3

Table of Contents

1.0 Understanding Safety Information.................................................4

1.1 Symbols Used in this manual ....................................................4

2.0 Introduction to the Unit .................................................................4

2.1 Overview...................................................................................4

2.2 Specifications ...........................................................................4

2.3 Unpacking and Inspection of the Instrument and Accessories...4

2.4 Display......................................................................................5

2.5 Touch Pad ................................................................................5

2.6 Vapor Purge..............................................................................5

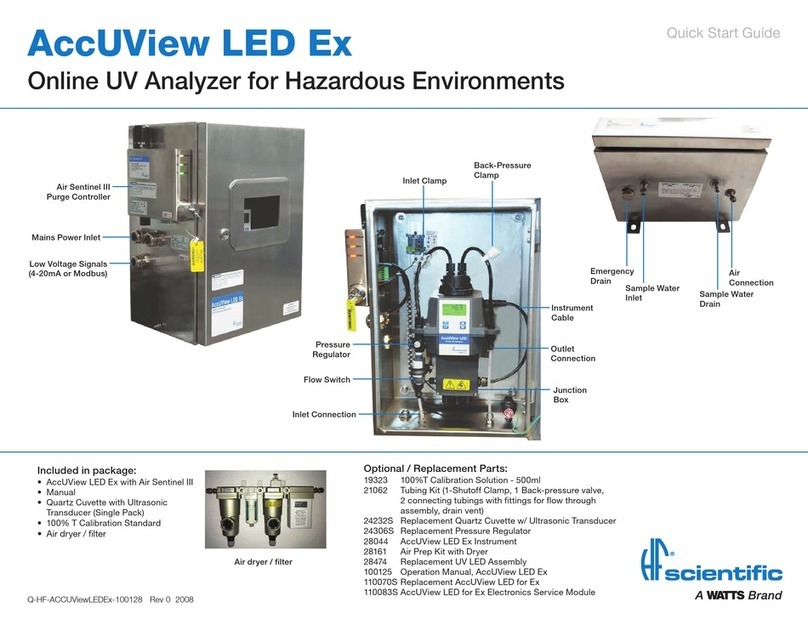

3.0 Installation and Commissioning.....................................................5

3.1 Mounting and Site Selection .....................................................5

3.2 Plumbing ..................................................................................6

3.2.1 Pressurized Systems..........................................................6

3.2.2 Drain Vent ..........................................................................6

3.3 Electrical Connections ..............................................................7

3.3.1 Power ................................................................................7

3.3.2 RS-485..............................................................................7

3.3.3 Relays................................................................................7

3.3.4 4-20 mA ............................................................................7

4.0 Operation .....................................................................................8

4.1 Warm-up ..................................................................................8

4.2 Routine Measurement...............................................................8

4.3 Security Access Feature ...........................................................8

4.4 Initial Operation.........................................................................8

5.0 Instrument Calibration...................................................................9

5.1 100%T Calibration ....................................................................9

5.2 ABS Calibration ........................................................................9

5.2 Calibration Error......................................................................10

6.0 Restore Factory Settings ............................................................10

6.1 Restoring Factory Settings......................................................10

7.0 Instrument Configuration (CONFIG mode)...................................10

7.1 Selecting the Output (O/P) ......................................................10

7.2 Setting the 4-20 mA ...............................................................10

7.2.1 Setting the 4 mA Level.....................................................10

7.2.2 Setting the 20 mA Level...................................................11

7.2.3 Setting the Error Level......................................................11

7.3 Configuring the RS-485 Port...................................................11

7.3.1 Setting the Baud Rate......................................................11

7.3.2 Setting the Address .........................................................11

7.4 Configuring the Alarms ...........................................................11

7.4.1 Alarm 1 ............................................................................12

7.4.2 Alarm 2 ............................................................................12

7.5 Enabling the Security Access..................................................12

7.6 Extended Settings ..................................................................12

7.7 Units.......................................................................................12

7.8 Speed of Response ................................................................12

7.9 LCD Backlight Brightness .......................................................12

7.10 Ultrasonic Cleaning...............................................................13

7.11 RS-485 Parameter - Bits ......................................................13

7.12 RS-485 Parameter - Parity....................................................13

7.13 RS-485 Parameter – Stop Bits..............................................13

7.14 Duty Cycle ............................................................................13

7.15 Desiccant Alarm ...................................................................13

7.16 4 mA Adjustment..................................................................13

7.17 20 mA Adjustment................................................................14

7.18 Saving Configuration Settings ...............................................14

8.0 Additional Features and Options.................................................14

8.1 Backlit LCD ............................................................................14

8.2 Ultrasonic Cleaning.................................................................14

8.3 RS-485 Output .......................................................................14

8.3.1 HF Online.........................................................................14

8.3.2 Simple Communication....................................................15

8.3.3 Modbus Communication .................................................15

8.4 Flow Alarm..............................................................................15

9.0 Routine Maintenance..................................................................15

9.1 Cleaning the Flow Through Cuvette ........................................15

9.2 Replacing or Installing the Desiccant Pouch............................15

9.3 Replacing the Source Lamp....................................................15

10.0 Troubleshooting........................................................................16

10.1 AccUView LED Fault Detection .............................................16

10.2 System Fail Message ...........................................................16

10.3 Diagnostic Chart...................................................................16

10.4 Technical and Customer Assistance......................................16

11.0 Accessories and Replacement Parts List ..................................17

12.0 Warranty...................................................................................20