ATTENTION: PLEASE READ AND UNDERSTAND ALL INSTRUCTIONS AND WARNINGS

BEFORE ASSEMBLING, INSTALLING OR USING THIS PRODUCT.

TRUCK STORAGE SOLUTIONS

SECURING YOUR REPUTATION®

©2015 KNAACK LLC

INSTALLATION MANUAL

STEEL & ALUMINUM SIDE BOX WITH

PACK RAT®DRAWER UNITS

NOTICE

MODELS

DANGER

Use specic aluminum upt components when installing WEATHER GUARD®

products to aluminum truck beds. Follow additional instructions if mounting

to an aluminum truck bed. There may be left over components depending on

upt.

Any modication or unintended use of this product shall immediately void all

manufacturers warranties. Manufacturer disclaims all liability for injuries to

persons or property resulting from any modication to, or unintended use of

this product.

Danger of explosion. Do not use this product for storing or transporting am-

mables, explosives, hazardous materials, or hazardous waste, such as contain-

ers of gasoline, solvents, gun powder, dynamite, propane tanks, acetylene

tanks and cutting torches. This product is only intended and safe for use in

storing and transporting small tools, equipment and other similar materials.

Any modications made to, or unintended use of this product, could create a

hazardous condition that can cause death, serious personal injury or property

damage.

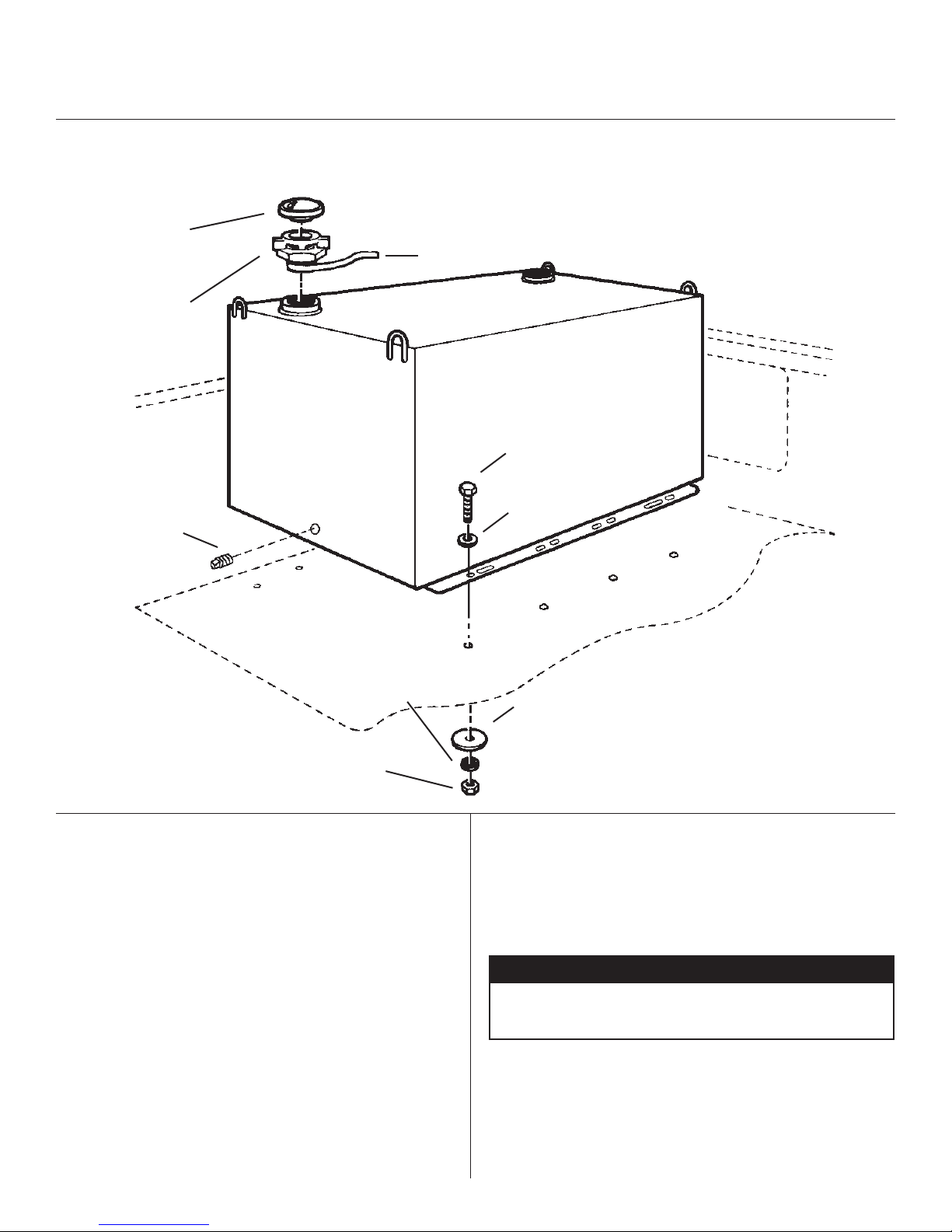

WARNING

Prior to drilling, so as not to cut or puncture fuel tanks, fuel lines, electric

wires, etc., check under vehicle for locations. All oor mounting bolts near the

gas tank area should be installed from the underside of the vehicle, to guard

against the gas tank being punctured in the event of a collision. This would

mean not using Blind Fastener in this area. Holes drilled in this area should be

3/8".

CAUTION

Transfer tank bottom must be fully supported by the oor of the truck bed so

as not to cause exing of the tank which could cause stress cracks and leak-

age of the tank. To keep debris out of your eyes when checking the underside

of the vehicle, or when drilling, always wear protective eyewear.

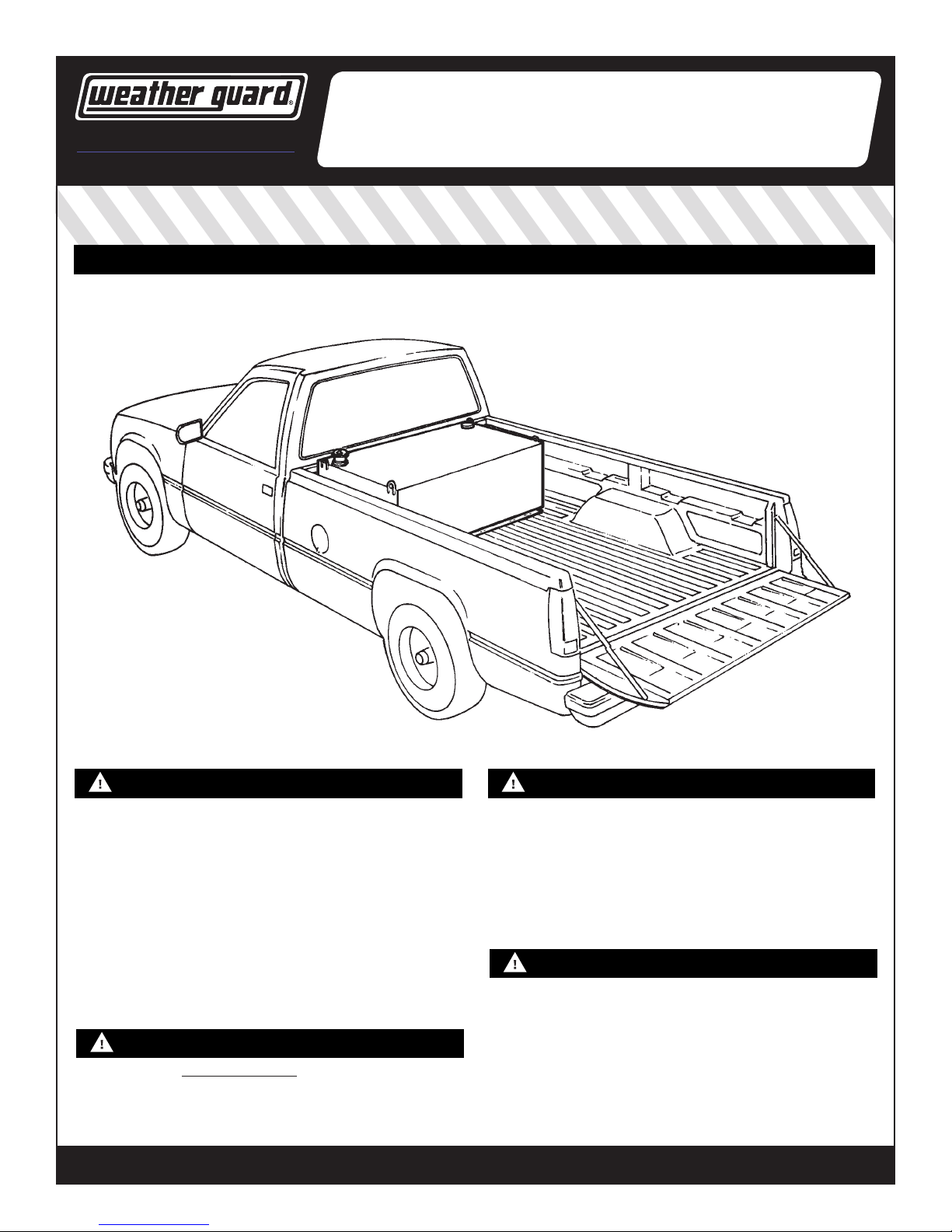

TRANSFER TANKS

Note: X represents the color code for your model: 3 = White | 5 = Black

350-X-01, 351-X-01, 352-X-01, 354-X-01, 357-X-01, 358-X-01, 359-X-01, 360-X-01