6

3.0 Theory of Operation

3.1 The Measurement

The CLX-Ex2 has two solenoid valves, one for sample water (FLOW)

and one for draining of the cuvette (PURGE). A third solenoid, along

with four check valves forms a reagent pump. Sample water flow is

controlled by the FLOW solenoid valve. The PURGE solenoid valve is

used to empty the cuvette in the measurement chamber.

The measurement chamber consists of a sample inlet, a purge drain,

and an overflow. The reagent is added from the check valves integrated

into the lower portion. A green LED provides the 515 nm source

lamp, a red LED is used for sample level and flow measurement. A

single detector is located 180º from the green LED. A replaceable

glass cuvette separates the LEDs from the detector and maintains

the measurement path length. Sample water flows in the inlet at the

bottom, through the measurement cuvette and out through an overflow

drain. This flow is used to both fill the cuvette and flush the system.

The reagents are dispensed from two replaceable bottles. One bottle

has a buffer to control the pH; the second has an indicator that contains

the DPD, which produces color when chlorine is present in the sample.

The degree of color is dependent on the amount of chlorine in the

sample water.

The measurement chamber is open to view operations. A white LED

backlights the chamber for a clearer view. The white LED will flash to

attract attention in the case of a warning or failure. Most warnings and

failures are also displayed on the screen. To prevent interference, the

white LED is turned off during measurements.

During normal operation the CLX-Ex2 will run through a timed cycle.

A simplified cycle will consist of the following sequences:

• Flushing – continuous sample flow

• Purging – PURGE valve opens

• Zeroing – no flow with cuvette full

• Adding Reagents – one pulse of the reagent pump

• Mixing with sample – sample flow pulses in

• Reading resulting sample – no flow with cuvette full

• Purging – PURGE valve opens to remove reacted sample

The cycle above is simplified and does not describe all the actions

and testing that occurs. The CPU continuously diagnoses the entire

system for correct operation and sample water flow. If an error occurs,

a message is posted to the message queue on the LCD screen.

The reagent is added by a single pulse of the reagent solenoid. When

the reagents require replacement, the PRIME button is pushed to bring

new reagents into the system. During PRIME the reagent solenoid is

pulsed several times to draw fluid from the two reagent bottles and

fill the tubes with new reagent. A complete PRIME takes less than

a minute.

The SERVICE button empties the cuvette, stops the flow of sample

water, and clears any errors. This provides a convenient way to replace

reagents and the measurement cuvette. If more extensive servicing

is performed, all power to the CLX-Ex2 should be removed. If the

CLX-Ex2 is to be turned off, it is recommended that the instrument be

placed in SERVICE mode before removing power. This ensures that

the cuvette is emptied and the flow is off.

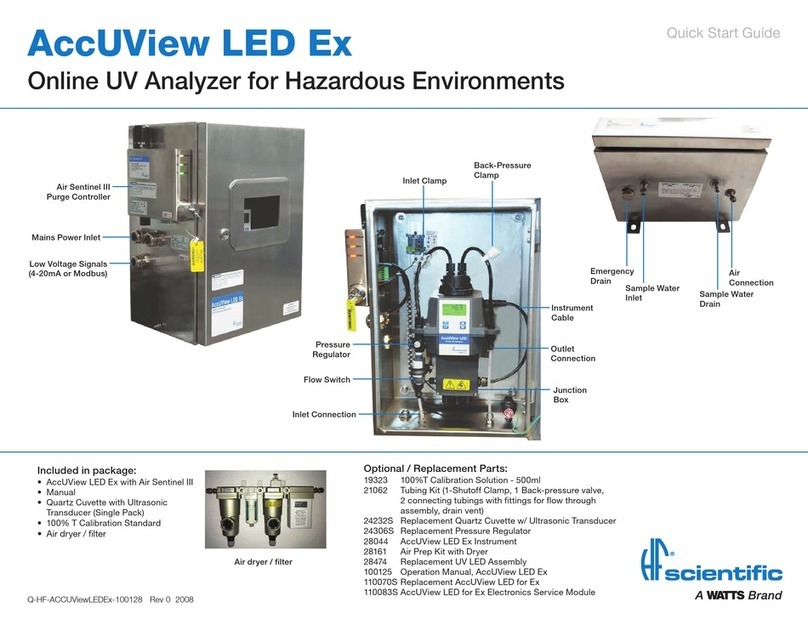

3.2 The Air Sentinel Controller

The Air Sentinel controller governs the power to the instrument. For

normal instrument operation air needs to passes through fitting on

the base of the main enclosure and constantly purge any vapors that

could build-up. All GREEN lamps indicate a safe operating condition.

Only when this condition is reached will power be applied to the

measurement portion of the instrument.

Start-up

At start-up with the enclosure door open the Air Sentinel will display a

RED PRESSURE lamp on the visual indicator indicates that the system

is not pressurized and no power is sent to the instrument.

Closing the door with the air pressure applied, will cause the Air

Sentinel to display a GREEN PRESSURE lamp and a RED TIMER

lamp. During this time the enclosure will undergo an automatic dilution

purge period of 5 minutes where at least 5 volumes of free space inside

the enclosure will be exchanged with clean purge air. No power is

applied to the rest of the instrument during this time.

After the enclosure air has gone through this purge period the Air

Sentinel will display all GREEN lamps. At this time the instrument is

deemed safe and power is applied to rest of the instrument.

Do not apply power to the Air Sentinel controller unless the area

has been properly tested and is known not to contain explosive

materials.

Bypass Key

Use of the bypass key disables the safety features and safe

operation of this instrument. It is imperative that this operation

be performed only after the area has been tested and known to

be safe.

If power is retained to the CLX-Ex2 after opening the enclosure

door while NOT in bypass mode, immediately close the

enclosure door and remove power to the instrument. Contact

HF scientific service department for further instruction.

Assuming the area has been tested and is known not to contain

explosive materials; a bypass service key is provided and can be

used. In this operating mode power will be retained to the rest of the

instrument even though the door is open. It is imperative that this mode

is only used after area is known to be safe. This operation disables the

safe operation of this instrument.

Upon turning the key, the indicator will display the RED BYPASS &

TIMER lamps. This is an indication of the maintenance mode. Power

is retained to the instrument. The key cannot be removed in this mode

of operation.

After maintenance has been performed the door should be closed

and latched. Air pressure will once again pressurize the enclosure. The

maintenance key can now be turned and removed and the key cover

replaced. The purge controller will display GREEN PRESSURE &

BYPASS lamps indicating a safe operation and power is kept applied

to the instrument. The TIMER lamp will remain RED for 5 minutes to

indicate a bypass operation had taken place.

WARNING

!