6

17. The OPC/Brake lever is a safety device. Never attempt to bypass its operation. Doing so makes the safety

device inoperative and may result in personal injury through contact with the rotating trimmer line. The

control lever must operate easily in both directions and automatically return to the disengaged position

when released.

18. Never operate the trimmer in wet grass. Always be sure of your footing. A slip and fall can cause serious

personal injury. If you feel you are losing your footing, release the OPC/Brake lever immediately and the

spindle will stop rotating within three seconds.

19. Operate only in daylight or good artificial light. Walk, never run.

20. Stop the spindle when crossing gravel drives, paths or roads.

21. If the machine starts to vibrate abnormally, stop the engine and check immediately for the cause.

Vibration is generally a warning of trouble.

22. Shut the engine off and wait until the spindle comes to a complete stop before cleaning the discharge

area. The spindle continues to rotate for a few seconds after the OPC/Brake lever is released. Never place

any part of the body in the trimmer line area until you are sure the spindle has stopped rotating and the

spark plug cap removed from the spark plug and contact cannot be made between the two.

23. Never operate the trimmer without proper trail shield, discharge cover, OPC/Brake lever or other safety

protective devices in place and working. Never operate with damaged safety devices. Failure to do so can

result in personal injury.

24. Muffler and engine can become hot and cause burns. Do not touch!

25. Only use parts and accessories made for this machine by the manufacturer. Failure to do so can result in

personal injury.

26. When starting the engine, pull cord slowly until resistance is felt, then pull rapidly. Rapid retraction of

starter cord (kickback) will pull hand and arm towards engine faster than you can let go. Broken bones,

fractures, bruises or sprains could result.

27. If situations occur which are not covered in this manual, use care and good judgement. Contact your

nearest Approved Service Dealer for assistance

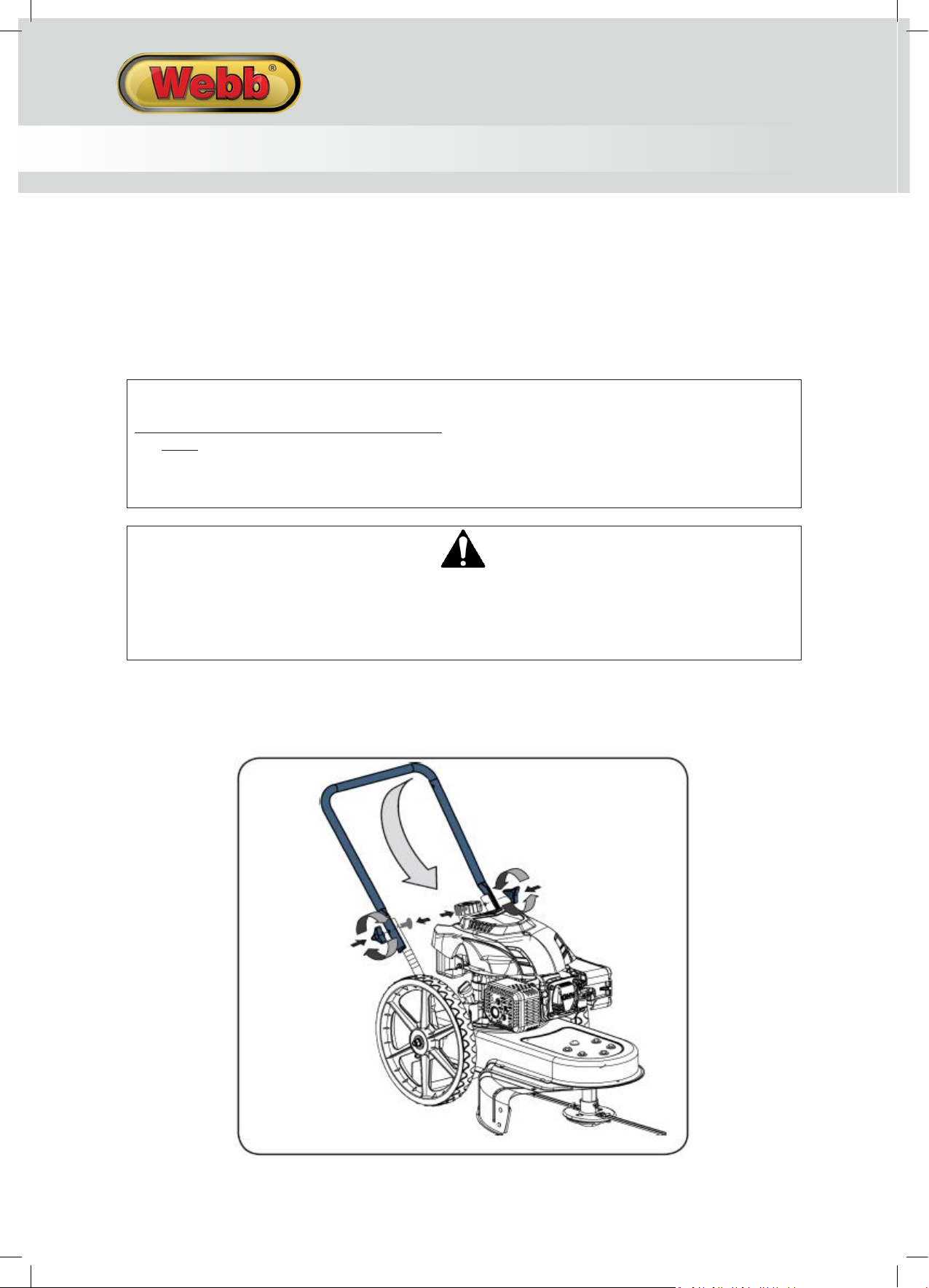

SLOPE OPERATION

Slopes are a major factor related to slip and fall accidents, which can result in severe injury. Operation on

slopes requires extra caution. If you feel uneasy on a slope, do not trim on it. If the slope is greater than 15

degrees, do not trim on it.

Do:

1. Trim across the face of slopes; never up and down. Exercise extreme caution when changing direction on

slopes.

2. Watch for holes, ruts, rocks, hidden objects, or bumps which can cause you to slip or trip. Tall grass can

hide obstacles.

3. Always be sure of your footing. A slip and fall can cause serious personal injury. If you feel you are losing

your balance, release the OPC/Brake lever immediately and the spindle will stop rotating within three (3)

seconds.

Do Not:

1. Do not trim near drop-offs, ditches or embankments, you could lose your footing or balance.

2. Do not trim slopes greater than 15 degrees.

3. Do not trim on wet grass. Unstable footing could cause slipping.

CHILDREN

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted

to the trimmer and the trimming activity. They do not understand the dangers. Never assume that children will

remain where you last saw them.

1. Keep children out of the trimming area and under care of a responsible adult other than the operator.

2. Be alert and turn the trimmer off if a child enters the area.

3. Before and while moving backwards, look behind and down for small children.

4. Use extreme care when approaching blind corners, doorways, shrubs, trees, or other objects that may

obscure your vision of a child who may run into the trimmer.

5. Keep children away from hot or running engines. They can suffer burns from a hot muffler.

6. Never allow children under 16 years of age to operate this machine. Children 16 and over should read and

understand the instructions and safe operation practices in this manual and on the machine and be

trained and supervised by an adult.