22615-76_02.docx

Introduction

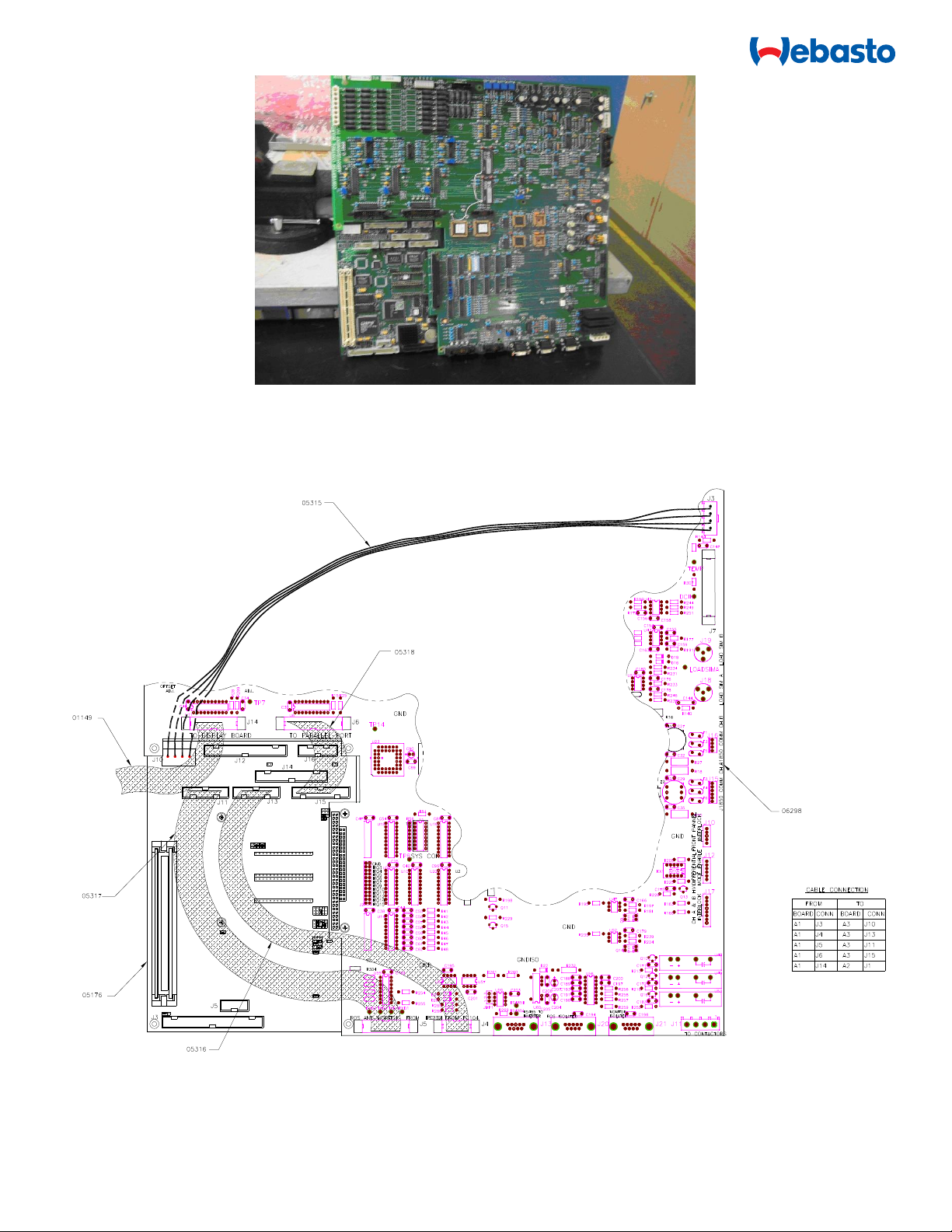

The #22615 kit is provided to allow the ABC-150 with Ampro PC104 computer board, to be converted to ICOP

VDX-6353RD, and allowing communication via CAN or/and ROS that exits in the unit. The kit contains the

following:

LABEL,CALIBRATION,OUTDOOR

CONNECTOR, SHORTING JUMPER, SHROUD, 2PIN, 0.100(2.54), 2800VACrms, 3.0A,

-55-120C, UL E66906

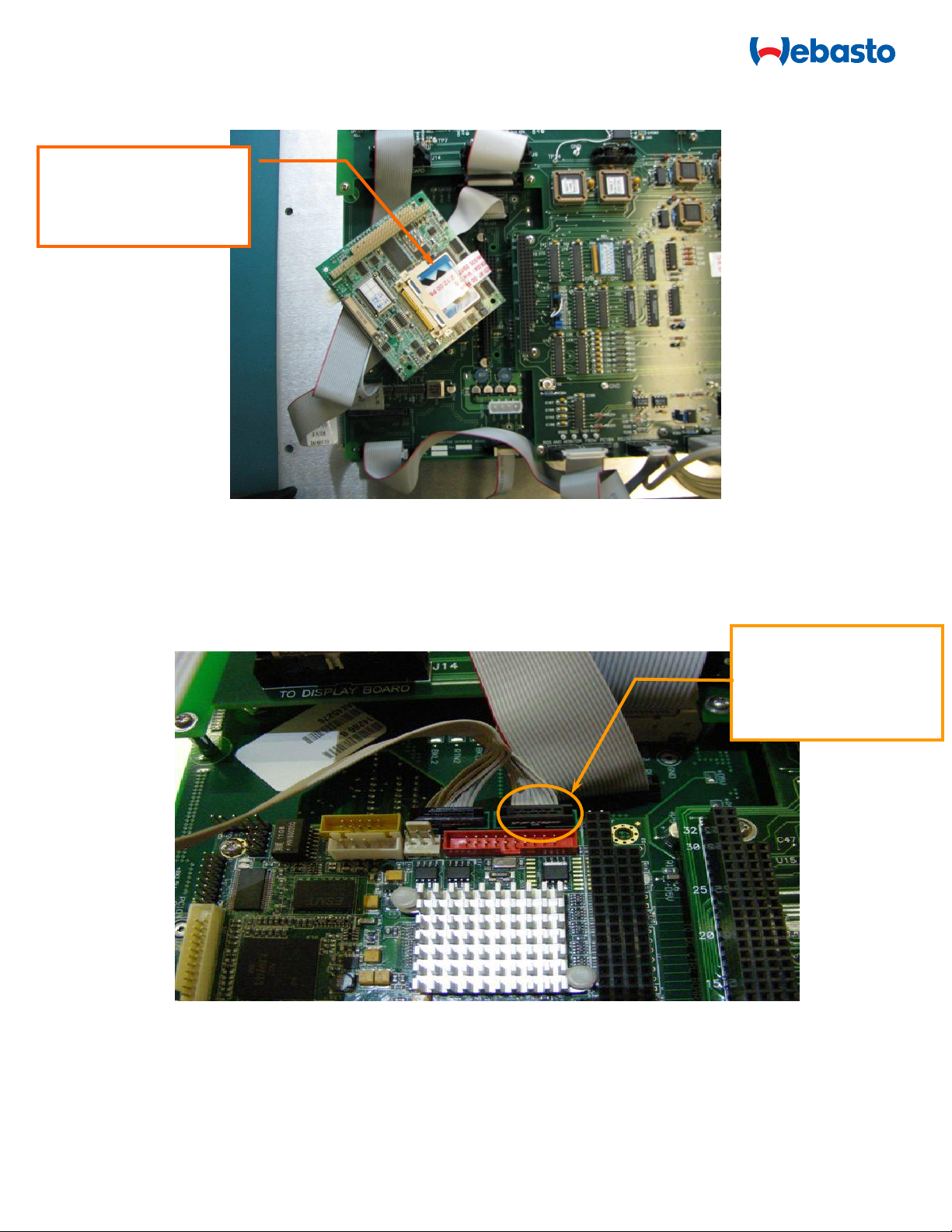

ASSY,MICROCIRCUIT,PROGRAMMED,AC INVERTER,ABC-150/170

PCBA, INTERFACE, PCM/PC-104, ABC

STANDOFF, FEM/FEM, RND, 4-40THR, 0.625"L, 0.187"OD, BRASS

STANDOFF, MALE/FEMALE, HEX, 4-40x0.625"L, 1/4"OD, NYLON

STANDOFF, FEM/FEM, HEX, 4-40X0.625"L, 1/4"OD, BRASS

STANDOFF, MALE/FEMALE, HEX, 6-32X0.625"L, 1/4"OD, BRASS

CABLE ASSY, PC104/CONVERTER CONTROL COM

KIT,COMPUTER,SINGLE BOARD W PC/104

COMPUTER,SINGLE BOARD W PC/104 AND CUSTOM BIOS,VORTEX86DX 800 MHZ CPU

W/256MB MEMORY,3.78in(96mm)X3.55in(90.2mm),-20C-70C

CABLE ASSY, 2mmx2mm MOLDED 26 PINS CONNECTOR WITH 1mm FLAT RIBBON 26C

CABLE 7inL, 30V, -20C-85C (SHIPPED WITHIN ITEM 10).

CABLE ASSY, 2mmx2mm MOLDED CONNECTORS WITH 1mm FLAT RIBBON 20C CABLE

8inL, 30V, -20C-85C (SHIPPED WITHIN ITEM 10).

ASSY,MACH211 PAL,U24,CONTROL BOARD,DC,(VDX-6353-D),P3

ASSY,FLASH STORAGE VDX-6353RD,HYB,ABC-150

NUT,6-32,HEX,W/TOOTH WASHER,ZN PL STL

KIT,SW,ROS V6.0/CAN V1.7.1/HYBRID,P3

KIT,OPTO ISOLATOR (485OPDR),ABC-150/170

OPTOISOLATOR,RS-422/485 ISOLATED REPEATER, 4.173inDx0.992inWx3.118inH,

10-30Vdc 0.7W POWER SUPPLY, 35mm DIN RAIL MOUNTED,2KV ISOLATED,-40C-

80C,UL,CE,FCC

ASSY,RAILING,DIN,MODIFIED,IPC/P3

END STOP,TERM BLOCK,DIN RAIL MOUNT

CABLE ASSY,OPTO ISOLATOR (485OPDR) TO INVERTER CONTROL BD,P3

CABLE ASSY,OPTO ISOLATOR (485OPDR) TO CONVERTER CONTROL BD,P3

WIRE,22AWG,19/34,TIN CU,BLACK,IRRADIATED PVC,300V,105C,UL 1430

WIRE,22AWG,19/34,TIN CU,RED,IRRADIATED PVC,300V,105C,UL 1430

CLAMP,WIRE HARNESS,NYLON,0.5(12.7),ELASTIC RELEASE,SCREW MOUNT

CABLE TIE,MOUNT,1.00(2.54)Lx1.00(2.54)Wx0.20(3.2)H ,ABS,0.50 lbs,BLACK,ACRYLIC

ADHESIVE BACKED v

CABLE TIE,MINI,3.1in,0.68inD,18 lbs,NATURAL,NYLON, BLACK

NUT,10-32,HEX,W/TOOTH WASHER,ZN PL STL

CABLE ASSY,INTERLOCK LOOP BACK,P3

Note 1: Items 10.1 through 10.3 are part of Kit P/N: 29594 (Item 10).

Note 2: Items 15.1 through 15.14 are part of Kit P/N: 21128 (Item 15).

Note 3: Item Num 18 only needed for 50Hz