Subject to change - No liability for errors and printing errors - September 2014

weatronic ® GmbH - Schmiedestraße 2A - 15745 Wildau

3

Content:

1. Scope of supply .................................................................... 4

2. Safety instructions............................................................... 5

3. Technical data........................................................................ 6

4. Care instructions .................................................................. 7

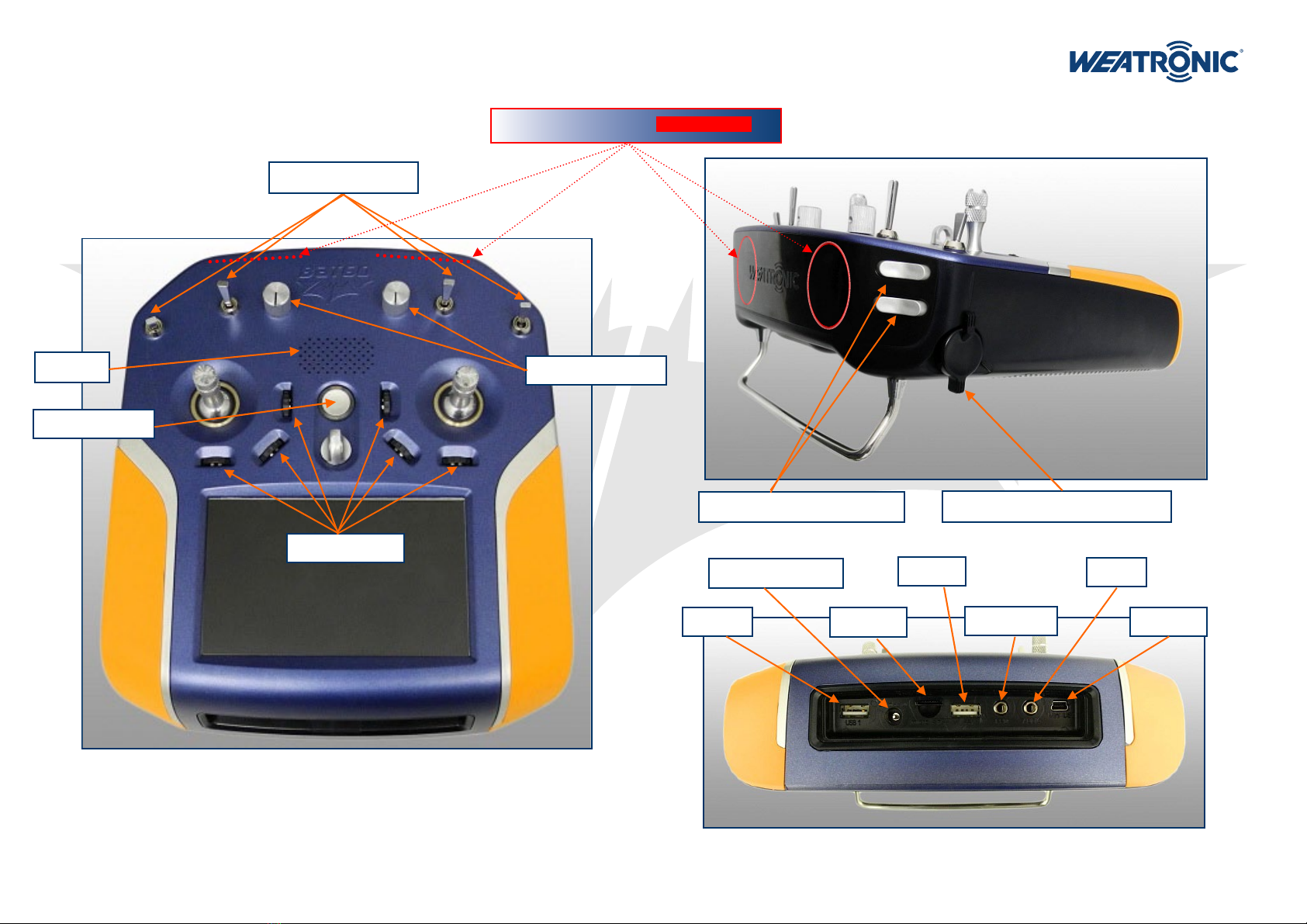

5. General overview................................................................. 8

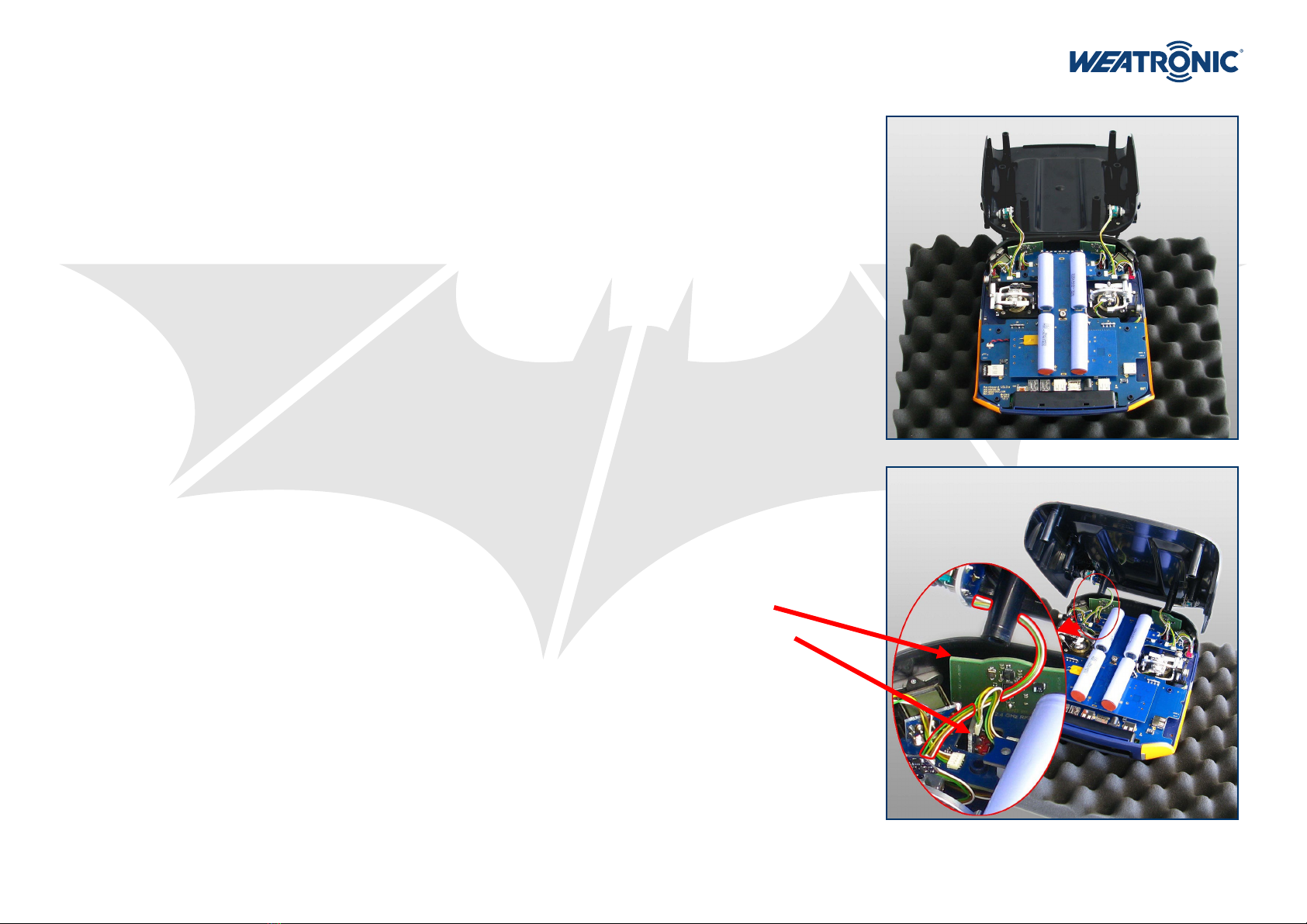

6. Overview about internal electronics............................... 9

7. How to open and close the BAT 60 ................................ 10

7.1. Open it................................................................................. 10

7.2. Close it ................................................................................. 10

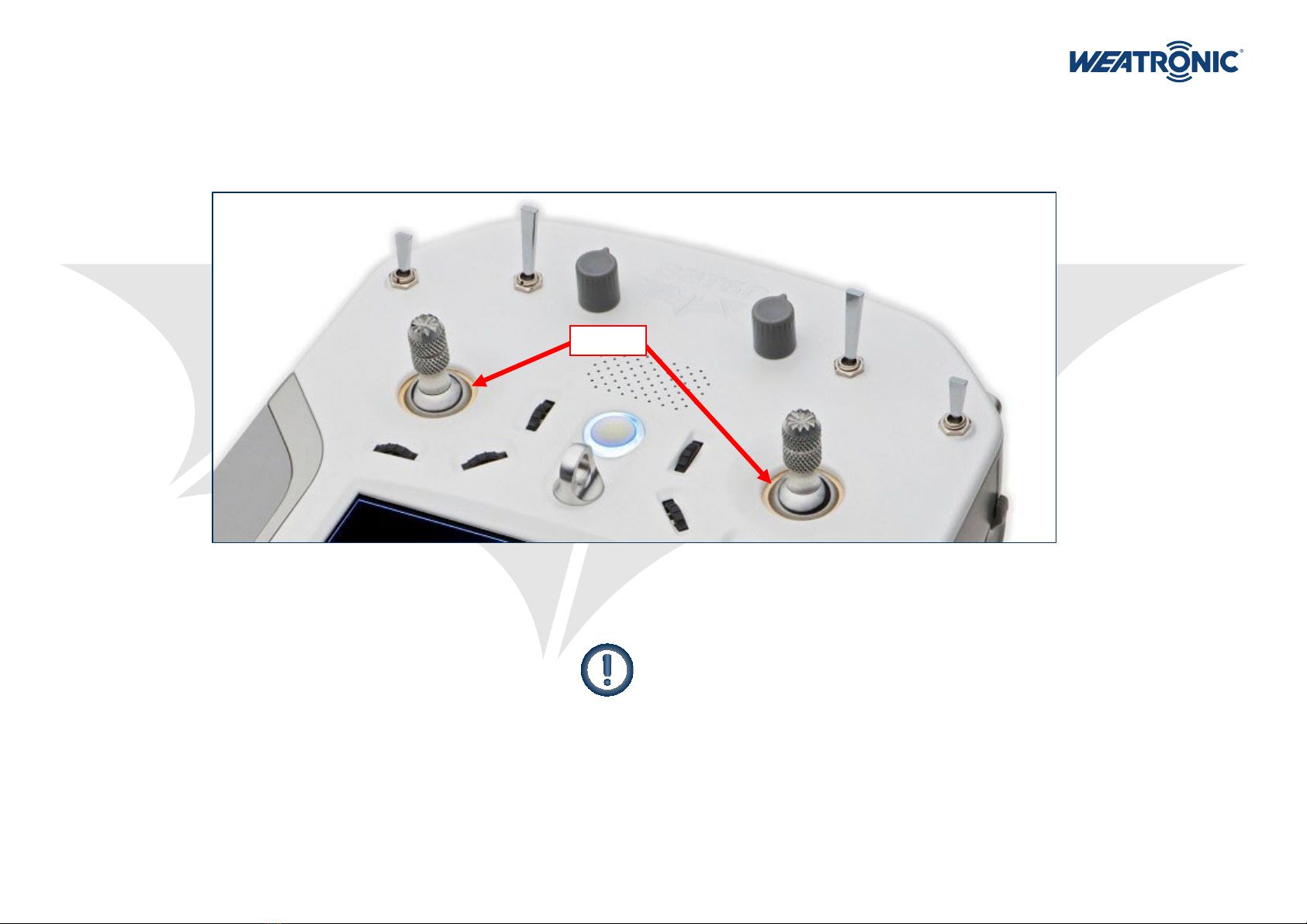

8. Mechanical stick adjustment........................................... 11

8.1. How to adjust the “spring force” ...................................... 11

8.2. How to adjust the “feedback characteristics” .................. 11

8.3. How to change the stick length......................................... 12

8.4. Laying of internal stick cables............................................ 13

9. Mechanical toggle switch adjustment.......................... 14

10. Hardware extras ................................................................. 16

11. Charging BAT 60 (10 - 19 Volt)......................................... 16

12. LED status information..................................................... 16

12.1. Transmitter is switched off and charging.......................... 16

12.2. Transmitter is switched on.................................................. 16

13. How to switch on/off......................................................... 17

13.1. ON .................................................................................. 17

13.2. OFF .................................................................................. 17

13.3. RESET .................................................................................. 17

14. Interface ............................................................................... 18

14.1. The display .......................................................................... 18

14.2. TOP INFO ROW.................................................................... 18

14.3. NAVIGATION ROW .............................................................. 19

14.4. Common interface symbols ................................................ 19

14.5. Common “pop-up” menus ................................................. 19

15. Calibration of potentiometers and sticks .................... 20

16. Software and firmware UPDATE..................................... 20

16.1. Update process of BAT 60 .................................................. 20

16.2. Update of weatronic receivers........................................... 20

17. Binding process .................................................................. 20

18. RC-equipment installation in your model.................... 20

19. “setup wizard” - how to add a new model ................ 21

19.1. 1st step: Model Configuration ........................................... 21

19.2. 2nd step: Select Stick Mode ............................................... 21

19.3. 3rd step: Receiver Configuration....................................... 21

19.4. 4th step: Servo Configuration graphic view ..................... 21

19.5. 5th step: Servo Configuration list view ............................. 21

20. weatronic programming philosophy ............................ 22

21. Menu structure ................................................................... 23

21.1. Model Settings .................................................................... 23

21.1.1. Model Configuration.................................................. 24

21.1.2. Receiver Configuration .............................................. 24

21.1.3. Servo Configuration ................................................... 25

21.1.4. Functions ..................................................................... 26

21.1.4.1. Function name ......................................................... 26

21.1.4.2. Function Setup ......................................................... 26

21.1.4.2.1. Flex Rate ................................................................ 26

21.1.4.2.2. Flex expo................................................................ 26

21.1.4.2.3. Flex Differential..................................................... 26

21.1.4.2.4. Fail Safe Pos. .......................................................... 26

21.1.4.2.5. Duration................................................................. 26

21.1.4.2.6. Curve Edit............................................................... 27

21.1.4.3. Control Assignment ................................................. 28

21.1.4.4. Trim Setup ................................................................ 28

21.1.4.5. FMO (Flight mode offset) ........................................ 28

21.1.4.6. Servo Assignment..................................................... 28

21.1.4.7. Gyro .......................................................................... 28

21.1.5. Function Mixers .......................................................... 29

21.1.6. Flight Modes ............................................................... 29

21.1.7. Virtual Switches .......................................................... 30

21.1.8. Timers .......................................................................... 30

21.1.9. Limiter ......................................................................... 30

21.1.10. Screen Adjustment ..................................................... 31

21.1.11. Control Map................................................................ 31

21.1.12. Servo Monitor ............................................................. 31

21.2. General Settings ................................................................. 32

21.2.1. Calibration .................................................................. 32

21.2.2. File Manager ............................................................... 32

21.2.3. Firmware Versions ...................................................... 32

21.2.4. PreFlight Test .............................................................. 33

21.2.4.1. Range Test ................................................................ 33

21.2.4.2. Failsafe Test .............................................................. 33

21.2.5. User Settings ............................................................... 33

21.2.6. Stick Control Config ................................................... 34

21.2.7. Unit Selection.............................................................. 34

21.2.8. Volume control ........................................................... 34

21.2.9. Brightness control....................................................... 34

21.3. Model Management........................................................... 34

21.3.1. Change model............................................................. 34

21.3.2. Add new model .......................................................... 34

21.3.3. Copy model ................................................................. 34

21.3.4. Delete model .............................................................. 35

21.3.5. Import/export.............................................................. 35

22. Declarations of Conformity............................................. 35

23. Disclaimer of warranty / damages................................. 36

24. Disposal instructions for countries within the EU..... 36

25. You need help? ................................................................... 36

BAT 60 - User Manual