2

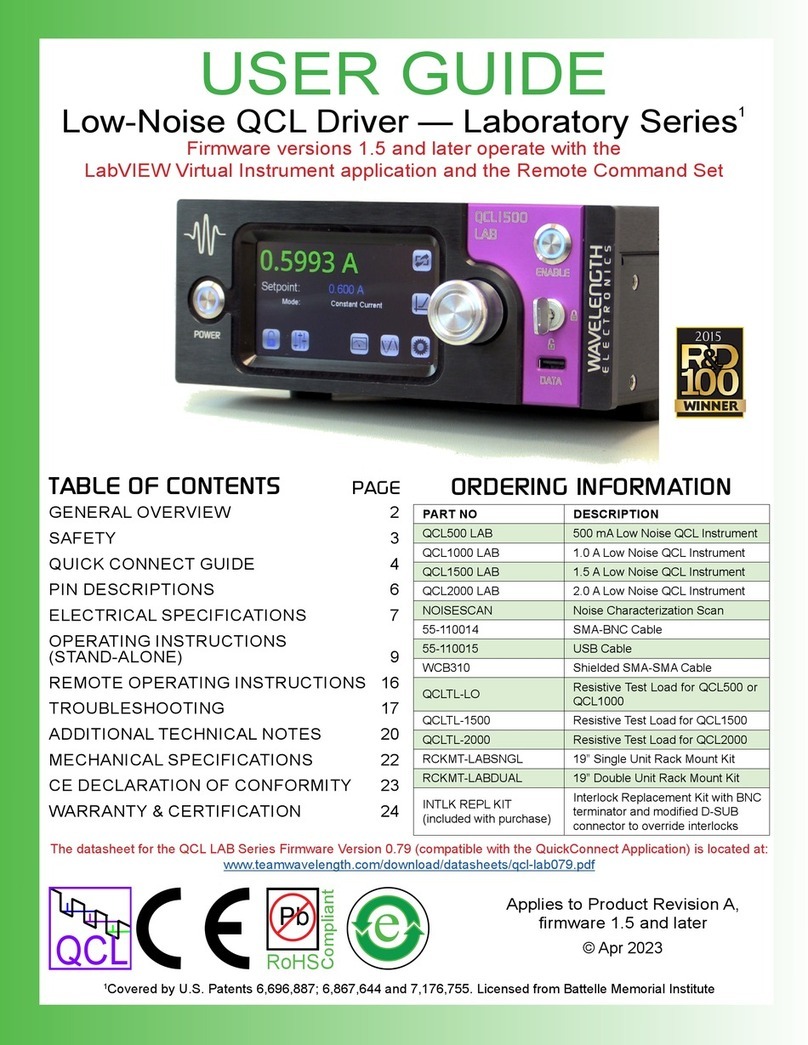

• Output currents of 500 mA, 1 A, 1.5 A, 2 A

• Low noise: <0.4 A RMS up to 100 kHz

(QCL500, typical)

• Compliance voltage is adjustable, 10 to 20 V

(NOTE: The unit will only deliver the voltage

that the load requires, up to the compliance

voltage limit.)

• Analog modulation up to 2-3 MHz

• Constant Current Mode operation

• Touchscreen with intuitive user interface

• CE compliant, compatible with CDRH laser

regulations

• Feature-rich for research projects

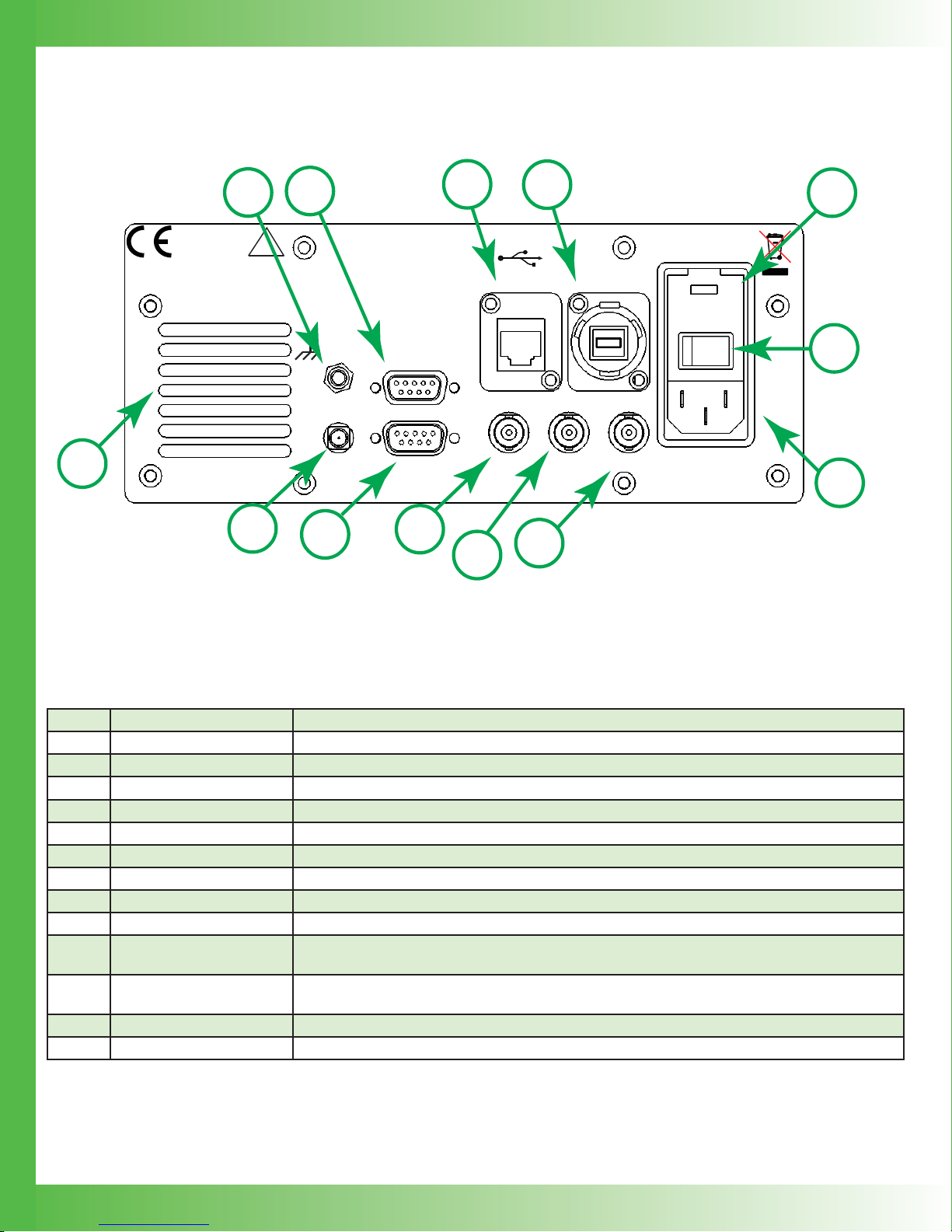

»USB and Ethernet interfaces with software

included

»Auto voltage/current scan function

»Data collection using a computer or USB

flash drive

»Field upgradeable firmware

»Sophisticated error handling

»Save and recall functions for specific set

ups

• Rack mountable: 2 U height and ½ rack width

• Safety features protect your QCL investment

»Adjustable soft-clamp current limit, with

Brick-Wall Never-Exceed circuitry

»Password protection available to lock out a

selectable control set

»Key switch, active, and passive interlocks

»Brown-out & overvoltage protection

»Power supply overcurrent protection

»Driver over-temperature protection circuit

»Relay shorts output when current is

disabled

»AC input and patented power supply

filtering

»2 second turn-on delay — adjustable

»1.5 msec current ramp

F E A T U R E S

GENERAL OVERVIEW

THE LOWEST-NOISE DRIVER

AVAILABLE

These low noise QCL instruments have the lowest current

noise density of any commercially available. Powering your

QCL with this patented1driver gives you narrow linewidth,

stable center wavelength, and repeatable scans.

INTUITIVE USER INTERFACE AND

SUPERIOR SOFTWARE CONTROL

With Wavelength’s plug and play instrument, you have the

ability to quickly set the controls using either the instrument or

a remote computer.

PROTECT YOUR QCL INVESTMENT

All the essential control and monitor functions you expect in a

Wavelength laser driver are incorporated into this instrument,

along with protection circuitry to safeguard your QCL from

minor power source faults, over-temperature conditions, and

electrical faults.

The soft-clamping current limit can be set without enabling the

driver output, and uses a brick-wall never-exceed limit circuit

to protect the QCL from potentially damaging overcurrent

situations.

OEM VERSION AVAILABLE

Once you have finalized your work, the QCL circuitry is

available in compact OEM versions.

APPLICATIONS

Due to their unique construction, QCLs operate with high

power in the near-IR through terahertz ranges. These

wavelengths are particularly suited to detection of molecules

significant to humans.

Applications for the lower noise QCL driver include: remote

detection of explosive materials, medical diagnosis using the

breath, non-invasive glucose testing, emissions monitoring of

the atmosphere or marine environments, and pharmaceutical

process quality control. Additional applications include

anesthesia and hospital air quality monitoring, leak detection,

and remote imaging.

1Covered by U.S. Patents 6,696,887; 6,867,644 and

7,176,755. Licensed from Battelle Memorial Institute