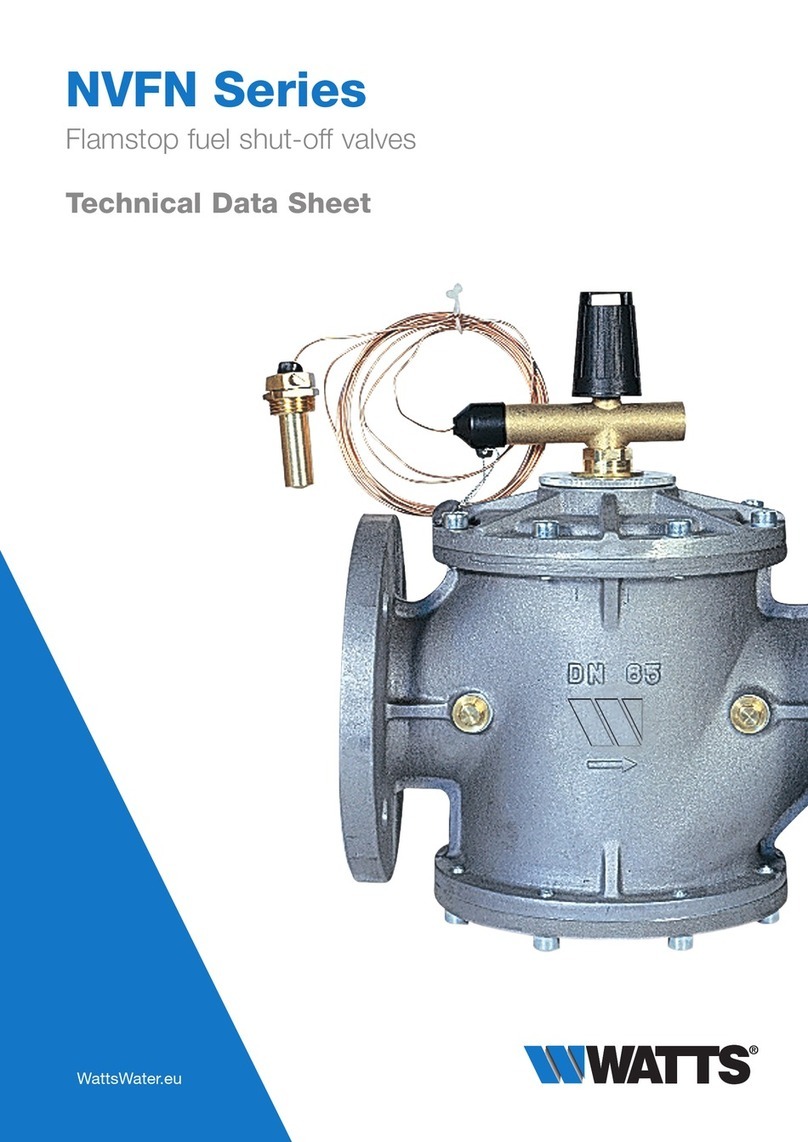

Watts Series CSM-81-F

Flow Measurement/Balancing Valves

Sizes: 21⁄2", 3", 4", 5", 6" and 8" (65, 80, 100, 125, 150, 200mm)

Installation Instructions

CSM-81-F

IS-CSM-81-F

The Watts Series CSM-81-F Flow Measurement/Balancing Valves are lubricated plug

valves designed for applications requiring balancing on medium to large flow rates. The

valve flanges are in accordance with ANSI B16.1 Class 125. Face to Face dimensions

are in accordance with ANSI B16.10.

Dimensions

▼

▼

▼

▼

▼

▼

▼

▼

▼

Q - Typ.

‘S’ places

equally spaced

on bolt circle -

both flanges

K

▼

▼

Max. Screw Length

C

D

B

A

F

▼

▼

▼

▼

A1

1”

▼

▼

MODEL NO.

ORDERING

SIZE (DN) DIMENSIONS WEIGHT

Code A A1 B C D F K Q S

Face to Bolt Flange

Center to Center to

Flange Square Dia. of Screw No.of

Face Circle Dia. Top Bottom

Thickness

Stem Holes Length Holes

in. mm in. mm in. mm in. mm in. mm in. mm. in. mm in. mm in. mm in. mm lbs. kgs.

CSM-81-F 036540 21⁄265 71⁄2191 51⁄2140 7 178 51⁄8130 315⁄16 99 11⁄16 17 11⁄431 3⁄419 21⁄264 4 29.5 13

CSM-81-F 036541 3 80 8 203 6 152 71⁄2191 57⁄16 137 43⁄16 106 3⁄419 11⁄431 3⁄419 21⁄264 4 39 18

CSM-81-F 036535 4 100 9 229 71⁄2191 9 229 61⁄2165 415⁄16 125 15⁄16 24 11⁄238 3⁄419 21⁄2 64 8 61.5 28

CSM-81-F 036542 5 125 101⁄2267 81⁄2216 10 254 73⁄4197 6 153 1 25 2 51 7⁄8 22 35⁄892 8 88 40

CSM-81-F 036543 6 150 101⁄2267 91⁄2241 11 279 73⁄4197 6 153 1 25 2 51 7⁄822 35⁄892 8 100 45

CSM-81-F 036544 8 200 111⁄2292 113⁄4299 131⁄2343 93⁄16 233 61⁄2165 11⁄829 2 51 7⁄822 35⁄892 8 172 78